You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[Project] Black & Blue

- Thread starter shadowscotland

- Start date

More options

Thread starter's posts- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

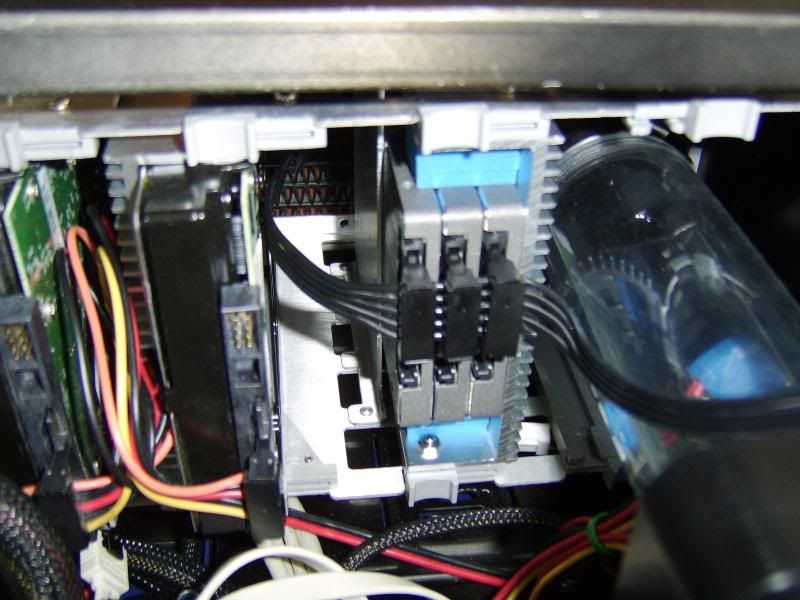

no fans on that rad - only fan in the build is bottom right in the last of my photo's.

Will be finishing this log this week - thanks to BitFenix, and some shiney nickel

Will be finishing this log this week - thanks to BitFenix, and some shiney nickel

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

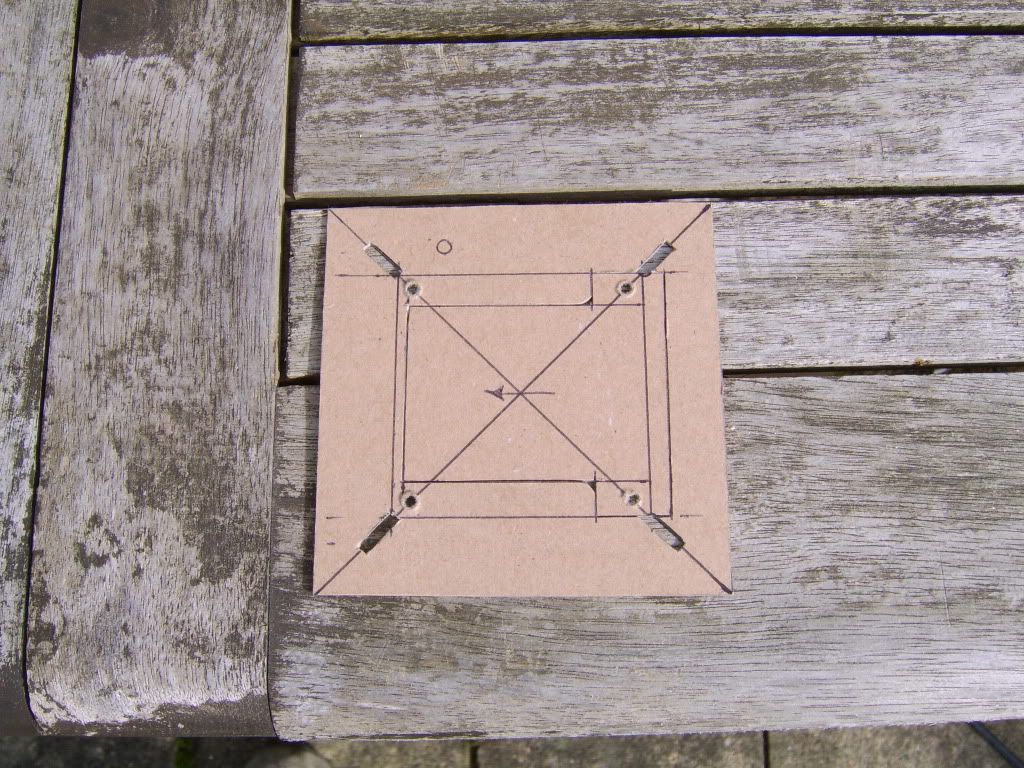

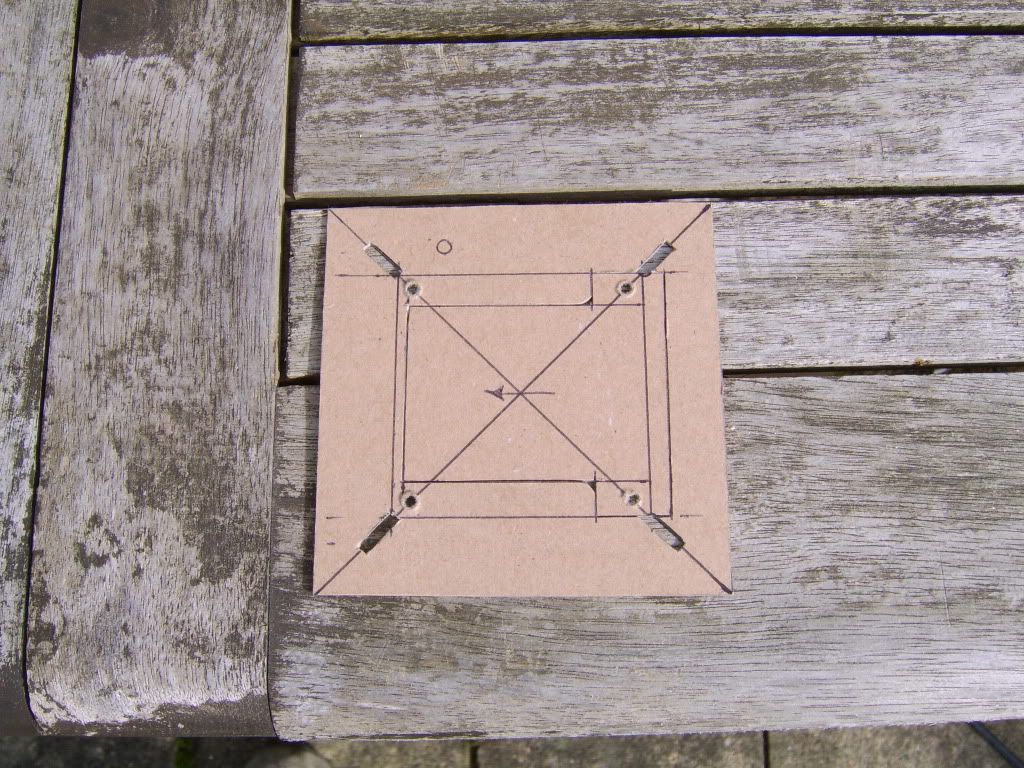

Sunny day update

Still on air and GPU is getting way to hot in games running passive.

and GPU is getting way to hot in games running passive.

