You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I got me 3D printer, awesome!

- Thread starter Pinter75

- Start date

More options

Thread starter's postsAh yeah I came across these driver things while I was looking for motors, I thought they were something todo with windows at first lol, I think they can be replaced on the Da Vinci Duo, but I have no idea where they are thoughDepends what board the printer uses, if its the stepper driver, it wouldn't affected anything else. Problem comes if the drivers are integrated rather than drop in type. But test it first and report back, we'll get you printing.

Deuse said that the printer had been stored in the shed for a few months, so Im thinking dampness could have killed the motor or whatevers wrong with it.

Hi guys, I have got the motor going in the end, it looks like when Deuse changed the cable for the motor, he fogot to plug in the new cable into the board as the old cable was still plugged in.

Anyway I have another problem, when printing with repetier host, no filament comes out of the hotend when printing, but it comes out fine when I select reload the filament on the printer? So atm its printing but nothing is coming out on the bed?

Anyway I have another problem, when printing with repetier host, no filament comes out of the hotend when printing, but it comes out fine when I select reload the filament on the printer? So atm its printing but nothing is coming out on the bed?

Hi guys, I have got the motor going in the end, it looks like when Deuse changed the cable for the motor, he fogot to plug in the new cable into the board as the old cable was still plugged in.

I knew you would get there. Not bad for free?

Anyway I have another problem, when printing with repetier host, no filament comes out of the hotend when printing, but it comes out fine when I select reload the filament on the printer? So atm its printing but nothing is coming out on the bed?

That would be a Repetier host setting somewhere. As I said I use Simplify3D.

There has got to be someone that ran it with Repetier host.

What temp have you got the hotend at? and have you setup slicer?

If you haven't click the green easy button on the top left in host.

You will see more there. If the temp isn't hot enough or to hot it won't extrude.

Bring your table down just a bit, then get Repetier host to extrude 100mm. What happens.

Last edited:

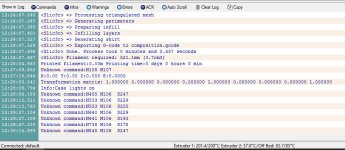

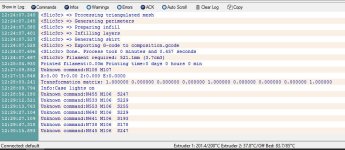

I have been though all the settings on repetier host and i have set the bed to get to 100c and the hotend at 225c,,it heats both up before it prints, but nothing is coming out.. I will give up for a while and try again later.. I thought i was home and dry when I got the motor working, no such luck.

But yeah I really appreciate this printer, thank you very much, I am going to try and put the 2nd hotend back together with my mate this weekend, now that the motor is working.. You say its easy to put together, it dont look easy to me hehe.

But yeah I really appreciate this printer, thank you very much, I am going to try and put the 2nd hotend back together with my mate this weekend, now that the motor is working.. You say its easy to put together, it dont look easy to me hehe.

I have been though all the settings on repetier host and i have set the bed to get to 100c and the hotend at 225c,,it heats both up before it prints, but nothing is coming out.. I will give up for a while and try again later.. I thought i was home and dry when I got the motor working, no such luck.

But yeah I really appreciate this printer, thank you very much, I am going to try and put the 2nd hotend back together with my mate this weekend, now that the motor is working.. You say its easy to put together, it dont look easy to me hehe.

WHAT!

Bed should be 90 tops. The hotend should match the filament your using.

Don't bother with the other hot end to till you get the other one working.

Are you sure the Host is not set to dry run? Unload the filament then start a print. And watch to see if the extruder motors goes round.

If not then it's the host. What are your start codes in Repetier host?

Well I give up with it for 1 day,, cant get any free printing/slicer software to work with the di vinci duo

Slic3r is built in to Repetier host. https://forum.voltivo.com/showthread.php?tid=9012&highlight=Slic3r

I asked you before. What Gcode are you using?

Look in the printers menu to see if anything is not right. You have setup Repetier host and Slic3r?

It's going to be something silly. You could on the forum I linked to here as they would be more help.

