haha you guys are bringing back some cool memories

I lusted after Alienwares from 2000-2008. In '09 I finally managed to order one. It cost me around £280 fully built with an E4500 and 8600 GT in. I immediately added 4gb more ram to the 2gb, stuck in a 9800GT and overclocked it to 3.2ghz. Then one day I was hovering around it and saw a lever on the right side panel. I thought "hey, I wonder what this does" so I pulled it... The side panel fell off and it took me about two hours to get it back on lmao. It wasn't even particularly full of wires but the catches are a PITA.

It remained on for about another year, with me being terrified to take it off

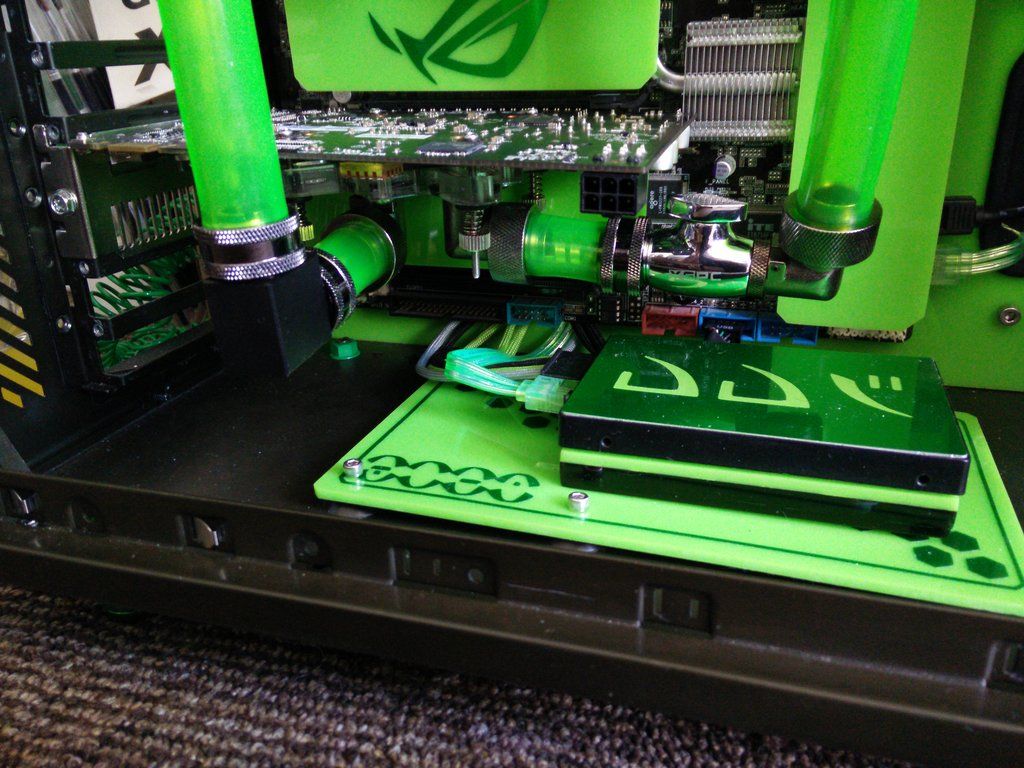

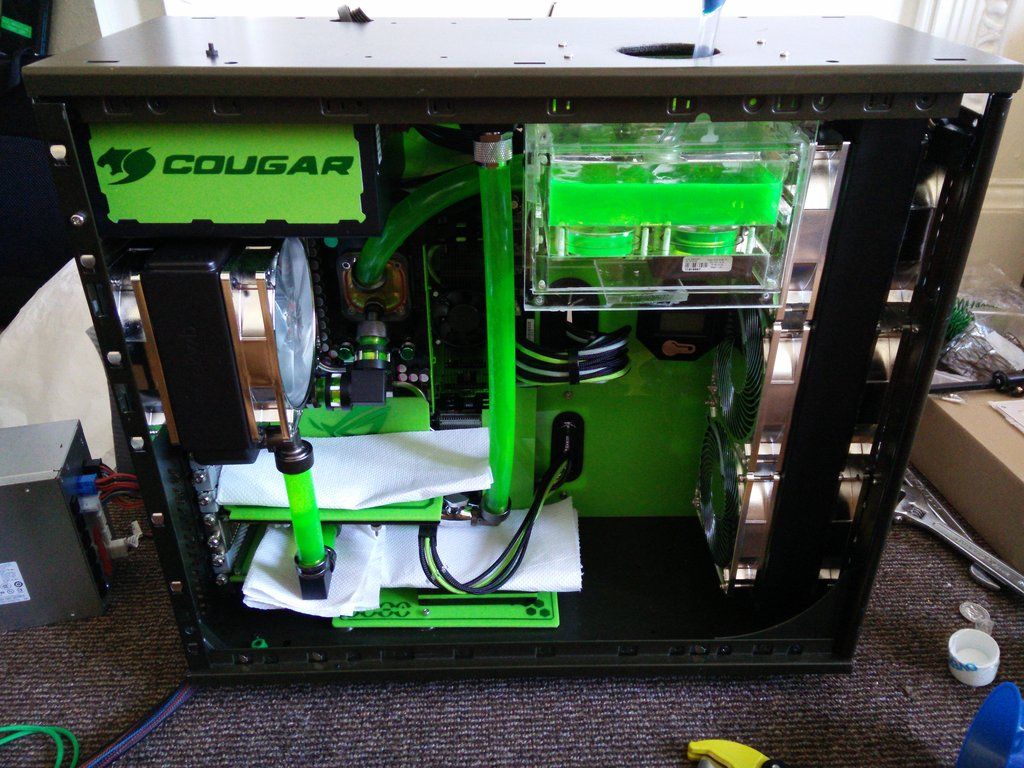

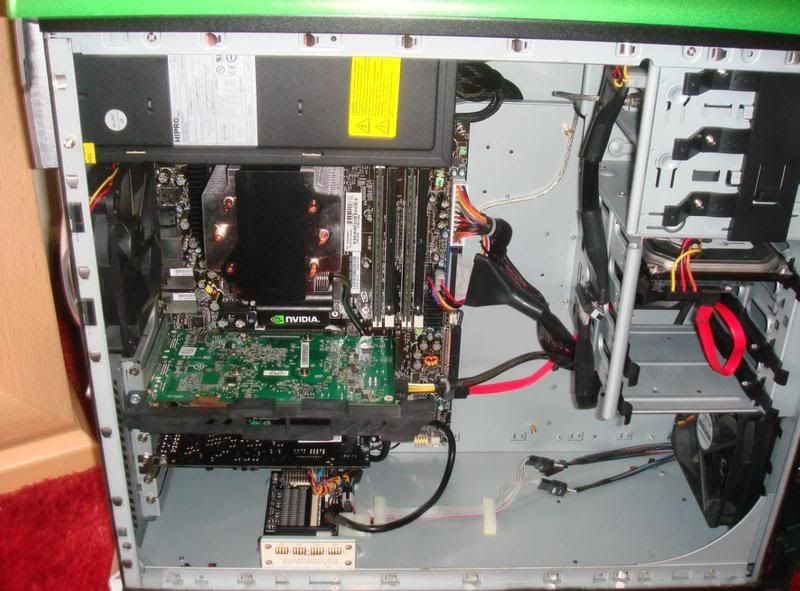

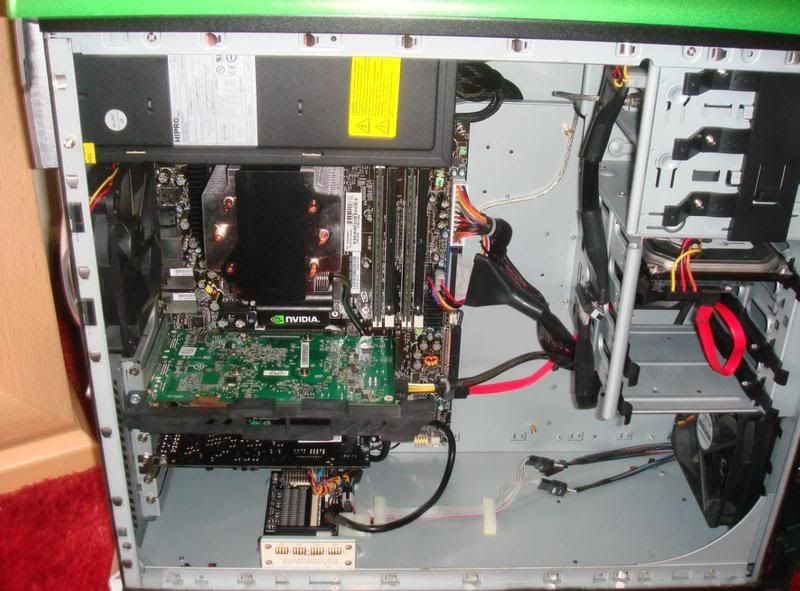

Dianoga is a tribute to the bogey, hence the green theme and candy apple green metallic stuff. Here she is the day I got her.

