You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HAF932 build log and custom filters

- Thread starter razer1978

- Start date

More options

Thread starter's postsThat mesh stuff, could you not cut a patch to directly cover the fan instead? That way it would be backed off from the front grill and won't be as conspicuous.

it could be fitted anywhere you like really, i just thought doing it like that would make it easier to clean as all i have to do is run a paint brush over the front and job done

a little update on temps, there's very little difference between with and without the mesh but thats based on the front filter only will do some proper testing when the drive bay and side filters are made and fitted

does anyone know if there's a spray glue that will hold this??? i know normal spray glue is ok with paper and card but never tried it steel on steel before

Where'd you get that stuff from? It's exactly what I've been looking for.

just google "Medium Fine Stainless Steel Woven Wire Mesh Fat Quarter" and you should find the "auction site" (hopefully doing this within the rules, if not please let me know mods

)

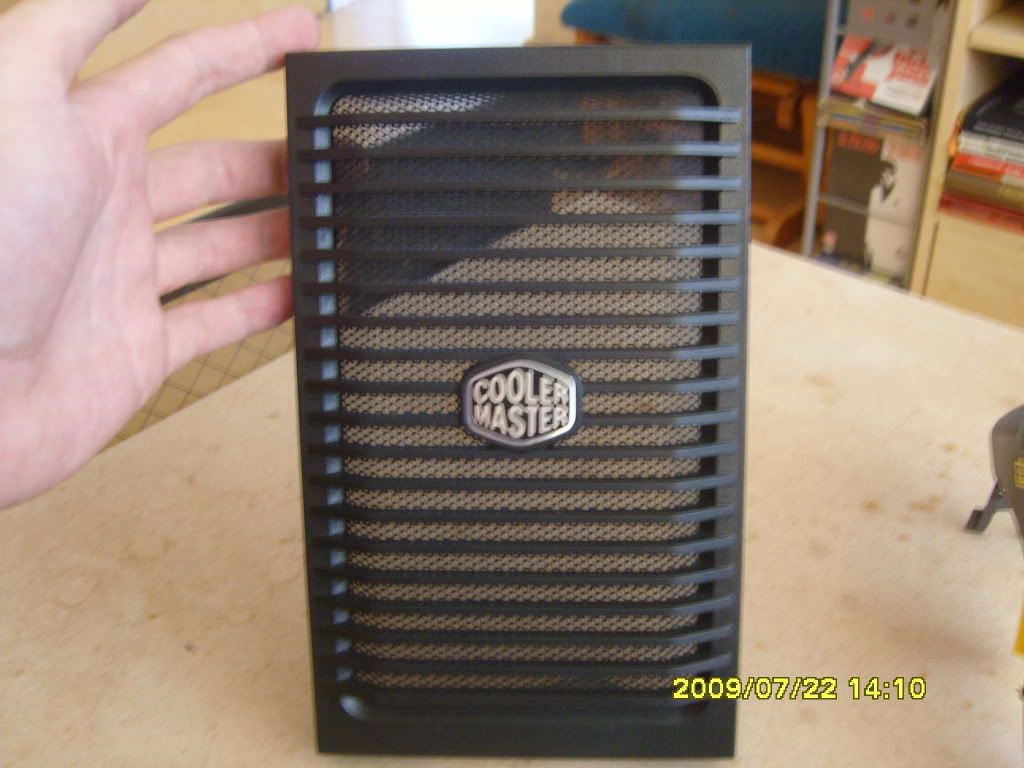

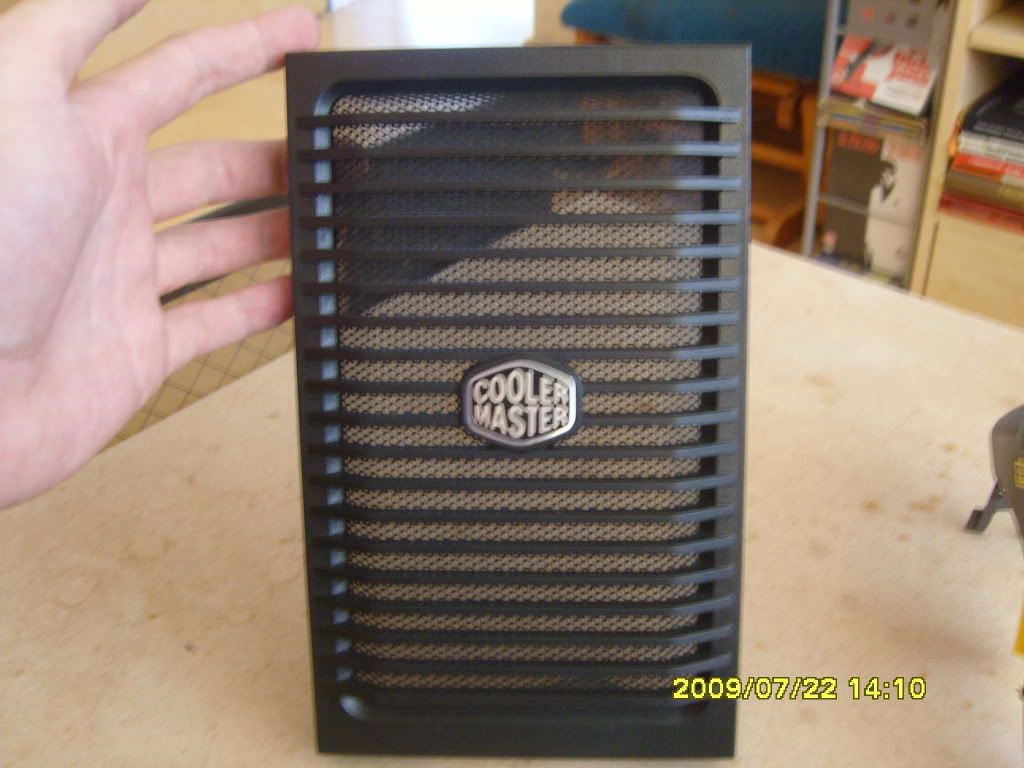

)Antec 900 side filter

update time , firstly i have ordered the ink stuff to colour the mesh and hopefully it won't take forever to turn up and as i plan to use hot glue to fix the mesh i want to wait till it's done, but i have been having a play and have fixed some to the side panel of my old 900