Look in the printers menu to see if anything is not right. You have setup Repetier host and Slic3r?

It's going to be something silly. You could on the forum I linked to here as they would be more help.

Your telling me it was something silly, I was printing with the wrong head.. stupid me. Well I presumed head 1 would be "head 1" in repetier, but nooooo, "its flipping head 2". So I have finally printed my test cube, and its came out pretty well too for my first print......

Hey deuse Ive noticed both heads say that they are heating up, so what actually needs putting back on the 2nd head? I see that the spring lever has been removed that you use to load/unload the filament?

But now repetier keeps using the 2nd non working head for bits in objects,, anyway to disable the head in repetier? The only way I can think of is to say its only got the 1 head,, but then it uses the 2nd head

Glad you sorted it out. The reason Repetier is using the second head is either

1-Settings in Repetier\Slic3r wasn't saved out before printing. I think it's the square disk icon. An easy mistake.

2-It's a 2 colour STL file. Remember not all STL files was checked for errors. I use this https://tools3d.azurewebsites.net/

In the options in Repetier. Tell it you only have one hotend\extruder.

The lever for the second hotend was in the bag. If there is not heating element in the hotend, then it can't heat up.

It's getting the temperature from the second Thermistor. Which by the first

Thermistor

. I think you really need to go to the forum

I posted and read up on the Printer and how to set it up.

Ah yeah that might be the reason that the 2nd extruder says its heating up. I downloaded a chess piece to print just for the sake of it, and it used the 1st extruder for the most of it, but the 2nd extruder for bits, then the print all went wrong when it had almost finished, because it was using the 2nd extruder aswell... I tried telling repetier that its only got 1 extruder, but then it uses the 2nd left extruder as the main default and theres nothing in slicer or the printer settings to tell it to use the other one as the main default, unless theres some gcode that I can use to tell it to use the right extruder as the main and only one?

I am using settings that has been posted on the voltivo.com forum for the da vinci duo, plus I have adjusted the settings a bit to slow things down, so there's less chance of it messing up the prints

I am using settings that has been posted on the voltivo.com forum for the da vinci duo, plus I have adjusted the settings a bit to slow things down, so there's less chance of it messing up the prints

Last edited:

Hey,

So in Repetier Host, under printer setting (Top right) make sure that it only has 1 extruder set up.

What Slicer are you using? Cura or Slic3r?

In cura, make sure that nothing is set to use another extruder such supports.

In Slic3r, under multiple extruders make sure it's set to 1 in all fields.

It could also be that the one working extruder is plugged into the 2nd extruder plug on the control board? (I'm not familiar with this printer so just making suggestions)

J.

So in Repetier Host, under printer setting (Top right) make sure that it only has 1 extruder set up.

What Slicer are you using? Cura or Slic3r?

In cura, make sure that nothing is set to use another extruder such supports.

In Slic3r, under multiple extruders make sure it's set to 1 in all fields.

It could also be that the one working extruder is plugged into the 2nd extruder plug on the control board? (I'm not familiar with this printer so just making suggestions)

J.

Im using Slic3r in repetier host. Basically repetier thinks that the non working extruder is the 1st extruder, but the non working one is the 2nd extruder, so somehow I need to find out a way to swap that around, then I will be able to tell repetier it has only has 1 extruder if you get me? So I have to tell repetier that it has 2 extruders so I can select the 2nd one to use as the main one in repetier, but it still uses the other extruder for bits of the prints for some reason. I think it was using the 2nd non working extruder for supports when I printed out the chess piece. On the printer it says that the first extruder is the working one, so its repetier thats got it wrong.Hey,

So in Repetier Host, under printer setting (Top right) make sure that it only has 1 extruder set up.

What Slicer are you using? Cura or Slic3r?

In cura, make sure that nothing is set to use another extruder such supports.

In Slic3r, under multiple extruders make sure it's set to 1 in all fields.

It could also be that the one working extruder is plugged into the 2nd extruder plug on the control board? (I'm not familiar with this printer so just making suggestions)

J.

I was thinking about totally disconnecting the 2nd extruder, and then repetier will have to see that the right working extruder is the main and only one? But I am going to see if my mate can get the 2nd extruder put back together tomorrow and then hopefully that will sort out the problem.

I hope that makes sense, as Im not that great at explaining stuff.

Edit: If repetier saw the 1st extruder as being the 1st, not the 2nd, then I would have been printing days ago.. But I cant really grumble as I cant aford a half decent 3d printer, and probably wouldnt of bought one for yrs, until they came down in price. So I say a big thankyou again to Deuse, and you must be mad to of given it away.

Last edited:

Im using Slic3r in repetier host. Basically repetier thinks that the non working extruder is the 1st extruder, but the non working one is the 2nd extruder, so somehow I need to find out a way to swap that around, then I will be able to tell repetier it has only has 1 extruder if you get me? So I have to tell repetier that it has 2 extruders so I can select the 2nd one to use as the main one in repetier, but it still uses the other extruder for bits of the prints for some reason. I think it was using the 2nd non working extruder for supports when I printed out the chess piece. On the printer it says that the first extruder is the working one, so its repetier thats got it wrong.

I was thinking about totally disconnecting the 2nd extruder, and then repetier will have to see that the right working extruder is the main and only one? But I am going to see if my mate can get the 2nd extruder put back together tomorrow and then hopefully that will sort out the problem.

I hope that makes sense, as Im not that great at explaining stuff.

Edit: If repetier saw the 1st extruder as being the 1st, not the 2nd, then I would have been printing days ago.. But I cant really grumble as I cant aford a half decent 3d printer, and probably wouldnt of bought one for yrs, until they came down in price. So I say a big thankyou again to Deuse, and you must be mad to of given it away.

How are you getting on with things?

Well my mate came yesterday, we put the filament lever back onto the 2nd head so it will work again, but it still wont work. I can hear the motor and it says the extruder is heating up, but nothing is comming through? I might just take it somewhere to be fixed, as Im thinking its blocked or the head is knackered.

It looks like for the da vinci 2.0 duo, you have to replace both heads as they look like they are in 1 unit. But I cannot find any parts for the printer at all online

It looks like for the da vinci 2.0 duo, you have to replace both heads as they look like they are in 1 unit. But I cannot find any parts for the printer at all online

Well my mate came yesterday, we put the filament lever back onto the 2nd head so it will work again, but it still wont work. I can hear the motor and it says the extruder is heating up, but nothing is comming through? I might just take it somewhere to be fixed, as Im thinking its blocked or the head is knackered.

It looks like for the da vinci 2.0 duo, you have to replace both heads as they look like they are in 1 unit. But I cannot find any parts for the printer at all online

Does the leaver grasp the filament? if not that's your problem. To make sure it's not jammed up get a piece of wire that will go in to the hotend hole.

Heat up the second hot end too 200 and then see if the wire goes up. If it does then it's either the gear\spring is not grasping the filament.

You can't buy any parts. If you ever short out the motherboard it's scrap. If the hotend wears out you only have one choice

and that is to fit a E3D V6.

Yeah the motor pulls in the filament, we even tried to push it in while it was loading. Then we tried a using a panel pin up the nozzle, but it wouldnt fit, I couldnt believe how small the holes are, as I dont think even a pin would fit.... We did notice the plastic wasnt even warm when we took it out,, so even tho the printer says its getting to 230c+, it might not be at all and I don't wand to touch it to find out.. Im am thinking though, if I took it somewhere to be sorted out, would they be able to get the parts any better then me?

So if the worst comes to the worst, the printer can use different sort of head, but Im guessing the carriage will need changing aswel to accept the E3D V6 head.

I have been trying other peoples settings in Slic3r for my printer but I keep getting quite rough prints if the print outs are slightly complicated, like I did 2 chess pieces and they printed out quite rough.

So if the worst comes to the worst, the printer can use different sort of head, but Im guessing the carriage will need changing aswel to accept the E3D V6 head.

I have been trying other peoples settings in Slic3r for my printer but I keep getting quite rough prints if the print outs are slightly complicated, like I did 2 chess pieces and they printed out quite rough.