This is going to be a collation of the upgrades I'm doing for my Ender 5 in case anyone else wants to see the pitfalls.

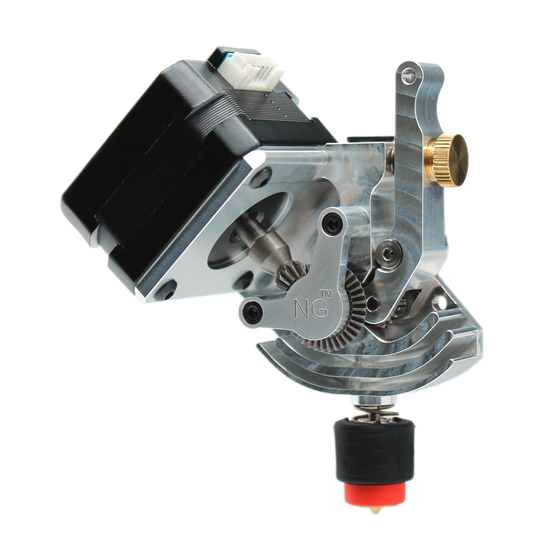

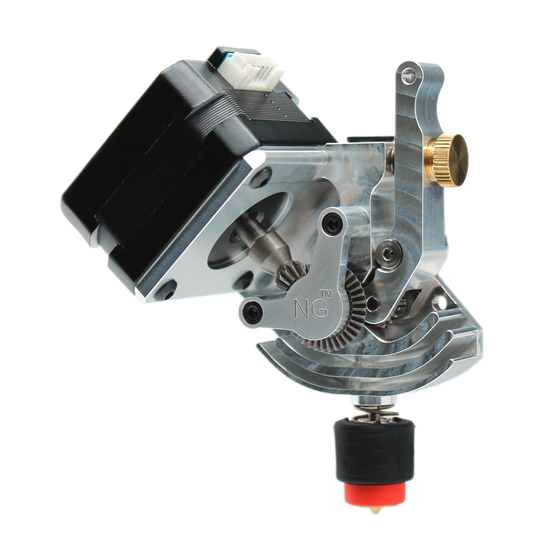

it comprises of two main things, firstly Micro-Swiss NG REVO Direct Drive Extruder:

Endorphin 3D

half core XY conversion. moves the stepper off the Y axis to the frame.

I'll also upgrade to klipper at the same time.

it comprises of two main things, firstly Micro-Swiss NG REVO Direct Drive Extruder:

Endorphin 3D

Endorphin 3D Printer

Endorphin is an Ender 5 mod to modernize and speed up your printer

endorphin3d.com

half core XY conversion. moves the stepper off the Y axis to the frame.

I'll also upgrade to klipper at the same time.