- Joined

- 7 Dec 2010

- Posts

- 223

i also reckon i didnt apply the TIM properly the first time.

does this look ok?

Looks a little light on amount, add more compound

i also reckon i didnt apply the TIM properly the first time.

does this look ok?

Your compound pattern is fine as the centre of cpu IHS is well covered. As IC Diamond mentioned apply a bit more and it should cover the IHS even more. I don't even get this pattern as the base of my heatsink is convex.

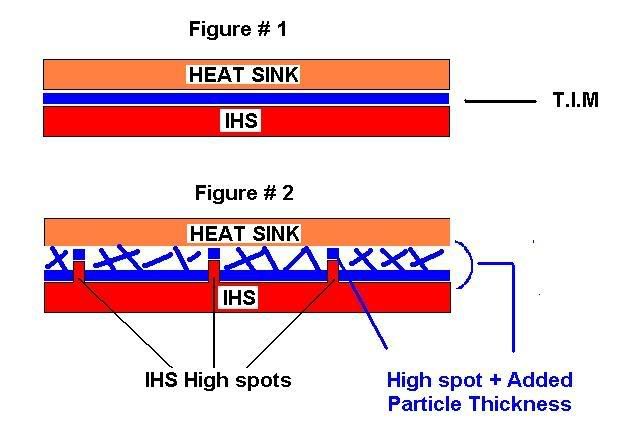

How I determined the cure time on ICD was to take two glass slides and a lapped synthetic IHS and clamp them together @ 50lbs then measure the thickness unloaded and loaded with compound with a micrometer.

Then I time the spread or time for the joint to resolve down to the average particle size at room temperature which takes about 2 hours hence we spec to 2 hours in operation before taking a reading.

I'm not sold on the pea application method. The cross method seems to produce more consistent results because you can better gauge the amount of compound your applying.

Received mine today, thank you very much IC.

Will test tomorrow when I have time. I have a question though; I'm currently on stock cooler, so will that provide enough pressure for the Diamond or Perihelion to work optimally?

NylonThighs

Thug

Joined: Feb 2011

Posts: 39

Love my IC Diamond, bought this for my i5 2500k and using it with my Xigmatech Dark Knight which doesn't get that good of a review. I went from idle temps of 35c (mx3) to 31c and max temps of 74c to 66c on an hour run on intelburntest. Impressive stuff, I used a pea sized blob and tested the day after fitting cooler. My mx3 was the same, tested day after fitting.

Edit: Should maybe mention that is with the i5 @ 4.6ghz not stock speed.

Last edited by NylonThighs; 9th Mar 2011 at 13:30.

ViRuS2k

Wise Guy

ViRuS2k's Avatar

Joined: Jan 2004

Location: UK

Posts: 2,954

4.2Ghz @1.36v

Noctua D14

-----------------------------

Very nice stuff,

41c idle / 75c load

MX4

42c idle / 78c load

slight differences but good diffrences none the less.

bash25

Thug

Joined: Jun 2009

Location: London

Posts: 59

My Results

Hi All,

Here are my results, using the following components;

Intel Core i7 920 D0 Stepping (SLBEJ)

Gigabyte EX58-UD5 Intel X58 Motherboard (Bios F12)

Patriot Viper 6GB DDR3 PC3-12800C8 1600MHz DDR3 Bundle

Coolmaster Cosmos RC1000 case - all fans replaced with Scythe Kaze-Jyun (2000 rpm)

Corsair H50

Asus 6870

OCZ Vertex 2E 60GB

500GB Western Digital Hard Drive

1TB Samsung F1 Hard Drive

First Test using AS5 on default settings;

Average Room Temp of 23.6C

CPU Temps (After 5 minutes idle) -> 31C - 34C

Prime 95 (After 1 hour of blend test) -> 66C - 72C

Second Test using AS5 on overclocked settings;

@ 3.8GHz, Vcore @ 1.225v, QPI/VTT @ 1.335v, IOH Core @ 1.240v and DRAM Voltage @ 1.660v

Average Room Temp of 23.2C

CPU Temps (After 5 minutes idle) -> 41C - 44C

Prime 95 (After 1 hour of blend test) -> 77C - 84C

Here are my results, using IC Diamond, after letting it set for about two hours to cure.

First Test using IC Diamondon default settings;

Average Room Temp of 22.6C

CPU Temps (After 5 minutes idle) -> 30C - 33C

Prime 95 (After 1 hour of blend test) -> 59C - 64C

Second Test using IC Diamond on overclocked settings;

@ 3.8GHz, Vcore @ 1.225v, QPI/VTT @ 1.335v, IOH Core @ 1.240v and DRAM Voltage @ 1.660v

Average Room Temp of 21.8C

CPU Temps (After 5 minutes idle) -> 36C - 39C

Prime 95 (After 1 hour of blend test) -> 68C - 76C

Bashy.

Here's the results for Diamond 2 weeks into testing, as per previous tests everything has been kept the same:

* Pea-sized blob

* 70lbs pressure

* Ambient temerature 21c

* Idling temps taking 1hr after bootup

* Loads temps taken after 1hr on full load

* 1 weeks use = approx 14hrs use & 7 on/off cycles

I have 2 weeks worth of data left for MX-2 & AS5 under these conditions.

And here will be the results for the ICD 24Carat TIM.

Well, test 1 shown a peak temperature change of only 1 degree, but the temps were much more stable, and the difference overall was possibly closer to 2 degrees on average. Test 2 shown a similar result, while the peaks were similar, the average of the ICD was lower and it took a lot longer to reach a sustained peak.

This of course is a comparison between a well bedded in TIM and one that was only applied this morning, so next week should show even bigger temperature reductions. All in all, this ICD TIM compares well, especially considering that the Tuniq TX-2 is a very good TIM in the first place.

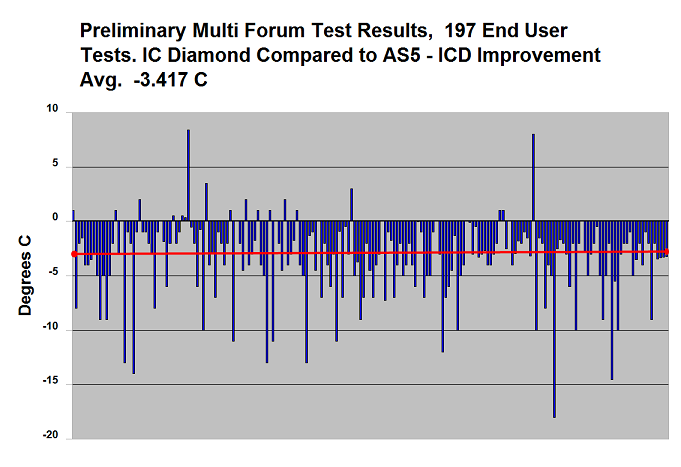

You know... after reading the first page with the results I find it amusing how far too many on this board seem to diss Arctic Silver 5 from todays thermal paste yet the difference is minimal.

Well in the old days people bought AS because it was what, a couple of degrees better than stock? difference was minimal as you say.

Point is cooling is the whole body thing - Lower case temp, better sink etc. A few degrees here and a few degrees there adds up to some substantial numbers.

Some tests shows 0 difference at idle some shows 3 degree's difference on load. Nothing overly breathtaking about like some people try to claim.

The thing to keep in mind when you are looking at the averages they also average power/watts. A power user vs an end user who under volts their system will generally experience a very different result.

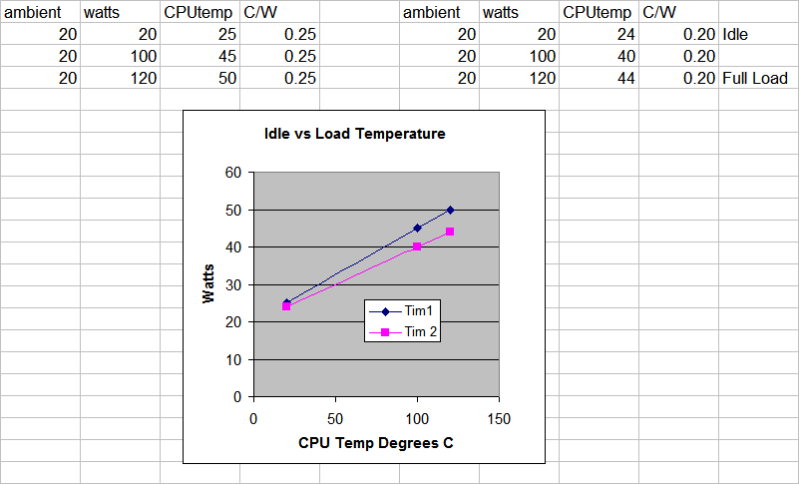

The C/W of a compound is a constant, so at low power you will observe in the temperatures a small difference, in the example below idle delta 1C - load 6C, double the watts to 240 and it's 12 C.

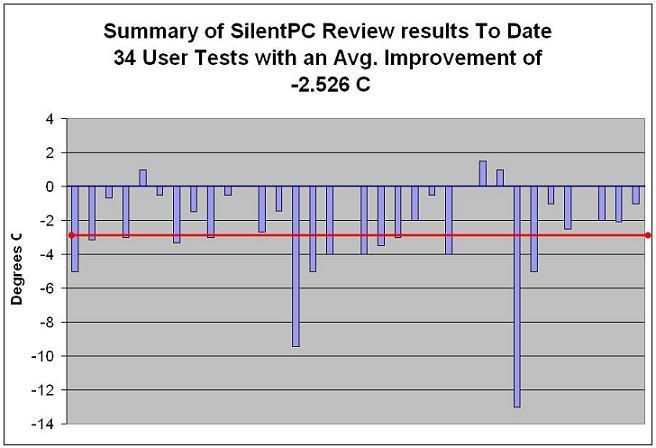

Granted you have the good and bad mounts which cancel each other out but you do have Power Users that cancel out low power users. My lowest averages were from Silent PC where most of the users were under volters.

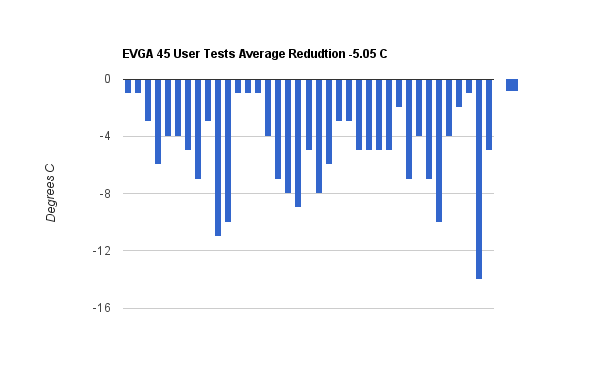

While not directly comparable as larger contact area will lower delta temps* GPU's run hot, more watts some as high as 350W.

Below is a power user comparison with an average 2X the under volting group

*Example my 1cm test die delta temps will be approx 2X higher than my 1 inch die @ the same Watts/power has to do with the watt density kind of like a soldering iron 30W will give you a nasty burn, spread it out a bit and you have a heating pad for your neck - it's all in the power density

https://spreadsheets.google.com/ccc?key=0AsYd6RE6aW3VdFM4d2VEM3FrMTB5dHhBQm5lR1MzYXc&hl=en#gid=0

The most amusing part is so many people act like a marketing campaign then the next they are preaching how they are real enthusiasts that only go by real world numbers. As well as reading a few others findings on page 2.

I've lost count the amount of posts saying AS5 is so outdated by too many people like as if you're going to gain 10 degrees. What's that all about...

I believe this is what it's about. Again the 3C comparison is not a one shoe fits all it just reflects average user power/watts

Is the main performance measure actually the temperature rise/ delta t?

Generally higher ambient temp will result in higher cpu coretemps and lower ambient temps will result in lower cpu coretemps.

So we are looking at the difference between ambient temp and load temp as a measure of TIM performance and it's effectiveness?

E.g

TIM1

ambient 18c

load temp 75C

delta t = 75 -18 = 57c

TIM2

ambient 20c

load temp 76C

delta t = 76 - 20 = 56c

So although with TIM1 coretemp was lower as ambient temp was lower, TIM2 actually performed better by 1C. Is this correct and is this how we should be looking at results especially if the ambient temp differs? Exactly right, you have to normalize the data so it is directly comparable which is the reason for the ambient request

Edit: In the quoted text TIM1 performed better, right?

You got it

Many thanks

Many thanks for clearing this up. This is one thing that was bothering me the most when comparing results. I gather similar procedure will be carried out for idle temps aswell.

Just one more thing about ambient temp.

I have been researching about ambient temp in relation to computers and it is mentioned that in computing, ambient temp refers to the temperature inside the pc case and not the room.

You mentioned in the earlier post that accurate reading of ambient temp is noted by taking several readings at the inlet of cpu cooler fan and then averaging them. In the picture below is the layout of fans in my HAF 922 case.

So will I need to place thermometer near the inlet to record several readings and then averaging them? Yes, Intel thermal docs has diagrams and much info on testing I juct can not put my fingers on the link right now

The 2 akasa viper 120m fans and the 140mm fan are pwm controlled by motherboard via akasa pwm splitter cable:

http://www.overclockers.co.uk/showproduct.php?prodid=CB-031-AK

So their speed varies from idle to load but they are in sync. So at full 100% cpu load, the akasa viper fans will spin at full 1900RPM while the 140mm fan I believe goes only up to 1000-1200RPM at full load.

At idle load, vipers spin around 850-900RPM and the 140mm fan I presume also spin at around same speed or may be less as HWmonitor doesn't give individual speeds for the pwm controlled fans.

The 3 remaining case fans spin at constant speeds.

At idle as the fans spin at their constant respective speeds, I guess the ambient temperature inside the case should be more or less similar in all the tests, though it will vary in the actual room at different points and as mentioned by you in earlier post.

Love all the fans - you have a thermal cascade -- CPU to TIM to IHS to TIM to Sink to Case Ambient to Room Ambient.

Change any of the parameters upstream or downstream and it will impact overall results.

Lower room temp 5C and it will lower your case temp/CPU temp.

Use a stock sink and CPU and case temps will change etc.

What's your case temp vs room?

@ IC Diamond

Do you mean the following intel diagram for taking ambient temp:

http://www.overclockers.com/forums/showpost.php?p=6376564&postcount=1

Looks familar

It seems we have to place thermometer very close to the fan intake or right infront of the fan and take several readings and then average temp.

Yes, but remember the motor generates heat, 75% of the fan air flow occurs in the last 25% of the fan length. I would be a little more out board than the Intel diagram as edges of the fan tend to be closer to local components and as the bulk of the flow is at or near the tip.

I can only think of two methods for doing so:

1 Take off the side panel and place the thermometer more or less in the required locations by hand as graphics card is in the way. So all this time side panel is off.

2 Take off the side panel and place thermometer close to the fan but not in the desired location. Put the side panel back on.

1 leave the case open, you do not really care for this measurement. If I was interested in the case flow for some reason, maybe trouble shooting airflow then I would leave it closed.

In either case at what interval should I record thermometer values and then average them. Would 3 be enough? I would probe the area first to look for problem areas if it fairly even do 2-3 if you have one or two sides that are higher by 2-5C do 4.

Assuming paste has been applied more than 2 hours run at full load a half hour to let it heat up and stabilize. Depending on the reaction time of your temperature device when it stabilizes I would take CPU temp and Ambient at the same time when ambient changes CPU temp will change a second or two later (might be one source of some of the fluctuation in the OCCT scores as a speculation as CPU adjust to changes in air temp) then average the readings 2 or 4 point or whatever you deem appropriate from your observations

Also whatever method I choose I will need to stick to it as the other method will affect the ambient temps relatively.

What do you think?good to go

Edit: Room temperature was 18C. The case ambient temp was 20C. I used the 2nd method as mentioned above and took the reading after 30mins.

My experiments are more or less similar but I am only doing them at intervals of 1 week each. So each of the three compounds are applied for 1 week one after the other and tested. So that will be 3 weeks total application + testing

Edit: I carried out MX-4 testing last week. Tomorrow I will be testing IC Perihelion and then next week from tomorrow I will be testing IC Diamond. The thing that is very thrilling and exciting for me is that it is total unknown until all testing is done and then results analysed!!. Oh boyI aim to keep the testing as accurate as I can using Intel Burn Test.

I didn't get this bit? Can you please enlighten me on this info?

Don't break the fan blades

Would this be a good method aswell for noting ambient temp inside the case as this seems to correlate with method2 mentioned above?

Results for Diamond after 3 weeks of testing, final test for this stuff will be next week which is quite timely as its getting warmer now & today it didn't take long at all to bring the room up to ambient temperature.

* Pea-sized blob

* 70lbs pressure

* Ambient temerature 21c

* Idling temps taking 1hr after bootup

* Loads temps taken after 1hr on full load

* 1 weeks use = approx 14hrs use & 7 on/off cycles