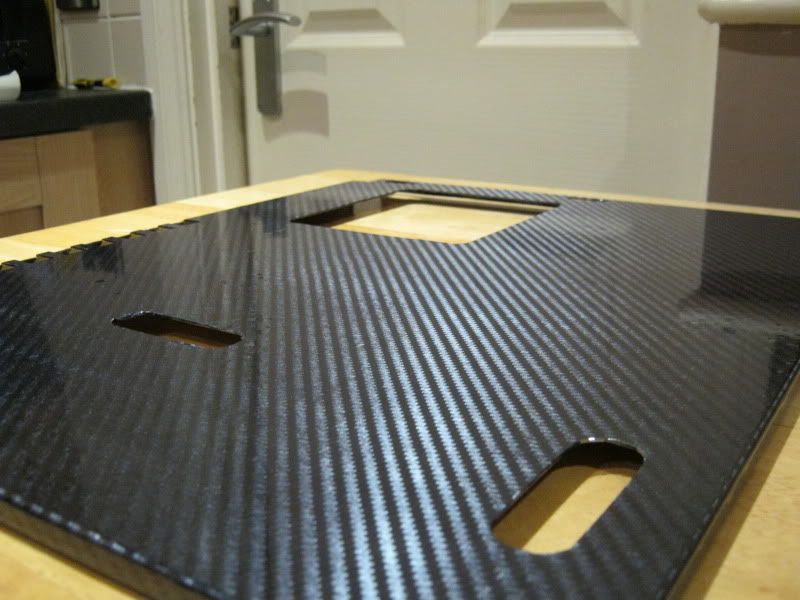

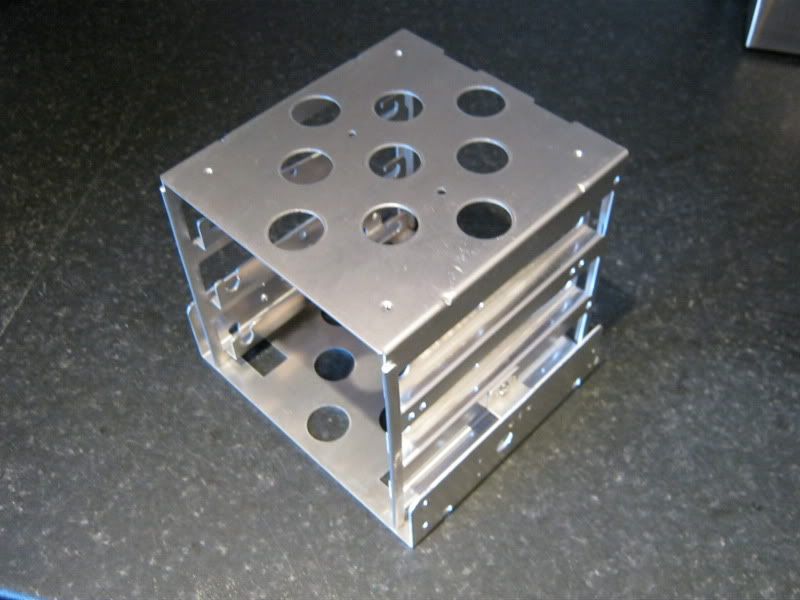

Motherboard tray:

