Associate

- Joined

- 7 Dec 2010

- Posts

- 223

PLEASE READ THOROUGHLY BEFORE TESTING/POSTING YOUR IC DIAMOND OR PERIHELION TEST RESULTS!!!

PLEASE ONLY POST WITH RESULTS WHEN YOU HAVE FULL RESULTS, OTHERWISE YOUR POST MAY NOT BE SEEN BY ALL IF YOU RESERVE THE POST FOR LATER RESULTS WITH IC7. PEOPLE TEND TO GO TO THE NEWEST POST, SO IF YOU WANT IT TO BE SEEN BY ALL, POST YOUR RESULTS ONCE YOU HAVE THEM ALL. ALL OTHER DISCUSSION/SUPPORT POSTS, GO RIGHT AHEAD!!

PLEASE BE SURE TO BENCHMARK YOUR CPU TEMPS WITH YOUR CURRENT TIM AND RECORD YOUR RESULTS BEFORE USING IC7 FOR TESTING. WE NEED BEFORE AND AFTER PLEASE!

ALSO, PLEASE MAKE SURE YOU DON'T CHANGE ANY VARIABLE OTHER THAN THE THERMAL COMPOUND USED FOR BEFORE/AFTER (I.E. SAME VOLTS/CLOCKS, COOLER, AND OTHER HARDWARE)

APPLICATION METHOD

For all those participating in the ICD/Perihelion giveaway, please follow this link to the Innovation Cooling website for more information on the products:

Innovation Cooling

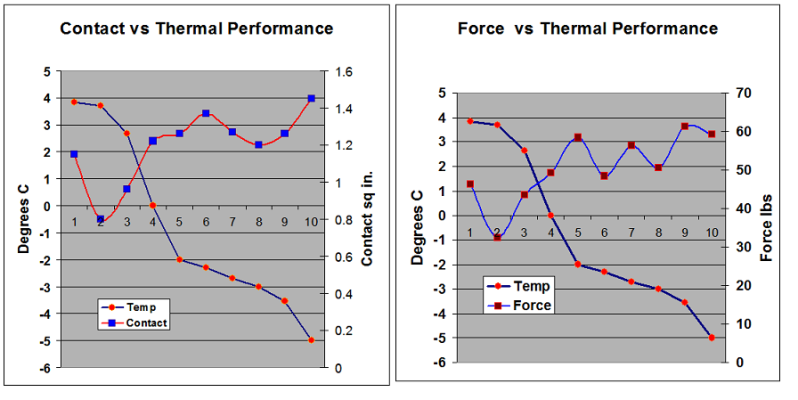

Proper application is the key to this product. The nature and consistency of this product is likely quite different from what most of you are used to in a Thermal Compound. We don't recommend use of traditional methods of applying the TIM like razor blades, lines, Rice size, etc. ARE ALL Big BIG NO NO's. Through extensive end user testing, the best overall application method has been determined to be a pea sized amount directly in the center of the CPU. The TIM should be adequately spread via the down force of the CPU cooler (a sufficient amount of down force will provide best results; minimum 50psi of down force should be the goal for optimum results. please see the Innovation Cooling website for more info). Also, for coolers/surfaces that have many peaks and valleys, it may be beneficial to wet the surface(s) with a small amount of ICD/Perihelion to initially fill the voids in the mounting surfaces...then proceed with recommended application as usual. Please click on the link below for application methodology and shoot me a PM if you have any questions.

Keep in mind, ICD/Perihelion has been formulated with the specific goals of providing superb thermal conductivity with short set times, but also for long term stability and performance without pump/bake out through extended thermal cycling or usage. This stuff is very stable over long periods of time.

Please do feel free to navigate through the whole Innovation Cooling website as there is tonnes of information on there that might prove beneficial.

HOW TO POST RESULTS

THE FORMAT IS AS FOLLOWS (ALL TEMPS IN C):

OPTIONAL INFO: PROCESSOR, VOLTS/CLOCKS, HEAT SINK/COOLING USED, ETC.

