- Joined

- 7 Dec 2010

- Posts

- 223

yknyong1 GT335M

Just some quick notes

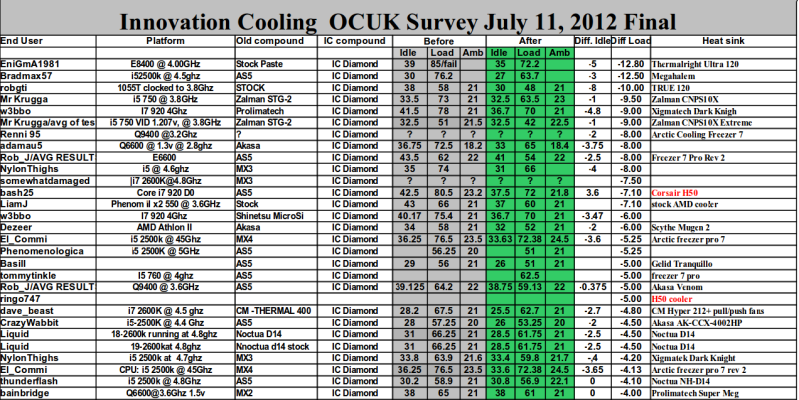

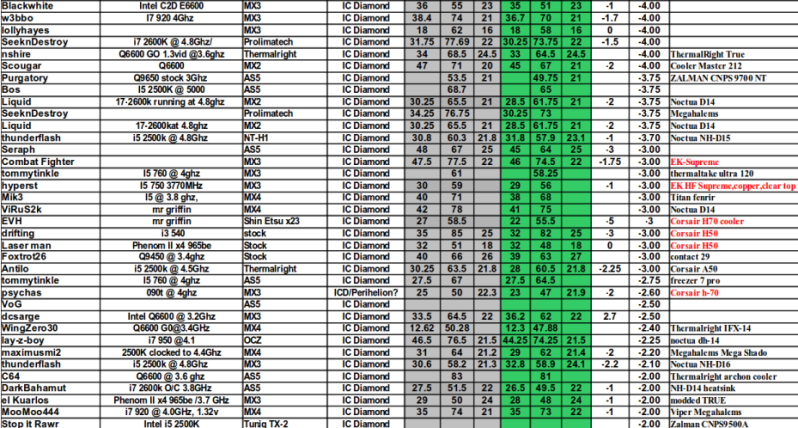

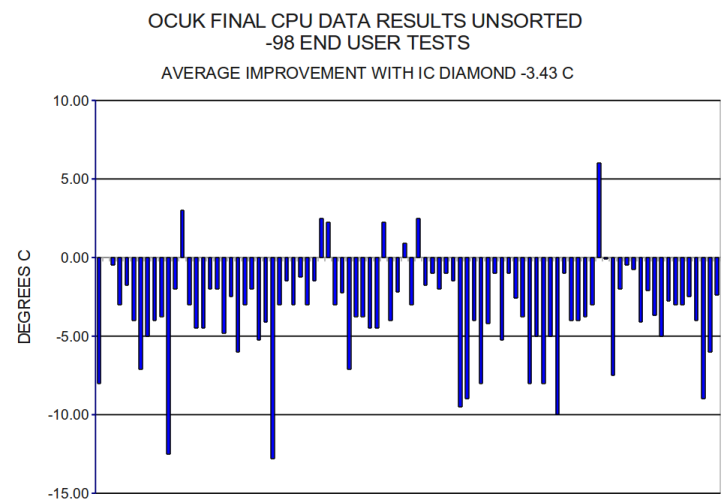

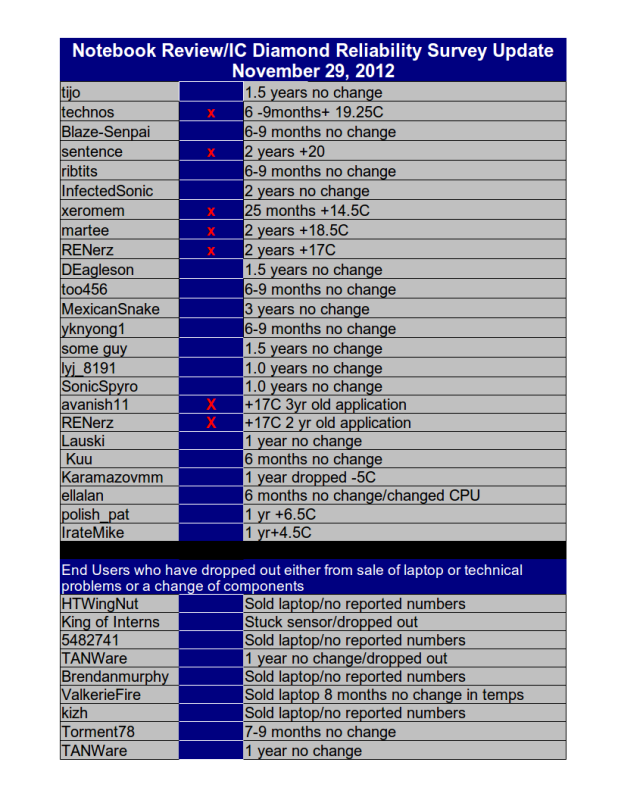

Looking at the data to date it looks to be trending that if you hit a year with no change you are probably clear for extended 1.5- 2- 3 year use. A temp rise above +5C within the first year is a pretty good indicator that you will hit + 20C by year 2.

A kind of a go- no go indicator, those that hit in the 20C range I would call a failure and would repaste and while you have the system apart consider lapping the sink or some mod as TanWare's to improve contact. To note I have a couple of retailers that have agreed to test market the Contact and Pressure indicating film and should retail around $5-$8. Note that we are not selling the product and will not profit from it, we are only promoting it's general use for end users as a tool for improving performance/reliability

I am assuming a 5C +/- error on these tests as most are sloppy about reporting ambients.

As noted in my previous post there does not appear to be any correlation yet as to higher initial temps leading to a failure. Technos started with an initial temp of 58 C and at close to the one year mark ended up 19.25 C while Karamazovmm whose initial temp was 95C ended the year at 90C basically unchanged. There are other examples but this happens to be one of the more extreme. This was a suprise to me as typically notebooks runan average of 15C higher than the overclocked systems so I was expecting some indication in that direction at this point perhaps needs more time.

Applied thermal compound is simple stuff as things go, two mating surfaces with some goop in between and there are not too many avenues to explore to explain a difference in results other than amount of compound applied (we assume everbody gets this one right) Then the contact and pressure between the two joining surfaces.

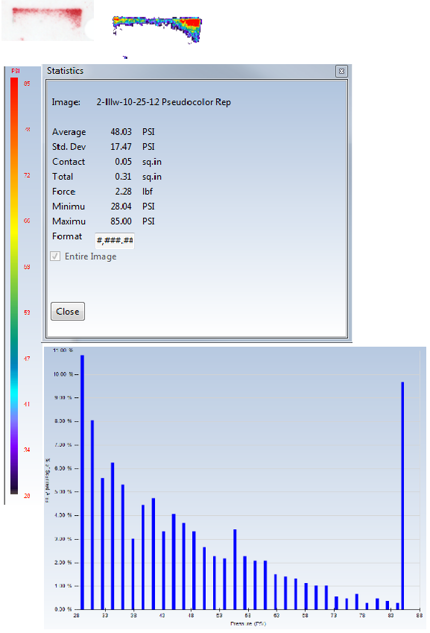

As we discovered with the C/P testing the weak point in this simple setup is in the contact and is a reasonble cause for good result or bad result or something in between.

