Spent some time working the loom around the bike, found a few random bits that had been altered/added in. Wanted to get the loom as close to stock as possible to make the wiring document I have as accurate as possible.

There were a number of splices and cuts in the middle area of the loom, so i did some unwrapping to find the correct wire colours and re-joined them and checked against the wiring diagram..

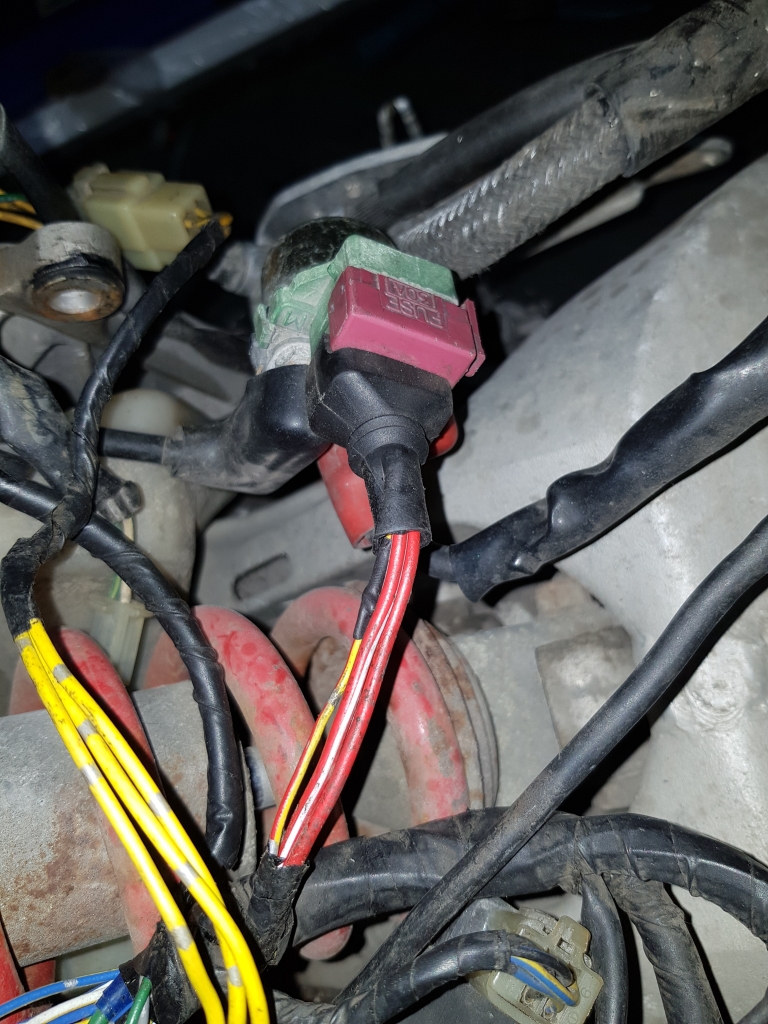

This was the wire that comes from the electric starter switch, and it seemed to have been looped, extended and then cut when it was removed I would guess. not sure what they would want to be turned on only when starting the starter?:

Stripped it back, removed the excess, and re-joined the wire and added some heatshrink:

Next there was a similar cut/splice done to the fuel pump line (you can see the re-wrapped starter cable in the background:

Not my neatest shrinkwrap job, but safe as houses

The bodgejobbery continues, now again, there was another splice off the pump side of the connector!

As the wire was not actually cut, I whipped the plug out of the connector, and slid some shrinkwrap over the top to make a neater repair.

Slid it back into the connector, and its sorted.

Next there was white wire that was sort of tacked, and cable tied to the main loom section, and it seemed to be coming from the three pin ignition switch. Clearly, someone wanted an ignition live, and rather than run it from the fuse box, they just soldered it to the main igntion live, and ran a LOOONG cable back, which was then split out into three wires, which were also snipped when the loom was removed.

Here is the three pin connector, with 4 wires coming out...

Here is the addition, at least it was soldered

Please ignore the badly installed spade connectors, I whacked them onto the cut ignition key switch wires to quickly allow me to test continuity of the various bits, and what each click of key enabled on the loom.

Removed, and re-wrapped:

One less wire to think about!

I decided to then pull the clocks apart, and see what's what.. This does not look factory...

It seems the bike was run as a naked bike for quite some time, as they fabbed up a neat little enclosure for the clocks, and made this rather odd looking frame from steel flat stock to hold them in place.

Little welded up enclosure:

Checked the clock's lights whilst they were out:

Not sure if I will keep them standard, lighting wise. But you can see some spots of paint deterioration in the face of the speedo, that will likely need to be corrected, as it will annoy me. I suspect I can just open it up, and re=paint the back of the clock face, but I will see what I can figure out when I get around to it. I could always grab a cheap clock from ebay and swap the face to keep the mileage accurate.

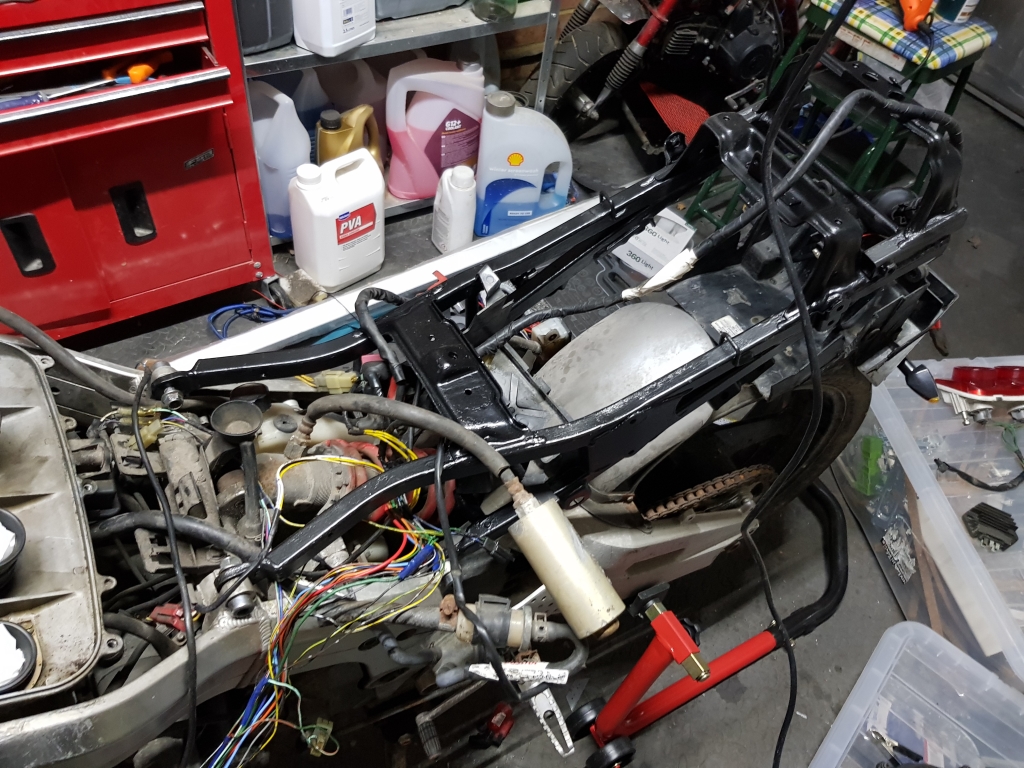

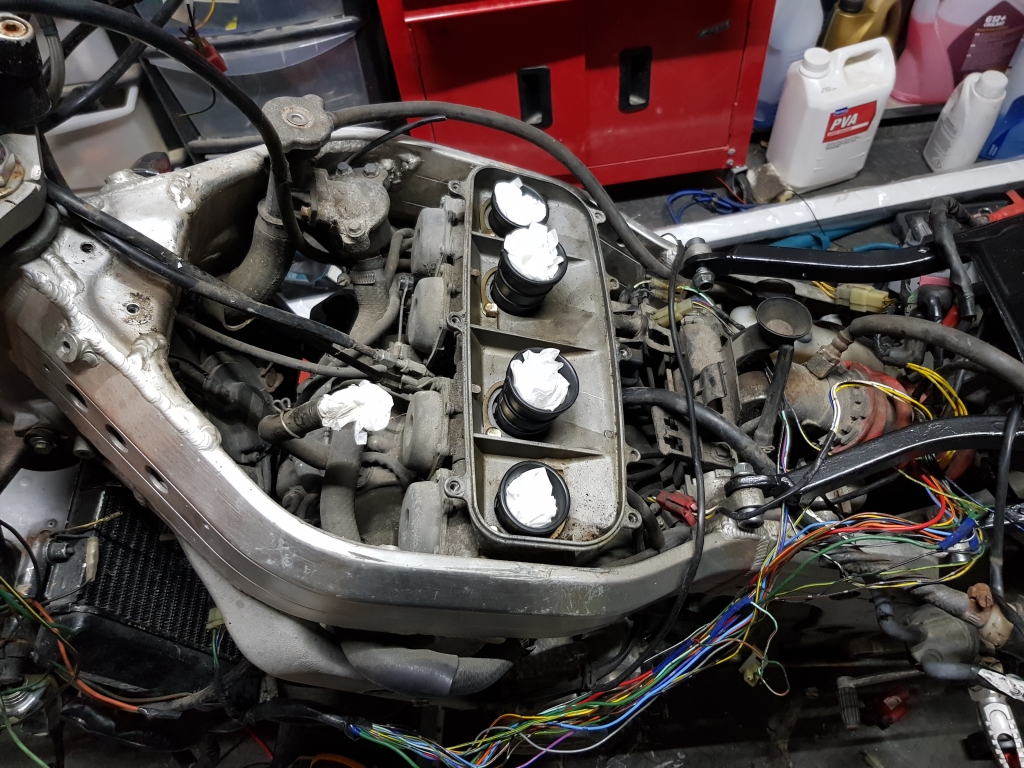

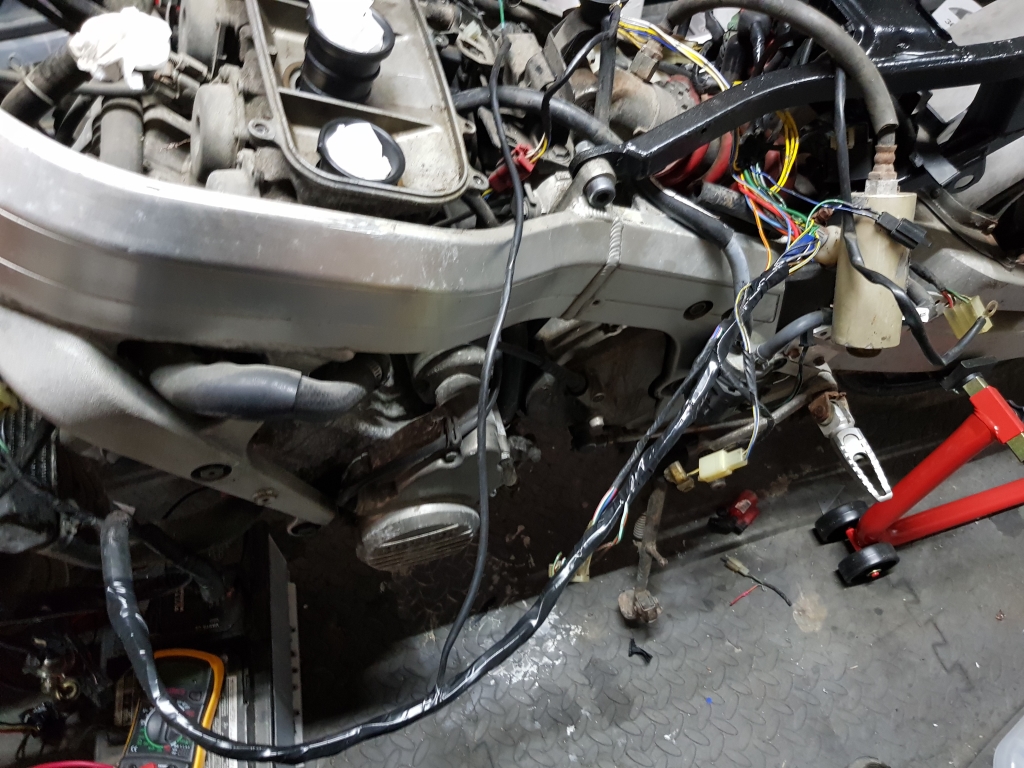

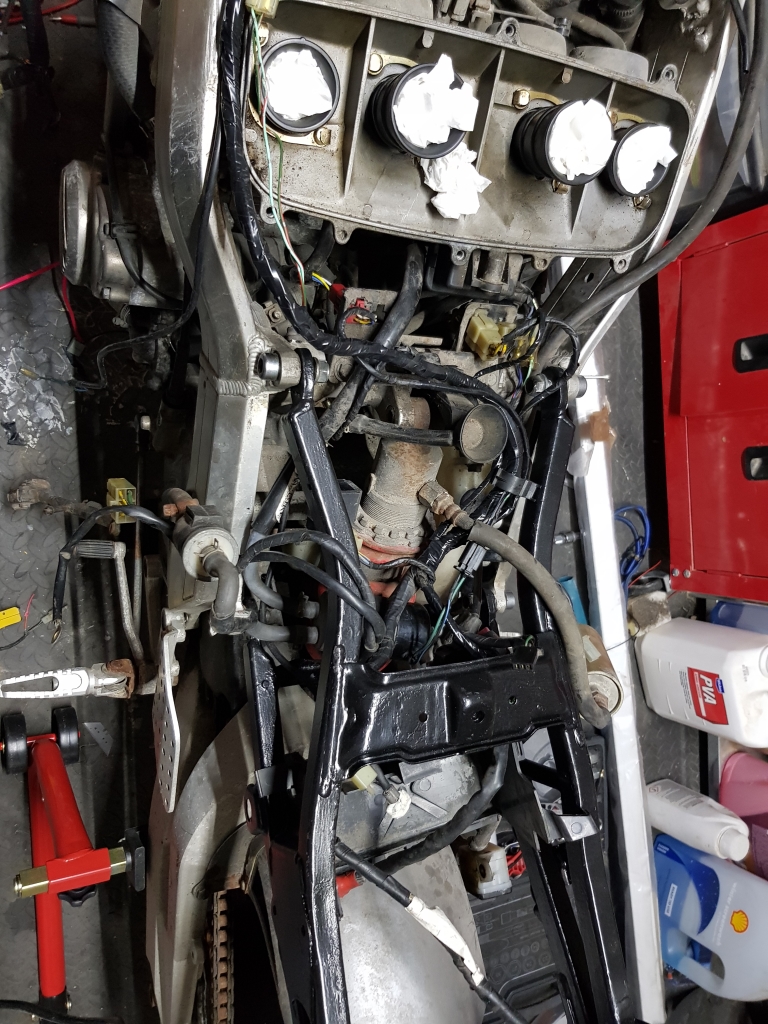

The bike is it stands right now:

Need to see if I can get the front fairing frame and clock holder section asap. I lobbed the controls up onto the MTB bars just to keep them from flopping about. I now do not think these controls are original, so I MAY look to replace them if they do not fit well on the original style drop bars I have coming. Although now I know they are not original, it explains why I was scratching my head when trying to match up the correct colours to the loom connectors. So I will just use the loom diagram, and the existing connectors to match them up, so i can go back to standard if i do replace them.

Still waiting for the wiring loom, hopefully here today.

Still waiting for the wiring loom, hopefully here today.