Ah right, 15 inch it is then!

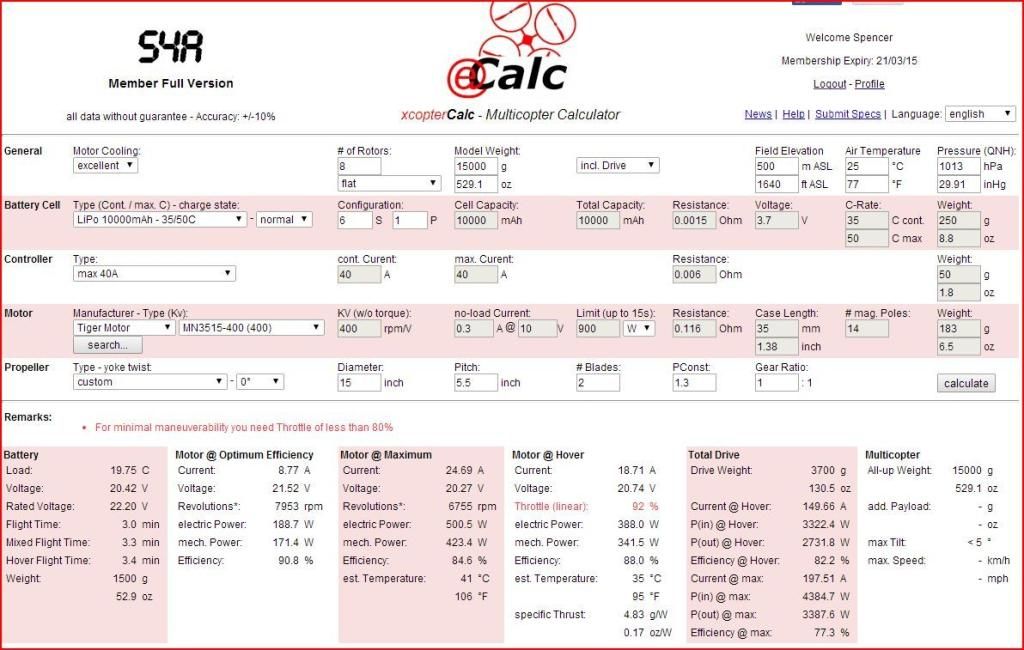

Lift required is just a function of AUW/#Motors so if the S1000 weighs 4.2Kg dry...

(4.2+10)/8 = 1.85kg per motor needed to get the rig off the ground.

Really, you need this to be as close to 50% of total power as possible, a little over or under won't hurt. If that's all that's available at 100% throttle, it will take off (just) but manoeuvring would be out of the question as there wouldn't be enough headroom for the motors to spin faster when needed.

These would get you nearer the target with 2kg of thrust per motor at 65% throttle.

Lift required is just a function of AUW/#Motors so if the S1000 weighs 4.2Kg dry...

(4.2+10)/8 = 1.85kg per motor needed to get the rig off the ground.

Really, you need this to be as close to 50% of total power as possible, a little over or under won't hurt. If that's all that's available at 100% throttle, it will take off (just) but manoeuvring would be out of the question as there wouldn't be enough headroom for the motors to spin faster when needed.

These would get you nearer the target with 2kg of thrust per motor at 65% throttle.

, wonder if this is Windows 8

, wonder if this is Windows 8

Counting the days until it's not cold, windy and dark all the blooming time

Counting the days until it's not cold, windy and dark all the blooming time