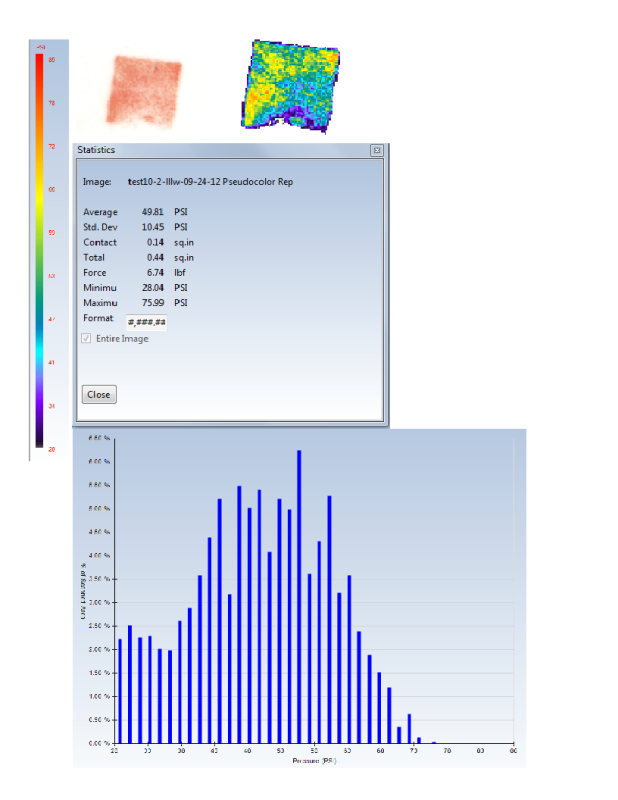

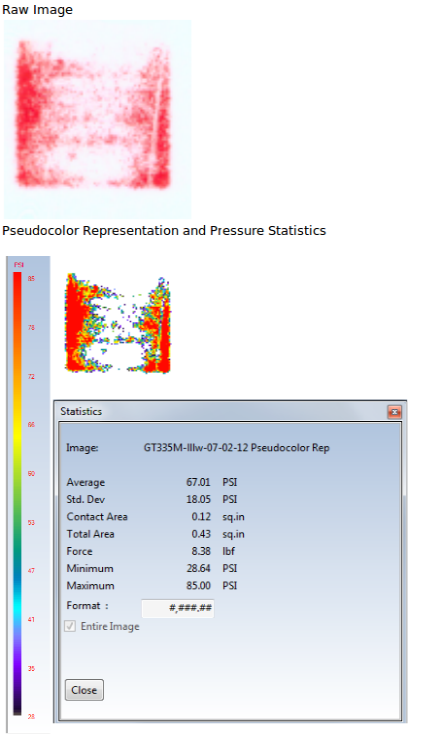

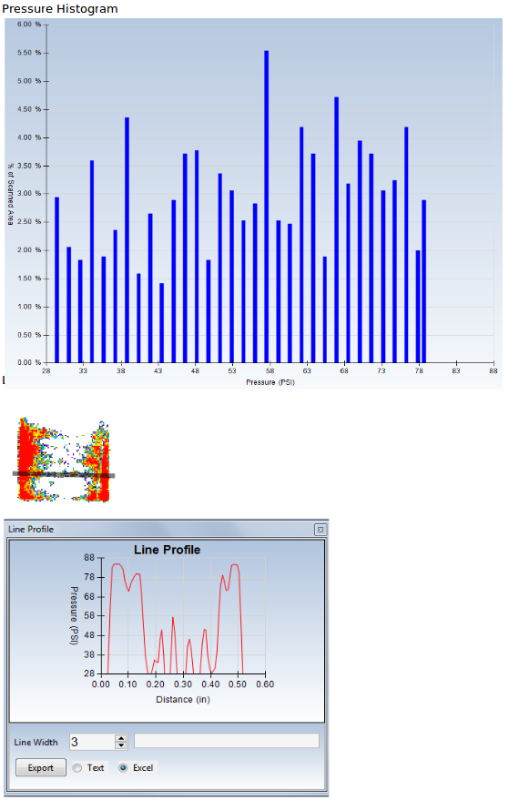

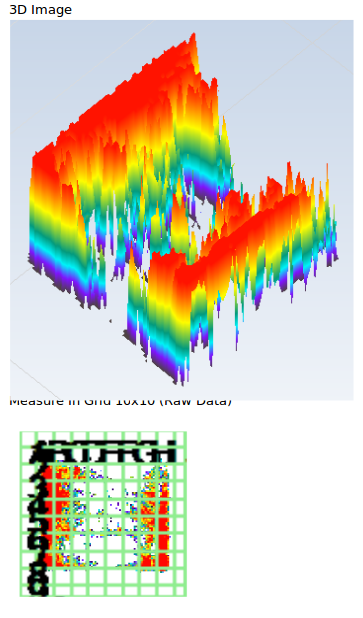

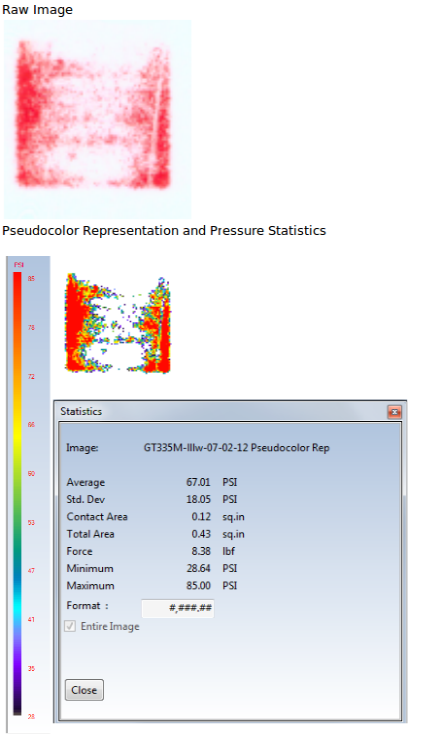

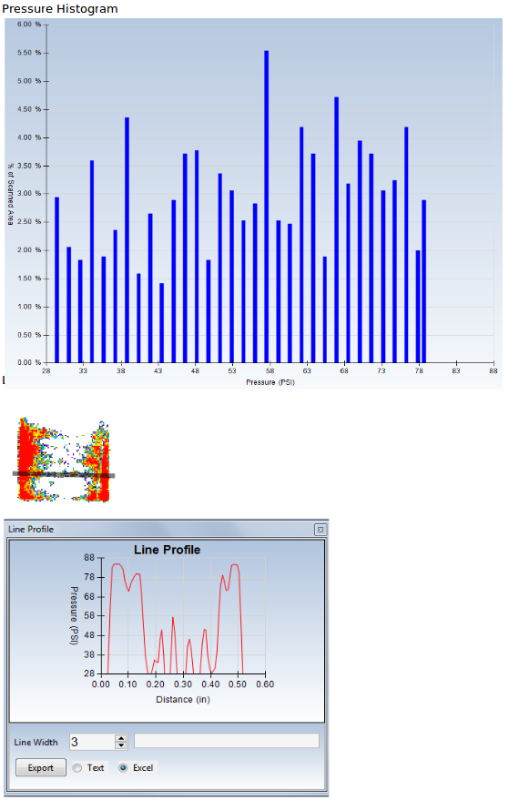

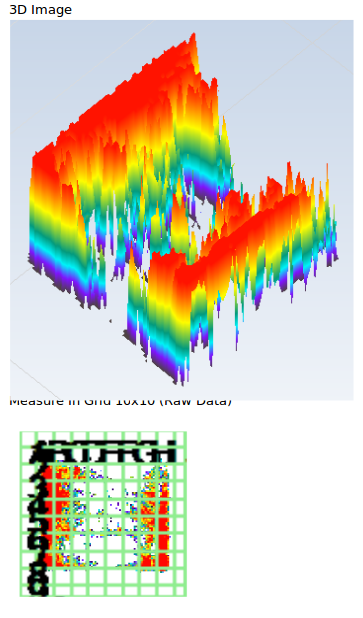

Note below yknyong1 contact area being worst case most of the heat transfer would be in the corner/edge area, a significat heat concentration more like a soldering Iron this edge corner/area would be the part of the joint to fail first and as the remaing paste is lightly contacted would then run at higher temps baking out initially then delaminating with further thermal cycling. This kind of contact is a likely canidate for early failure

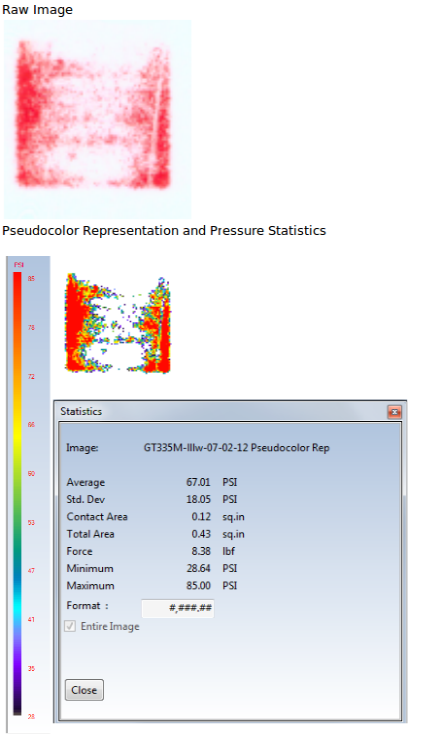

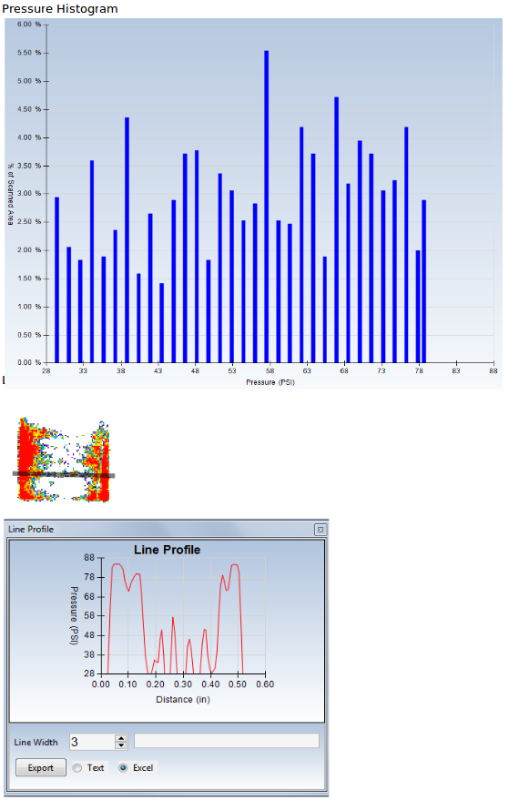

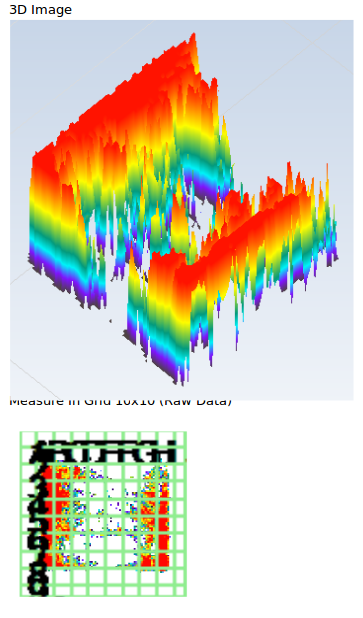

the following BlazeSempai example at the other end is full contact with thermal and mechanical loads in sync with each other fully/evenly distributed across the entire processor and would be a likely canidate for long term use.

This is as simple as it gets.

yknyong1- Apple Macbook Air13 i5

BlazeSempai p 8700