Results/review as promised:

Introduction

Innovation Cooling have been around for a few years now and have added themselves to the already bloated list thermal paste manufacturers which while giving the consumer more choice, also makes it a little more difficult when it comes to buying (and determining) which is the the best paste.

Looking at their website

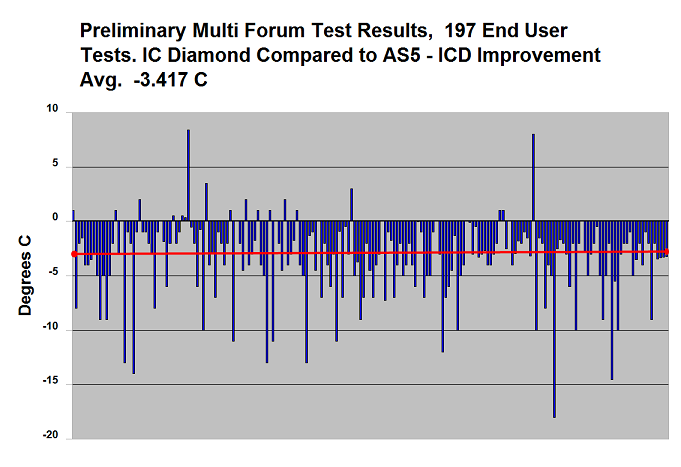

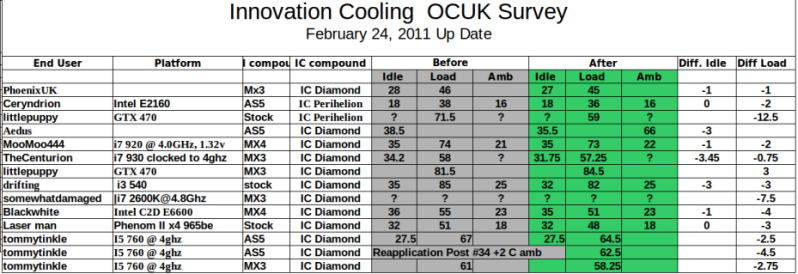

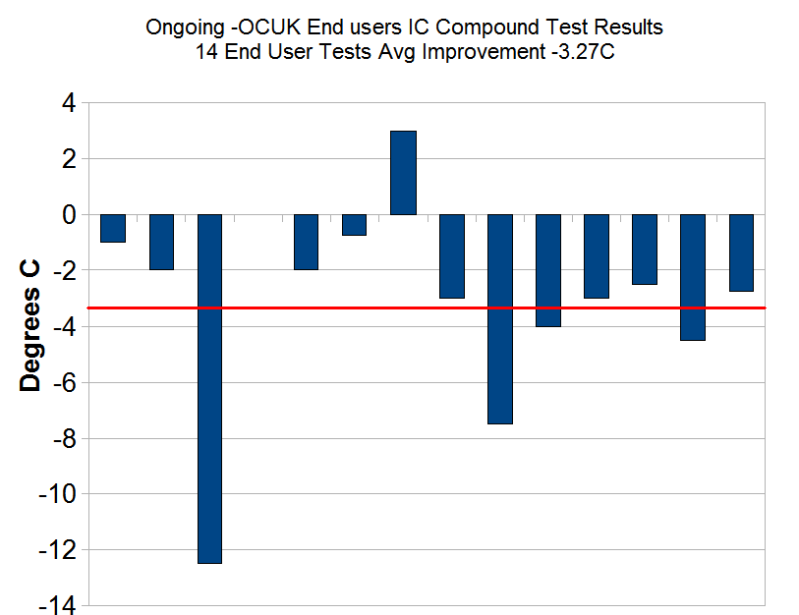

HERE, there are some very optimistic claims that the IC Diamond paste averages a 4.12 reduction in temperatures compared to other thermal compounds. While I don't mean to be a cynic, I have never been one to put a lot of faith into manufacturers claims. Too many times have I bought fans on the manufacturers claim it was as powerfull as a jet yet silent as a mouse fart only to find it pushes as much air as a mouse fart and is as noisy as a jet! What IC are doing though is, like it's name, innovative. Instead of testing it just by themselves, they are giving the pastes away to people to post back with their own results. This is genius in that people get free paste, innovation cooling get free advertisement and the 'reviewer' will already be 'on-side' for getting some new, free paste. Win-Win?

Perhaps so, but looking at some of the methods people use to 'compare' pastes, it's hardly surprising that IC win in most of the submitted results. Most of the 'reviews' I have seen were rough and ready:

'I remounted my cooler with IC diamond and saw an immidiate 10c drop in temps'.

Gimme a break please! If you are going to post results at least take the time to present some more info such as testing methodology and setup configuration.

Now I really am being cynical and perhaps biased AGAINST IC Diamond before I begin as comments such as these get my back up as they are misleading. You could replace thermal paste with toothpaste and see an immidate drop if your previous mount was not good or you had lower ambients! There's more to it than just swapping out the cpu cooler and where you stop is dependant on how anal you wnat to be with the details (see methodolgy).

This is going to be a brief comparison between the pastes I had to hand while conducting the review. I would have liked to compare against a wider range inc Indigo and AS5 but unfortunately didn't have any available.

So, I will mainly be comparing the IC diamond to the MX3 paste as Arctic cooling is widely recognised as one of the most popular TIM's around and as such is a stalwart among overclockers. I'll also throw in some Prolimatech (PK1?) paste which comes packaged with their megalehems heatsink. For good measure I also had a little Shinetsu MicroSi MPU 3.7 left so will also use that for comparison too. I won't be using the cheaper Perihelion in comparison to the CPU pastes, instead this will be replacing the stock thermal gunk that Asus use on their graphics cards as a basis for comparison.

Methodology

Testing thermal pastes is never easy and regardless of what measures you take there will always be someone who says 'you don't wanna do it like that bla bla bla' (yes this includes me too) so I'll be using the three times lucky method by mounting with the same paste three times and taking a reading (idle/load), averaging the core temp across the cores and then finding the average of the three tests to give a final figure. By doing this I will reduce the impact of a bad mount affecting temperature readouts.

e.g Mount one 35/34/37/39 = 36.25 avg

Mount one avg = 36.25

Mount two avg = 37.50

Mount three avg = 35.75

Avg cpu temp = mount 1 + mount 2 + mount = 109.5 / 3 (avg) = 36.5c

I will be using the following CPU for my test:

CPU = Intel I7 920 (D0) @ 4Ghz 1.275 vcore, 1.275 QPI, 1.65 CPU PLL.

CPU Heatsink = Prolimatech Super Mega inc 2x 140mm Prolimatech Vortex (Push/Pull @ 1000rpm).

Temps will be monitored by RealTemp 3.60.

Ambient temp fluctuations can have a very big impact on temperatures so I will be conducting the test in an air conditioned room set to 21c.

Some pastes require a bedding in period. While I don't have time to bed each paste in I will do some quick heat runs (Prime small FFt's 30 mins then shut down for 30 mins with the test taken upon next boot). While I will confess this is not the best method, it will at least give the pastes some bedding in time.

Application

First off, cleaning the CPU and heatsink surface. For this I will be using Isopropyl Alcohol to ensure each surface is squeeky clean.

Applying the paste. Some people prefer the spreading method, some prefer the line or X method. IC however recommend the blob method which entails a recommended 5mm blob in the centre of the CPU IHS, relying on the pressure of the mount to evenly spread the paste.

Here's one I made earlier using MX3:

While 5mm is slightly more than usual this is because of the high viscosity of the paste.

Here's a shot of the 'spreadability' of the pastes:

The IC Diamond is a very 'thick' and dry paste in comparison to both the MX3 and Prolimatech pastes. Spreading this paste would be far from easy hence IC's recommendation for the blob method I would wager.The MicroSi paste was even 'drier' followed by IC Perihilion (not pictured) which was rediculously thick and very similar to pastes found on stock GPU's.

Luckily for me, the CPU heatsink I'll be using (Prolimatech Super Mega) comes with an additional spring set that allows a crushing 70 pounds of pressure!

The same method will be used for applying all of the pastes on test.

Results

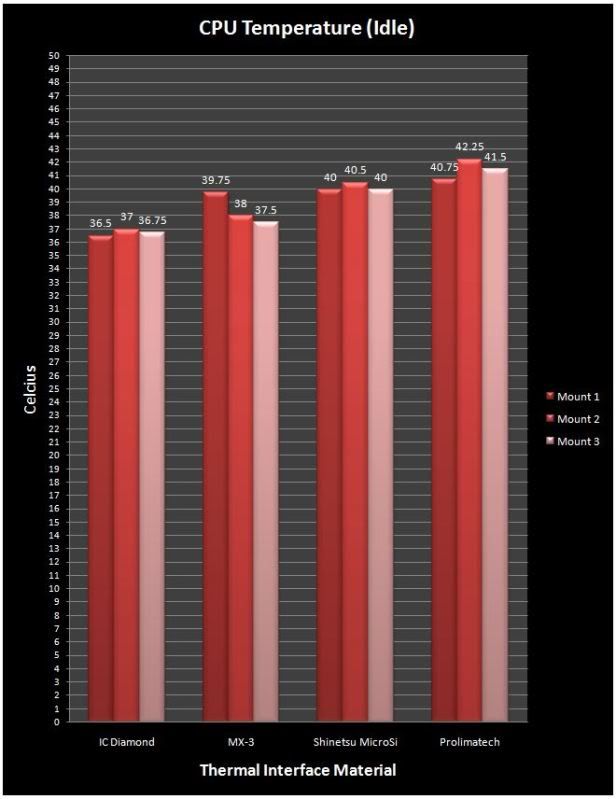

First off, let's take a look at the idle temperatures:

The above figures were taken in Windows 7 using Realtemp 3.60 after 5 minutes of the system being booted up with only nominal background programs running.

Wow! Don't you just hate it when you're proven wrong? The idle temps of the IC Diamond were well below any of the other pastes on test, including the overclockers favourite, MX-3, bettering it by some 2c! As you can see, temperatures are definately affected by mounting, even using the same procedure, hence the three mount procedure.

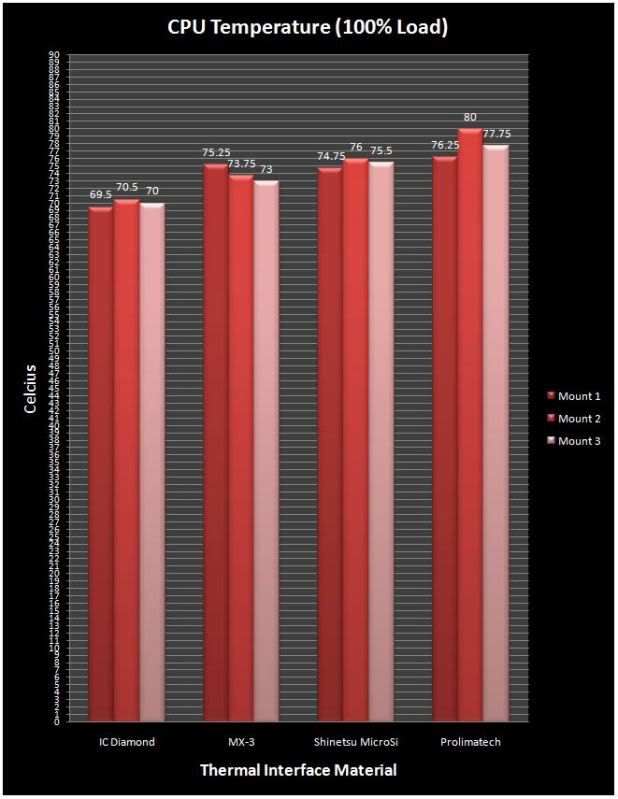

Now for the important test - Load temps:

Load temps were taken after 30mins of Prime 95 26.5 (Hyperthreading enabled) All cores loaded 100% via Small fft test.

Again we see the IC Diamond coming out on top, beating it's nearest competitor MX-3 by a clear margin once again. Amazingly it is some 7-8c better than the Prolimatech paste which is (was) highly regarded. It is interesting to note that temperatures were much more consistant between mounts using the thicker pastes than the thinner ones.

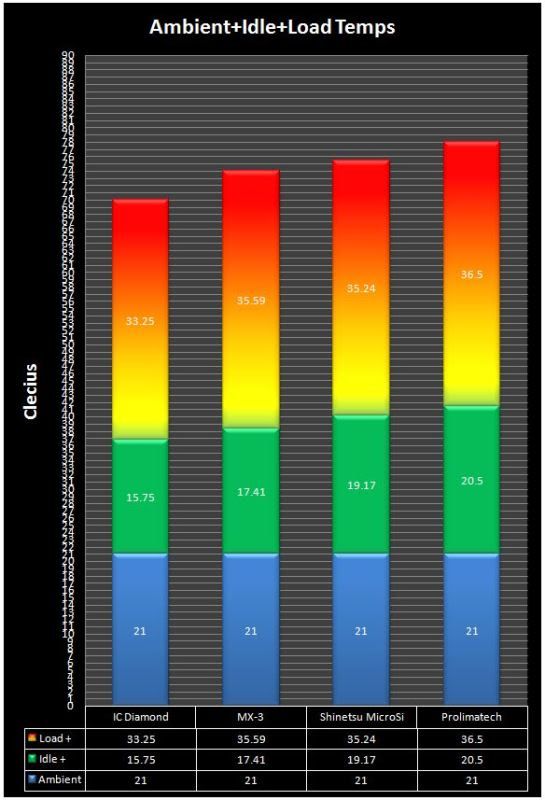

Let's look at things a little closer:

Here's where things get a little interesting. While the idle + load temps fall in favour of the IC Diamond, bizarrely the worst performing combatent, the Prolimatech has the best idle/load difference (+16c) closely followed by the MicroSi paste with IC Diamond and MX-3 bringing up the rear in that order. So if the idle temps were reversed, the worst performing paste would actually be the best! Despite this, IC Diamond still maintains is lead over the other pastes with room to spare.

Conclusion

Without a doubt, the IC Diamond is the clear winner in this short test and by a clear margin. It beat it's nearest competitor, Arctic Coolings MX-3 by some 4c on average and stomped all over Prolimatech by 8c! It's extremely low idle temps gave it a headstart over the other pastes which resulted in the load temps being lower again still, compounded it's overall advantage. Put this down to the (extremely) thick paste, the diamond dust or the magicians at Innovation Cooling, either way they have created a Paste that will re-ignite the recently stagnent CPU TIM market. When folk ask me whats the best CPU paste I usually went with either MX-3 and previously, my old favourite Arctic Silver 5, my recommendations (and thus my opinions) have since changed.

IC Diamond does what it claims to do, drops temperatures by a clear amount when compared to other leading brands.

IC Diamond - Sorry for doubting you, I am now a believer, well done!

The Good

- Temperature drop

The Mediocre

- Excess pressure required to extrude the paste from the syringe

- VERY thick paste. Don't expect to be able to spread this easily.

The Bad

- Twice the price of it's nearest competitor but you do get what you pay for.

9/10

Innovation Cooling - Sorry for doubting you, I am now a believer, well done! Thanks for providing the paste for this review.

. I don't know what happened as my post was no 33 in the give away thread yet some people who posted later on got it first

. I don't know what happened as my post was no 33 in the give away thread yet some people who posted later on got it first .

. .

.