, firstly i have ordered the ink stuff to colour the mesh and hopefully it won't take forever to turn up and as i plan to use hot glue to fix the mesh i want to wait till it's done, but i have been having a play and have fixed some to the side panel of my old 900

firstly i had already removed the window in the side due to the extra cooling i was using before so that was 1 less thing to do but it's only screwed on anyway with little black captive nut things

today i will be using my hot glue gun set to hot and scissors

first cut the mesh to just a little bigger than is needed to cover the area you want the mesh to be, in this case i want the whole side covered

now lay the mesh in place and run the hot glue over the mesh making sure you keep the glue gun close to both so the glue gets to the side panel

leave to set for a couple of mins then pull the mesh tight and then glue the other side, in this case i glued the bit in the middle and then the sides and finished by doing the black mesh part and that's about it

great for them long hot summer days

still need to do something about where the window was so if anyone has any ideas i would be most grateful

anyway enjoy, i'm hoping the ink cone's tomorrow and it works so i can Finnish the filters for my HAF

update time

, firstly i have ordered the ink stuff to colour the mesh and hopefully it won't take forever to turn up and as i plan to use hot glue to fix the mesh i want to wait till it's done, but i have been having a play and have fixed some to the side panel of my old 900

, firstly i have ordered the ink stuff to colour the mesh and hopefully it won't take forever to turn up and as i plan to use hot glue to fix the mesh i want to wait till it's done, but i have been having a play and have fixed some to the side panel of my old 900firstly i had already removed the window in the side due to the extra cooling i was using before so that was 1 less thing to do but it's only screwed on anyway with little black captive nut things

today i will be using my hot glue gun set to hot and scissors

first cut the mesh to just a little bigger than is needed to cover the area you want the mesh to be, in this case i want the whole side covered

now lay the mesh in place and run the hot glue over the mesh making sure you keep the glue gun close to both so the glue gets to the side panel

leave to set for a couple of mins then pull the mesh tight and then glue the other side, in this case i glued the bit in the middle and then the sides and finished by doing the black mesh part and that's about it

great for them long hot summer days

still need to do something about where the window was so if anyone has any ideas i would be most grateful

anyway enjoy, i'm hoping the ink cone's tomorrow and it works so i can Finnish the filters for my HAF

Associate

- Joined

- 20 Oct 2008

- Posts

- 586

- Location

- Cornwall

More good stuff razer, and let me know when your paint arrives, as I need to know more about it - if it breaches the rules, can you please PM me the info about it (the ink) so i can order some once I know if it works for you....!

thanks steve  i will look at the rules again later but the place i got the ink from only do stuff like paint and miniatures so wouldn't think it would be a rule break but i will check to make sure

i will look at the rules again later but the place i got the ink from only do stuff like paint and miniatures so wouldn't think it would be a rule break but i will check to make sure

right time for a small update and at the end i would like you guys to help me decide something

first up i have redone the 120mm filter i made using the old ultra fine mesh

again i will be using my trusty soldering iron set to 420'c

i started off by cutting the mesh slightly bigger than the frame, luckily i had a bit left over from making the 900 side panel, and using the soldering iron gentley press into the mesh until plastic comes through the mesh, leave to set for a few seconds and it's nice and strong then you can streatch the mesh over so it's nice and tight and then do the same with the other corners and then go down the sides