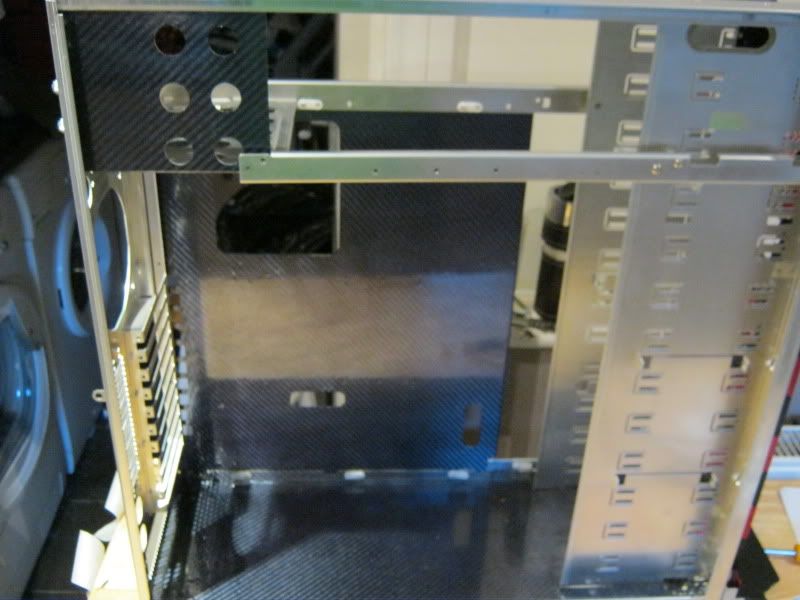

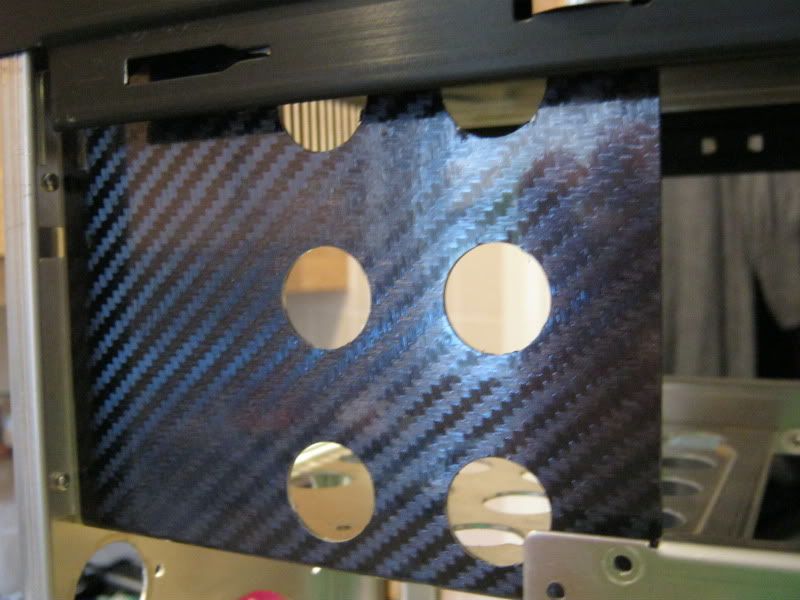

Here's how the tray looks in situ:

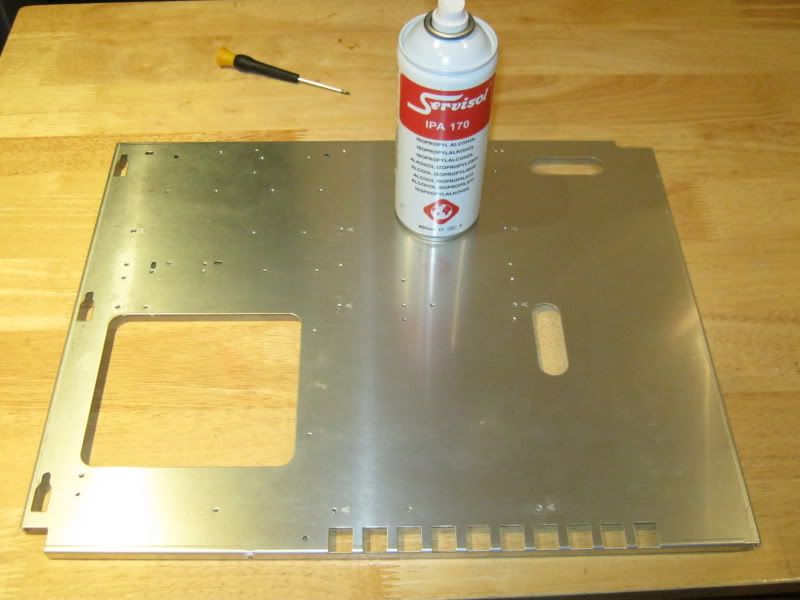

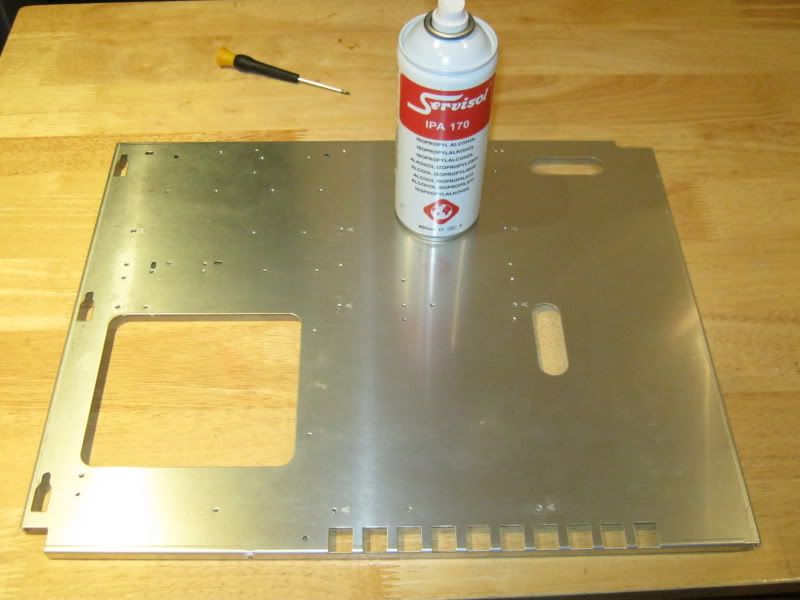

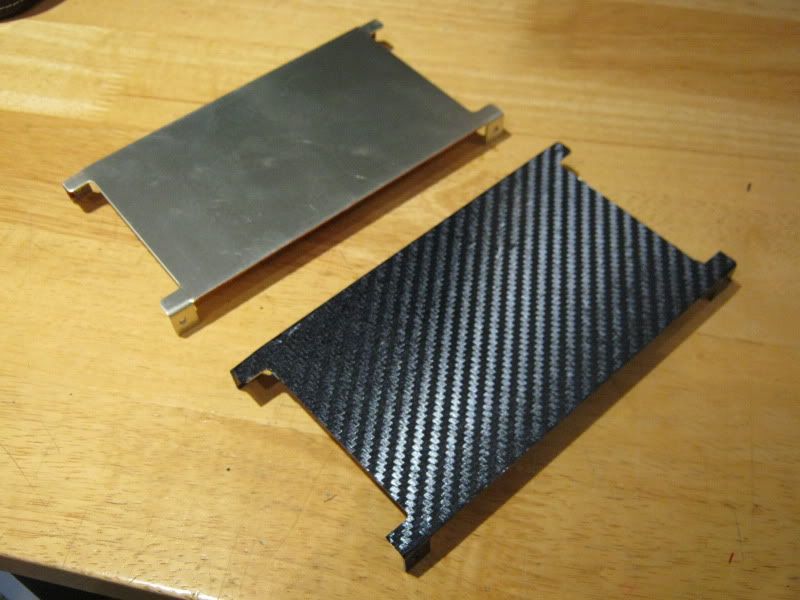

Tray removed and cleaned with IPA to remove and grease/fingerprints that may affect adhesive:

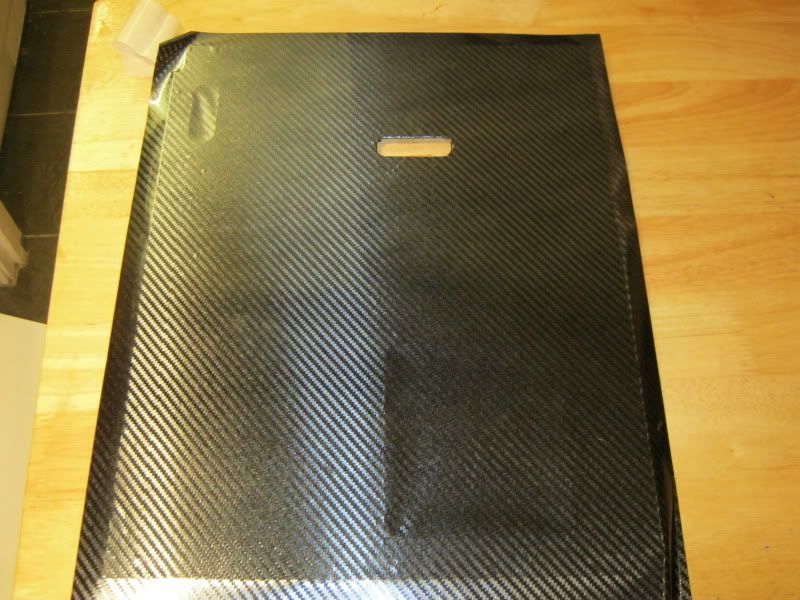

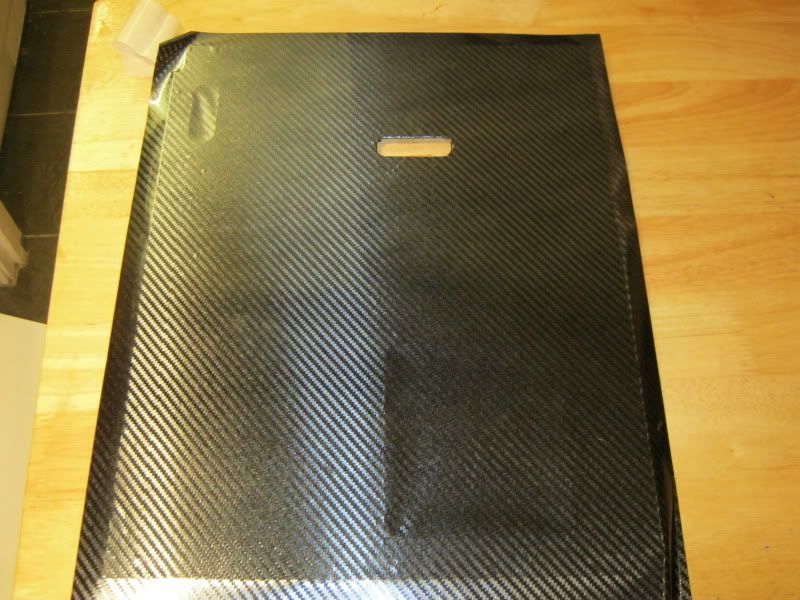

Template cutting:

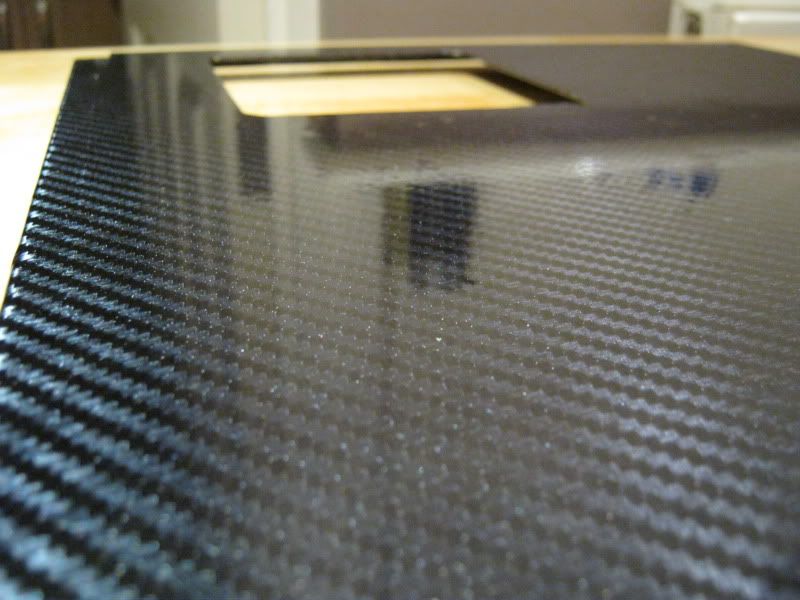

Removal of bubbles. I was gutted with initial application due to the severe bubbles that wouldn't budge, hardly noticable in the photo but it looked like woodchip wallpaper so these had to be 'popped' with a pin; very therapeutic truth be told :

:

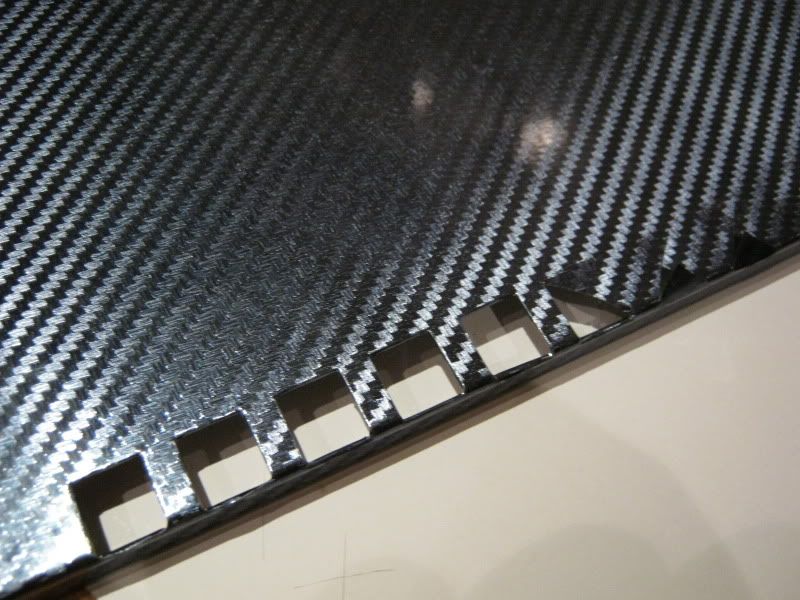

Motherboard tray mount holes: Odd shapes which made it extremely difficult to get the edges right but looks ok:

Next up: Cutting the cable holes and pci slots!

Here's how the tray looks in situ:

Tray removed and cleaned with IPA to remove and grease/fingerprints that may affect adhesive:

Template cutting:

Removal of bubbles. I was gutted with initial application due to the severe bubbles that wouldn't budge, hardly noticable in the photo but it looked like woodchip wallpaper so these had to be 'popped' with a pin; very therapeutic truth be told

:

:

Motherboard tray mount holes: Odd shapes which made it extremely difficult to get the edges right but looks ok:

Next up: Cutting the cable holes and pci slots!

:

:

.

.