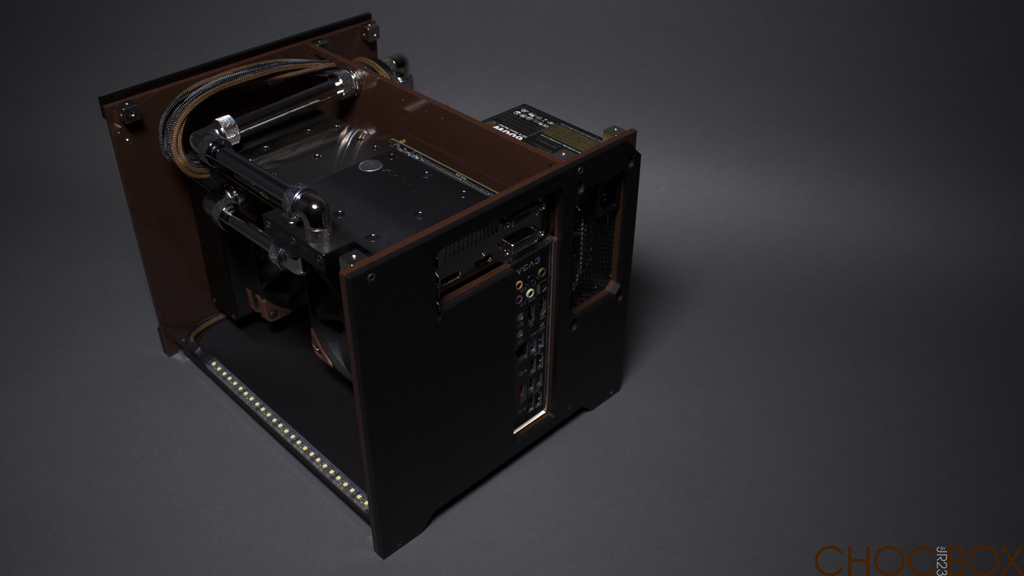

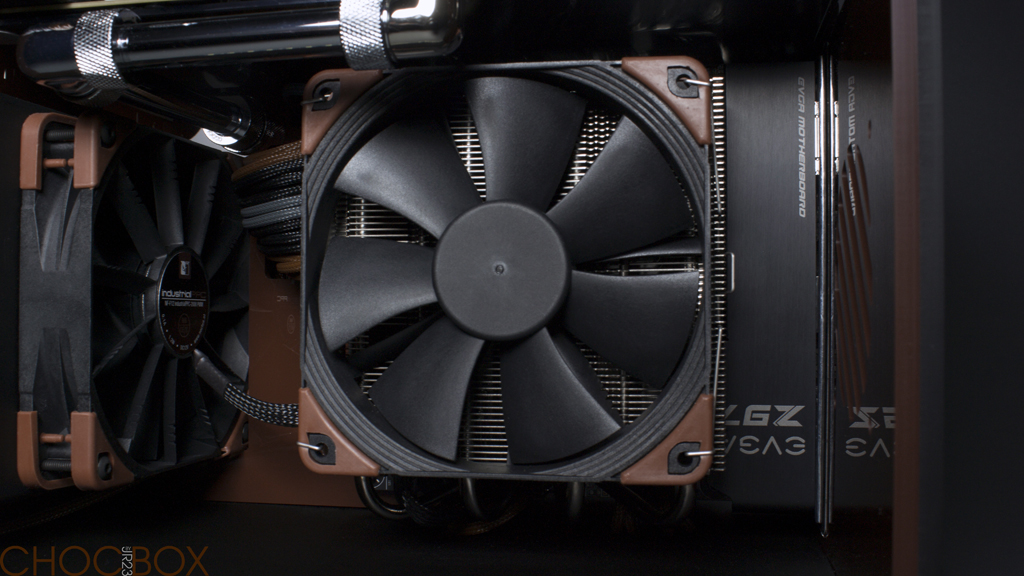

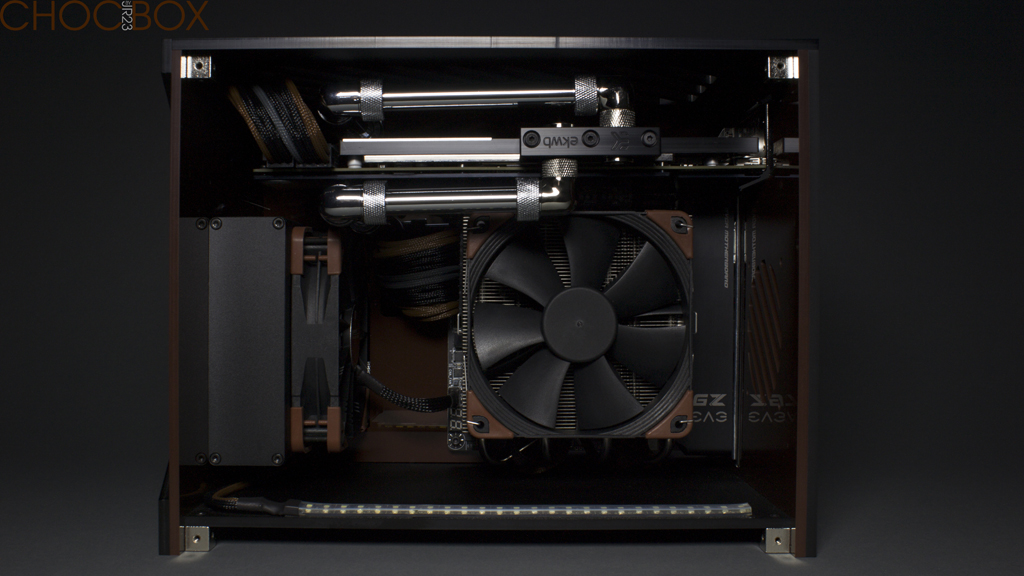

I love this build, not only bcos I rly like noctua stuff, I duno it just looks really classy build with a touch of bringing sexy back to the aircooler

I do wonder tho if you ever thought in a moment of madnesss doing the coolant brown

it could have been a bubbly chocolate fondue!

Thank you, brown coolant has come up in conversation on other build logs. The only other brown build i've seen in person is 'The Bear' and I don't think classy would be a word I would use to describe it. That had brown painted metal parts, brown painted plastic parts, brown coolant, brown acrylic and they just didn't come out looking that coherent. It's an extremely difficult colour to match, not only can it be too light or dark, it can be too red, too yellow and too blue all at the same time. And it's not like there are many alternatives when it comes to brown.

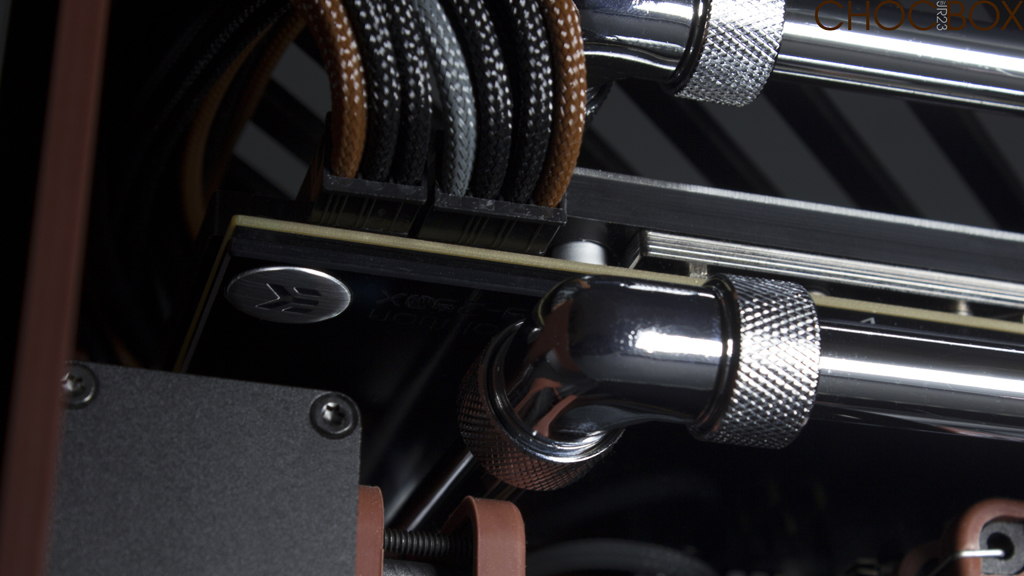

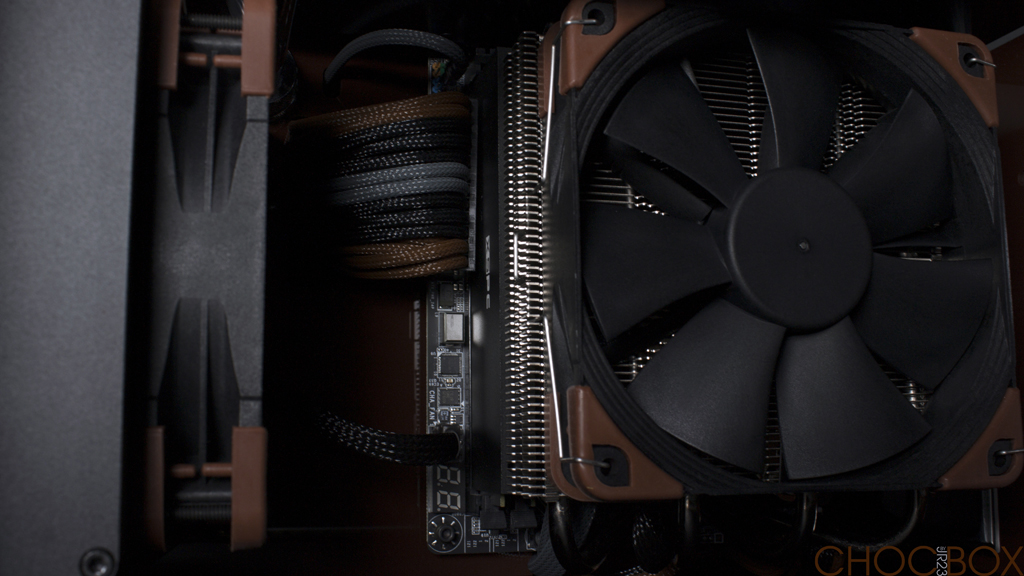

So far i've been extremely lucky in that the acrylic used in the case matches the fans very closely. Infact absolutely amazingly considering all I told Parvum was "can you make it brown acrylic, brown like chocolate" and i'd never seen the fans at that point. Selecting the sleeve was another challenge right now there is Teleios available in brown and... not much else. As it turns out when laid tight over black wire it looks right. But if it hadn't I would have gone with all grey or black to avoid a potential 'nearly' matched colour, if it's not going to match i'd sooner contrast it which is why I often default back to black. Finding or even mixing brown coolant would have been the same story all over again and at the end of the day it would have only been visible in the res, which is in the back of the case sitting right in the centre of a brown interior. I honestly think it would be too much brown for one, a pain to match and a lot more effort to maintain. If I run clear I think things will still look plenty brown enough in the back and it should give me the least trouble.

I'm not worried about a little trouble, time or money if it's going to provide aesthetic value to the build but in my opinion it wouldn't of really worked.