and the finished filter

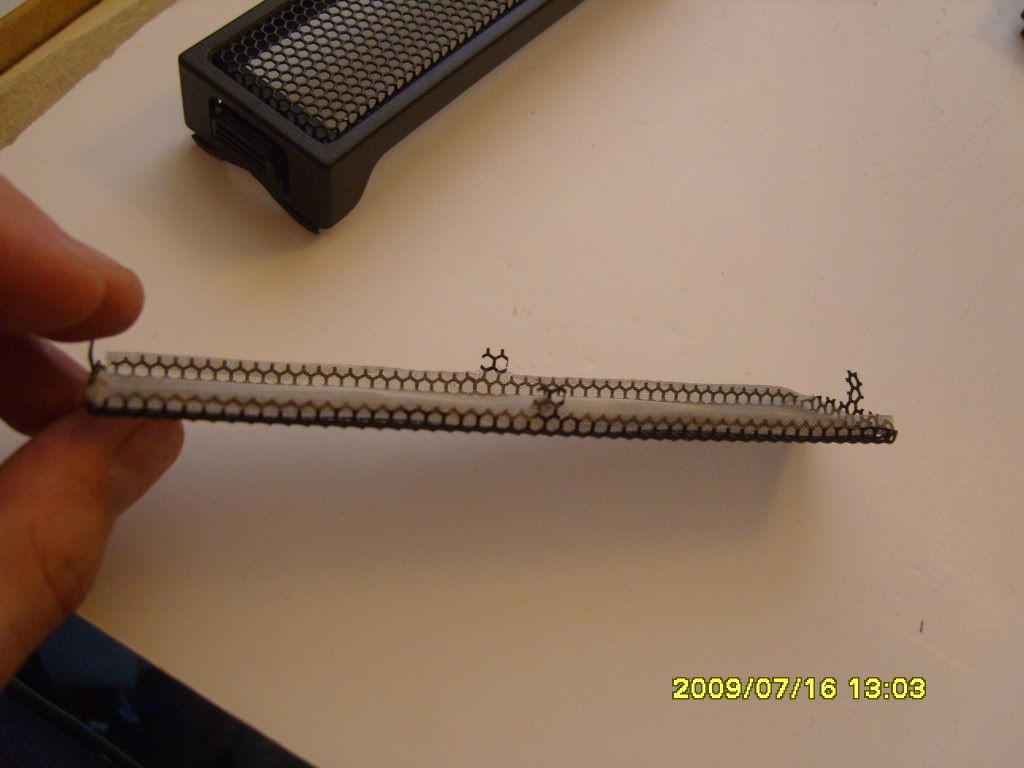

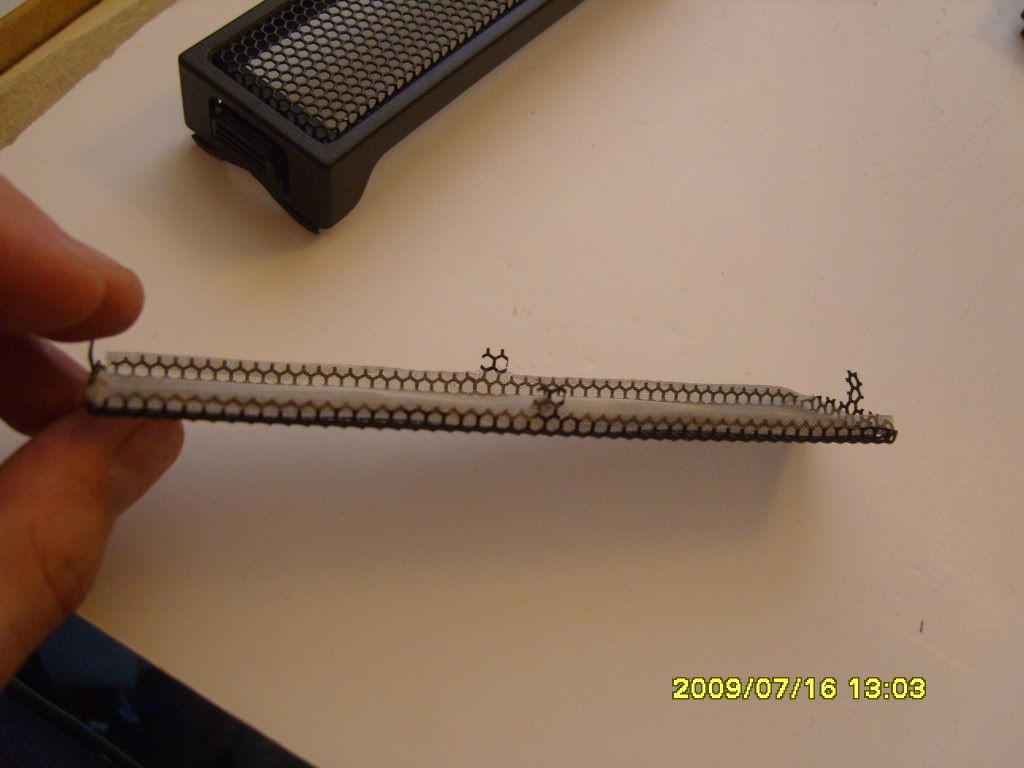

anyway on with the drive bay filters, i've made 2 prototypes 1 using the meathord above and one made by just cutting and folding the mesh in place

1 using the meathord above and one made by just cutting and folding the mesh in place

i will start with the folded one, basicly i just moulded the mesh behind the stock mesh front

