Associate

- Joined

- 6 Mar 2013

- Posts

- 444

It's great to see the L1.0 live on OCUK!

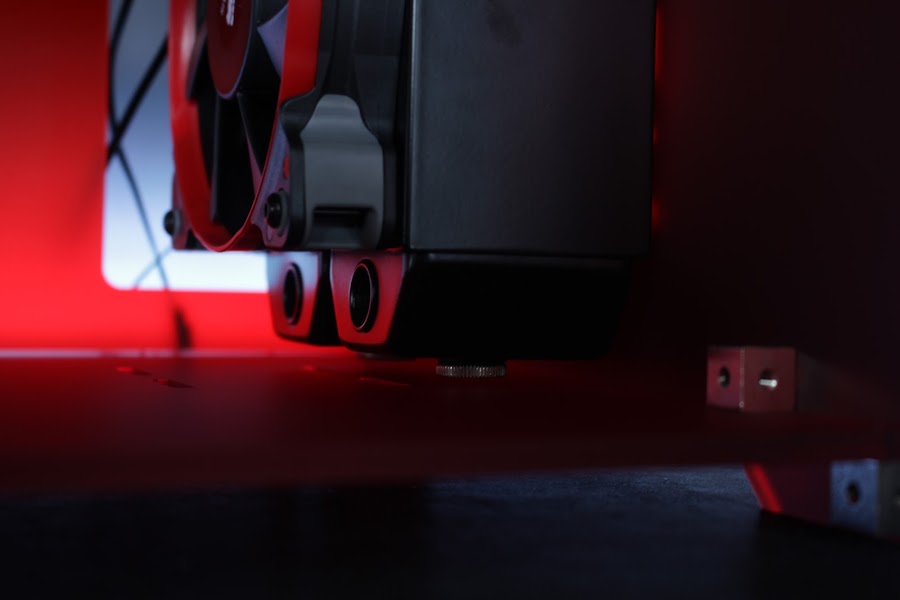

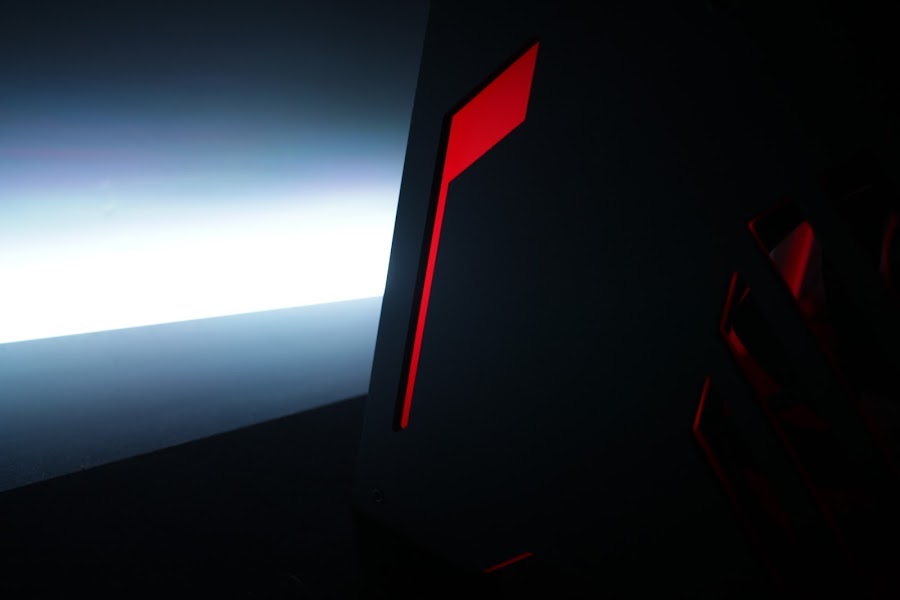

So you can all get a better feel for our new case here are some pictures of a build in a retail L1.0, this was the first finished sample cut 4 months ago and wasn't modified for this build at all. Since then it has attended i55 and i56 with OCUK and two smaller LAN's making a total of 9 car journeys as an assembled case. Ontop of being carried all around my house, Ricoh Arena, the NEC, up stairs, down stairs it has had X1.0 builds inside it and R1.0 360 builds on top of it. But it still stands just as magnificent on my desk being used every day.

Just a simple thing but we wanted to give the freedom to mount radiators either way around, as a keen team of builders we know how much it can help with making a clean loop to have the ports at the other end.

Also there is clearance for 60mm thick radiators everywhere, although simple there is also a little hole for cables and tubes to pass through the midplate hidden behind the front radiator. Allowing anyone to fit their components without modifying the case at all but not littering every panel with cable holes was also a priority and this made for an elegant compromise.

The modularity of the case makes working in the pedestal easy allowing use to fix the mounting plates to their radiators before fitting in the case. Depending on the order of your build the rad mounts also make it possible to remove the entire front or rear of the case, or leave them in place and remove the floor entirely.

By alternating short and long screws you can make it really simple clean or replace fans in the pedestal without disturbing the loop. We also left enough clearance for user to mount aftermarket dust filters.

As with the midplate we tried not to add hundreds of holes the midwall most users would never fill, a lot of time was taken to reach a sensible compromise of usability and clean aesthetics throughout the interior.

We have retained our distinctive mid wall bend from the S2.0 leaving lots of room in the back chamber for cables, tubing, drives and reservoirs! Although unconventional it worked out well for this build leaving more of the fabric of the case visible to show off from the front.

If you want to see a little more of this build there are more pictures in the project log: αclass 2.0 by JR23

Thanks for looking guys as well as all of the kind comments on here, if you have any questions about the L1.0 we will keep an eye on this thread and do our best to answer them. We look forward to seeing your builds in 2016.

Regards, Parvum Team

So you can all get a better feel for our new case here are some pictures of a build in a retail L1.0, this was the first finished sample cut 4 months ago and wasn't modified for this build at all. Since then it has attended i55 and i56 with OCUK and two smaller LAN's making a total of 9 car journeys as an assembled case. Ontop of being carried all around my house, Ricoh Arena, the NEC, up stairs, down stairs it has had X1.0 builds inside it and R1.0 360 builds on top of it. But it still stands just as magnificent on my desk being used every day.

Just a simple thing but we wanted to give the freedom to mount radiators either way around, as a keen team of builders we know how much it can help with making a clean loop to have the ports at the other end.

Also there is clearance for 60mm thick radiators everywhere, although simple there is also a little hole for cables and tubes to pass through the midplate hidden behind the front radiator. Allowing anyone to fit their components without modifying the case at all but not littering every panel with cable holes was also a priority and this made for an elegant compromise.

The modularity of the case makes working in the pedestal easy allowing use to fix the mounting plates to their radiators before fitting in the case. Depending on the order of your build the rad mounts also make it possible to remove the entire front or rear of the case, or leave them in place and remove the floor entirely.

By alternating short and long screws you can make it really simple clean or replace fans in the pedestal without disturbing the loop. We also left enough clearance for user to mount aftermarket dust filters.

As with the midplate we tried not to add hundreds of holes the midwall most users would never fill, a lot of time was taken to reach a sensible compromise of usability and clean aesthetics throughout the interior.

We have retained our distinctive mid wall bend from the S2.0 leaving lots of room in the back chamber for cables, tubing, drives and reservoirs! Although unconventional it worked out well for this build leaving more of the fabric of the case visible to show off from the front.

If you want to see a little more of this build there are more pictures in the project log: αclass 2.0 by JR23

Thanks for looking guys as well as all of the kind comments on here, if you have any questions about the L1.0 we will keep an eye on this thread and do our best to answer them. We look forward to seeing your builds in 2016.

Regards, Parvum Team