Before Compound:

Ambient Temp:

Idle Temp:

Load Temp:

ICD/Perihelion

Ambient Temp:

Idle Temp:

Load Temp:

Added 5/22 - Cure Time- Cure Time averages 2 hours in most situations for sinks with adequate pressure loading with maybe .5C more overnight. Lightly pressure loaded sinks may take a day or more depending on the amount of pressure

If you have any problems or need support, please feel free to post here for now. Remember, proper application and good even heat sink pressure (goal should be minimum of 50psi or more) are crucial for peak performance. Too much or too little compound will impact your results so please do visit the Innovation Cooling website for Application Instructions with images and explanations. For those with direct touch heatpipe coolers, you might want to try wetting the contact surface of the cooler with a tiny amount of ICD to fill any small voids before proceeding with the normal application method.

If anyone has any questions, please feel free to post up. .

*** HEADS UP *** Post # 149

For the people running the test I would recommend using LinX. I have just done a run with Perihelion and noticed the load temps where 5'C better with Noctua NT H1. However after looking at the LinX results you can see that the Noctua NT H1 was infact causing thermal throttling with the time/GFLOP going all over the place. Anything from 31 GFLOP to 48 GFLOPs. Obviously using Primeor .... you would never know and Noctua NT H1 would come out on top.

I am going to let Perihelion bed in some more and re run the test. Interesting, very impressed.

I'm using a pea size as recommended and works very well.

It might be worth adding this to the first post otherwise results could be invalid.

*** HEADS UP ** # 2 post #162

Guys if you are going to use IBT/Linx for testing the compounds, make sure your GFlops values are more or less same in all the tests otherwise your results will be invalid.

For example

MX-3 or any other thermal compound: 33-35GFlops in IBT

IC Diamond: 40-45GFlops in IBT

What will happen is that your temps will be higher in the case of IC Diamond as you are getting higher GFlops values even if IC Diamond is better than MX-3.

So you need to get GFlops values in a similar range for both compounds. So it should be e.g:

MX-3 or any other thermal compound: 43-45GFlops in IBT

IC Diamond: 43-45GFlops in IBT

Consistent/same GFlops values across all tests

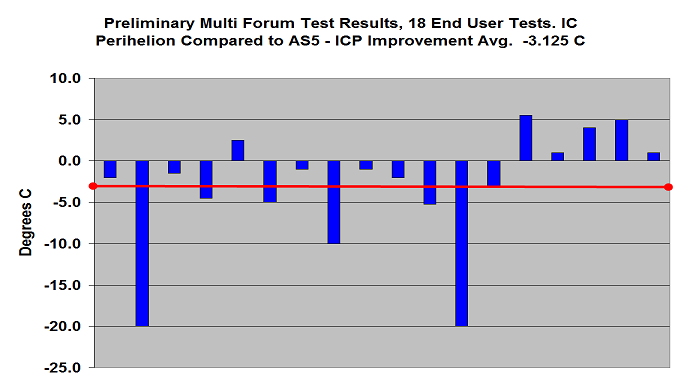

Ongoing/preliminary Test Results to Date

PLEASE ONLY POST WITH RESULTS WHEN YOU HAVE FULL RESULTS, OTHERWISE YOUR POST MAY NOT BE SEEN BY ALL IF YOU RESERVE THE POST FOR LATER RESULTS WITH IC7. PEOPLE TEND TO GO TO THE NEWEST POST, SO IF YOU WANT IT TO BE SEEN BY ALL, POST YOUR RESULTS ONCE YOU HAVE THEM ALL. ALL OTHER DISCUSSION/SUPPORT POSTS, GO RIGHT AHEAD!!

PLEASE BE SURE TO BENCHMARK YOUR CPU TEMPS WITH YOUR CURRENT TIM AND RECORD YOUR RESULTS BEFORE USING IC7 FOR TESTING. WE NEED BEFORE AND AFTER PLEASE!

ALSO, PLEASE MAKE SURE YOU DON'T CHANGE ANY VARIABLE OTHER THAN THE THERMAL COMPOUND USED FOR BEFORE/AFTER (I.E. SAME VOLTS/CLOCKS, COOLER, AND OTHER HARDWARE)

APPLICATION METHOD

For all those participating in the ICD/Perihelion giveaway, please follow this link to the Innovation Cooling website for more information on the products:

Innovation Cooling

Proper application is the key to this product. The nature and consistency of this product is likely quite different from what most of you are used to in a Thermal Compound. We don't recommend use of traditional methods of applying the TIM like razor blades, lines, Rice size, etc. ARE ALL Big BIG NO NO's. Through extensive end user testing, the best overall application method has been determined to be a pea sized amount directly in the center of the CPU. The TIM should be adequately spread via the down force of the CPU cooler (a sufficient amount of down force will provide best results; minimum 50psi of down force should be the goal for optimum results. please see the Innovation Cooling website for more info). Also, for coolers/surfaces that have many peaks and valleys, it may be beneficial to wet the surface(s) with a small amount of ICD/Perihelion to initially fill the voids in the mounting surfaces...then proceed with recommended application as usual. Please click on the link below for application methodology and shoot me a PM if you have any questions.

Keep in mind, ICD/Perihelion has been formulated with the specific goals of providing superb thermal conductivity with short set times, but also for long term stability and performance without pump/bake out through extended thermal cycling or usage. This stuff is very stable over long periods of time.

Please do feel free to navigate through the whole Innovation Cooling website as there is tonnes of information on there that might prove beneficial.

HOW TO POST RESULTS

THE FORMAT IS AS FOLLOWS (ALL TEMPS IN C):

OPTIONAL INFO: PROCESSOR, VOLTS/CLOCKS, HEAT SINK/COOLING USED, ETC.

Before Compound:

Ambient Temp:

Idle Temp:

Load Temp:

ICD/Perihelion

Ambient Temp:

Idle Temp:

Load Temp:

Added 5/22 - Cure Time- Cure Time averages 2 hours in most situations for sinks with adequate pressure loading with maybe .5C more overnight. Lightly pressure loaded sinks may take a day or more depending on the amount of pressure

If you have any problems or need support, please feel free to post here for now. Remember, proper application and good even heat sink pressure (goal should be minimum of 50psi or more) are crucial for peak performance. Too much or too little compound will impact your results so please do visit the Innovation Cooling website for Application Instructions with images and explanations. For those with direct touch heatpipe coolers, you might want to try wetting the contact surface of the cooler with a tiny amount of ICD to fill any small voids before proceeding with the normal application method.

If anyone has any questions, please feel free to post up. .

*** HEADS UP *** Post # 149

For the people running the test I would recommend using LinX. I have just done a run with Perihelion and noticed the load temps where 5'C better with Noctua NT H1. However after looking at the LinX results you can see that the Noctua NT H1 was infact causing thermal throttling with the time/GFLOP going all over the place. Anything from 31 GFLOP to 48 GFLOPs. Obviously using Primeor .... you would never know and Noctua NT H1 would come out on top.

I am going to let Perihelion bed in some more and re run the test. Interesting, very impressed.

I'm using a pea size as recommended and works very well.

It might be worth adding this to the first post otherwise results could be invalid.

*** HEADS UP ** # 2 post #162

Guys if you are going to use IBT/Linx for testing the compounds, make sure your GFlops values are more or less same in all the tests otherwise your results will be invalid.

For example

MX-3 or any other thermal compound: 33-35GFlops in IBT

IC Diamond: 40-45GFlops in IBT

What will happen is that your temps will be higher in the case of IC Diamond as you are getting higher GFlops values even if IC Diamond is better than MX-3.

So you need to get GFlops values in a similar range for both compounds. So it should be e.g:

MX-3 or any other thermal compound: 43-45GFlops in IBT

IC Diamond: 43-45GFlops in IBT

Consistent/same GFlops values across all tests

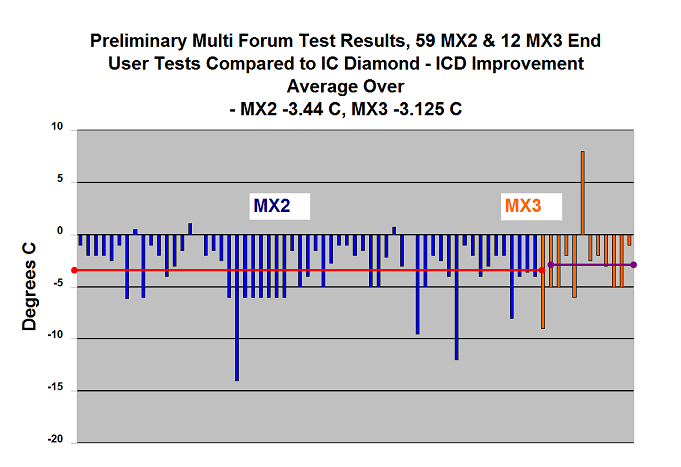

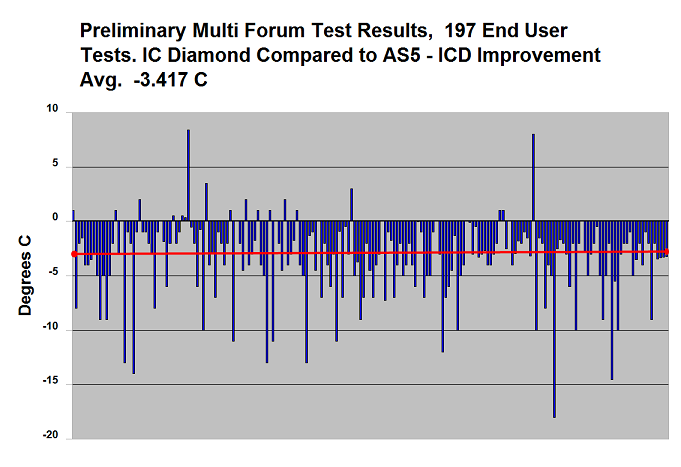

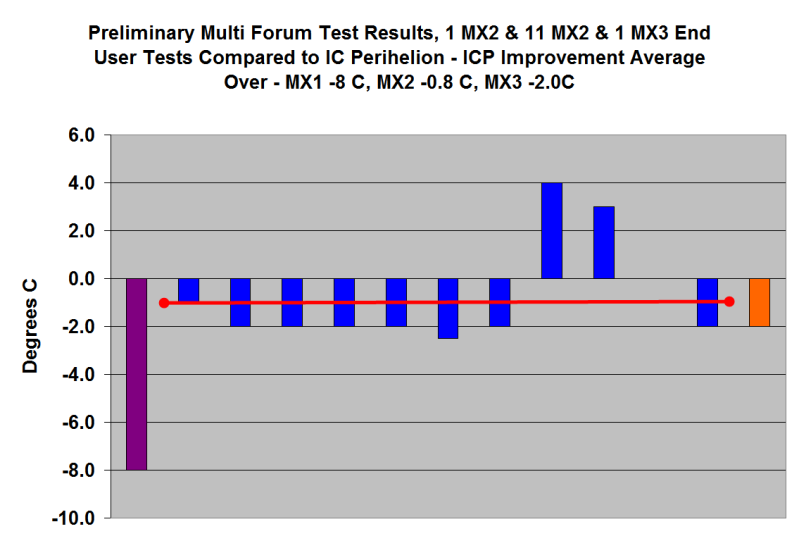

Ongoing/preliminary Test Results to Date

Last edited:

)

)