- Joined

- 17 Mar 2014

- Posts

- 241

hey there

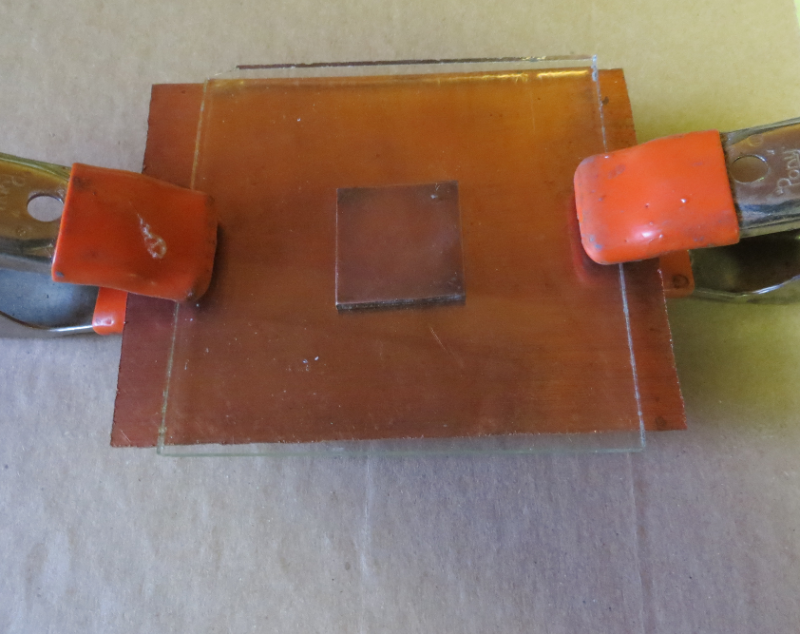

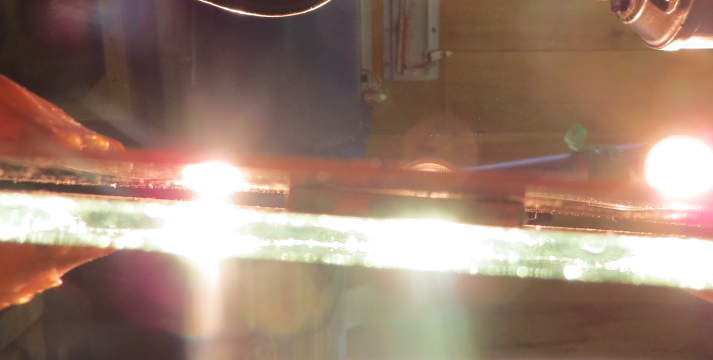

Depends on the size of the IHS. if it is a naked core gpu (like in the ati model above) then it would be too much.However a larger IHS will need more.

Edit just looked at the core.....nah looks like you have too much on there. For a IHS that size a blob in the centre will do.

Depends on the size of the IHS. if it is a naked core gpu (like in the ati model above) then it would be too much.However a larger IHS will need more.

Edit just looked at the core.....nah looks like you have too much on there. For a IHS that size a blob in the centre will do.

Last edited: