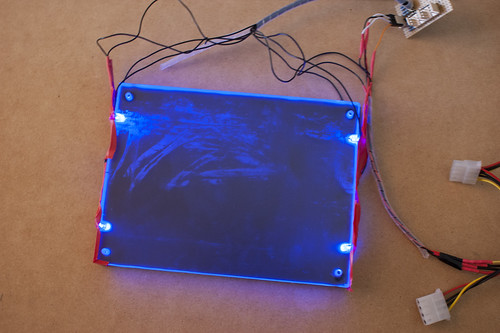

In this post I will show some pictures of more new hardware, a long with a prototype light box I'm trying to make this uses 10mm Frosted Acrylic currently with a 5mm gloss acrylic underneath to bounce the light upwards, using 4 blue 5000cmd LED's placed in each corner. I will be looking to get some mirror acrylic and see what sort of effect that creates but here is the gloss black for now.

New hardware, got myself some Noiseblocker XL2 fans for the radiators (Might get some more for general case fans later on:

Singular Shot of fan:

All four attached to the 480:

And staying in control with Zalaman MFC1-Plus:

http://farm8.staticflickr.com/7114/7781231892_359d814645.jpg

As for the prototype lightbox

The setup:

How it looks from shallow angle:

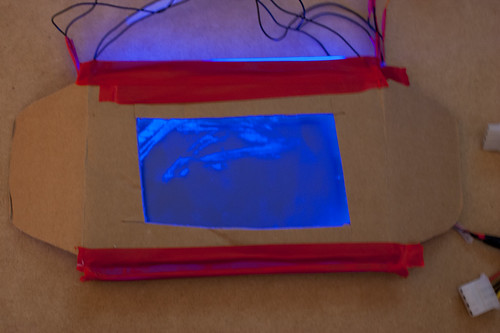

How it looks from above notice the more perpendicular you go the less light is viewable:

With a cardboard shroud around, this is because it will be attached to the panels of the case (cardboard = aluminium sheet):

Please note that this was a spare piece of acrylic due to the imperfections in the face which you can see from the above pictures, as always you can view the rest of the images over on my flickr (

Link Here.) and if you have any questions please don't hesitate to ask.

Regards

-Ninja