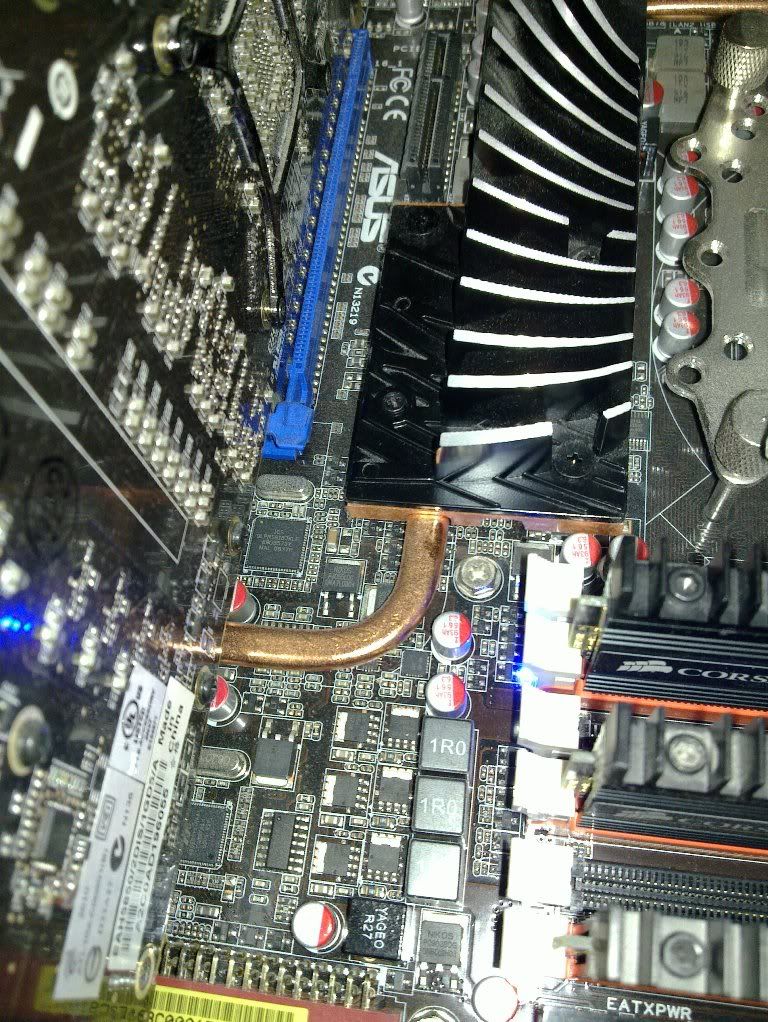

That's a shame and an unfortunate consequence of using voltage regulator driven fan controllers.