it has the advantage of being removable, but is slightly trickier to make

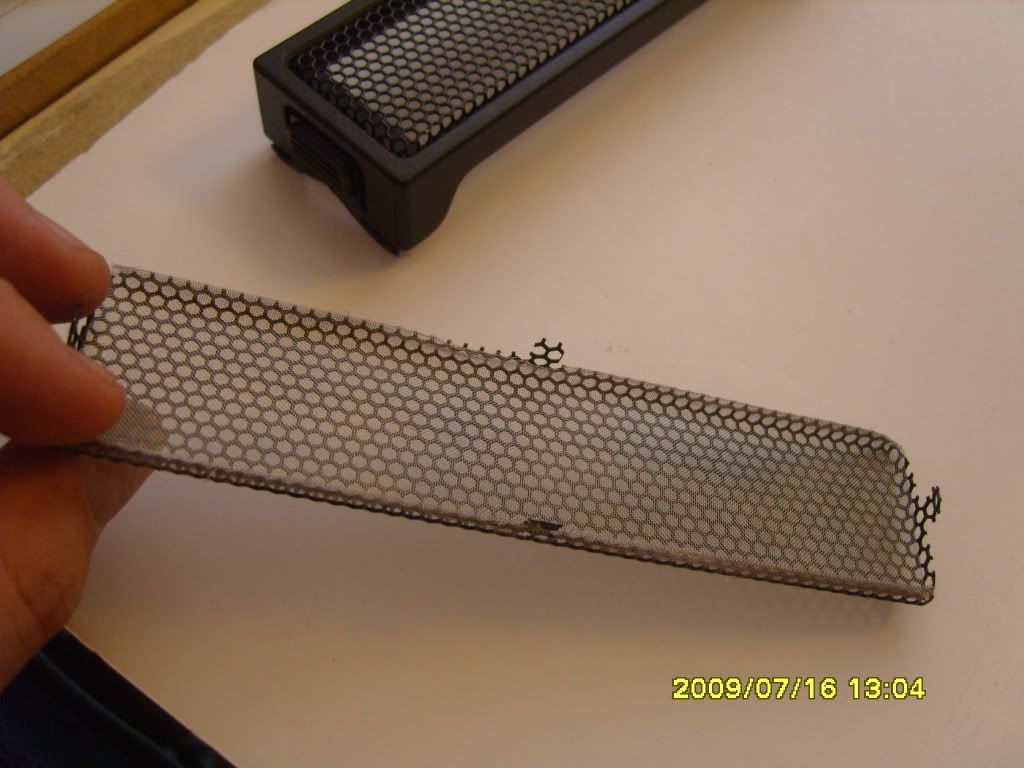

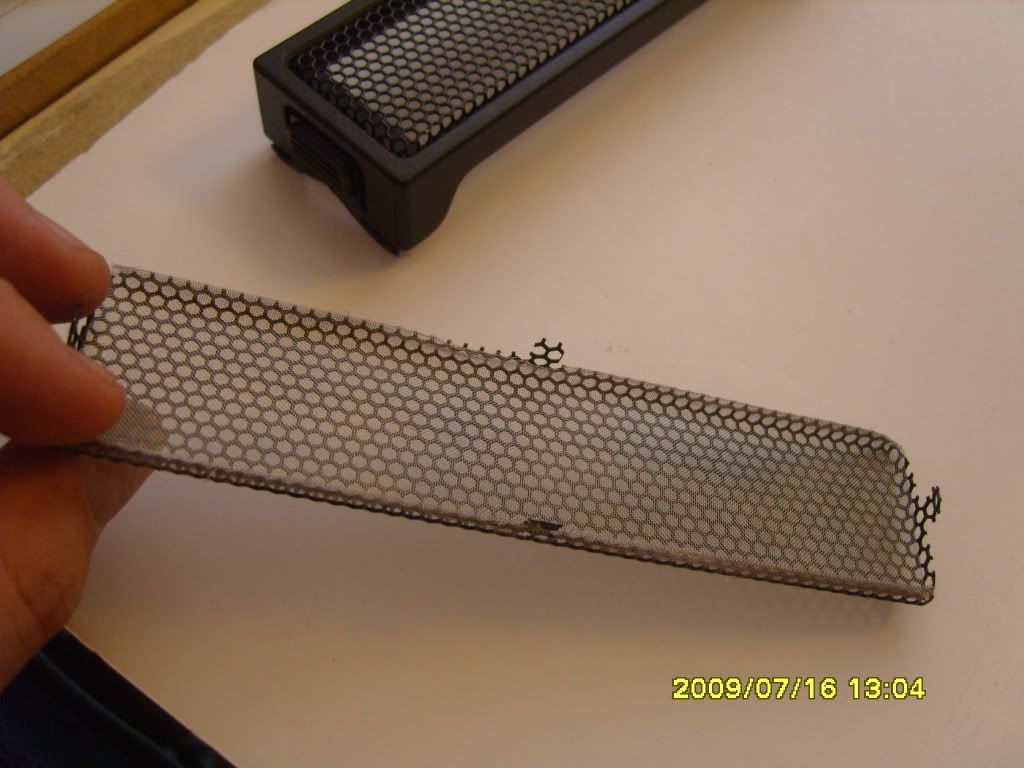

now onto the other version, this one is very simple and quite quick to make as all you need is to cut out a straight piece of mesh with no folding ect

and using a soldering iron do the same as above with the 120mm fan filter, starting at one end and moving upto the other making sure you keep it tight and then finishing by doing the sides

and here's the finished ver2 , much more hidden than the first one but could end up filling the void with dust

, much more hidden than the first one but could end up filling the void with dust  and would need the removal of the black mesh at the front to clean out (not really hard but in time the tabs holding the mesh in place will snap)

and would need the removal of the black mesh at the front to clean out (not really hard but in time the tabs holding the mesh in place will snap)

so now it's decision time what one do you like the look of best? keeping in mind that hopefully the mesh will be ether black or red when complete and i will be putting the mesh behind the side bits ether side of the main front filter

what one do you like the look of best? keeping in mind that hopefully the mesh will be ether black or red when complete and i will be putting the mesh behind the side bits ether side of the main front filter

ver1 is the top one and ver2 is below

so answer's on a post card....................... or just post on here also any questions feel free to ask

also any questions feel free to ask

i will look at the rules again later but the place i got the ink from only do stuff like paint and miniatures so wouldn't think it would be a rule break but i will check to make sure

i will look at the rules again later but the place i got the ink from only do stuff like paint and miniatures so wouldn't think it would be a rule break but i will check to make sureright time for a small update and at the end i would like you guys to help me decide something

first up i have redone the 120mm filter i made using the old ultra fine mesh

again i will be using my trusty soldering iron set to 420'c

i started off by cutting the mesh slightly bigger than the frame, luckily i had a bit left over from making the 900 side panel, and using the soldering iron gentley press into the mesh until plastic comes through the mesh, leave to set for a few seconds and it's nice and strong then you can streatch the mesh over so it's nice and tight and then do the same with the other corners and then go down the sides

and the finished filter

anyway on with the drive bay filters, i've made 2 prototypes

1 using the meathord above and one made by just cutting and folding the mesh in place

1 using the meathord above and one made by just cutting and folding the mesh in placei will start with the folded one, basicly i just moulded the mesh behind the stock mesh front

it has the advantage of being removable, but is slightly trickier to make

now onto the other version, this one is very simple and quite quick to make as all you need is to cut out a straight piece of mesh with no folding ect

and using a soldering iron do the same as above with the 120mm fan filter, starting at one end and moving upto the other making sure you keep it tight and then finishing by doing the sides

and here's the finished ver2

, much more hidden than the first one but could end up filling the void with dust

, much more hidden than the first one but could end up filling the void with dust  and would need the removal of the black mesh at the front to clean out (not really hard but in time the tabs holding the mesh in place will snap)

and would need the removal of the black mesh at the front to clean out (not really hard but in time the tabs holding the mesh in place will snap)

so now it's decision time

what one do you like the look of best? keeping in mind that hopefully the mesh will be ether black or red when complete and i will be putting the mesh behind the side bits ether side of the main front filter

what one do you like the look of best? keeping in mind that hopefully the mesh will be ether black or red when complete and i will be putting the mesh behind the side bits ether side of the main front filterver1 is the top one and ver2 is below

so answer's on a post card....................... or just post on here

also any questions feel free to ask

also any questions feel free to askjust a quick update for those still interested, been having a few problems finding a way to paint the mesh, i tried the ink i said about before but results were poor, the best way i've found so far is permanent marker but even that isn't perfect as it has a hue of reddish purple, so hopefully tomorrow will give spraying it a go, not to confident it will work my guess is it will clog up all the holes but fingers crossed

right here go's

i have decided to go with mesh over the stock to keep the look the same as the main front and sides when i get chance to do it

start with placeing the stock mesh on top of the the filter mesh and folding over one side of the stock mesh panel as tight as possible

then cut to size and repeat on the other side

then fold the ends and cut where needed to keep things tidy

and the end result, well until i find a way to paint the mesh

and here's the mesh in black permanent marker

anyway there you go until next time that is fingers crossed spraying it will sort the colour problem then i can crack on with the rest of the front and the side one

fingers crossed spraying it will sort the colour problem then i can crack on with the rest of the front and the side one

right here go's

i have decided to go with mesh over the stock to keep the look the same as the main front and sides when i get chance to do it

start with placeing the stock mesh on top of the the filter mesh and folding over one side of the stock mesh panel as tight as possible

then cut to size and repeat on the other side

then fold the ends and cut where needed to keep things tidy

and the end result, well until i find a way to paint the mesh

and here's the mesh in black permanent marker

anyway there you go until next time that is

fingers crossed spraying it will sort the colour problem then i can crack on with the rest of the front and the side one

fingers crossed spraying it will sort the colour problem then i can crack on with the rest of the front and the side one*** Finally Finished ***

A long time coming i know but it's finally finished

i thought i would re do the guide from scratch as i had to re make all the filters anyway, so first thing this morning (11am), i started by adding a second coat of paint to the mesh and striped off all the bit's that needed filters making

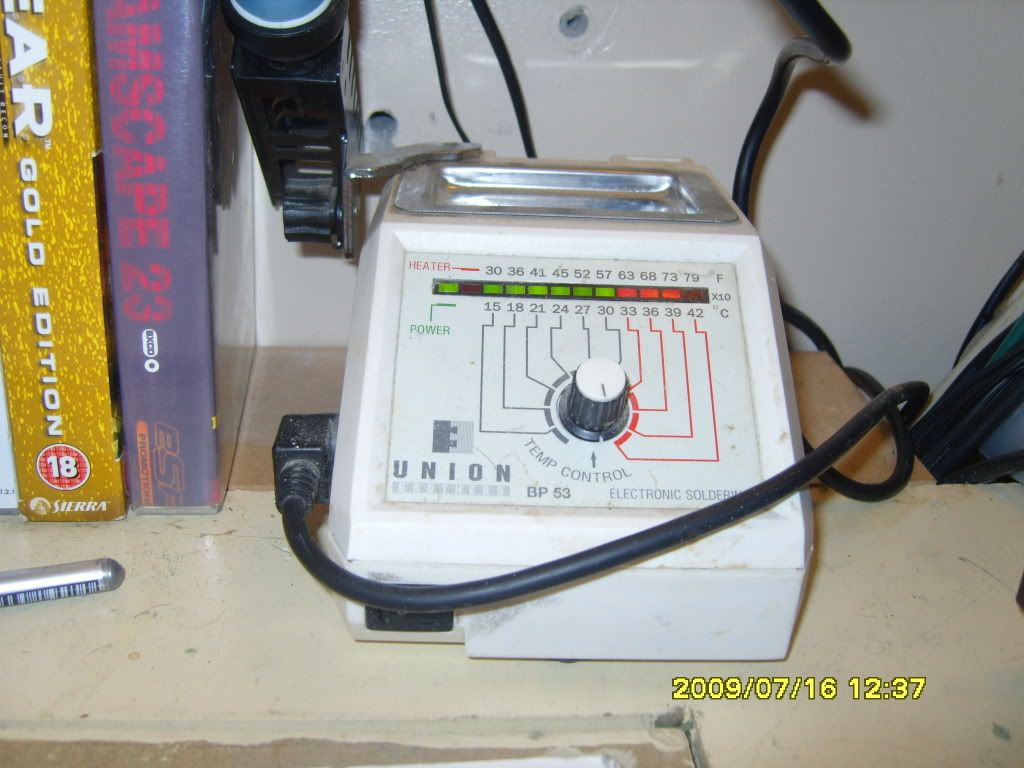

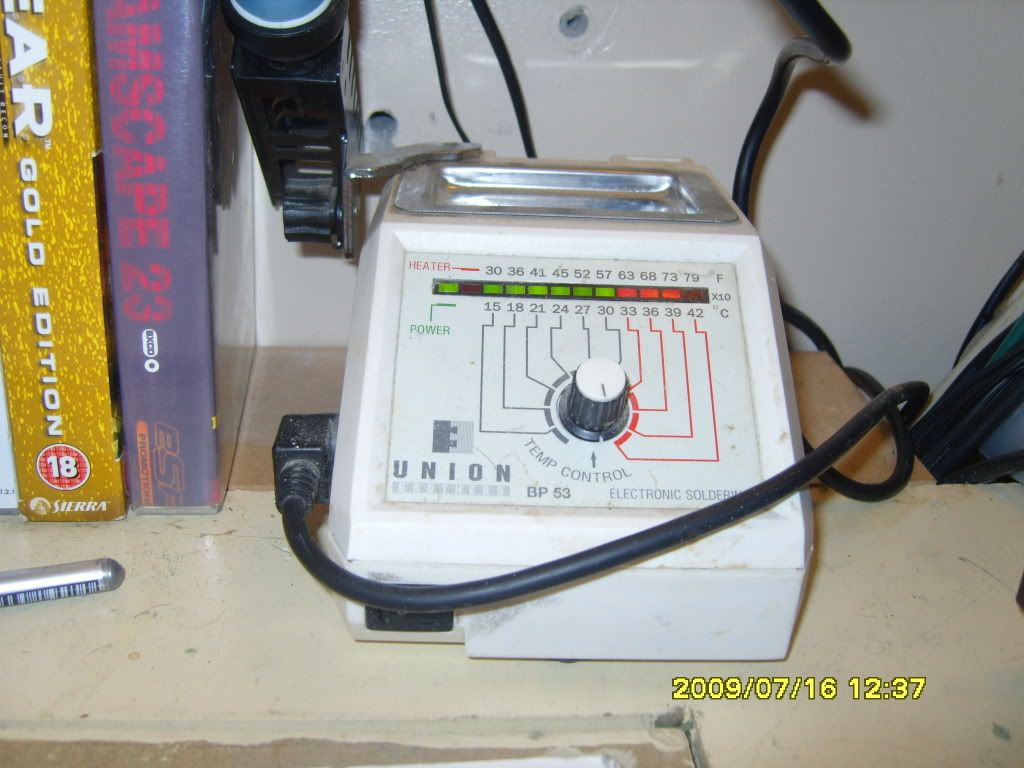

my little helper

i will be using scissors, a hot glue gun (set to hot), a soldering iron (set to very hot (420'c)) and a screwdriver (Philips no1) and plasti kote gloss super paint, and the medium fine mesh

the HAF is so easy to take apart with only 9 screws holding the front side rails and top port/switch panel in place, 4 of the screws are under the front main mesh panel, 3 screws are under the rubber tray insert and the other 2 are behind the top switch/port panel

here's the sizes i cut the mesh to fit each part, please note some trimming will be needed on some parts but will get to that later

main front 235mm x 145mm

drive bay 171mm x 50mm, 5 needed in total

side panel 330mm x 300mm

side front 240mm x 60mm, 2 needed in total

i'm going to start with the side panel, first i measured and cut the mesh to the size above

then using my hot glue gun starting in one corner i pressed the end of the gun into the mesh and lightly pulled the trigger making sure not too much glue come out and so it didn't go everywhere

then keeping the mesh as close to the side panel as possible run glue all round the outside edge finishing by dotting glue around some of the fan mounting points

here's the finished panel with fan fitted

next up the front side panels, i removed the side rails as described above, then because the stock mesh is fixed to the side rail i had to cut off the melted plastic holding the 2 parts together

then cut the mesh to size and pressed into the side rail then replaced the stock mesh over the top and melted the plastic through the holes and top & bottom, sorry for the lack of pic's in this part i got distracted by the kids so there are none of taking apart ect but it's quite straight forward and if you get stuck i will do my best to help out

and the finished part

half done, now time for the main front filter, those who have read the rest of the thread will already know how to do this bit but i will go over it again just so it's easy to follow (i hope )

)

as before i cut the mesh to size, removed the stock mesh panel and placed the cut mesh in place pressing gently into shape then replaced the stock mesh panel

and here's the finished part

i think it looks much better than it did in silver

last up it the drive bay covers, i have decided to go with mesh over the stock to keep the look the same

so as before cut the mesh to size above, and place the stock mesh panel in the centre

then on one side fold the mesh over the stock stuff and then do the same the other side making sure it stays as flat as possible and cut as you see in the pic

then you need to cut off the corners as seen in the pic then fold up and cut along the tab slightly bigger then the tab so you can fold the mesh round it so when you come to fit this back into the plastic drive bay cover

and then fold round the end and tab keeping the corners as tidy as possible

and then place back into the plastic frame remembering to make sure the mesh stays flat and don't get caught on the frame, and here it is the finished part

and here's the finished case, with the mesh being black it's hard to see from a distance but looks great that way, but i do plan in the future to make red filters to see how that will look

A long time coming i know but it's finally finished

i thought i would re do the guide from scratch as i had to re make all the filters anyway, so first thing this morning (11am), i started by adding a second coat of paint to the mesh and striped off all the bit's that needed filters making

my little helper

i will be using scissors, a hot glue gun (set to hot), a soldering iron (set to very hot (420'c)) and a screwdriver (Philips no1) and plasti kote gloss super paint, and the medium fine mesh

the HAF is so easy to take apart with only 9 screws holding the front side rails and top port/switch panel in place, 4 of the screws are under the front main mesh panel, 3 screws are under the rubber tray insert and the other 2 are behind the top switch/port panel

here's the sizes i cut the mesh to fit each part, please note some trimming will be needed on some parts but will get to that later

main front 235mm x 145mm

drive bay 171mm x 50mm, 5 needed in total

side panel 330mm x 300mm

side front 240mm x 60mm, 2 needed in total

i'm going to start with the side panel, first i measured and cut the mesh to the size above

then using my hot glue gun starting in one corner i pressed the end of the gun into the mesh and lightly pulled the trigger making sure not too much glue come out and so it didn't go everywhere

then keeping the mesh as close to the side panel as possible run glue all round the outside edge finishing by dotting glue around some of the fan mounting points

here's the finished panel with fan fitted

next up the front side panels, i removed the side rails as described above, then because the stock mesh is fixed to the side rail i had to cut off the melted plastic holding the 2 parts together

then cut the mesh to size and pressed into the side rail then replaced the stock mesh over the top and melted the plastic through the holes and top & bottom, sorry for the lack of pic's in this part i got distracted by the kids so there are none of taking apart ect but it's quite straight forward and if you get stuck i will do my best to help out

and the finished part

half done, now time for the main front filter, those who have read the rest of the thread will already know how to do this bit but i will go over it again just so it's easy to follow (i hope

)

)as before i cut the mesh to size, removed the stock mesh panel and placed the cut mesh in place pressing gently into shape then replaced the stock mesh panel

and here's the finished part

i think it looks much better than it did in silver

last up it the drive bay covers, i have decided to go with mesh over the stock to keep the look the same

so as before cut the mesh to size above, and place the stock mesh panel in the centre

then on one side fold the mesh over the stock stuff and then do the same the other side making sure it stays as flat as possible and cut as you see in the pic

then you need to cut off the corners as seen in the pic then fold up and cut along the tab slightly bigger then the tab so you can fold the mesh round it so when you come to fit this back into the plastic drive bay cover

and then fold round the end and tab keeping the corners as tidy as possible

and then place back into the plastic frame remembering to make sure the mesh stays flat and don't get caught on the frame, and here it is the finished part

and here's the finished case, with the mesh being black it's hard to see from a distance but looks great that way, but i do plan in the future to make red filters to see how that will look

little update:

been doing testing about the temperature impact of adding filters to my case, here's what i have so far

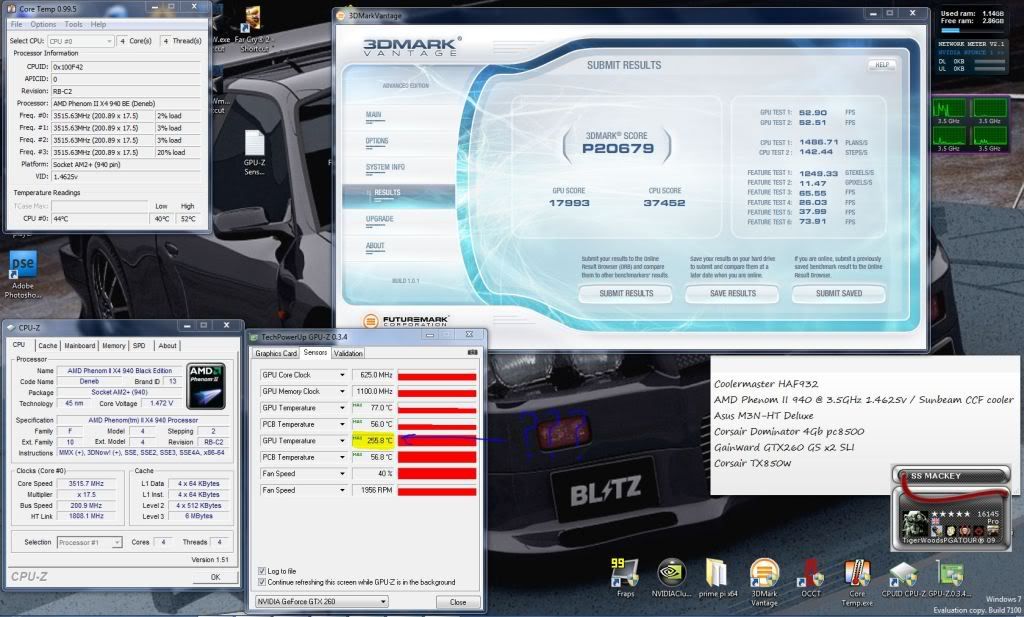

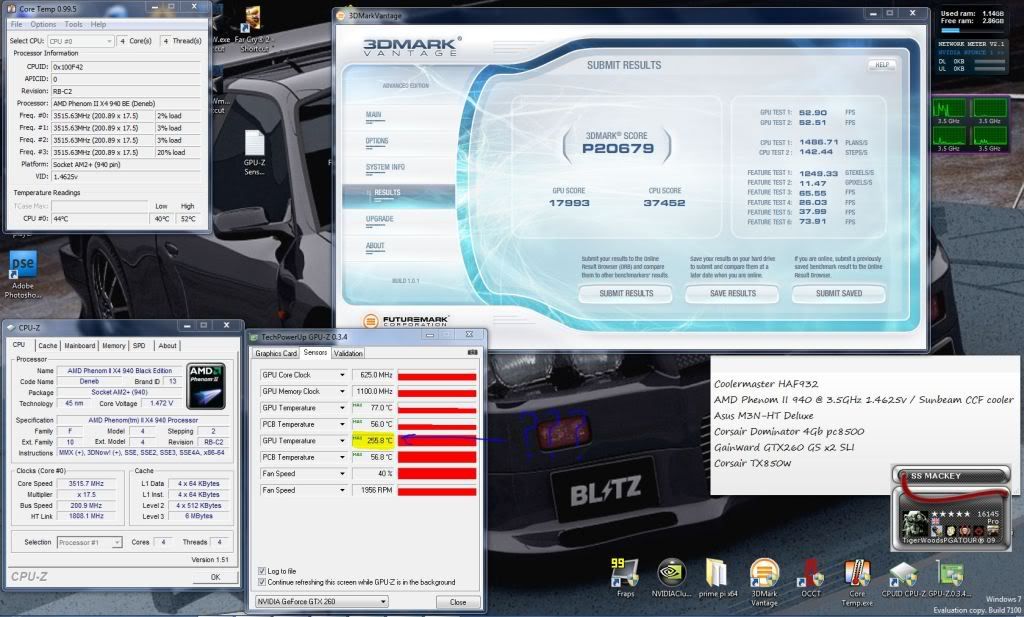

this screeny is my system without any filters ambient temperature 29.9'c

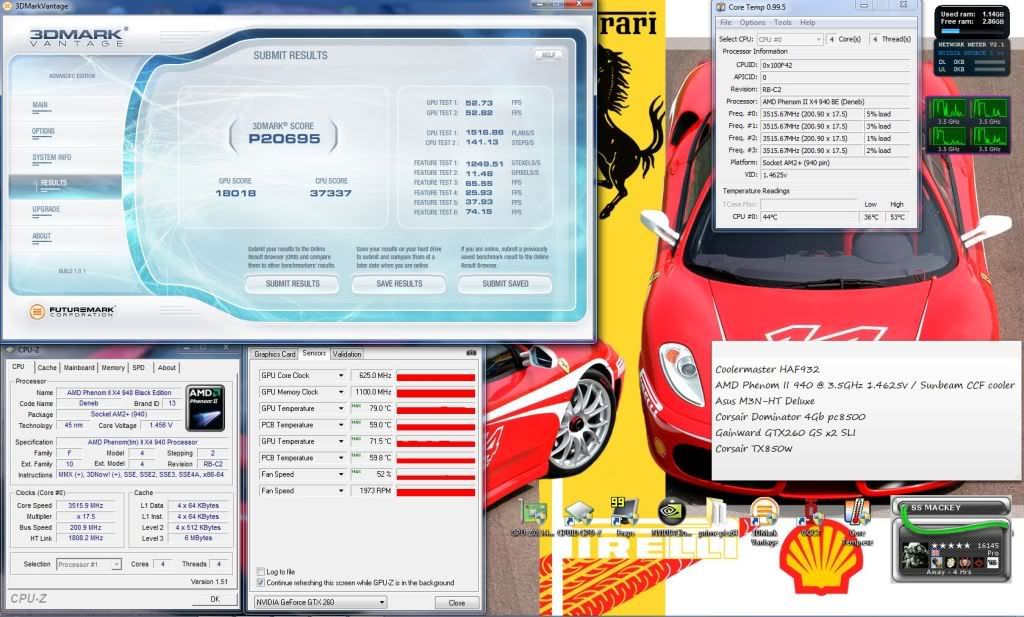

and this one is with the front only filtered ambient temperature 29.7'c

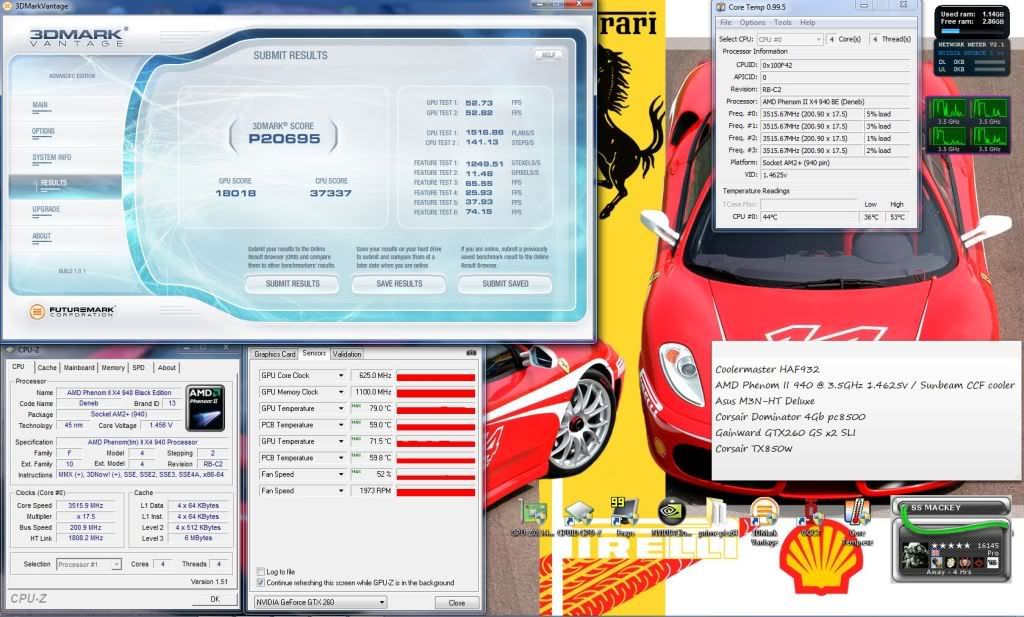

and last up is front and side filtered, note the ambient temperature is a little higher than it was when i run the above 2 tests at 31.6'c

now i know it's only 3d mark and don't really test the system as much as let's say prime or occt but i did run the test's 3 times on each config and the max temp after the 3rd run was recorded using windows snipping tool (so hope this is in win7 HP)

and as you can see not much difference if any and when you factor in the difference in ambient temperature you get an about 1'c increase in GPU and GPU-PCB temps and the CPU there's a 1'c increase over the un filtered and totally filtered but the ambient temp is about 2'c higher so not sure how to conclude on that???

there's a 1'c increase over the un filtered and totally filtered but the ambient temp is about 2'c higher so not sure how to conclude on that???

i have a new cooler coming soon (Tuniq Tower 120) so will update when it's fitted, hopefully it will help me get past the 3.5GHz barrier

anyway thanks for all the support from you guys and i hope i have inspired you to hunt some of this stuff down and have a go yourself and i would be interested to know what some of the better modders out there come up with

been doing testing about the temperature impact of adding filters to my case, here's what i have so far

this screeny is my system without any filters ambient temperature 29.9'c

and this one is with the front only filtered ambient temperature 29.7'c

and last up is front and side filtered, note the ambient temperature is a little higher than it was when i run the above 2 tests at 31.6'c

now i know it's only 3d mark and don't really test the system as much as let's say prime or occt but i did run the test's 3 times on each config and the max temp after the 3rd run was recorded using windows snipping tool (so hope this is in win7 HP)

and as you can see not much difference if any and when you factor in the difference in ambient temperature you get an about 1'c increase in GPU and GPU-PCB temps and the CPU

there's a 1'c increase over the un filtered and totally filtered but the ambient temp is about 2'c higher so not sure how to conclude on that???

there's a 1'c increase over the un filtered and totally filtered but the ambient temp is about 2'c higher so not sure how to conclude on that???

i have a new cooler coming soon (Tuniq Tower 120) so will update when it's fitted, hopefully it will help me get past the 3.5GHz barrier

anyway thanks for all the support from you guys and i hope i have inspired you to hunt some of this stuff down and have a go yourself and i would be interested to know what some of the better modders out there come up with

Associate

- Joined

- 3 Jan 2009

- Posts

- 555

- Location

- bristol england

how much dust does it stop a lot of it ?

coolGoing to give this a try when i get my HAF. My dad works for a pipeline filtration company and is going to get me loads of stainless steel cloth offcuts to use

if you need any help just leave a message on here or something, would also be nice to have some other pics on here of what other have

if you need any help just leave a message on here or something, would also be nice to have some other pics on here of what other have doe's this anwser your questionhow much dust does it stop a lot of it ?

this is the intake filter of the cool clean air box i have under my computer that will as soon as i get a new jigsaw will be feeding nice cool air into the bottom of the HAF i made 2 days ago and this is how much dust and other crap it's hovered up, it is on the floor but as you can see does a good job of blocking dust and on a pc on a desk won't get anywhere as dusty

i'm going to get a couple of cans of spray duster soon and give the hole case a good clean out and then check it once a week for signs of dust

I love the look and features it's just the lack of dust filters bothers me, I'm fairly certain come payday I'll be ordering one though

good man you won't regret it, as i said above would really like to see how you get on so feel free to post your pic's here

What grade mesh did you use for the final product?

I did read the thread but hadn't noticed it mentioned anywhere.

Nice going by the way. I am considering a new case. I currently have A+ Case Twin-Engine Tower. Decent for cooling but not overly impressed by the build quailty esp for the front fan.

I was considering the Antec 1200 OR the Coolmaster Storm Sniper now the HAF has caught my eye and I don't know what to get. Decision decisions hmmm

I did read the thread but hadn't noticed it mentioned anywhere.

Nice going by the way. I am considering a new case. I currently have A+ Case Twin-Engine Tower. Decent for cooling but not overly impressed by the build quailty esp for the front fan.

I was considering the Antec 1200 OR the Coolmaster Storm Sniper now the HAF has caught my eye and I don't know what to get. Decision decisions hmmm

What grade mesh did you use for the final product?

I did read the thread but hadn't noticed it mentioned anywhere.

Nice going by the way. I am considering a new case. I currently have A+ Case Twin-Engine Tower. Decent for cooling but not overly impressed by the build quailty esp for the front fan.

I was considering the Antec 1200 OR the Coolmaster Storm Sniper now the HAF has caught my eye and I don't know what to get. Decision decisions hmmm

i used the medium fine mesh for the filters, the ultra fine was way to ristrictive but the medium fine is just about perfect

as for your new case dilemma, i had a antec 900 and was happy with it so the 1200 should be good as well, if the build quality is as good as on the HAF then the sniper is also a nice case, it really boils down to what you want out of a case, the most important things to me were massive airflow, cable management and options like multi rad mounting possibility's, hole on motherboard tray for easy access to cpu back plate and top or bottom psu mounting oh and it's quite, much quieter than my old 900

i was also considering the 1200 and tjo7 but the HAF had everything i needed and more

also i know with my old 900 it was quite hard to strip the case so getting at the top fan was a mission where as with the HAF it's just 4 screws