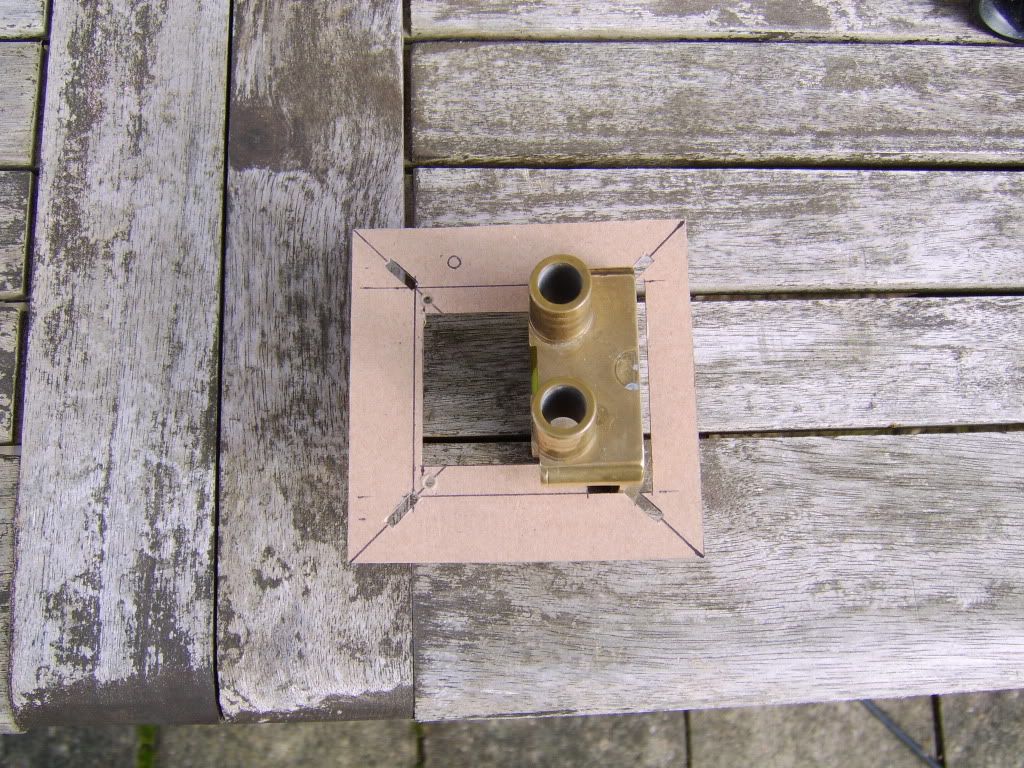

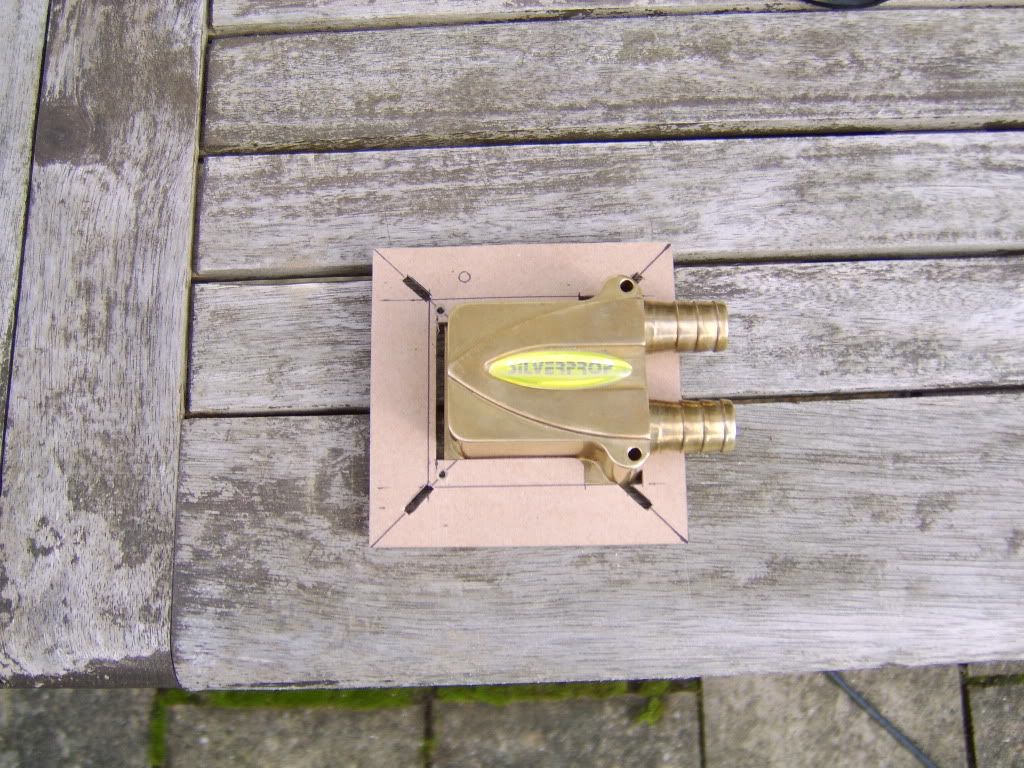

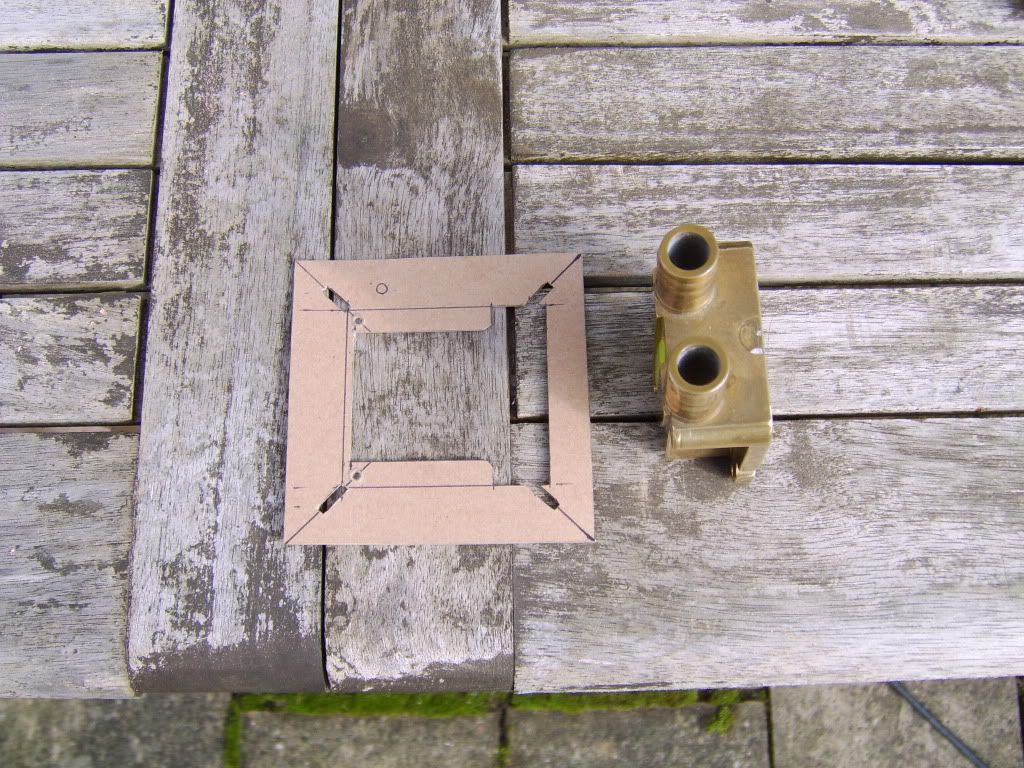

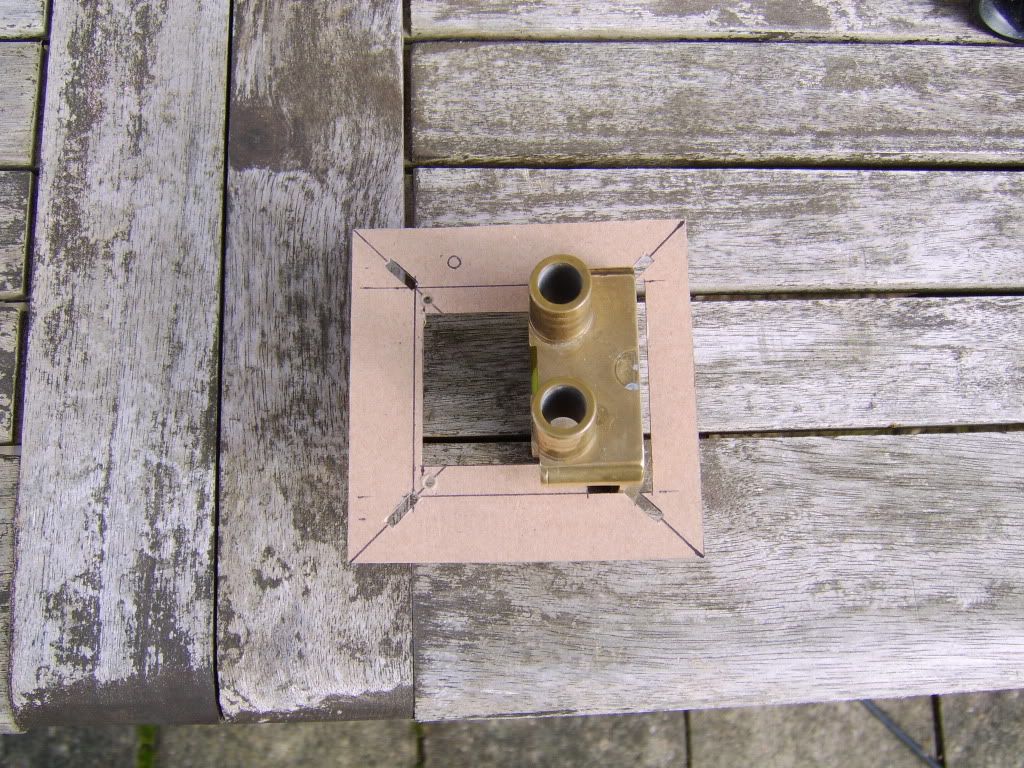

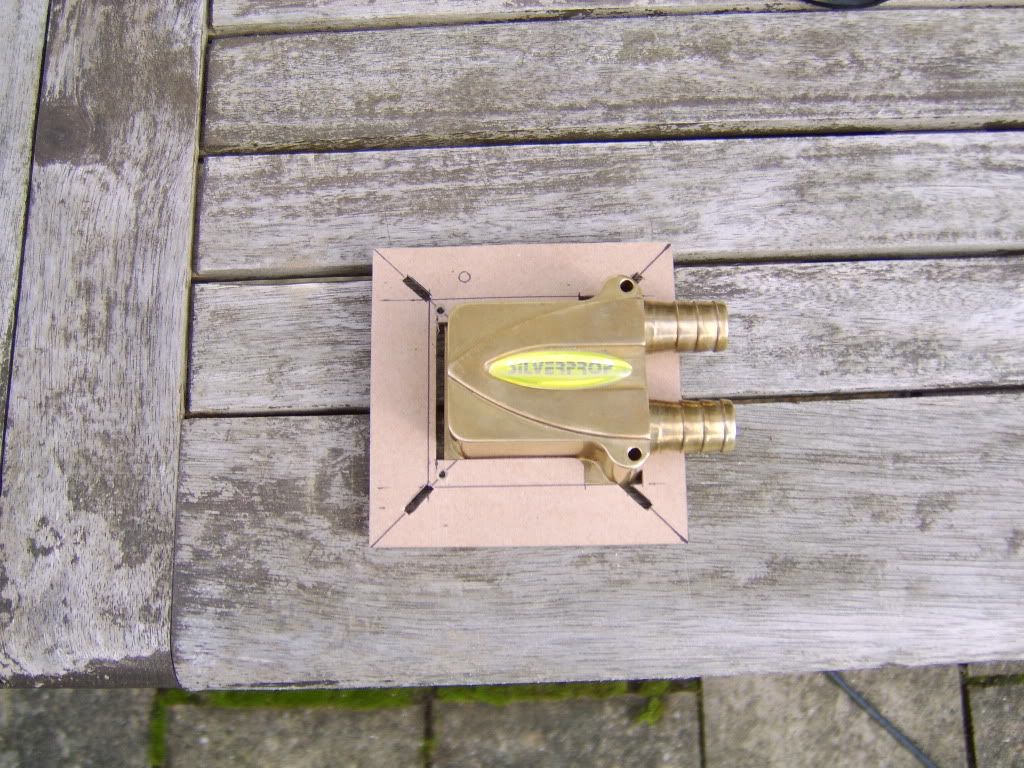

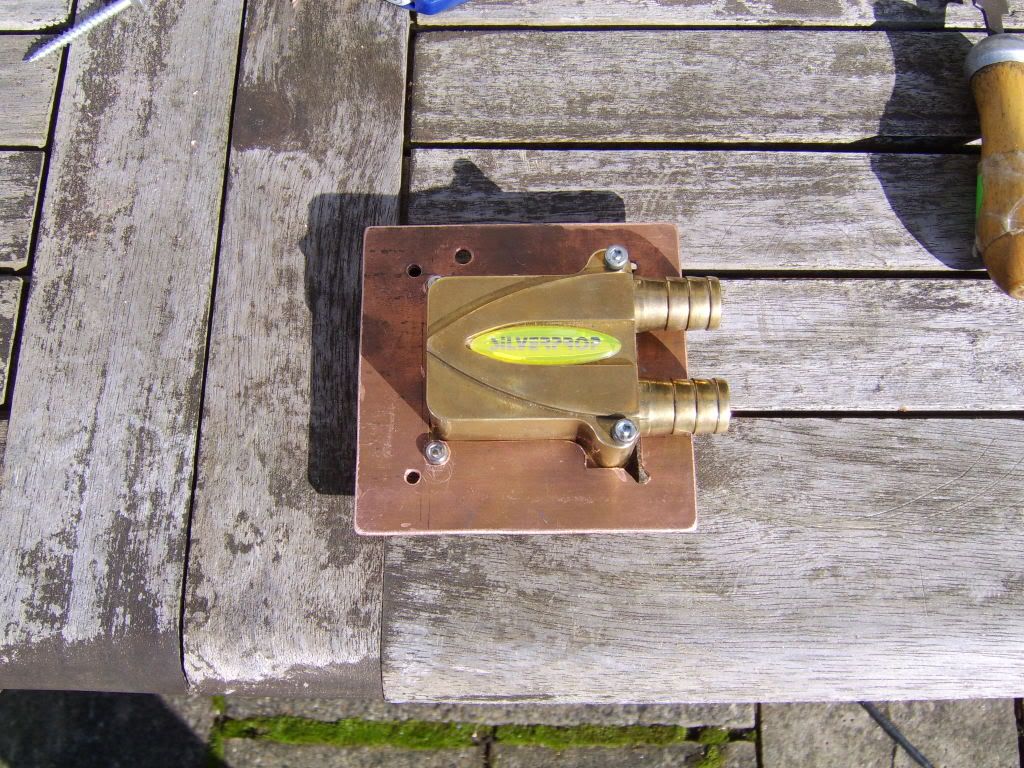

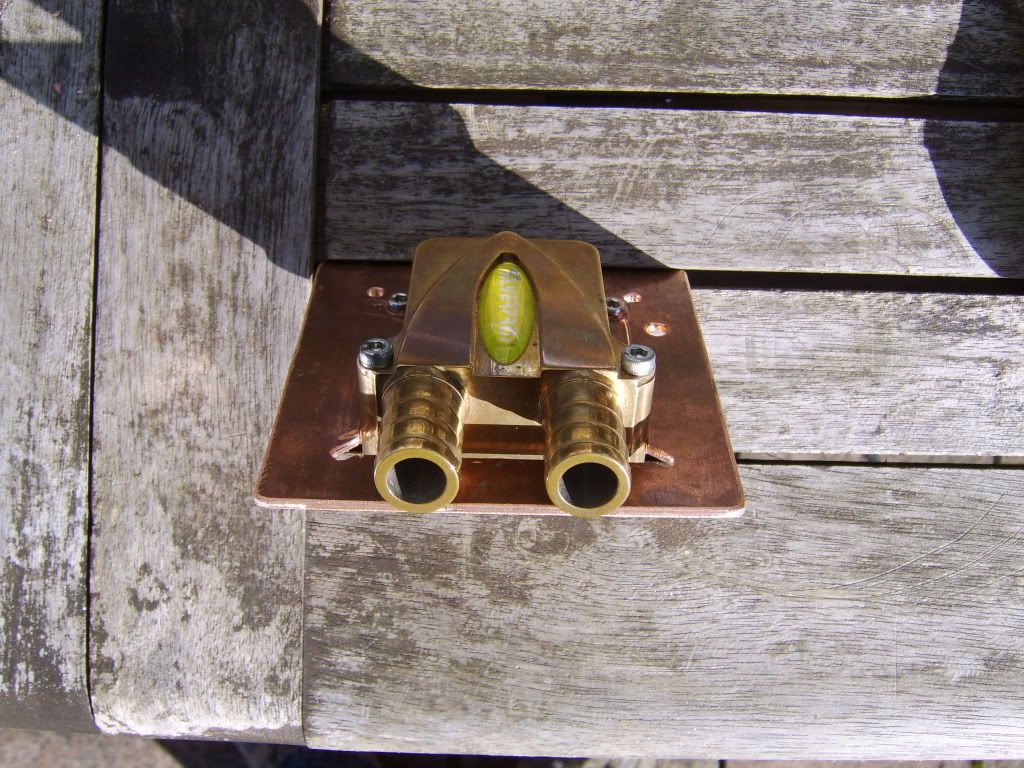

SO some tools are needed as I was never happy with the silverprop block only having the two fixings - custom bracket needed, and off we go.

I did the card and perspex last night - onward to the main even

Still on air

and GPU is getting way to hot in games running passive.

and GPU is getting way to hot in games running passive.SO some tools are needed as I was never happy with the silverprop block only having the two fixings - custom bracket needed, and off we go.

I did the card and perspex last night - onward to the main even

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

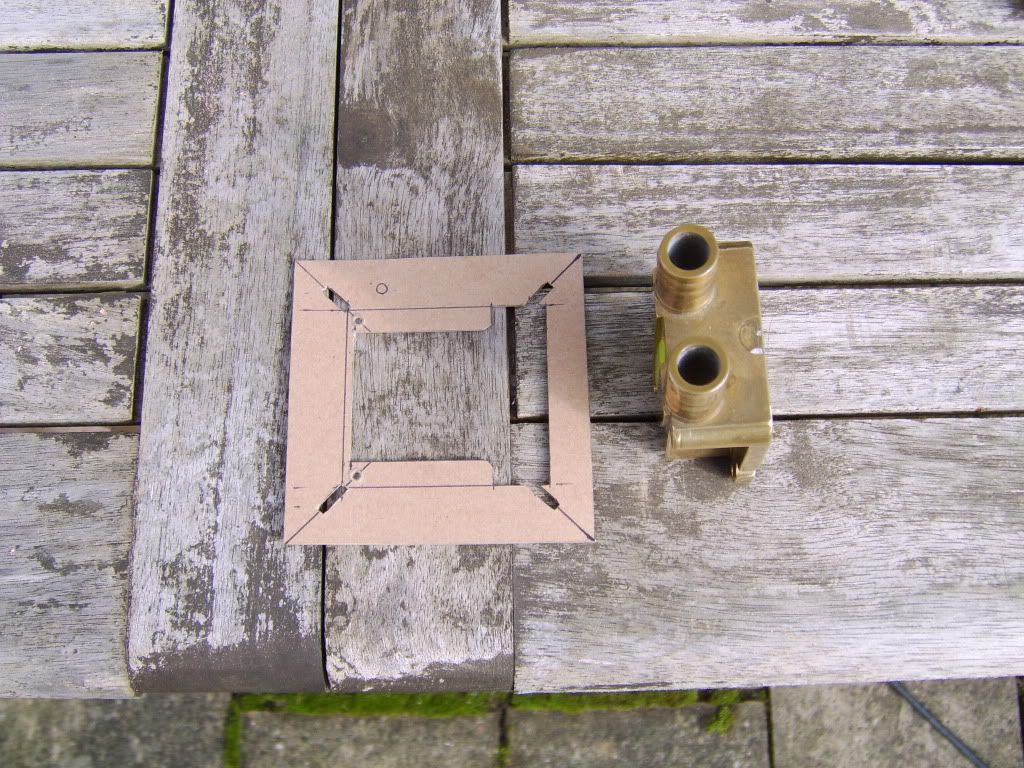

With the all metal construction and intergrated barbs adding a full 'loop' bracket does present some problems.

Shuffle to the right for final position

Shuffle to the right for final position

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

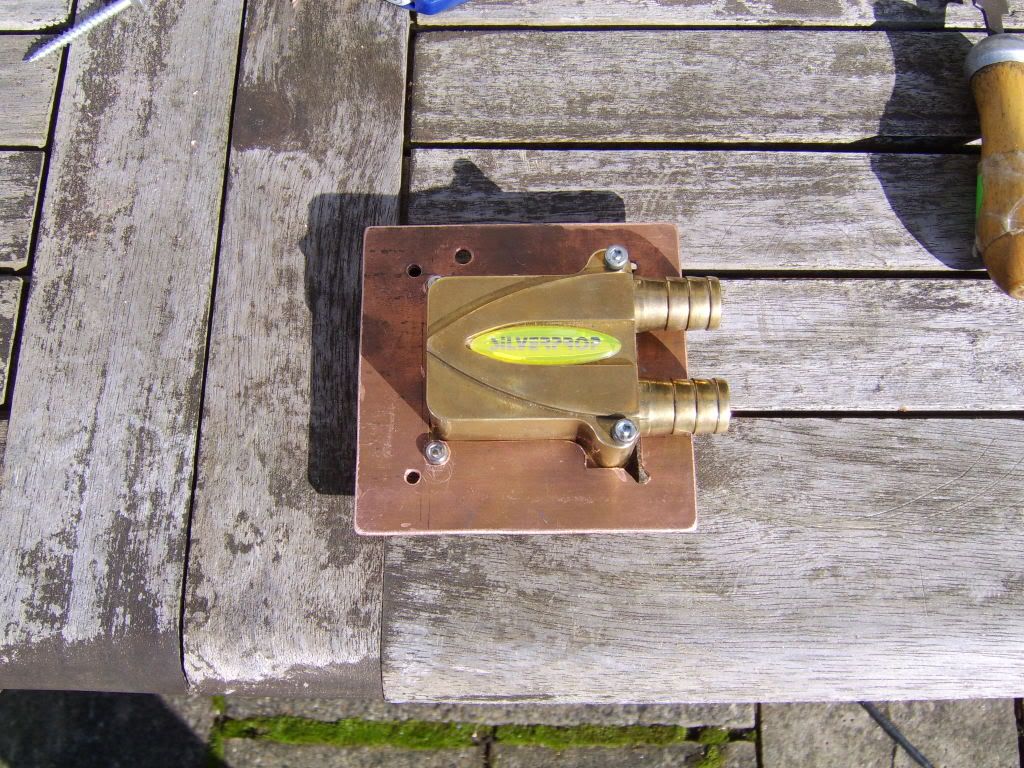

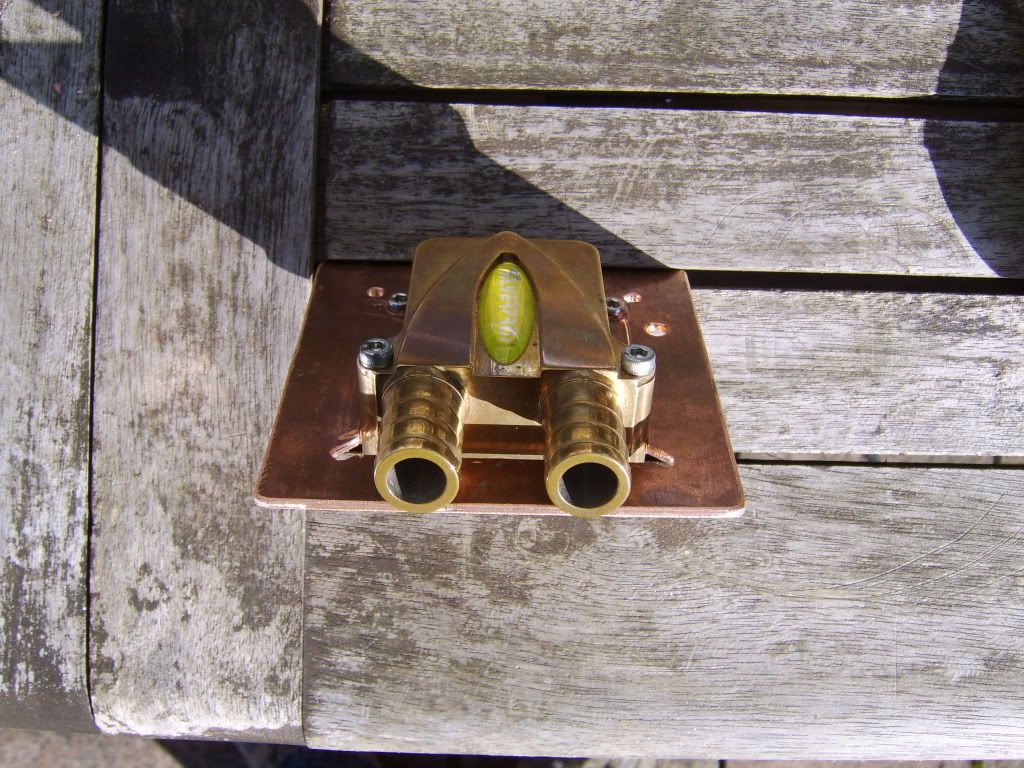

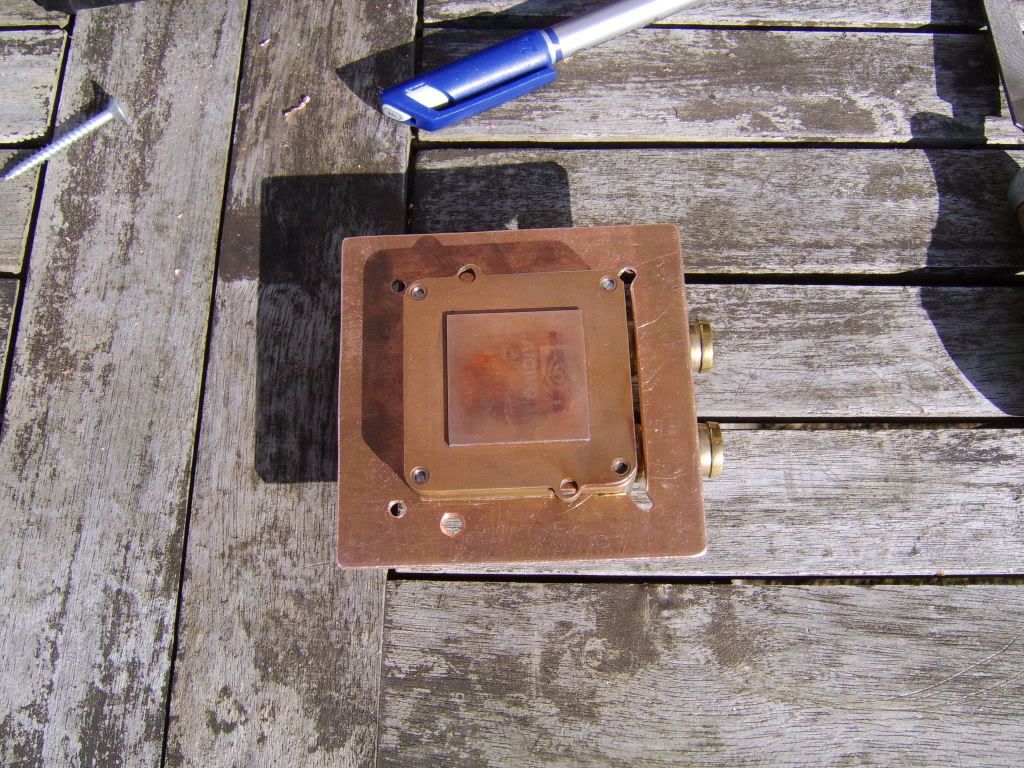

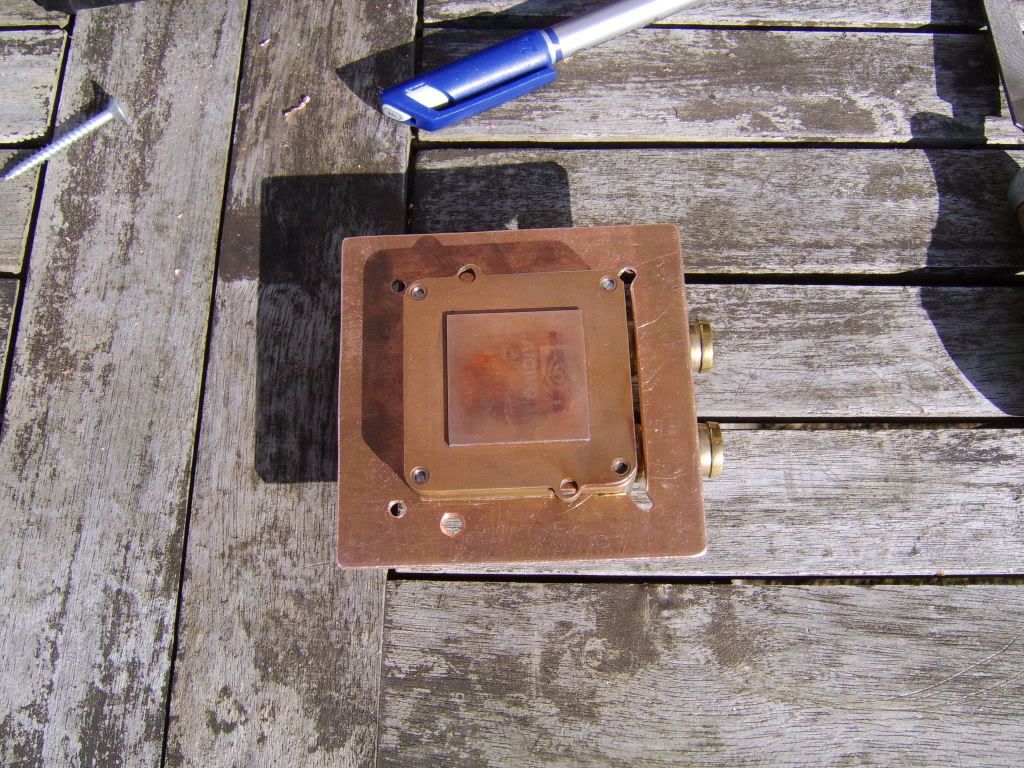

2mm copper sheet is from a watercooled psu mod I did years ago

Slice and dice with the trusty dremel clone (branded disks are a must)

Doh! cut along wrong line but saved it before I cut to far.