JR

Last edited:

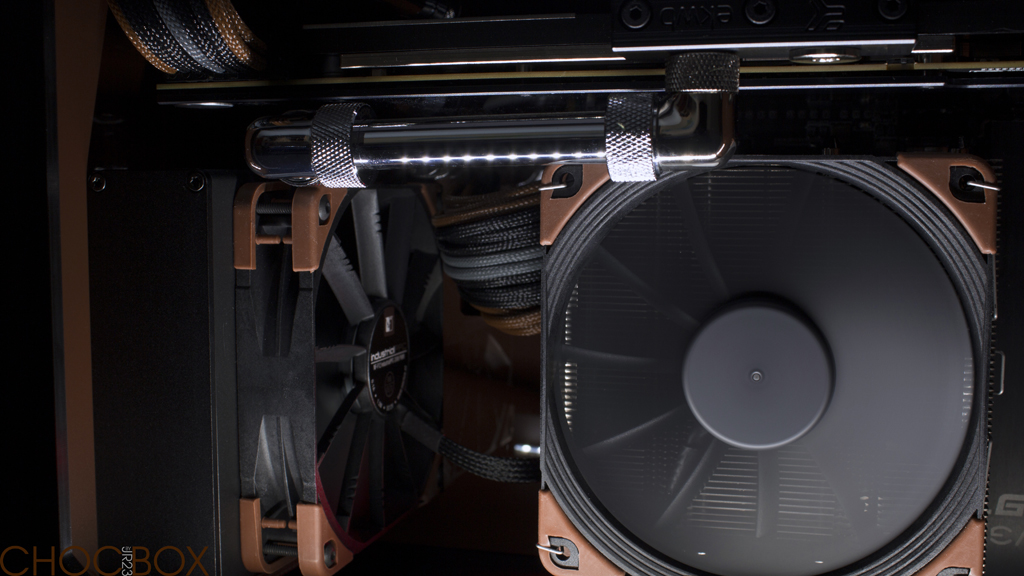

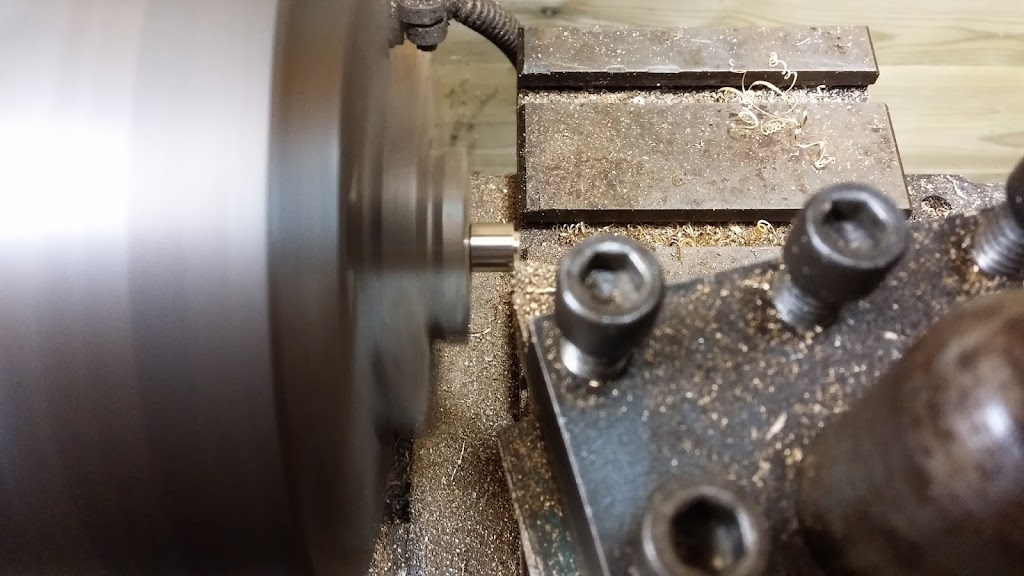

what could this special shape chocolate be for?

what could this special shape chocolate be for?