chipperhead said:Ok, how much do we all need to chip in for you not to go away that weekend?

Messing with the Golf vs catch up with a load of uni mates....... No chance

Spent most of this morning sourcing the following parts:

Radiator, slimline fan, heatwrap, heater matrix and brake hose fittings ordered. They should arrive tomorrow.

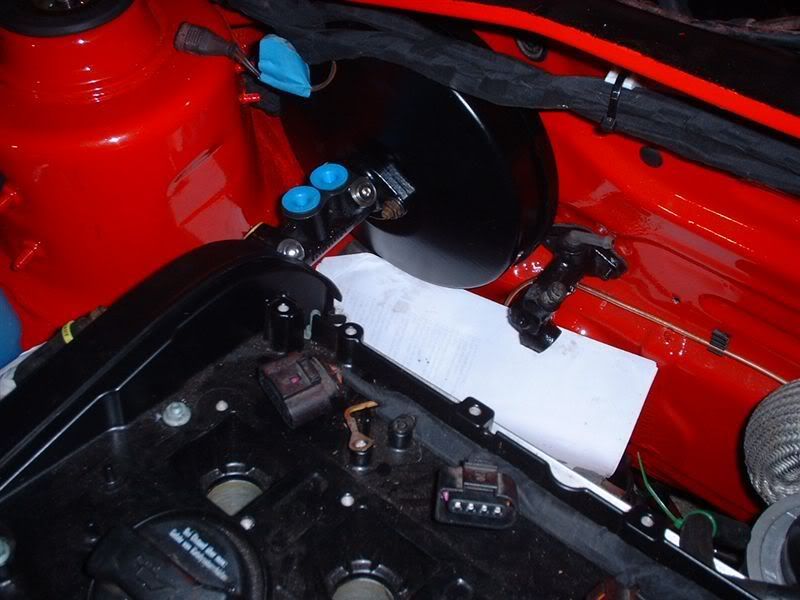

