Soldato

- Joined

- 1 Jun 2010

- Posts

- 7,057

- Location

- Bedford

Much better contact and pressure

I tried both washers. The smaller washer with 3mm thickness just didn't cut it with the IFX-14 mounting system.

Placing it underneath the mounting plate, and securing the plate at one end slightly by giving the UNC screw one or two turn at that end meant the distance significantly increased between the bottom of UNC screw and hollow pillar on the other end.

This required enormous downward force on the other end in order to try to secure the 2nd UNC screw into the hollow pillar and even then it proved impossible and I just had to abandon the smaller washer as I was afraid of damaging cpu/socket pins.

Better to be safe than sorry!!

On the other hand the larger washer proved to be a very good companion for IFX-14 mounting system and infact I am already using it as I am typing this post

The following pics give a better story!!

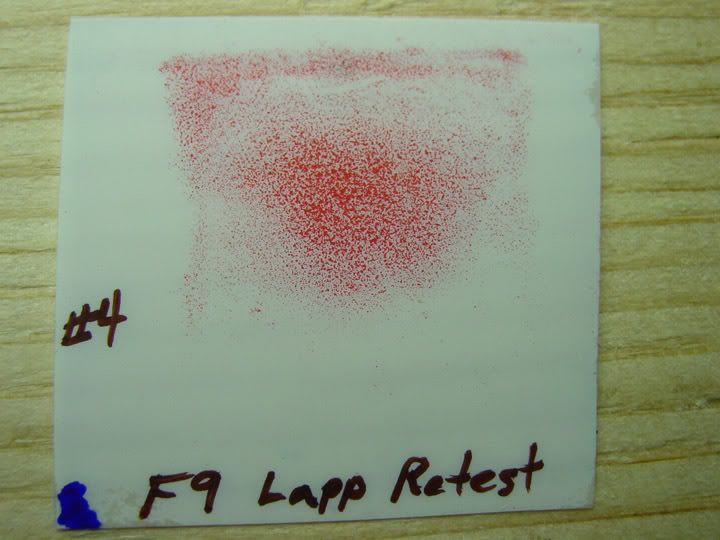

Here are the pressure and contact patterns!!

Although I am not sure why there is a slight peculiar missing contact or contact gap at the bottom

I then decided to turn IFX-14 the other way round and repeated contact and pressure test and voila!!

What a difference from unlapped contact!!

Ofcourse the pics don't show the patterns as well, as shiny surface of the paper means some reflection. Plus this is all hand lapping as I can't afford belt sander being a student . So the overall lapping results won't be on par with belt sander results. Also bearing in mind that Q6600 cores reside in the upper half of the IHS as discussed previously.

. So the overall lapping results won't be on par with belt sander results. Also bearing in mind that Q6600 cores reside in the upper half of the IHS as discussed previously.

However one thing I have noticed is that my washer modded lapped contact and pressure patterns seem to resemble the data point 10 pattern more or less on IC website:

http://www.innovationcooling.com/ICDtroublshooting.htm

So IC Diamond, what do you make of it?

I tried both washers. The smaller washer with 3mm thickness just didn't cut it with the IFX-14 mounting system.

Placing it underneath the mounting plate, and securing the plate at one end slightly by giving the UNC screw one or two turn at that end meant the distance significantly increased between the bottom of UNC screw and hollow pillar on the other end.

This required enormous downward force on the other end in order to try to secure the 2nd UNC screw into the hollow pillar and even then it proved impossible and I just had to abandon the smaller washer as I was afraid of damaging cpu/socket pins.

Better to be safe than sorry!!

On the other hand the larger washer proved to be a very good companion for IFX-14 mounting system and infact I am already using it as I am typing this post

The following pics give a better story!!

Here are the pressure and contact patterns!!

Although I am not sure why there is a slight peculiar missing contact or contact gap at the bottom

I then decided to turn IFX-14 the other way round and repeated contact and pressure test and voila!!

What a difference from unlapped contact!!

Ofcourse the pics don't show the patterns as well, as shiny surface of the paper means some reflection. Plus this is all hand lapping as I can't afford belt sander being a student

. So the overall lapping results won't be on par with belt sander results. Also bearing in mind that Q6600 cores reside in the upper half of the IHS as discussed previously.

. So the overall lapping results won't be on par with belt sander results. Also bearing in mind that Q6600 cores reside in the upper half of the IHS as discussed previously.However one thing I have noticed is that my washer modded lapped contact and pressure patterns seem to resemble the data point 10 pattern more or less on IC website:

http://www.innovationcooling.com/ICDtroublshooting.htm

So IC Diamond, what do you make of it?

Last edited:

.

.