OK, got a bit cocky after the (relative) success of my first wcool (in sig) so I thought I'd try something a bit more challenging, I also fancied dual core and seeing as I had some ddr2 sat around (yes the decision really was that arbitrary) and partly the price seeing as its a plaything I went for the intel 830 dual 3ghz.

Thought I'd document this, started being a laugh but its got more and more complicated as time has gone by..

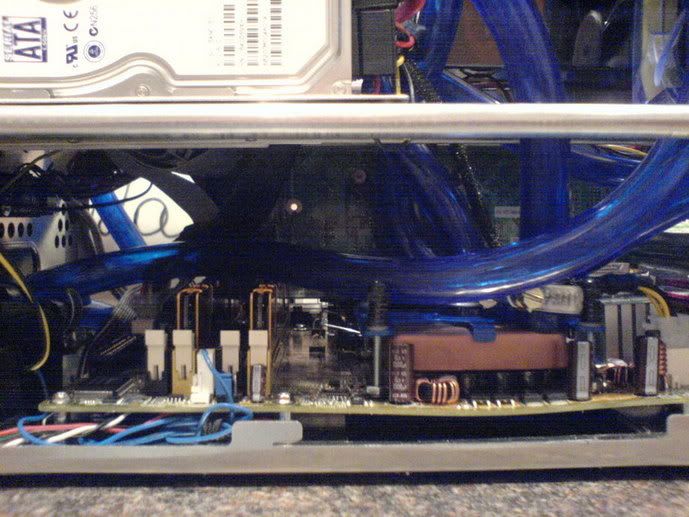

Final specs are:

P4 830 dual 3ghz

1gb crucial ballistix ddr2 5400

200gb sata hdd

xfx 6800 ultra pci-e

asus p5ld2 vm mobo

aspire xqpack case

Swiftech 6000 cpu block

swiftech 350 pump

DD maze 4 gpu block

black ice extreme 120.1

5.25 bayres

I chose the aspire because of the all acrylic sides, also because it's small (perhaps too small by the looks of things??) I also think it looks pretty funky and again, it wasn't expensive, the mobo was pretty much a choice of 1 but I have asus in my main pc and it seems pretty solid, the 6800 ultra was the first card that came up in the mm that fitted the bill, I have a 2405fpw it'll have to drive so my options for gfx are a bit limited to high end stuff.. bummer eh!

It begins..

cheers ocuk for making me daydream all day at work that aprticular day after the "there are boxes here, what have you bought now" text from my long suffering wife.

Thought I'd document this, started being a laugh but its got more and more complicated as time has gone by..

Final specs are:

P4 830 dual 3ghz

1gb crucial ballistix ddr2 5400

200gb sata hdd

xfx 6800 ultra pci-e

asus p5ld2 vm mobo

aspire xqpack case

Swiftech 6000 cpu block

swiftech 350 pump

DD maze 4 gpu block

black ice extreme 120.1

5.25 bayres

I chose the aspire because of the all acrylic sides, also because it's small (perhaps too small by the looks of things??) I also think it looks pretty funky and again, it wasn't expensive, the mobo was pretty much a choice of 1 but I have asus in my main pc and it seems pretty solid, the 6800 ultra was the first card that came up in the mm that fitted the bill, I have a 2405fpw it'll have to drive so my options for gfx are a bit limited to high end stuff.. bummer eh!

It begins..

cheers ocuk for making me daydream all day at work that aprticular day after the "there are boxes here, what have you bought now" text from my long suffering wife.

I should have realised a 120.1 wouldn't fit into a 120 sized hole) so to not have the tubes having to do too much acrobatics I wanted to point the barbs into the case, guess what?? yep, first requirement for the £10 dremel clone I got down at the local b&q!

I should have realised a 120.1 wouldn't fit into a 120 sized hole) so to not have the tubes having to do too much acrobatics I wanted to point the barbs into the case, guess what?? yep, first requirement for the £10 dremel clone I got down at the local b&q!

and I really don't want to be dreaming up solutions at 1am!

and I really don't want to be dreaming up solutions at 1am! ics..

ics..