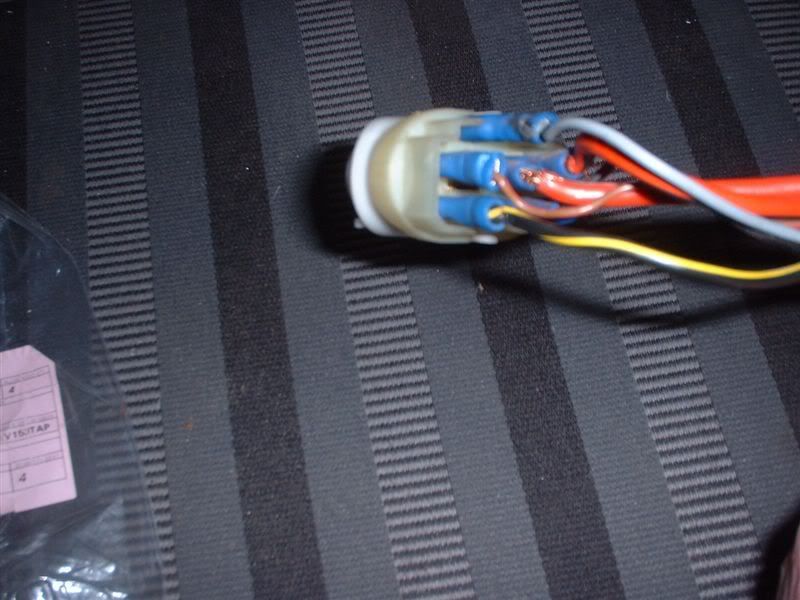

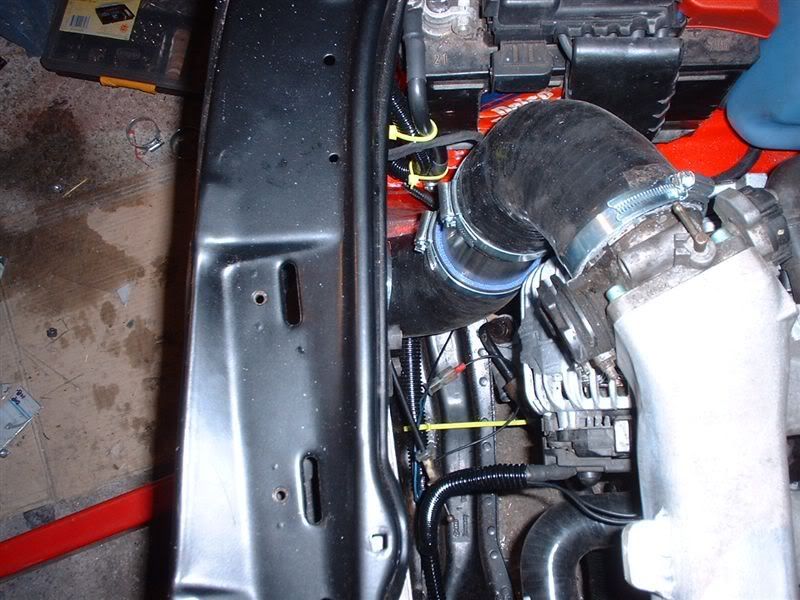

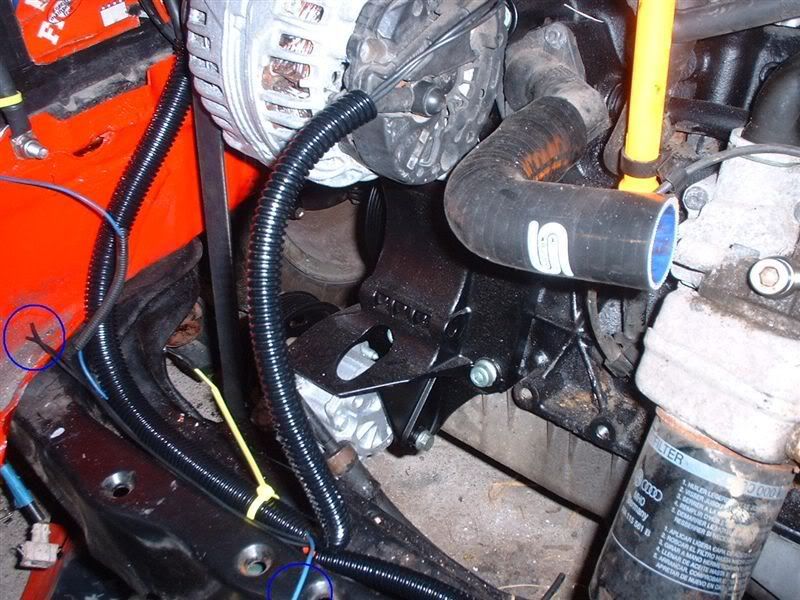

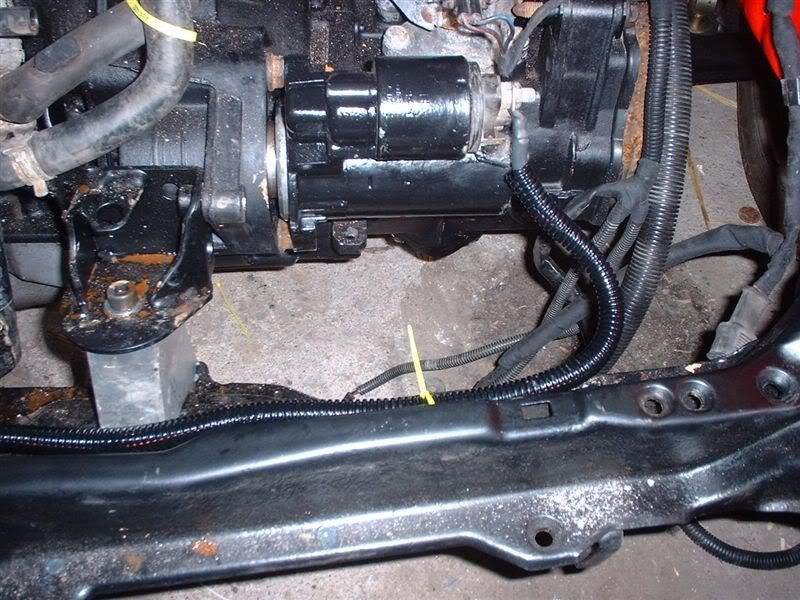

Finished the bay wiring loom today:

Battery earth feeds done

Alternator done

Starter done

All the above will be clipped in place when the engine comes out, as I need to drill holes for the clips.

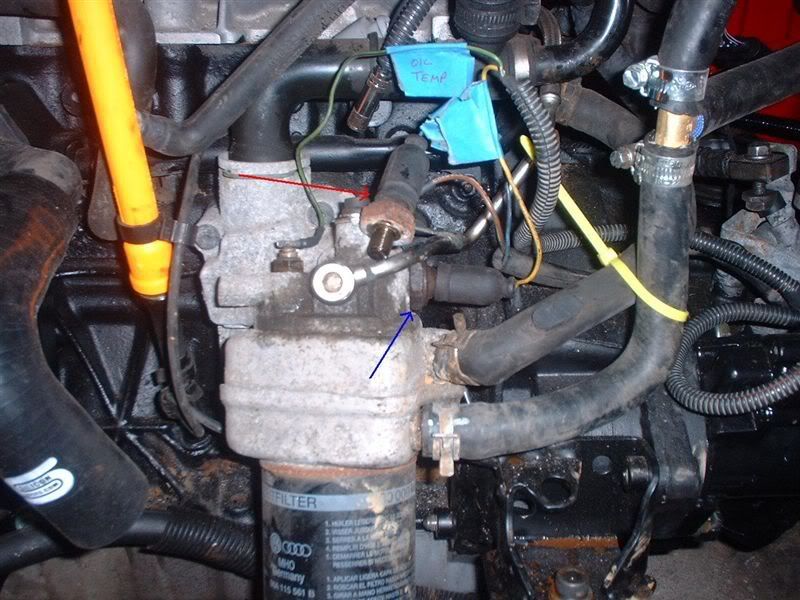

Engine block earthing done

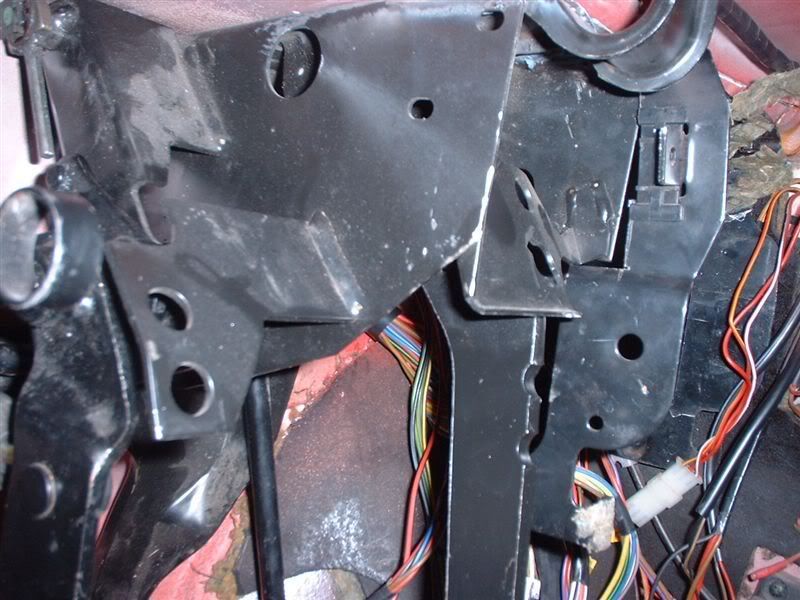

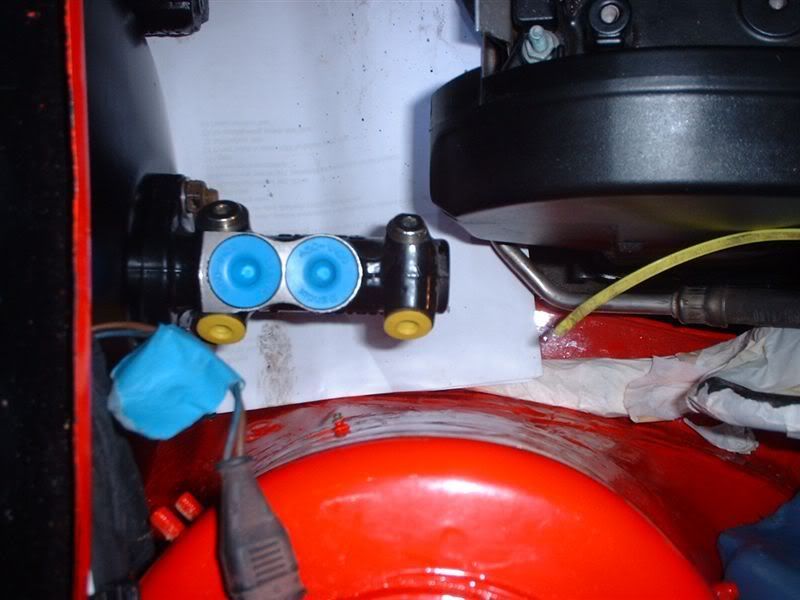

Spent a frustrating 2 hours trying to get the pedal box to line up properly so it pushes the clutch master cylinder in a straight line. The bracket I had welded on needs to be moved slightly (again!!!!). Will get it done tomorrow.