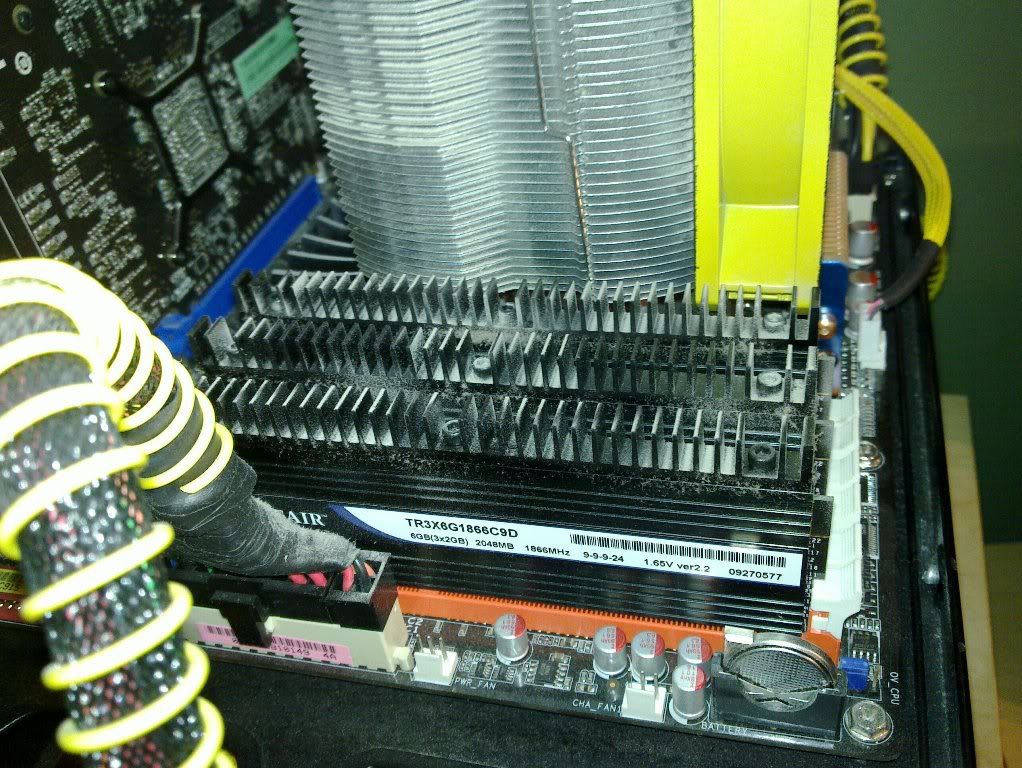

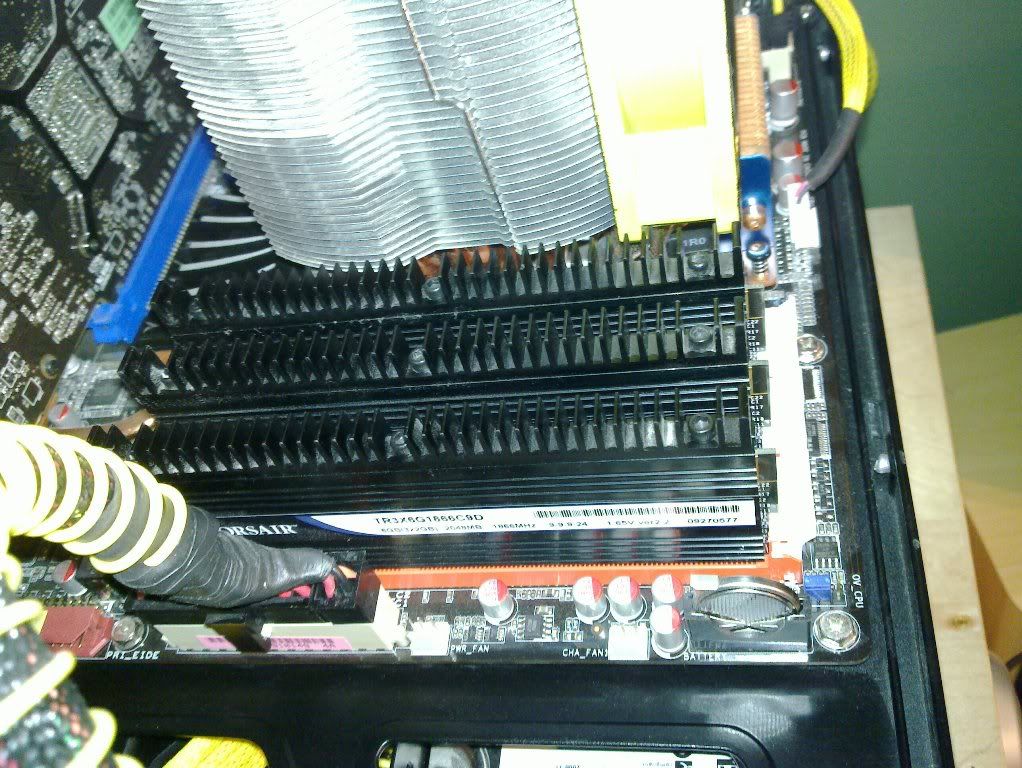

I wonder if you could modify the heatsinks already present to increase their size. You might even be able to incoroprate the case of the drive to increase the area for heat dissipation.

Just thinking out loud.

Edit: actually it may be fine as is because GTs use very little current compared with most fans. Less current drawn means less wattage to be dumped as heat.

I wonder if you could modify the heatsinks already present to increase their size. You might even be able to incoroprate the case of the drive to increase the area for heat dissipation.

Just thinking out loud.

Edit: actually it may be fine as is because GTs use very little current compared with most fans. Less current drawn means less wattage to be dumped as heat.

Last edited: