You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

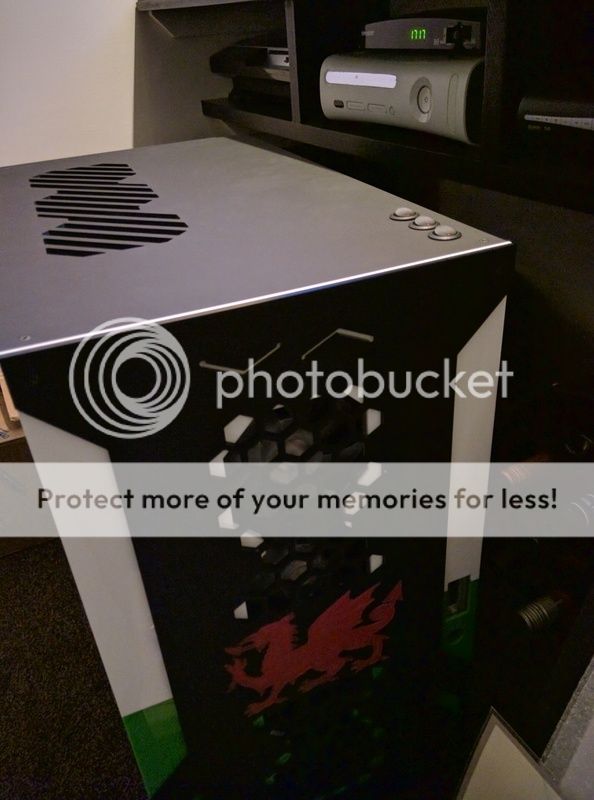

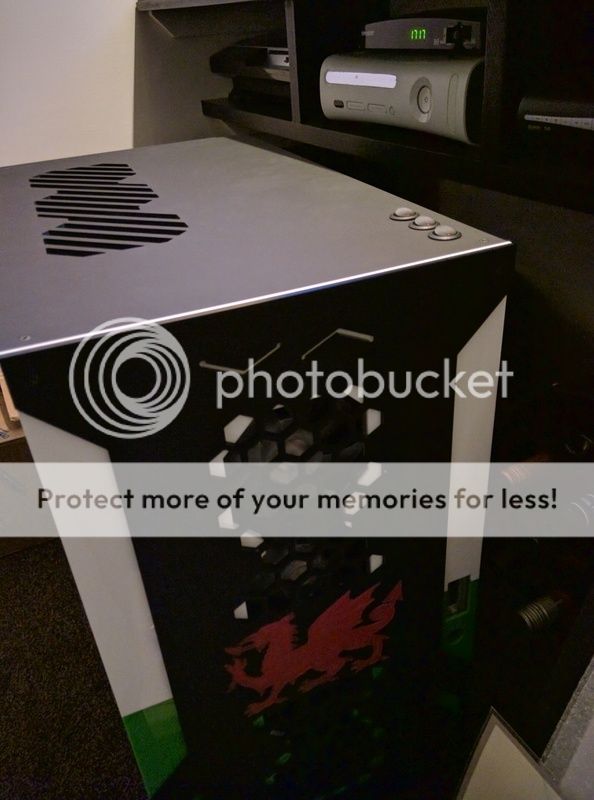

A Window To Wales

- Thread starter OJ46

- Start date

More options

View all postsOnly had a couple minutes spare today, but didn't want to waste it sooooo...

First I ripped the face off an Aquaero.

Then heatsinked up a pair of em.

Before mounting the one to control the top loop.

Which looked cool with the roof panel off

And also left just about enough room for cable management

First I ripped the face off an Aquaero.

Then heatsinked up a pair of em.

Before mounting the one to control the top loop.

Which looked cool with the roof panel off

And also left just about enough room for cable management

Not sure if this'll come under "Cool!", "Don't care" or "Why the $%#! didn't you tell me this before?!" but assuming that Aquaero 6 LT's are like 5 LT's, you can - if you have room to mount it - mount one with the screen and have the other one as a slave connected by Aquabus. Just did a quick Google and it looks like although it's possible, you lose features on one. Discussion here if it's of interest.

Always planned on keeping them completely separate to be honest mate, got the one in the roof for the top loop and will mount the other between the bottom radiators to control that loop.

Original plan was to use a smaller top reservoir then mount the 2 Aquaero's below with screens on, but decided it looked better with a longer res & pump housing attached so hid the Aquaero's instead

Are you stripping the anodizing off the backplate before you paint it? Don't do what I did and get the water temperature too hot or you'll scare yourself

They do come up rather nice in raw aluminium, but you could probably do a better job of finishing the surface than me because you're painting, I wanted to keep the alu.

Was hoping to get away with just sanding to a decent surface then spraying it, so will try that first and see how it goes! If it all goes **** up then guess I'll be stripping it properly

Sooooooo MOAR ISSUES! The EL Panel for the floor arrived today, which put a smile on my face right up until the moment I connected it to the PSU and turned it on. It works, but only for about ½ a second before going off again for 2½ seconds, flashing like this constantly but not staying on... If anyone has any ideas WTF could be wrong that would be brilliant because I'm stumped! Should add I connected it to a Molex which I also tried with a different, smaller panel and all was good with that one, which baffled me more.

In slightly better news I owe a massive thanks to Cenedd, that £2.50 spacer you suggested worked a treat cheers mate

In slightly better news I owe a massive thanks to Cenedd, that £2.50 spacer you suggested worked a treat cheers mate

First up I've not heard back re the EL Panel yet so that is still on hold...

Anyway, you know when you have one of those days where your head really isn't right, and you know everything's going to go wrong? And then it does, but you keep ploughing on anyway? Yep, today was one of those days

Lets start with a moan! Ordered 2 of these Monsoon temperature sensors and both came without rubber o-rings. Not just they weren't pre fitted, they were non existent. Good job I had some spares!

Then screwed one in and the thread is that tight I actually had to use pliers to remove it. Hardly screaming 'quality product' so lets just hope it actually works once fitted.

Better news: It points in the right direction!

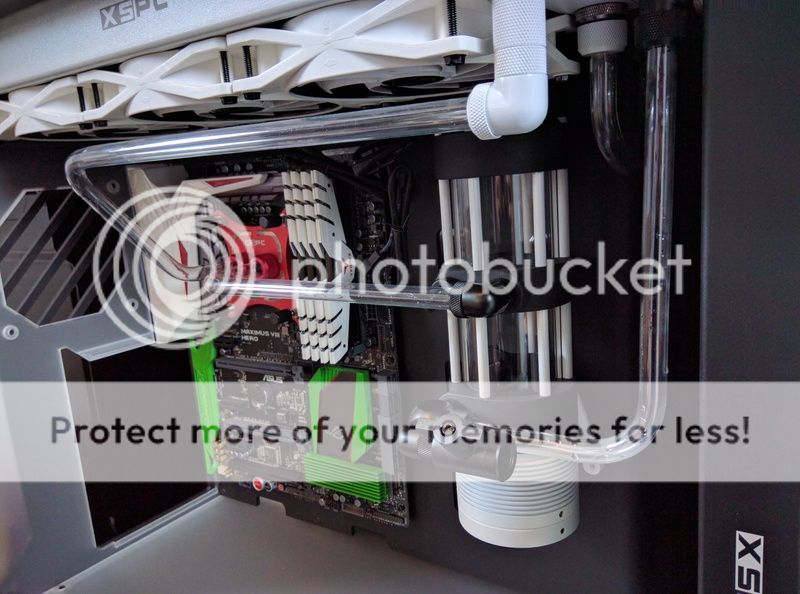

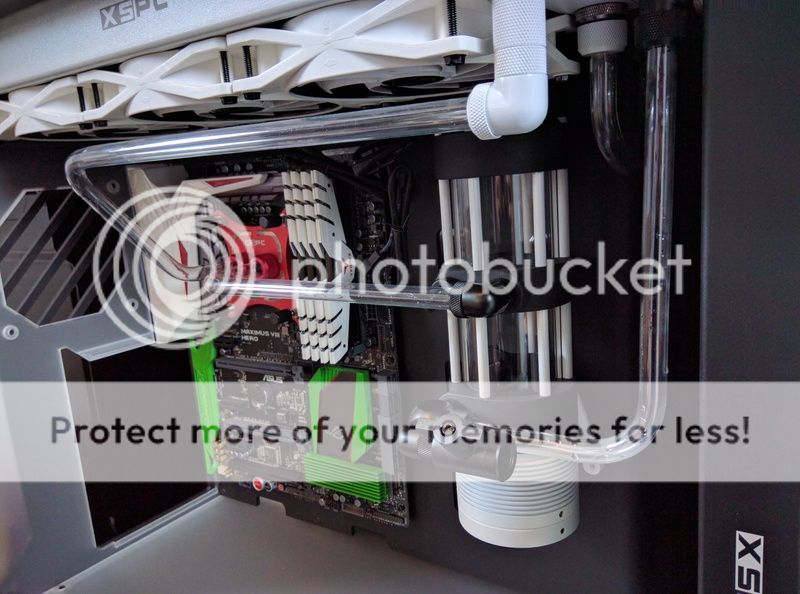

So onto the loop. Firstly I re did the small piece joining the 2 radiators so it (in my eyes at least) looks better. Then changed the CPU > reservoir so it A) looked straight and B) went into the other port on the res. Reasoning? To hide the temperature sensor and cable

Finally I got the last section done, but unfortunately it's not perfect by a long way as I was getting massively frustrated by then

Not too bad, and as you may have noticed I also added a draining valve. Looks fugly but worth spoiling the looks a little for the hassle it removes later on

The new, smoother, loop. May shorten it a bit so it doesn't drop down quite so low.

Sensor hidden, tap added

Fairly happy with how it looks but might still change a few things...

And that's when I should have called it a day as my head really wasn't good by then... But I didn't. I wanted to refit the old CPU cooler and install the GPU to test.

So what exactly did my extremely sleep deprived and ****ed off mood end up doing to the build I hear you ask? Well it damn near cost me a £200+ motherboard. How? Well, after removing the CPU cooler I cleaned the CPU up, chucked a pea of paste on and attempted to install the crap cooler, but the pile of junk wouldn't 'click' into the motherboard. So I removed it again... Dripping a nice glob of thermal paste over both the motherboard and RAM.

But wait, that's not so bad! It got worse. Removed the CPU so I could clean it up properly and in a ****ed off mood I was rushing about a bit and yep, snagged a couple of the motherboard CPU pins with some kitchen roll, bending them up and to one side...

So that was fun! After shouting '****' so many times the neighbours probably thought the entire series of Father Ted was on TV I bent them back as straight as I could, installed the CPU & cooler and held my breath... THANK **** FOR THAT, IT LIVES!!

Finally got around to trying out the GPU and happy to say it worked like a charm. Not pretty, but I'll take 'working' for now...

Installed the drivers and 3Dmark etc to stress it and all appears OK, so will give it one more thrashing when I get 10 minutes just to double check and then it will be put under water. That's it for now folks, I'm off to chill with a bucket full of our home made wine and some crap TV

Anyway, you know when you have one of those days where your head really isn't right, and you know everything's going to go wrong? And then it does, but you keep ploughing on anyway? Yep, today was one of those days

Lets start with a moan! Ordered 2 of these Monsoon temperature sensors and both came without rubber o-rings. Not just they weren't pre fitted, they were non existent. Good job I had some spares!

Then screwed one in and the thread is that tight I actually had to use pliers to remove it. Hardly screaming 'quality product' so lets just hope it actually works once fitted.

Better news: It points in the right direction!

So onto the loop. Firstly I re did the small piece joining the 2 radiators so it (in my eyes at least) looks better. Then changed the CPU > reservoir so it A) looked straight and B) went into the other port on the res. Reasoning? To hide the temperature sensor and cable

Finally I got the last section done, but unfortunately it's not perfect by a long way as I was getting massively frustrated by then

Not too bad, and as you may have noticed I also added a draining valve. Looks fugly but worth spoiling the looks a little for the hassle it removes later on

The new, smoother, loop. May shorten it a bit so it doesn't drop down quite so low.

Sensor hidden, tap added

Fairly happy with how it looks but might still change a few things...

And that's when I should have called it a day as my head really wasn't good by then... But I didn't. I wanted to refit the old CPU cooler and install the GPU to test.

So what exactly did my extremely sleep deprived and ****ed off mood end up doing to the build I hear you ask? Well it damn near cost me a £200+ motherboard. How? Well, after removing the CPU cooler I cleaned the CPU up, chucked a pea of paste on and attempted to install the crap cooler, but the pile of junk wouldn't 'click' into the motherboard. So I removed it again... Dripping a nice glob of thermal paste over both the motherboard and RAM.

But wait, that's not so bad! It got worse. Removed the CPU so I could clean it up properly and in a ****ed off mood I was rushing about a bit and yep, snagged a couple of the motherboard CPU pins with some kitchen roll, bending them up and to one side...

So that was fun! After shouting '****' so many times the neighbours probably thought the entire series of Father Ted was on TV I bent them back as straight as I could, installed the CPU & cooler and held my breath... THANK **** FOR THAT, IT LIVES!!

Finally got around to trying out the GPU and happy to say it worked like a charm. Not pretty, but I'll take 'working' for now...

Installed the drivers and 3Dmark etc to stress it and all appears OK, so will give it one more thrashing when I get 10 minutes just to double check and then it will be put under water. That's it for now folks, I'm off to chill with a bucket full of our home made wine and some crap TV

To be fair to Monsoon I have used quite a lot of their parts in the past and this is the first issue I've had, so hopefully this is a one off and normal service will be resumed.

Never used anything made by Phobya yet, mainly because of things I've read on here... Are they really THAT bad? Always good to know who to avoid!

A small drain built into a T-piece would look far better mate, the current design is pretty much the worst of all worlds IMO. Even being male on one end would help as at least then it could be screwed into spare radiator ports without sticking out quite so far. Took me ages to decide where to put the hideous thing in the loop, plan A was to put a fill port for the res through the top of the case & then tip the case over to empty...

That was honestly the first time I've ever made a complete mess with thermal paste, but trust me to go from a blob of harmless mess to damaged pins in 10 seconds flat! It has helped me decide one thing though: When the CPU is de-lidded I'll definitely be using Kryonaut rather than liquid metal! I know it doesn't perform as well but sounds a lot safer idea when being done by a sleep deprived idiot, and will still be far better than the rubbish Intel use

Never used anything made by Phobya yet, mainly because of things I've read on here... Are they really THAT bad? Always good to know who to avoid!

A small drain built into a T-piece would look far better mate, the current design is pretty much the worst of all worlds IMO. Even being male on one end would help as at least then it could be screwed into spare radiator ports without sticking out quite so far. Took me ages to decide where to put the hideous thing in the loop, plan A was to put a fill port for the res through the top of the case & then tip the case over to empty...

That was honestly the first time I've ever made a complete mess with thermal paste, but trust me to go from a blob of harmless mess to damaged pins in 10 seconds flat! It has helped me decide one thing though: When the CPU is de-lidded I'll definitely be using Kryonaut rather than liquid metal! I know it doesn't perform as well but sounds a lot safer idea when being done by a sleep deprived idiot, and will still be far better than the rubbish Intel use

That's what confused me most mate, everything else I've bought off them came with an o-ring fitted plus a spare one, so to have both missing seemed double odd. So long as it doesn't leak once it's fitted though it's all good, just hope I never need to remove it again!

Haha very much doubt that! The amount of work I've got left combined with the minuscule amounts of time I get to actually crack on and do something, I'd be very surprised if this is finished before the end of March. A week or 2 off work and it'd be finished, but being self employed that's not really an option so unfortunately I'm stuck with the odd 30 minutes here and there. Never mind, knew it would be a slow one

Haha very much doubt that! The amount of work I've got left combined with the minuscule amounts of time I get to actually crack on and do something, I'd be very surprised if this is finished before the end of March. A week or 2 off work and it'd be finished, but being self employed that's not really an option so unfortunately I'm stuck with the odd 30 minutes here and there. Never mind, knew it would be a slow one

Yes and no. They're a budget option. If that's what you're in the market for, fantastic...but the build quality isn't that premium quality you get from the more expensive brands. Functional more than stylish shall we say. Definitely a place in the market for them though.

With some components I'd be happy taking the chance but not sure it's worth the risk when there's water involved. For the sake of a couple quid extra wouldn't want to risk £1k of components... Says the lad who bought Monsoon fittings cos they're cheap

Still don't know why nobody does a tap with a male thread one end. Only saves 5mm length but it's almost always what you want, no?

Got any res ports on the back of the res (out of sight)? Wouldn't get you the last bit of the res or pump drained but would do most. You're not going to get the rad drained without tipping anyway.

Another option would be to make more of the drain. You could slap a 90 on the T and angle it down. Then run PETG downwards and have the tap (and safety stop on the end) out the way at the bottom somewhere where it doesn't disturb your clean lines.

Nothing on the back unfortunately, otherwise could just run it out the back out of sight and jobs a good'un.

That's not a bad idea to run a piece of PETG into the lower compartment mate but unfortunately it has just one problem: It would go straight through the middle of the dragon

I can confidently say it won't be the last time!

Apparently the best combo is Kryonaut in the normal place (between Integrated Heat Spreader [IHS] and water block) and CLU between IHS and CPU die. It is possible to remove the IHS completely but then you need special mounting kits and maybe some shims to stop the block crumbling the edge of the die...and the temperatures people have reported are higher anyway - assuming you're not using silly stuff like phase change and LN2.

The CLU is actually quite easy to apply. You just squeeze a tiny blob out of the syringe and it sits there as a ball on the CPU. Then you spread it with the little brush supplied. Tricky bit is that you have to put the IHS back on the top the right way round and then hold it in place while you drop the lever on the CPU socket - it slides otherwise.

I used some clear nail varnish to insulate the gold dot contacts on the top of the CPU. Might have been paranoid but a certain level is healthy, right?!

I'd say CLU is probably the cleanest of all the TIMs I've used....and I can always manage to get some on me/board/table/case!

Ah, that's not sounding anywhere near as bad as I thought. The whole 'liquid metal' thing just screamed "PITA ass to apply and blows **** up if not done perfectly", but if it's quite good to use I'll definitely have to look into it a bit more

Guessing if it slides there's a chance the liquid will also slide, dripping down onto a contact... You're losing me again!! Haha good shout on the nail varnish though, wouldn't have thought of that.

If you're THAT bad with normal paste but did the liquid metal tidily then it must be worth a look though right?

I bought a monsoon temp sensor too and it also arrived with no o ring! But mine threaded in fine.

Have you seen this guys?

https://www.overclockers.co.uk/bits...nd-1x-g1-4-rotatory-matt-black-wc-661-bp.html

Hmm, seems like mine wasn't a two-off then! Not looking good for quality control at Monsoon, who do they think they are? EK?

That's a good looking tap mate and one I'd somehow missed, definitely a bonus having a rotary connector rather than using a non rotary extension. Only problem is it also comes with Bitspower prices... If I hadn't already got 2 cheaper ones that would have quite possibly won my money though

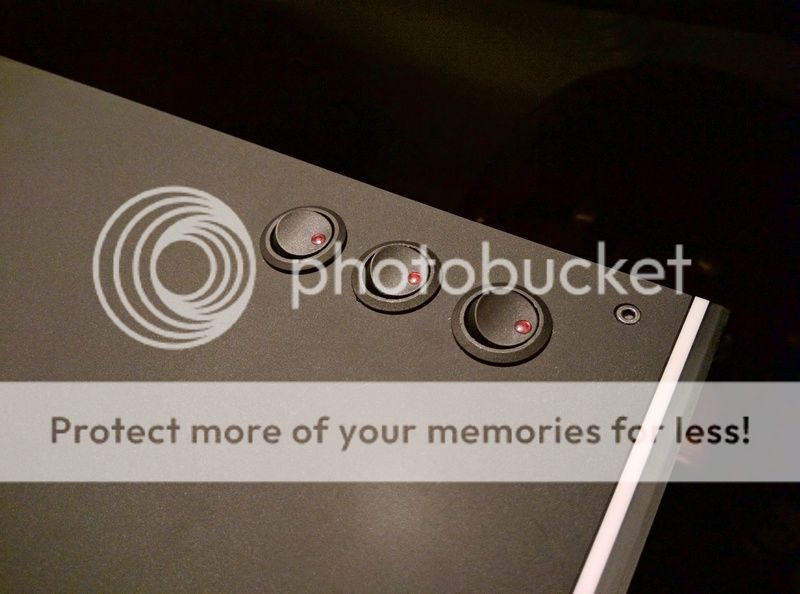

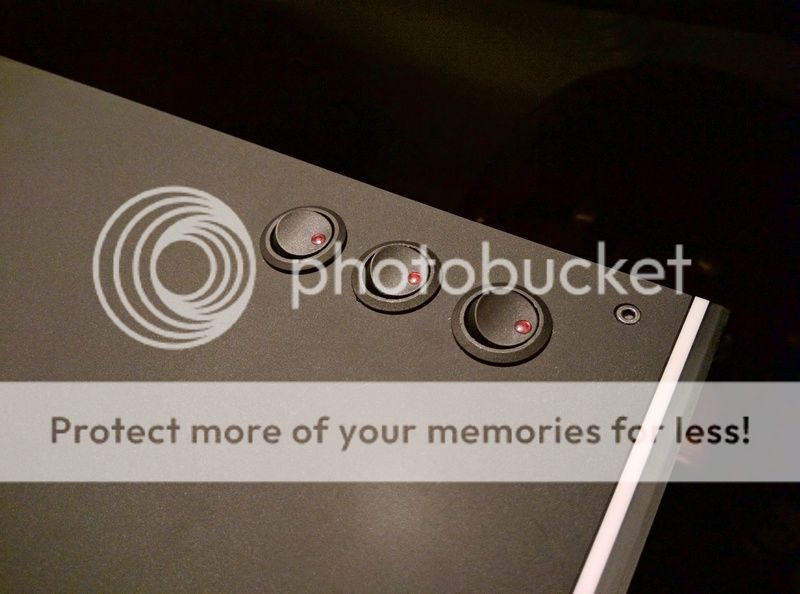

Had another spare few minutes today (sorry for another tiny update!) so the case grew some lumps

Unfortunately that is all for now. I was going to wire em up and also run some benchmarks on the GPU, but then remembered the U20's 6 Nations was on so got a bit distracted

Unfortunately that is all for now. I was going to wire em up and also run some benchmarks on the GPU, but then remembered the U20's 6 Nations was on so got a bit distracted

Having it go through the motherboard tray under the reservoir ain't a bad idea mate, may have to give that one a try

Still not liking the sound of metal being that close to extremely expensive components though, think I need a big dose of 'man the **** up' lol although even Thermal Grizzly Kryonaut has got to be better than the rubbish Intel use as standard if I do wuss out

To the updates! Ran a quick GPU benchmark / stress test to make sure everything was working properly, with CPU @ stock, GPU @ stock and RAM @ XMP. The scores? Time Spy 7189 with a GPU score of 7649. Chucked the Temp & Power limits up to max and added a quick +46MHz onto the core for a quick test and it improved to 7237 (GPU 7717 / CPU 5353) without breaking a sweat, hitting 1987MHz. Fire Strike at the same clock scored 17956 (graphics 22873 / physics 13203 / combined 8666). Under water 2GHz+ should be fairly easy without causing any instability, so quite impressed so far

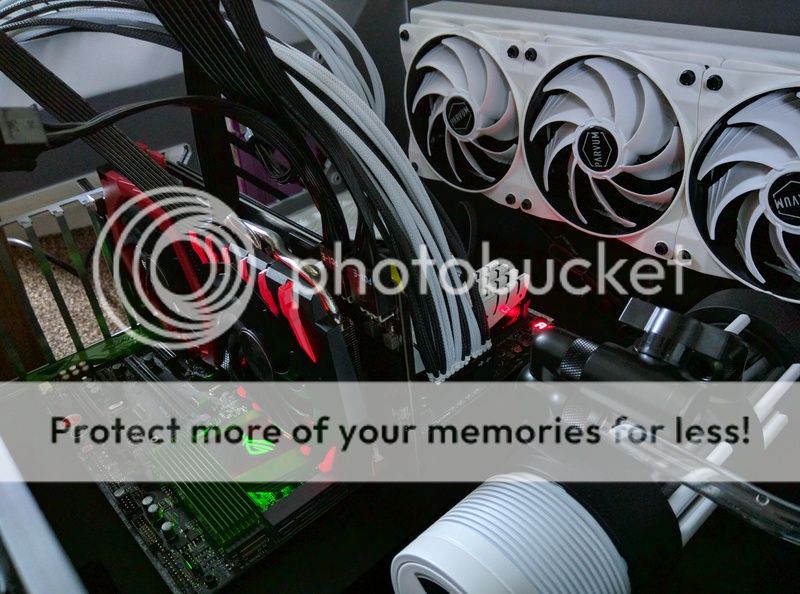

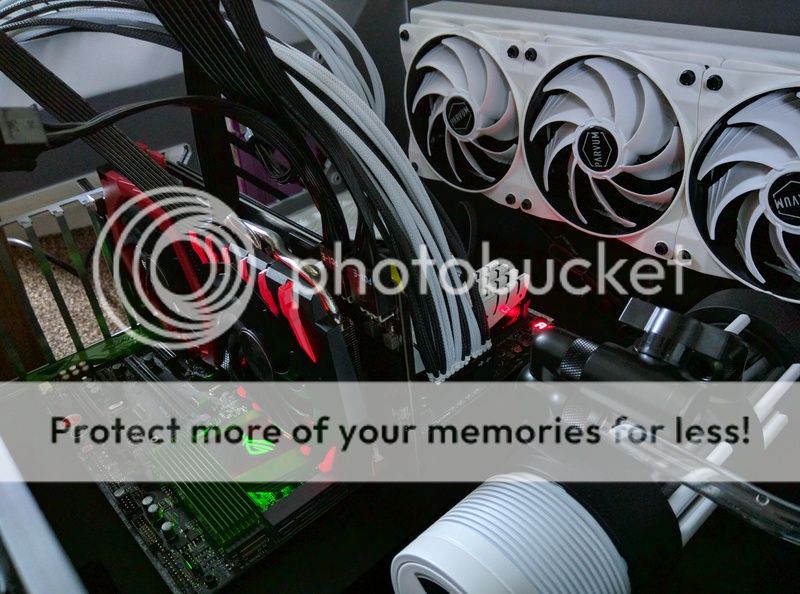

Only running a quick bench but couldn't resist a quick play to see what she's gonna look like lit up...

Not sure why the green fans have such an awful blue tinge in pics (look far better in reality) but damn, Parvum did one mighty fine job of that dragon. Looks awesome lit up cheers guys #OneHappyCustomer

#OneHappyCustomer

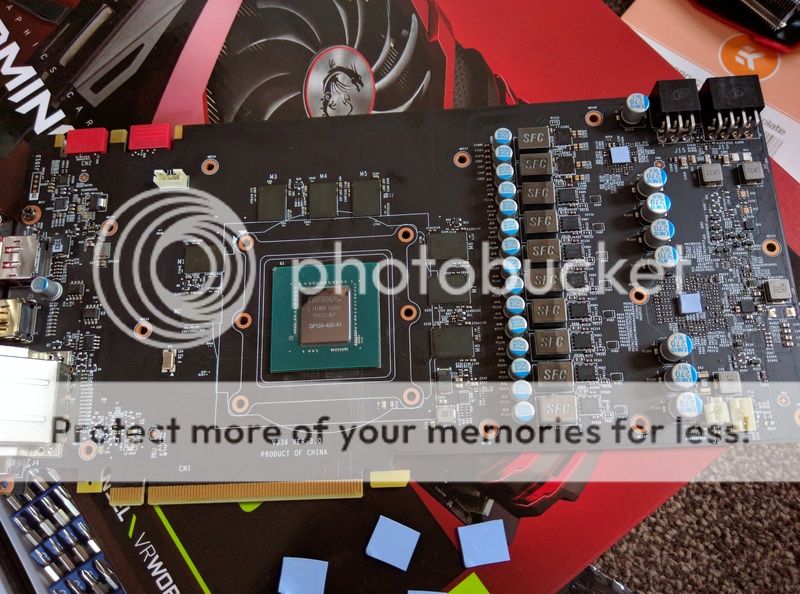

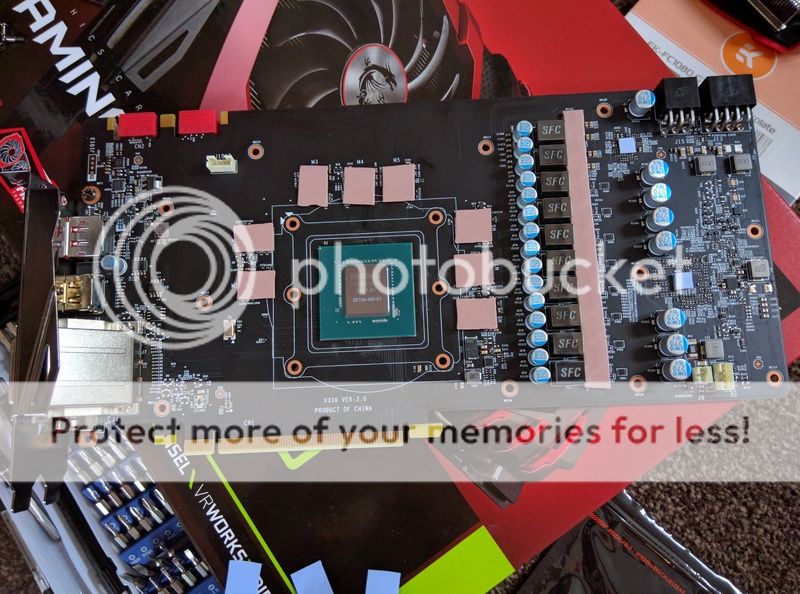

Back to work: Testing done, time to strip the card and fit the block. Backplate will have to wait until a later date.

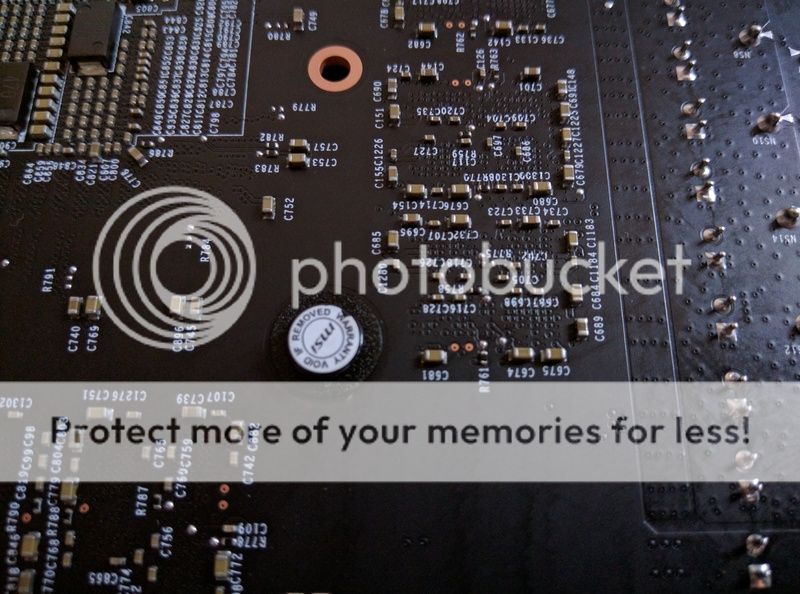

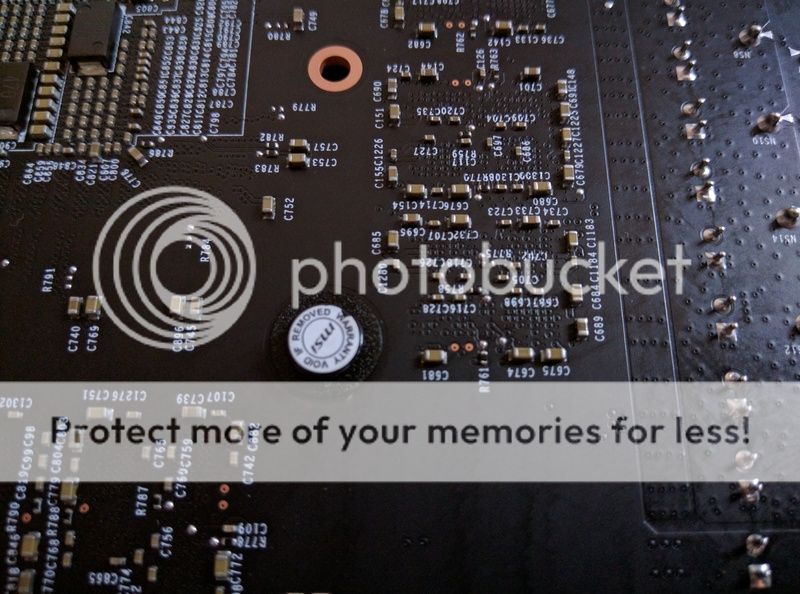

Pfft, warranties are for pansies

That's one fair sized blob of thermal paste...

That's better...

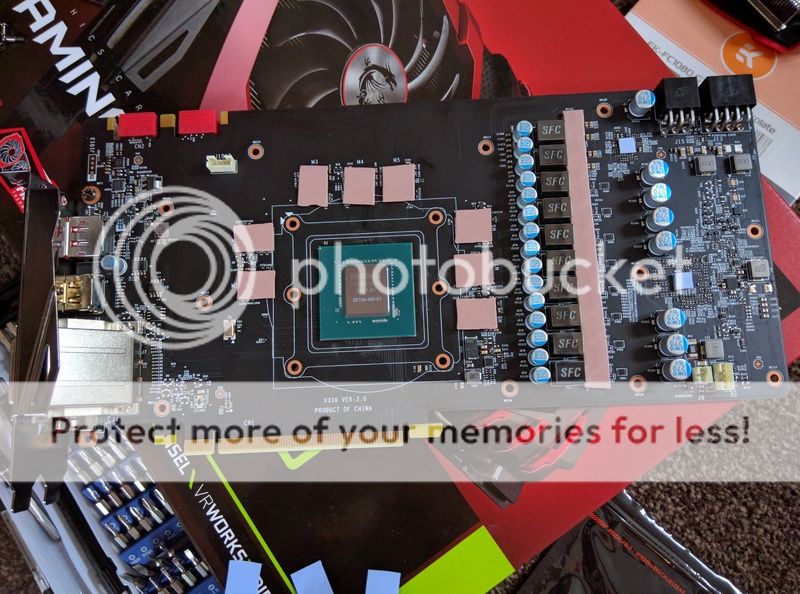

The EK stuff might be adequate, but adequate wont do, so Thermal Grizzly it is

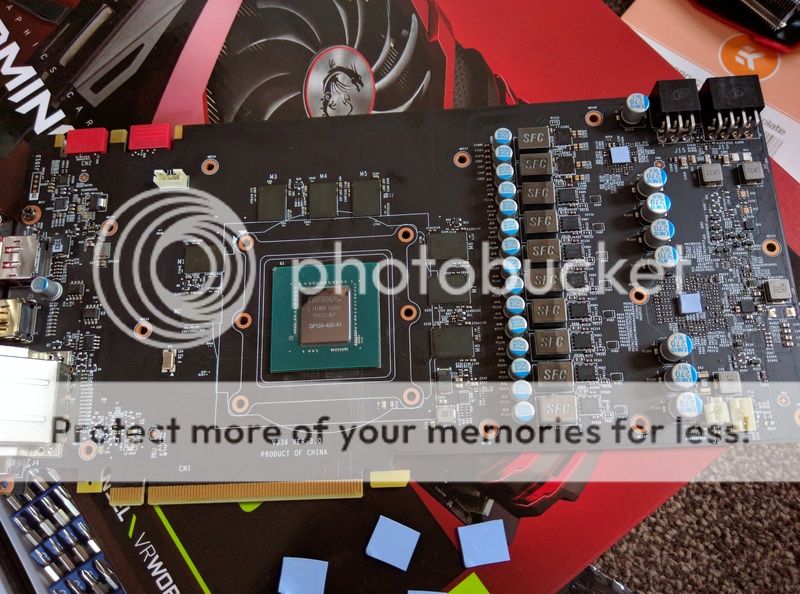

Naked board. Why do they always look so good without the fugly plastic covers?

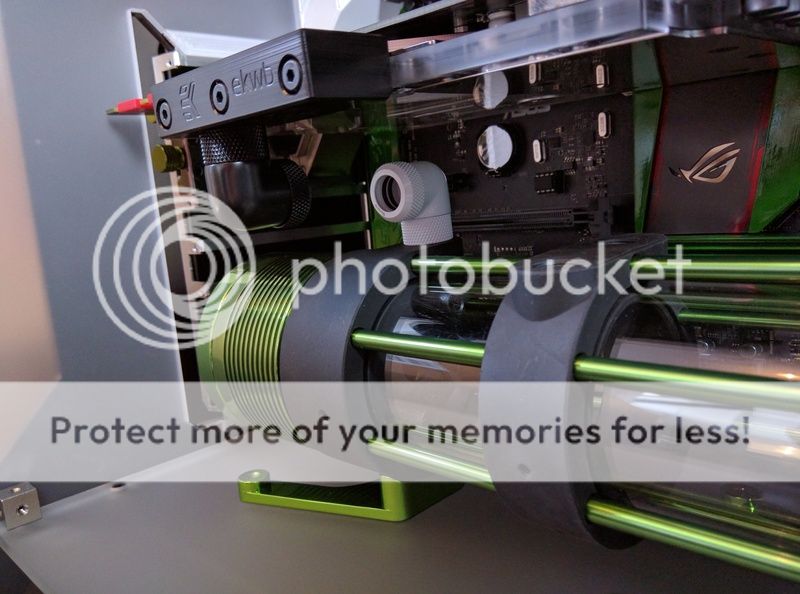

Mmmmmmmm, sexy block is sexy

That's it for today, now need to figure out how I'm going to route the bottom loop... Almost be a shame to hide the motherboard after time spent painting it but gotta be done!

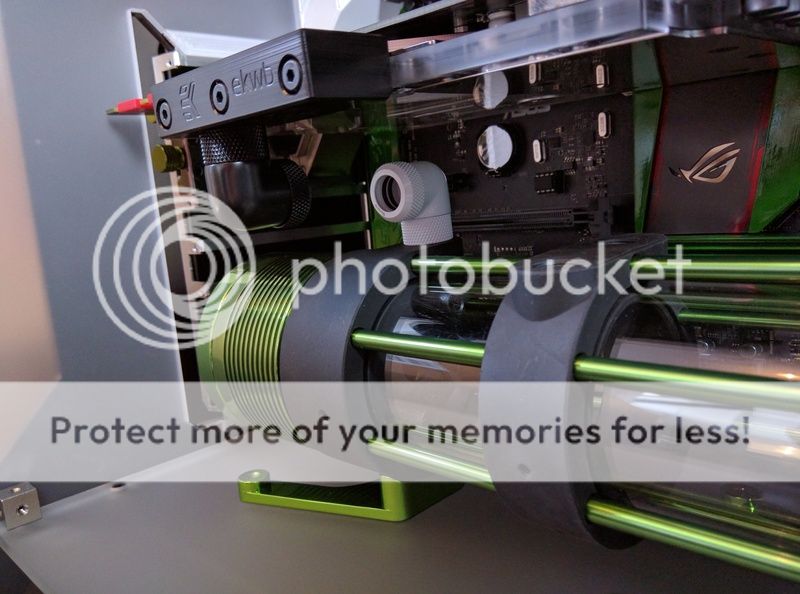

Going to mount the bottom reservoir underneath the GPU. I know some people are going to hate the look of this, but hey, I said from the beginning this was going to have some 'different' design ideas

Just need to decide which way the legs should face now... First one looks more balanced, so going with that

Quick 1½mm spacer under each 90° and jobs a good'un

Other option was the taller, simpler mounts, but not sure I'm really liking that so much, stands far too high off the floor.

Plan is to run a straight tube from pump to GPU, then have a 90° off the right hand port with a pipe running parallel > 90° bend through into lower compartment, mirrored again from one of the centre ports of the reservoir. Thoughts? Nice idea or fugly bodge job?

Still not liking the sound of metal being that close to extremely expensive components though, think I need a big dose of 'man the **** up' lol although even Thermal Grizzly Kryonaut has got to be better than the rubbish Intel use as standard if I do wuss out

To the updates! Ran a quick GPU benchmark / stress test to make sure everything was working properly, with CPU @ stock, GPU @ stock and RAM @ XMP. The scores? Time Spy 7189 with a GPU score of 7649. Chucked the Temp & Power limits up to max and added a quick +46MHz onto the core for a quick test and it improved to 7237 (GPU 7717 / CPU 5353) without breaking a sweat, hitting 1987MHz. Fire Strike at the same clock scored 17956 (graphics 22873 / physics 13203 / combined 8666). Under water 2GHz+ should be fairly easy without causing any instability, so quite impressed so far

Only running a quick bench but couldn't resist a quick play to see what she's gonna look like lit up...

Not sure why the green fans have such an awful blue tinge in pics (look far better in reality) but damn, Parvum did one mighty fine job of that dragon. Looks awesome lit up cheers guys

#OneHappyCustomer

#OneHappyCustomer

Back to work: Testing done, time to strip the card and fit the block. Backplate will have to wait until a later date.

Pfft, warranties are for pansies

That's one fair sized blob of thermal paste...

That's better...

The EK stuff might be adequate, but adequate wont do, so Thermal Grizzly it is

Naked board. Why do they always look so good without the fugly plastic covers?

Mmmmmmmm, sexy block is sexy

That's it for today, now need to figure out how I'm going to route the bottom loop... Almost be a shame to hide the motherboard after time spent painting it but gotta be done!

Going to mount the bottom reservoir underneath the GPU. I know some people are going to hate the look of this, but hey, I said from the beginning this was going to have some 'different' design ideas

Just need to decide which way the legs should face now... First one looks more balanced, so going with that

Quick 1½mm spacer under each 90° and jobs a good'un

Other option was the taller, simpler mounts, but not sure I'm really liking that so much, stands far too high off the floor.

Plan is to run a straight tube from pump to GPU, then have a 90° off the right hand port with a pipe running parallel > 90° bend through into lower compartment, mirrored again from one of the centre ports of the reservoir. Thoughts? Nice idea or fugly bodge job?

It probably would be...but you won't do it for the same reason that didn't go for the '[more than] good enough' 1070 or the 'good enough' 3.5mW/K EK thermal pads. Once you mask off the contacts on the top of the cpu (green board part) there's nothing else to short out for quite some distance. It would have to escape the confines of the IHS, travel across the cpu, find its way out of the socket, onto the motherboard and then be enough of it to bridge some traces...which are probably insulated by the top-coat on the board anyway. If you've put that much too much paste on the top of the die, you're gonna have problems getting the IHS back on the top!

Haha that's very true, this will be my last build for a very long time so determined to do things properly

Will definitely be stealing your idea of using clear nail varnish just to make sure!

Think you had trouble with the fans looking the wrong colour in pics before. As long as they look good in thefleshfin, it's all good. Dragon looks really nice.

That's true, just slightly irritating that it doesn't look as good in the pictures as it should do. Might have to cheat and alter the colour balance with GIMP for the final shots

Thanks, I love how the added details show up so well when it's lit up

Most of them will honour the warranty if you block up a card. As long as you've not obviously done something stupid, that is. They'll probably want the original heatsink and fan back on it - whether that's for completeness, their testing or a knowing plausible deniability I'm not sure.

That's good to know, although obviously hoping it isn't needed! Heard MSI are one of the better companies when it comes to warranties so fingers crossed.

They ditched the metal frame around the GPU?I'll admit that it was a pain to clean the goop out from the edges and the corners...but it looked sort of cool. Different from just another CPU/GPU/APU/FPU.

This is the first one I've ever 'blocked' so no idea

Cool. Hadn't spotted those existed. There are 'better' ones available but the price gets ridiculous. Looks like those are a good balance between cost and performance. Two different thicknesses presumably....unless the block for the 1080 only requires one - it was 0.5mm and 1mm for the 980Ti.

Yeah the small squares are 0.5mm and the long piece is 1mm. Not the best thermal pads you can buy but as you said, they're better than the EK ones and aren't stupidly expensive, so well worth the cash for a small upgrade.

Because the heatsinks and fans are so big....and we've all been conditioned by Apple (and others) to see slim and clean as beautiful.

Must admit I was quite surprised at how big the stock cooler was, looks so much sleeker with the EK block on

Did you try the third way which would be to have the legs spread (no innuendo intended)? Like this > <

Otherwise, the first one.

I did mate but wasn't overly keen on it, think the first pic is definitely winning!

Nope. Not unless you were going for a more industrial look....and then the green pump cover would need to be black or chrome. Look at me talking colours like I've got a Scooby!

Think they could look good in the right build but like you said, doesn't really go with this one so going to stick with the lower, more interesting mount

I think I understand what you mean. You might want to consider soft tube from pump to gpu - with the same 90's as you've got. It'd just give the pump some vibration isolation and you wouldn't see it anyway - or if you do it'll be straight and clear and you won't notice the difference. You'd need some rubber under the feet or between the feet and pump/res too. Depends how much the noise irritates you - me, it's a fairly personal vendetta.

Luckily the PC will be on carpet under my desk, so pump vibration noise isn't really much of an issue for me. Soft tubing would be easier and add some isolation from pump vibration but I think it would always irritate me that it wasn't exactly the same as the other pipes, so I'll have to go with the noisy option. Planning on using soft tubing in the bottom compartment though where it doesn't show

If you have the exit pipe from the gpu running horizontally across the case, it will match up with the other horizontal pipes that are parallel. When it then bends 90° downwards, it'll be parallel (bends willing!) to the drain tube's downward section.

The tube from lower compartment to res will presumably follow this in parallel. Looks like there will be pass-throughs and step-drills on your shopping list!

That was actually my initial plan, but unfortunately the radiator in the bottom is right where the pipe would need to pass through the floor so I decided running them all parallel towards the motherboard was the neatest / easiest solution. Not quite as fancy but should look OK if it all goes to plan

Yep, definitely better lit up

After playing about some more, leaving the legs pointing different directions and giving it more thought I've decided Cenedd was right. And I was wrong. Again. Going to have the legs like this now...

The left hand pipe goes straight between pump and GPU, then the centre & right hand pipes both stay parallel with it towards the MoBo > 90° bend and down through the floor. Can you guess where the right hand one lines up?

Yes, that little cross. Smack bang in the middle of the only awkward connection: The massive bloody front USB!

Luckily, after a small amount of yellow star words were uttered, I found this:

Problem solved

Now the proper fun begins, as it's time to strip the entire case back to a flat pack, clean all of the radiators, mount the bottom reservoir, sort the lower compartment (soft tubing, I'm bored of bending this hard stuff!), sleeve the GPU cables and then rebuild the whole thing again. Oh yes, forgot I also need to paint the GPU backplate, make the vinyl floor, sort all of the lighting, get the faulty EL panel replaced etc etc. Could be quite some time but will leave it until I get a decent sized update before posting again, so see you all in a few weeks / months / years time!!

The left hand pipe goes straight between pump and GPU, then the centre & right hand pipes both stay parallel with it towards the MoBo > 90° bend and down through the floor. Can you guess where the right hand one lines up?

Yes, that little cross. Smack bang in the middle of the only awkward connection: The massive bloody front USB!

Luckily, after a small amount of yellow star words were uttered, I found this:

Problem solved

Now the proper fun begins, as it's time to strip the entire case back to a flat pack, clean all of the radiators, mount the bottom reservoir, sort the lower compartment (soft tubing, I'm bored of bending this hard stuff!), sleeve the GPU cables and then rebuild the whole thing again. Oh yes, forgot I also need to paint the GPU backplate, make the vinyl floor, sort all of the lighting, get the faulty EL panel replaced etc etc. Could be quite some time but will leave it until I get a decent sized update before posting again, so see you all in a few weeks / months / years time!!

There is mate, but unfortunately it would leave the hideously ugly beast of a cable protruding out into the case, and then where the case has 2 massive holes for cables to go through I bet you can guess where the USB falls... Yep, right between em

With the small connector it should now be completely out of sight behind the reservoir, just got to wait for it to arrive now to check before ripping everything apart. I know it's 99.9% guaranteed to work but somehow find myself being so much more cautious with this build it's actually starting to scare me

With the small connector it should now be completely out of sight behind the reservoir, just got to wait for it to arrive now to check before ripping everything apart. I know it's 99.9% guaranteed to work but somehow find myself being so much more cautious with this build it's actually starting to scare me

You honestly think that would help? I'm not sure any woman has ever told a man he was right about anything, it's just a series of words they all find impossible to link together

That's true, as annoying as it was (and could have been if I hadn't found an easy solution!) it could definitely have been a lot worse. Worst case was leave the front USB unplugged, which as I'll be spending most of my time using a Linux distro that seemingly hates front USB ports isn't really an issue. Could come in handy for chucking a controller in quick when gaming though...

For some reason the actual bending hasn't annoyed me in the slightest, just wish I'd get the odd one in the right place and/or in the right direction. Good thing with the bottom loop is they should all be out of sight apart from the right hand side one... *Bodge job in coming!*

That's true, as annoying as it was (and could have been if I hadn't found an easy solution!) it could definitely have been a lot worse. Worst case was leave the front USB unplugged, which as I'll be spending most of my time using a Linux distro that seemingly hates front USB ports isn't really an issue. Could come in handy for chucking a controller in quick when gaming though...

For some reason the actual bending hasn't annoyed me in the slightest, just wish I'd get the odd one in the right place and/or in the right direction. Good thing with the bottom loop is they should all be out of sight apart from the right hand side one... *Bodge job in coming!*

Didn't have to take the missus into town for a driving lesson today, so had a spare hour that I wasn't expecting to have and couldn't resist another little update...

The result? Where the PC once stood we now have this sad looking collection of parts...

Yep, fully torn apart with the radiators lined up ready to be flushed later

Also got the reservoir mounted, the pass-throughs done and the bottom Aquaero mounted. Not too bad for a random spare hour

Hoping if I can get work finished on time there might be another spare hour tonight to get some vinyl done... Hopefully, possibly but probably not! Laters

The result? Where the PC once stood we now have this sad looking collection of parts...

Yep, fully torn apart with the radiators lined up ready to be flushed later

Also got the reservoir mounted, the pass-throughs done and the bottom Aquaero mounted. Not too bad for a random spare hour

Hoping if I can get work finished on time there might be another spare hour tonight to get some vinyl done... Hopefully, possibly but probably not! Laters

Cenedd;30500347 said:Surely a random spare hour is what you expect it to take...rather than the 6 hours it usually turns into!

Pass-throughs are looking good. I'd be tempted to do them in metalwork...but that's 'cos I've expended all my bending-related colourful language!

For the first time since the build began not a single thing went wrong today... Thinking about it I probably should have pulled an all nighter and got it finished while the going is good

Just hope they line up now when the GPU is fitted. Measured it all a dozen times so there's hope lol you mean chrome pipes? That's an idea I'm not sure my sanity could take, getting the PETG right makes me swear enough!

LePhuronn;30500361 said:that acrylic is sick

Thanks, hopefully it'll look even better once it's lit up! A new inverter was supposed to have been posted today, so hopefully it'll be here this week and I can get the EL panel done

You might be right mate, although if I'm having one of those days it usually starts hinting at me to quit about 3 minutes in when I notice blood dripping onto something

Ah, now I get ya. Just looked and Barrow do extenders up to 40mm long, so could easily do extenders from the pass-throughs, then a 90° > straight pipe into reservoir / GPU... Damn you, that's actually sounding like it could look OK! Will try it with PETG first but might give that a look afterwards just to see

Ah, now I get ya. Just looked and Barrow do extenders up to 40mm long, so could easily do extenders from the pass-throughs, then a 90° > straight pipe into reservoir / GPU... Damn you, that's actually sounding like it could look OK! Will try it with PETG first but might give that a look afterwards just to see