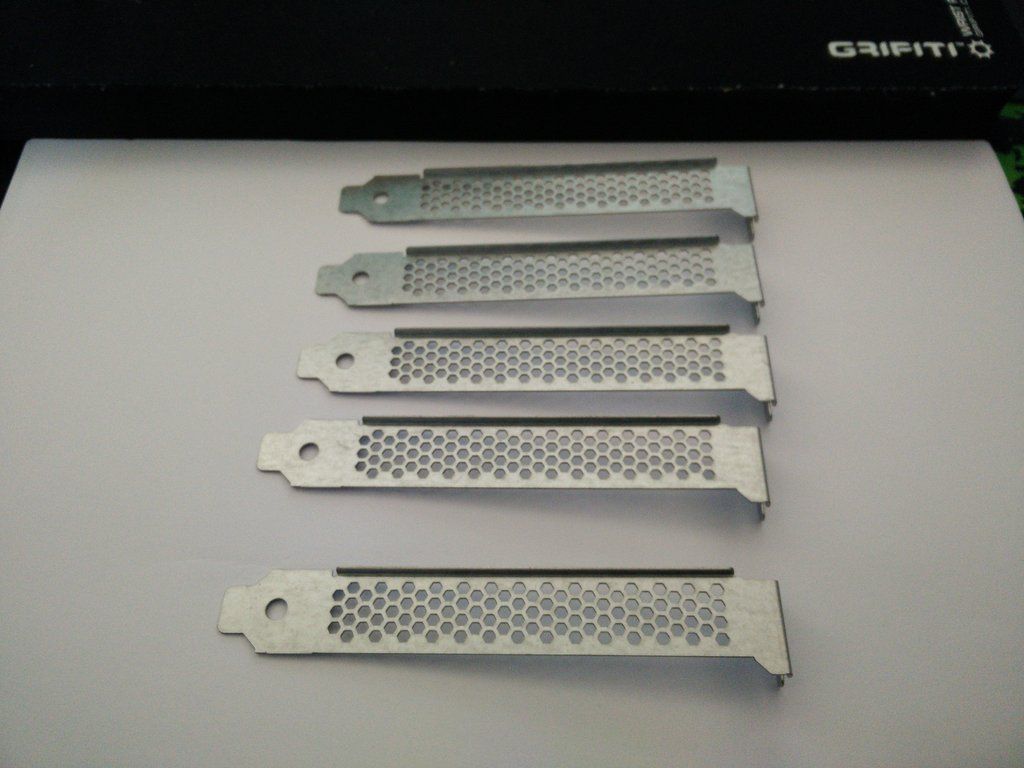

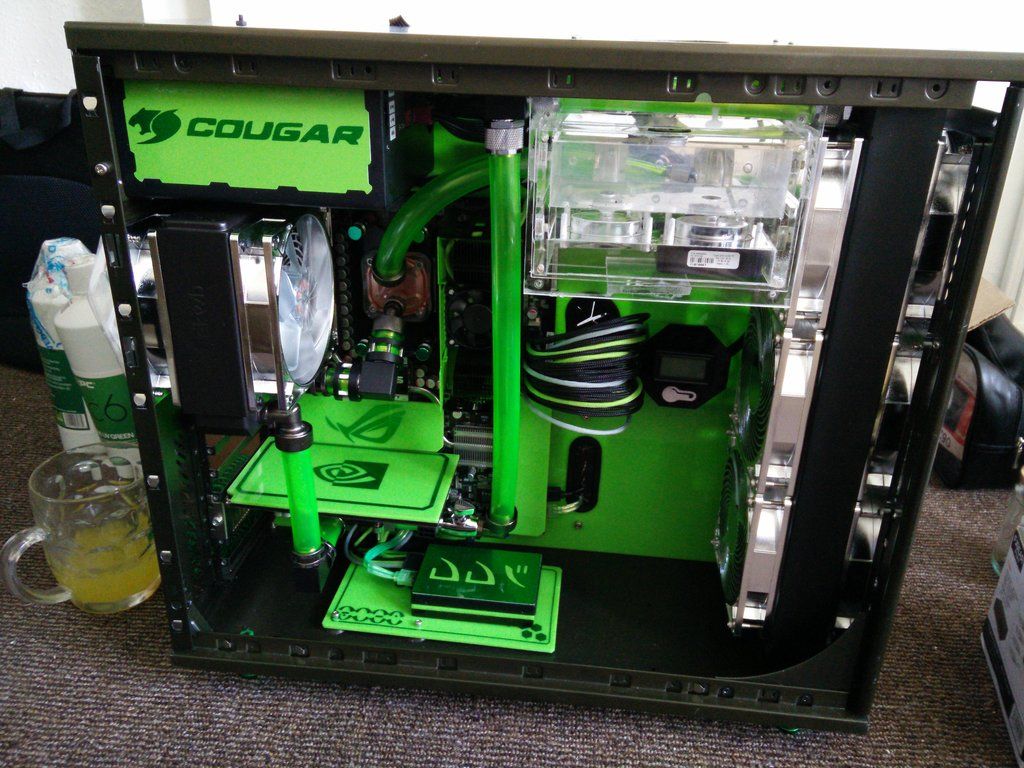

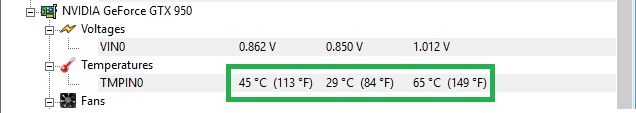

Before.

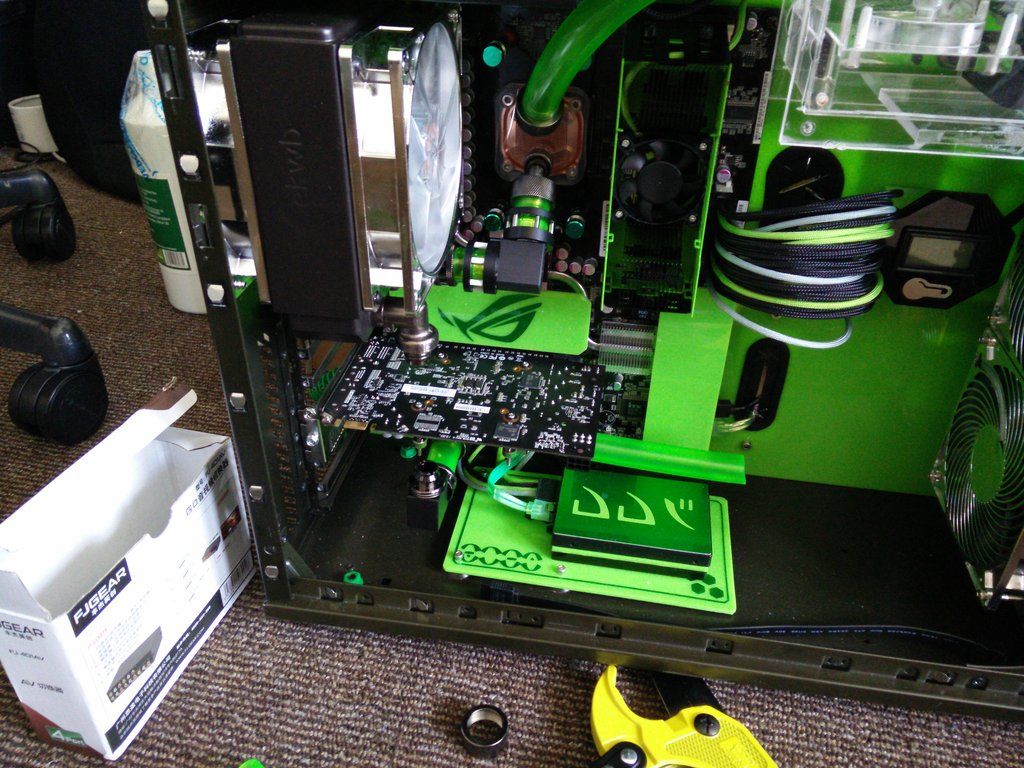

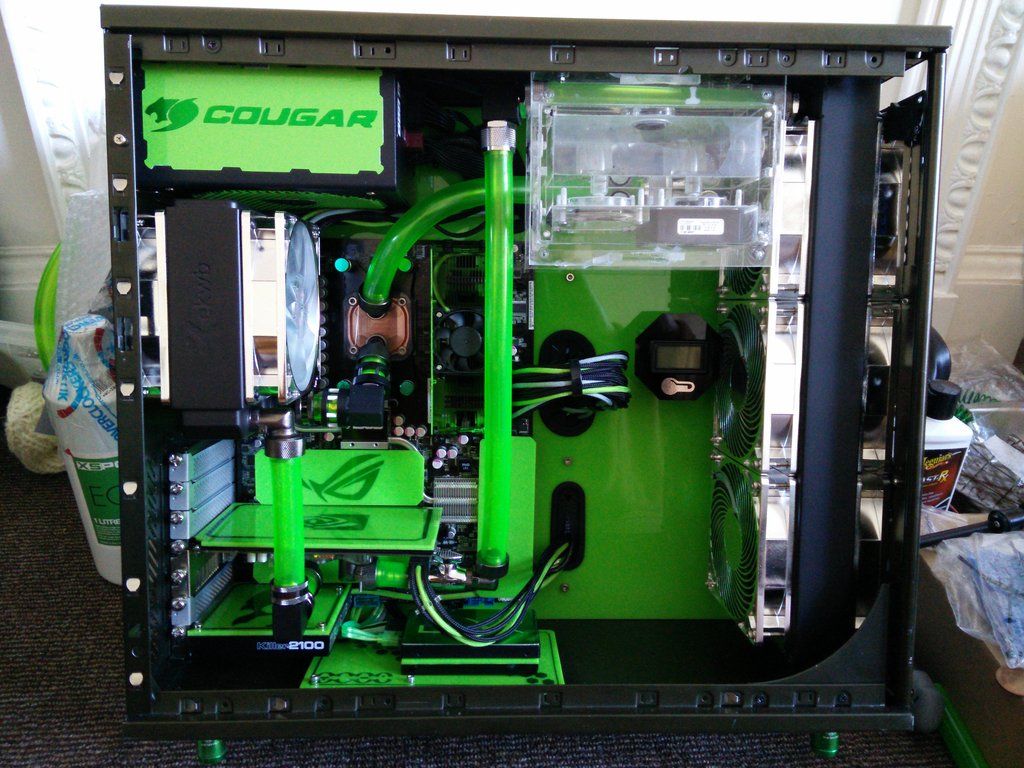

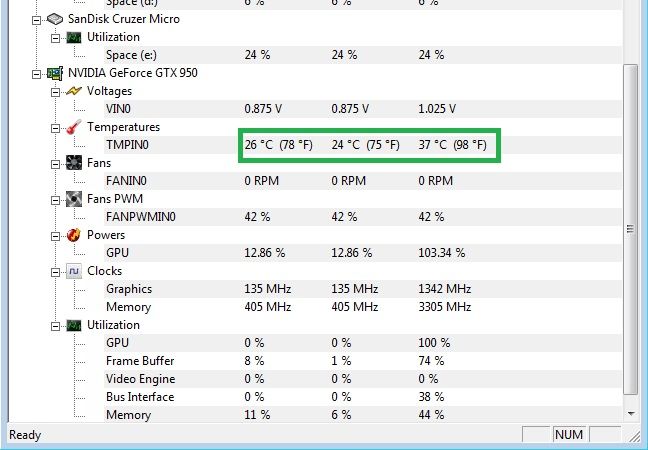

After.

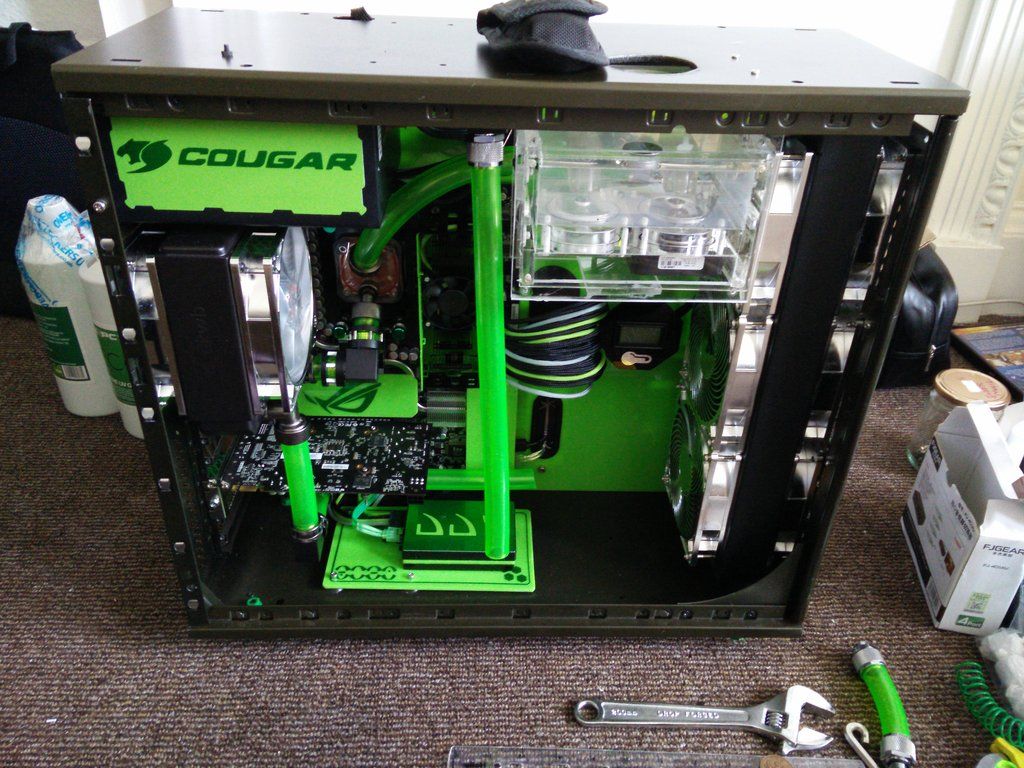

Now you can see where I get my user name from (ALXAndy). The case I am using now is the ALX version. Dark green interior, alu instead of steel, chrome instead of flat silver etc.

In a way I wish I'd have kept the green panels and put them onto the ALX shell and chrome.

I lusted after Alienwares from 2000-2008. In '09 I finally managed to order one. It cost me around £280 fully built with an E4500 and 8600 GT in. I immediately added 4gb more ram to the 2gb, stuck in a 9800GT and overclocked it to 3.2ghz. Then one day I was hovering around it and saw a lever on the right side panel. I thought "hey, I wonder what this does" so I pulled it... The side panel fell off and it took me about two hours to get it back on lmao. It wasn't even particularly full of wires but the catches are a PITA.

It remained on for about another year, with me being terrified to take it off

Dianoga is a tribute to the bogey, hence the green theme and candy apple green metallic stuff. Here she is the day I got her.

Before.

After.

Now you can see where I get my user name from (ALXAndy). The case I am using now is the ALX version. Dark green interior, alu instead of steel, chrome instead of flat silver etc.

In a way I wish I'd have kept the green panels and put them onto the ALX shell and chrome.