Extra cut

G92 holes and counter sunk holes for block fixings

And done for now - paint or polish at a later date

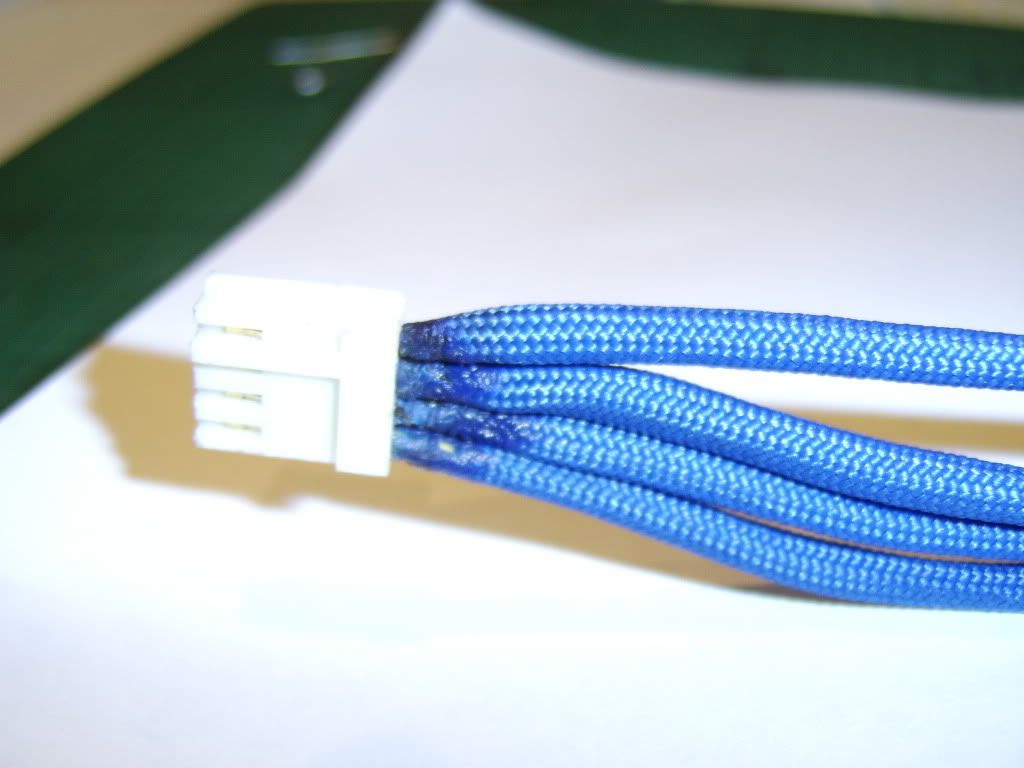

Oh look what I found on the bay - paracord braiding

Slice and dice with the trusty dremel clone (branded disks are a must)

Doh! cut along wrong line but saved it before I cut to far.

Extra cut

G92 holes and counter sunk holes for block fixings

And done for now - paint or polish at a later date

Oh look what I found on the bay - paracord braiding

Last edited:

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

Loop changes - inc. EK purge (want nothing more to do with them)

The rad had some quite old barbs attached - high quality, but not as great an ID as I'd like so these were swapped to some bitspower ones.

The metal primochill ghost barbs are also being swapped out to match the bitspower fatboys.

Both have the same ID at the thread end - but the bp barbs have a wider ID at the barb tail end.

Now most of the watercooling community use there tube res like this.

flow in and out at the base with a fill port (or just a plug at the top)

I use my res inverted so I get the benifit of a sealed loop after bleeding (con-compressable liquid and all that)

With the advantages of a res for air bleeding durring filling.

It also remove the need of some tubing (res acts as oversided tube - in at top out at base)

Add a male to male connection and you have a neat x-top/tube res combo

The rad had some quite old barbs attached - high quality, but not as great an ID as I'd like so these were swapped to some bitspower ones.

The metal primochill ghost barbs are also being swapped out to match the bitspower fatboys.

Both have the same ID at the thread end - but the bp barbs have a wider ID at the barb tail end.

Now most of the watercooling community use there tube res like this.

flow in and out at the base with a fill port (or just a plug at the top)

I use my res inverted so I get the benifit of a sealed loop after bleeding (con-compressable liquid and all that)

With the advantages of a res for air bleeding durring filling.

It also remove the need of some tubing (res acts as oversided tube - in at top out at base)

Add a male to male connection and you have a neat x-top/tube res combo

Last edited:

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

EK-D5 xtop rev2 (above) and Koolance POV-RP450

The spiral is better on the Koolance, but the pump fixing is more secure on the Ek

The latest revision of the RP450 has a stronger fixing (but looks overkill)

Now Koolance have been making and improving pump/res combo's for a while.

The various one and two pump bay res are well know.

But the D5 pump top (COV-RP450) basically does what my ek homebrew did above.

That the Ek tube as my koolance one still hasn't arrived (will edit when it does)

Tube can be screw (via a cuppling) directly into the pump top.

Last edited:

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

Remember this - the ek backplate

Well it's to be replaced with this - the koolance backplate

After the imperial threads are drilled out for M4 rods (the stock rods were snapped by previous owner)

And I can finally reattach the socket hold down plate.

Now it's all back up and running (with a SI-128 attached to the rods) I'm thinking of using the koolance

stock thumb nuts and springs, luckily my bits box has some old Danger Den rods of the right thread

EDIT: my new parts have been shipped to italy by mistake

As the shop didn't have any other spare I'm still waiting on the italian/german postal services to get it back to the warehouse.

Well it's to be replaced with this - the koolance backplate

After the imperial threads are drilled out for M4 rods (the stock rods were snapped by previous owner)

And I can finally reattach the socket hold down plate.

Now it's all back up and running (with a SI-128 attached to the rods) I'm thinking of using the koolance

stock thumb nuts and springs, luckily my bits box has some old Danger Den rods of the right thread

EDIT: my new parts have been shipped to italy by mistake

As the shop didn't have any other spare I'm still waiting on the italian/german postal services to get it back to the warehouse.

Last edited:

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

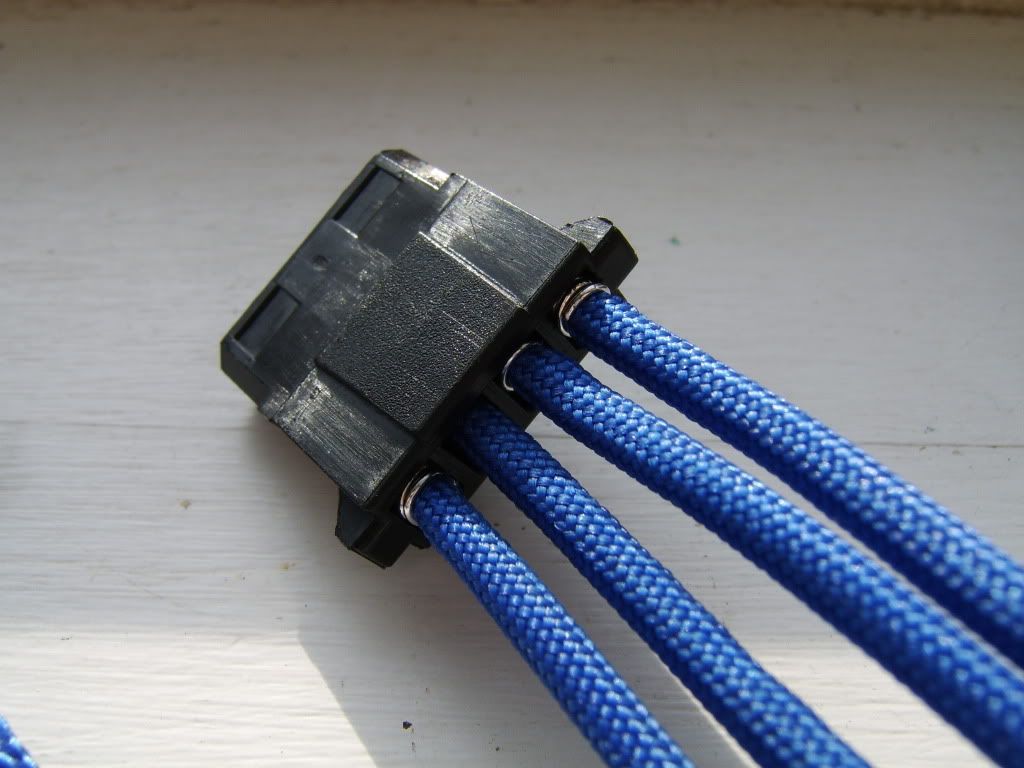

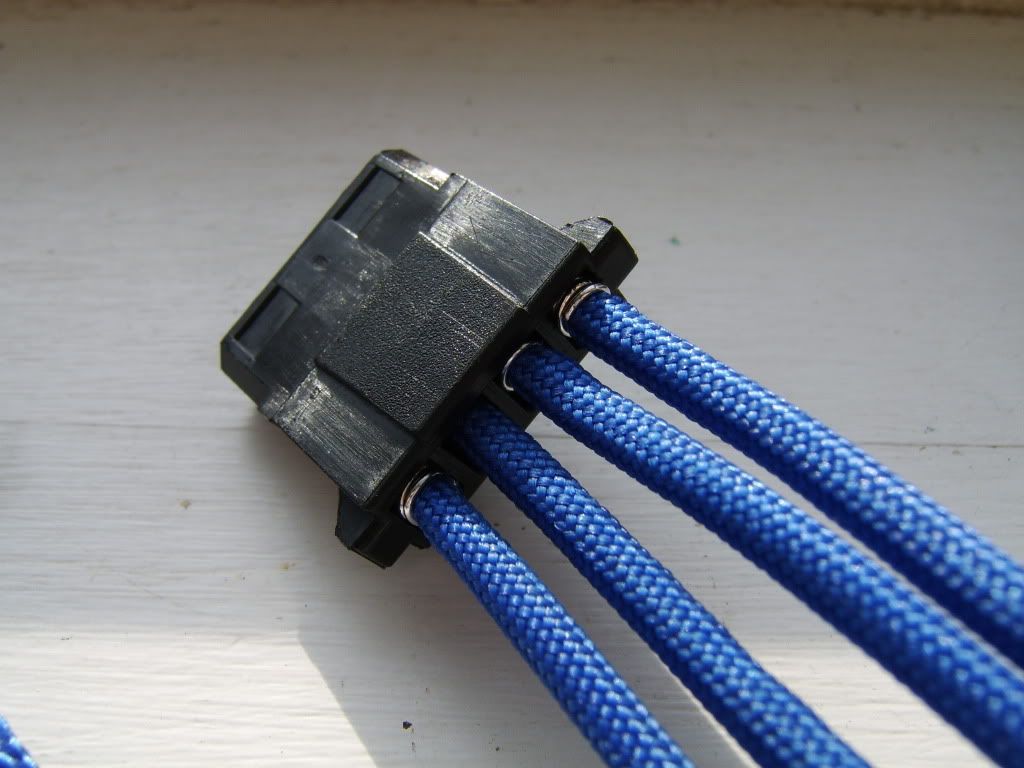

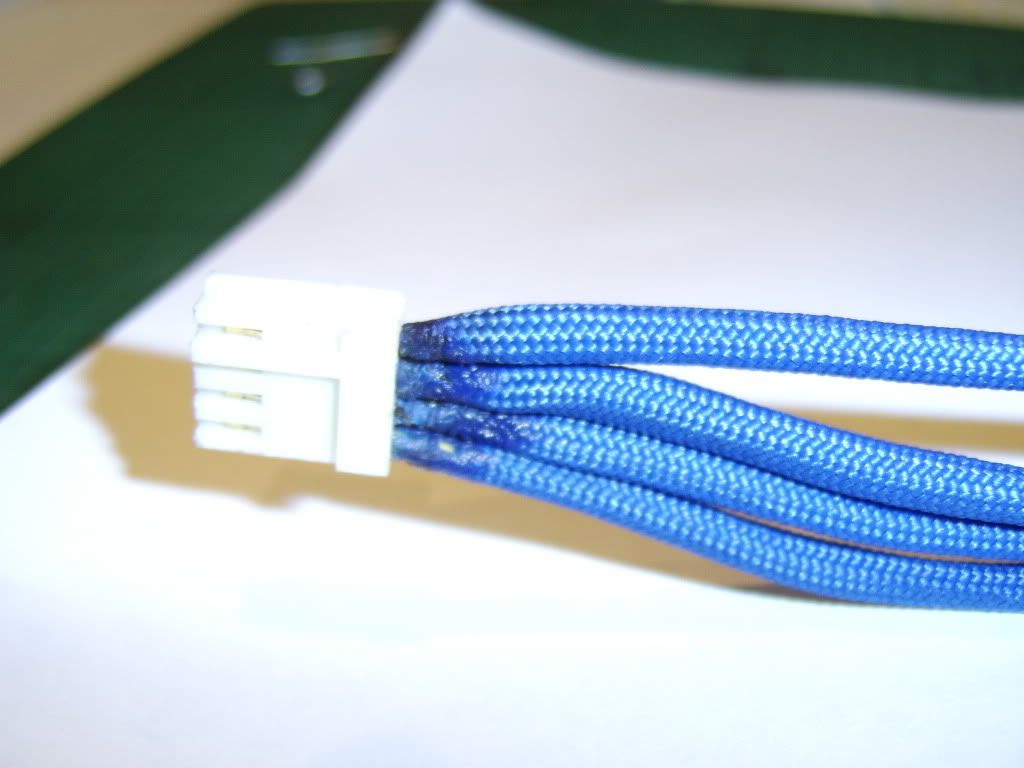

The res still hasn't arrived  so I started on the braid. Paracord style

so I started on the braid. Paracord style

Standard black braid (left) - bitfenix braid (below) - paracord (on top)

The braid is attached to the wire with a 5mm silver plated split ring (like a mini key ring)

The double wires were much harder - needed a few goes to get what I wanted.

Left to right are the order I did them.

Double ring - wide ring - tight ring (but rotated) - tight single ring, correct position

so I started on the braid. Paracord style

so I started on the braid. Paracord styleStandard black braid (left) - bitfenix braid (below) - paracord (on top)

The braid is attached to the wire with a 5mm silver plated split ring (like a mini key ring)

The double wires were much harder - needed a few goes to get what I wanted.

Left to right are the order I did them.

Double ring - wide ring - tight ring (but rotated) - tight single ring, correct position

Caporegime

- Joined

- 18 Sep 2009

- Posts

- 30,550

- Location

- Dormanstown.

May I ask why you went for the EK purge?

You're one of the more experienced WC'ers here, so I'm intrigued.

Also, I like your work, especially the home made stuff

You're one of the more experienced WC'ers here, so I'm intrigued.

Also, I like your work, especially the home made stuff

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

May I ask why you went for the EK purge?

You're one of the more experienced WC'ers here, so I'm intrigued.

EK were rude to the point of slanderous to many member of the community prior to accepting the nickle corrosion issue was their fault. - First strike

They said it was isolated, it's not. - strike two

Well over half of all the people I know with nickle blocks have had rma or are still waiting for an EN version of their block.

After my EK supreme HF started corroding - my retail boxed block was refused an RMA.

Reason no invoice - was got from EK own shop (it was a gift from my now dead relative)

computer says 'no' customer service - Third strike and your out.

I want nothing to do with a company like that.

Also, I like your work, especially the home made stuff

I try - time I have, lot's of money I don't.

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

Post man has finally been - ordered these two items on the 28th of Feb.

On there way to me they've left germany to be sent to italy (in error)

Back to germany to be sent to newmarket and finally via RMSD to me in london

On the up side I did get a bag of sweeties as a sorry.

Was very impressed with the quality - really nicely machined piece of Acetal

And the acrylic is good and thick - with a keen thread.

All O rings have a recess to sit it, nickle plated plugs.

Even the anti cyclone plate screws are rust proof (acrylic - don't need to be strong thankfully)

Every part speaks quality

As with the EK res - I've used the base as a top section.

But unlike the EK, the base has many more options and no air pockets when inverted.

I can see why Koolance now offer a 80mm ID tube, as the 60mm one looks a bit small.

It's still wider that the EK but due to the pump surround it looks undersized.

From a fuctional point of view it's perfect.

As I no longer need a 90 to connect both my rad and fill port to the top of the res

And the res/pump top connection is massively better that before

Hats off to koolance with how when fully tighten the in/out lets line up.

Some Mayhems Biocide extreme and my recently serviced Yesico are both on they way to me.

Should have the pc back to being uber ultra quiet this week

With the slightly smaller res my loop should be just under a litre (instead of just over)

Bottle of nano fluid ...

On there way to me they've left germany to be sent to italy (in error)

Back to germany to be sent to newmarket and finally via RMSD to me in london

On the up side I did get a bag of sweeties as a sorry.

Was very impressed with the quality - really nicely machined piece of Acetal

And the acrylic is good and thick - with a keen thread.

All O rings have a recess to sit it, nickle plated plugs.

Even the anti cyclone plate screws are rust proof (acrylic - don't need to be strong thankfully)

Every part speaks quality

As with the EK res - I've used the base as a top section.

But unlike the EK, the base has many more options and no air pockets when inverted.

I can see why Koolance now offer a 80mm ID tube, as the 60mm one looks a bit small.

It's still wider that the EK but due to the pump surround it looks undersized.

From a fuctional point of view it's perfect.

As I no longer need a 90 to connect both my rad and fill port to the top of the res

And the res/pump top connection is massively better that before

Hats off to koolance with how when fully tighten the in/out lets line up.

Some Mayhems Biocide extreme and my recently serviced Yesico are both on they way to me.

Should have the pc back to being uber ultra quiet this week

With the slightly smaller res my loop should be just under a litre (instead of just over)

Bottle of nano fluid ...

Last edited:

Soldato

- Joined

- 13 Mar 2006

- Posts

- 6,712

Don't koolance also have something of a chequered history...

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

Your not wrong Monkey Puzzle, I was very close to selling off all my loop.

After a play with a TY-140's an aquaero I may still do that...

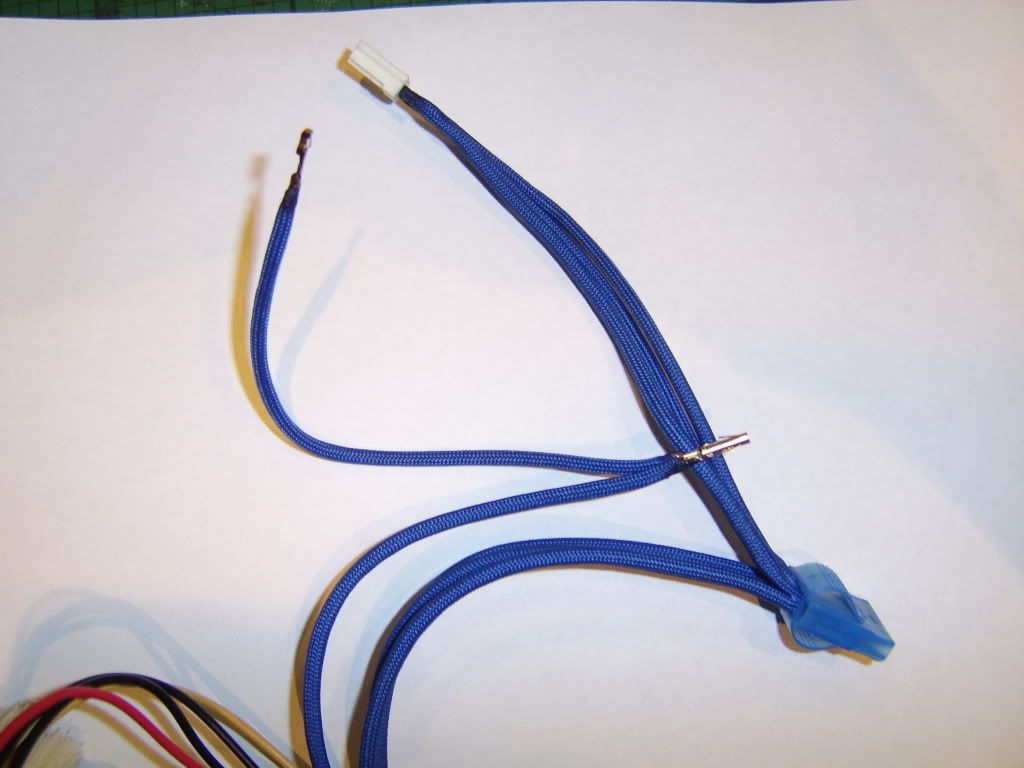

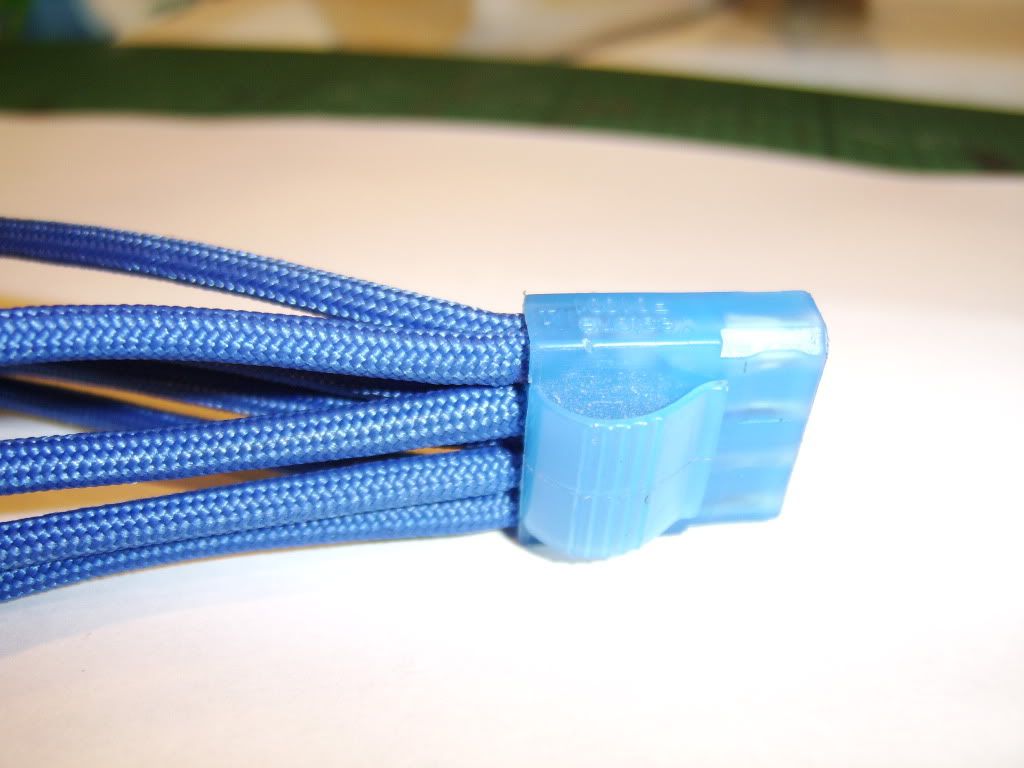

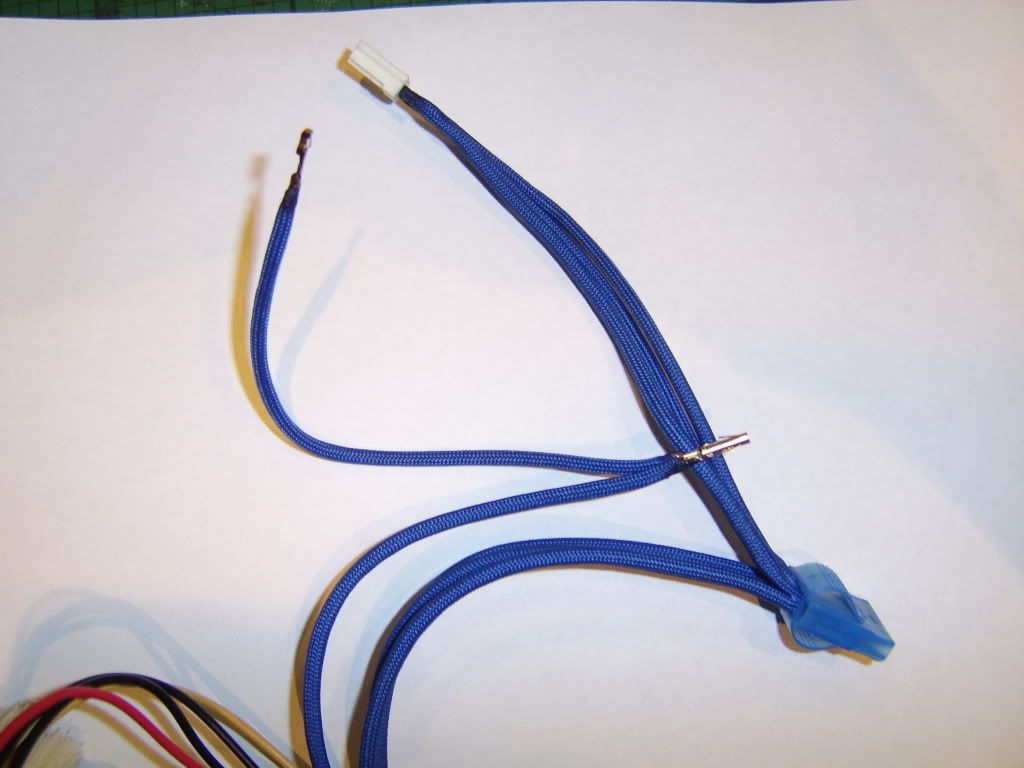

But on with the current show, been using the paracord again.

I must say that it takes more time to slide the cord over a long wire.

It sort of 'sticks' to the wire as the friction increases.

So catapiller pinching required - easy but adds some time over the mdpc stuff.

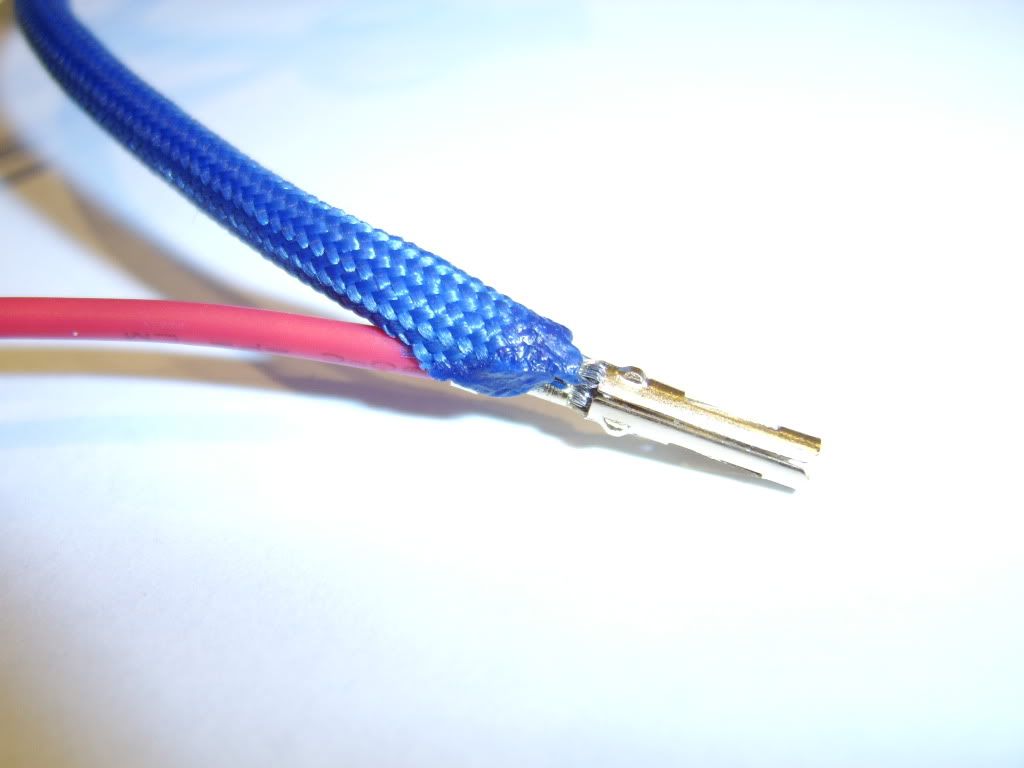

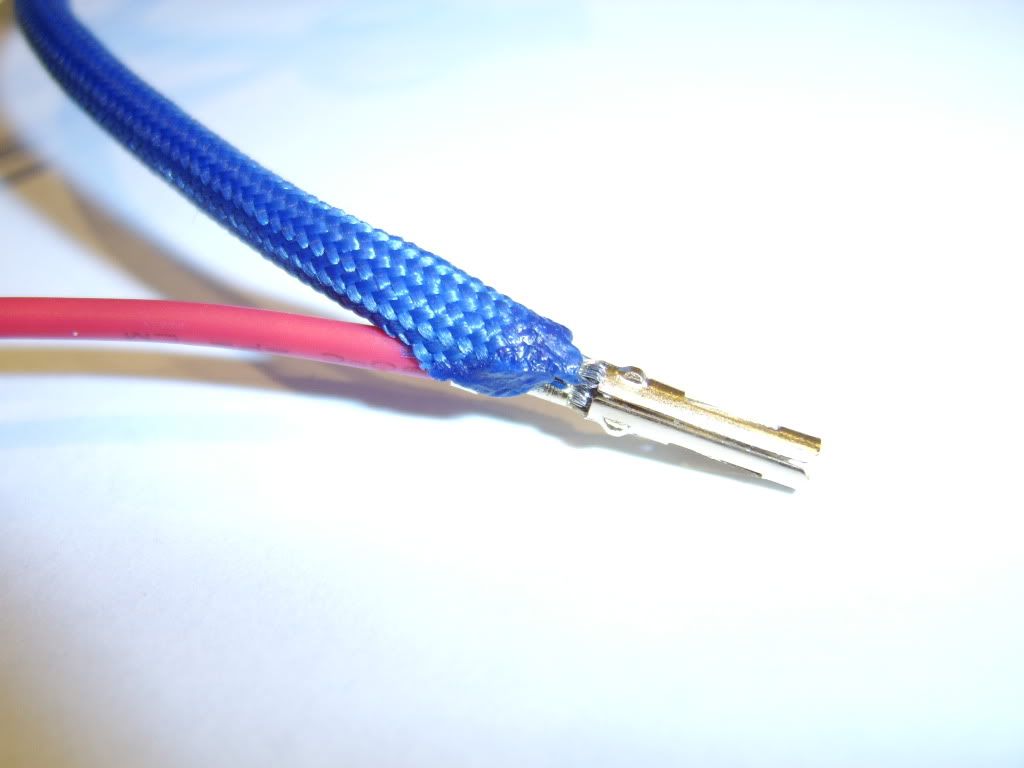

Used the heatsinkless method on the pins - heat/melt/roll between fingers - worked a treat.

Also opened out some split rings and added these as cable separators.

Stops the 'shoelace' look, keeps them tidy, and looks a bit different.

After a play with a TY-140's an aquaero I may still do that...

But on with the current show, been using the paracord again.

I must say that it takes more time to slide the cord over a long wire.

It sort of 'sticks' to the wire as the friction increases.

So catapiller pinching required - easy but adds some time over the mdpc stuff.

Used the heatsinkless method on the pins - heat/melt/roll between fingers - worked a treat.

Also opened out some split rings and added these as cable separators.

Stops the 'shoelace' look, keeps them tidy, and looks a bit different.

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

Using the heatshrinkless braiding method with a match (lighter ran out) takes forever.

Should have just gone out in the rain and got a cheapo disposable one or a refill can.

Wasn't a straight forward job as I needed to thread the paracord over a floppy power pin (Xonar) as well as a molex.

As ever a safety pin was used to remove the pins from their plastic sockets.

Gold plated contacts as standard on my Jesico.

Need to do the silver wire work - but not tonight

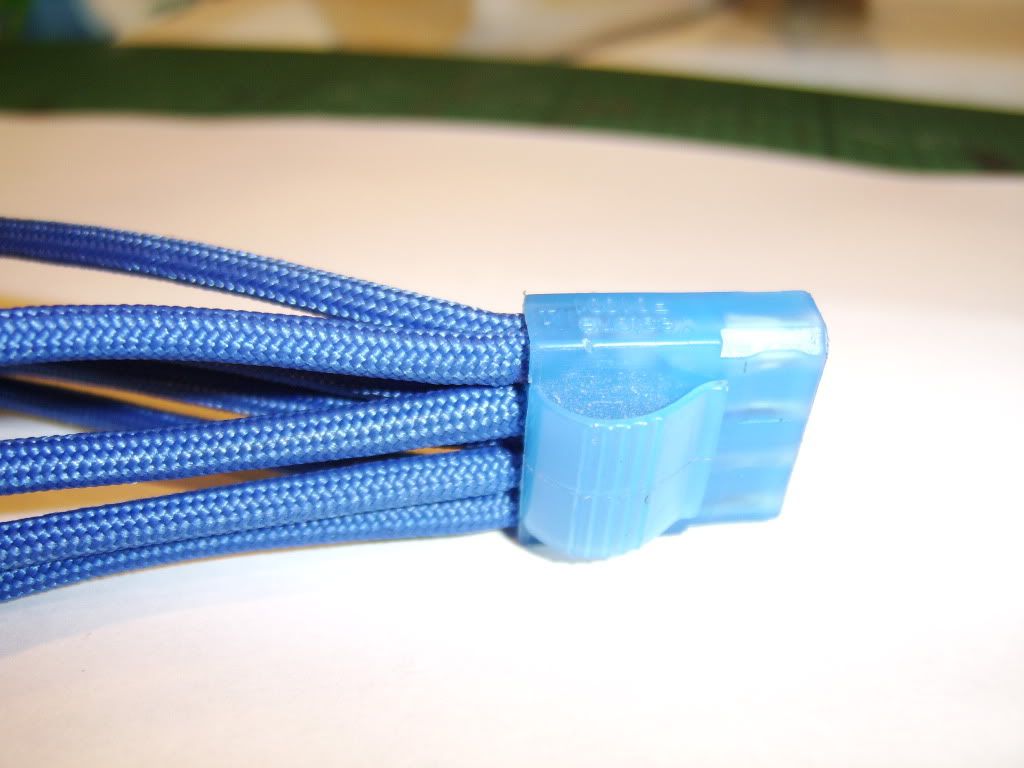

Last pin of Second of three molexs on the cable

Last pin on the Third or three

Last pin to power to power my Xonar

In she goes

Nice snug fit

least successfull part - but better that separate heatshrink

Burned the last one as really fiddlely with tiny wires and no lighter.

Should have just gone out in the rain and got a cheapo disposable one or a refill can.

Wasn't a straight forward job as I needed to thread the paracord over a floppy power pin (Xonar) as well as a molex.

As ever a safety pin was used to remove the pins from their plastic sockets.

Gold plated contacts as standard on my Jesico.

Need to do the silver wire work - but not tonight

Last pin of Second of three molexs on the cable

Last pin on the Third or three

Last pin to power to power my Xonar

In she goes

Nice snug fit

least successfull part - but better that separate heatshrink

Burned the last one as really fiddlely with tiny wires and no lighter.

Last edited:

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

Thanks biffa

My Loop's in bits again the fault that many of the early pump tops had (locking cowl unscrewing) happened to me.

the fault that many of the early pump tops had (locking cowl unscrewing) happened to me.

The new rev2 fixes the issue (and looks a lot better that the 1.1 and 1.2 fix).

In the process of moding mine so it works like the Rev2

Back on air atm - but made my own s1155 x-bracket for a NH-U12F which i might share when my little one is back at school next week.

My Loop's in bits again

the fault that many of the early pump tops had (locking cowl unscrewing) happened to me.

the fault that many of the early pump tops had (locking cowl unscrewing) happened to me.The new rev2 fixes the issue (and looks a lot better that the 1.1 and 1.2 fix).

In the process of moding mine so it works like the Rev2

Back on air atm - but made my own s1155 x-bracket for a NH-U12F which i might share when my little one is back at school next week.