Managed to get some time away from work. Hopefully I can tell you a bit more about this fill port. It's all quite simple.

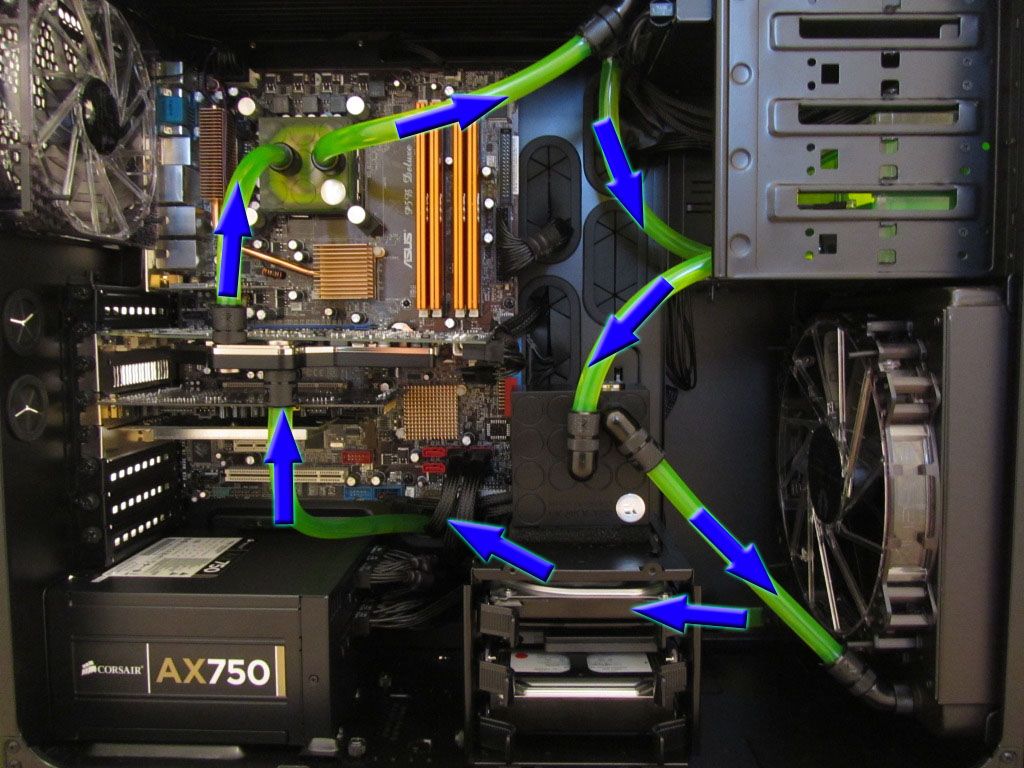

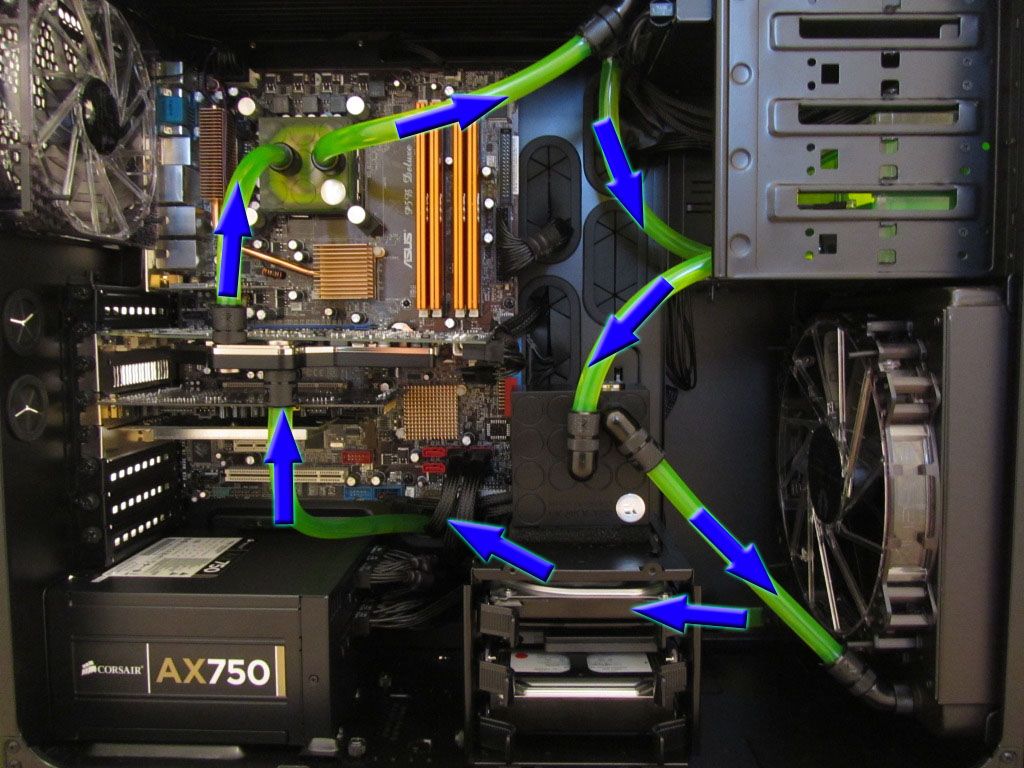

The location: The drain port must be at the lowest point in your loop, else it simply wont drain fully.

The bits needed:

-OcUK Fillport Black Nickel - Knurled - Universal [45247]

http://www.overclockers.co.uk/showproduct.php?prodid=WC-075-OE&groupid=962&catid=1529&subcat=2059

-OcUK G1/4 - Screw in Seal Cap - Knurled - Shiny Silver

http://www.overclockers.co.uk/showproduct.php?prodid=WC-076-OE&groupid=962&catid=1529&subcat=2059

-1/4" Thread Rotary T Piece for 3/8" ID - 1/2" OD (10-13mm) Tubing : Black Nickel

(Not from OcUK)

Unfortunately OcUK don't stock any T-pieces, so I had to go elsewhere for that. But do a google I'm sure you can find one easily...

The setup:

-You will need a hole, obviously, in the bottom of your case. I drilled out an existing hole, large enough to fit the "Fillport" fitting through.

-The T-Piece has 2 compression fittings at the top, plus a standard G1/4 thread at the bottom. Your loop is plumbed into the two compression fittings (bear in mind to get the right size T-piece for the tube, mine was 3/8").

-The bottom of the T-piece is then screwed into the fill port we fitted in the first step.

-Now all is left it to screw the "Seal Cap" into the bottom side of the bulkhead filling port.

Let me know if you need any more help or don't understand!

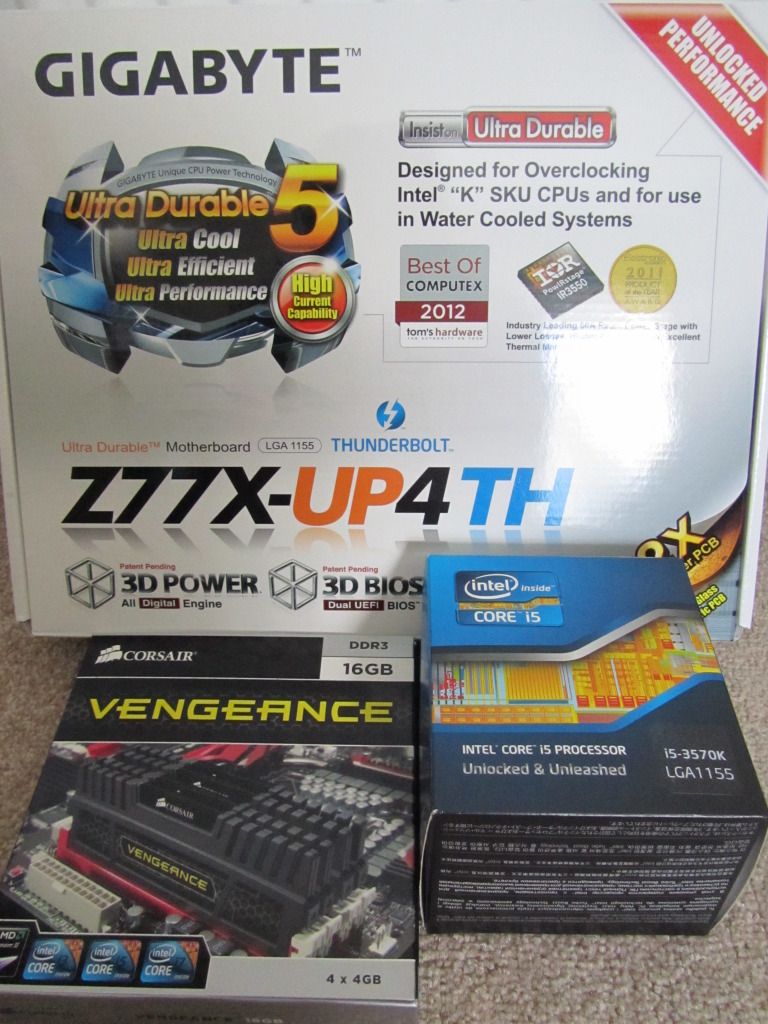

Its a Gigabyte UP4, i5 3570K with 16Gb of Corsair Vengeance. Colours match far better now!!

Its a Gigabyte UP4, i5 3570K with 16Gb of Corsair Vengeance. Colours match far better now!!