You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project: Silent Overkill

- Thread starter Cenedd

- Start date

More options

Thread starter's postsThat'd be the snappy 'shutter' speed on my phone. I could freeze the bubbles with the flash....but wash out all the colour or just bounced off the glass. It's pink, by the way, because of the temperature of the coolant. Changes from blue to red from 20 to 50°C and it's usually somewhere in the middle because I've got the rad fans set to only spin up at 36°C and stay on until it drops below 34.

Yeah, I've not mentioned that until I'd given it enough time to be sure it was the problem. I think it has...but it's still odd. In a nutshell, I'd managed to drop a screw onto the Farbwerk when I was reassembling everything. It seems that was responsible for the occasional drop in the res level reading - to the point it set off the alarms. Everything else worked ok though....odd.

Yeah, I've not mentioned that until I'd given it enough time to be sure it was the problem. I think it has...but it's still odd. In a nutshell, I'd managed to drop a screw onto the Farbwerk when I was reassembling everything. It seems that was responsible for the occasional drop in the res level reading - to the point it set off the alarms. Everything else worked ok though....odd.

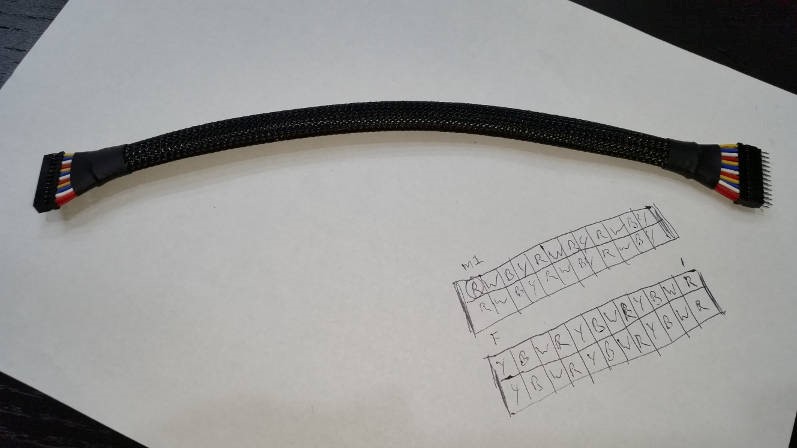

Cable done and sanity nearly intact....pretty much like it was before

So far it seems to have fixed the problem where the buttons on the screen would stop working after a while until you cold booted it. I think the pins I used this time were better and the crimper definitely was. I picked some up at the same time as a USB 3.0 20-Pin Internal Header MF Extension Cable. The pins are the same as the USB3 internal header you see.

Also, removing the screw sitting on the PCB of the Farbwerk seems to have resolved the issue with the level sensor (the new one) occasionally misreporting very low levels. The level sensor is plugged into Aquabus (4 pin to include power) on the Farbwerk so it's not quite as bizarre as it first sounds.

You can see the double-row pin header on the right hand side to make one end male.

So far it seems to have fixed the problem where the buttons on the screen would stop working after a while until you cold booted it. I think the pins I used this time were better and the crimper definitely was. I picked some up at the same time as a USB 3.0 20-Pin Internal Header MF Extension Cable. The pins are the same as the USB3 internal header you see.

Also, removing the screw sitting on the PCB of the Farbwerk seems to have resolved the issue with the level sensor (the new one) occasionally misreporting very low levels. The level sensor is plugged into Aquabus (4 pin to include power) on the Farbwerk so it's not quite as bizarre as it first sounds.

You can see the double-row pin header on the right hand side to make one end male.

But that's only 96 crimps: 24 pins at each end, two sets of wings to crimp on each pin.

I'd love to find pre-made cables like you get for Arduino's etc but they're all 2.54mm pitch which are larger wire and larger pins. Only way I've found would be to order a pair or USB3 internal extensions - 20 pins so you'd need two sets to get to 24 wires required - and then put those wires into some 2x12 shells. The extensions are available in 12cm or 30cm but at £12.30 each plus £8 shipping, plus the 2x12 shells off ebay and the male-to-male pin headers, you're getting to silly money for a cable! Much cheaper to crimp your own....if a little soul-destroying.

I'd love to find pre-made cables like you get for Arduino's etc but they're all 2.54mm pitch which are larger wire and larger pins. Only way I've found would be to order a pair or USB3 internal extensions - 20 pins so you'd need two sets to get to 24 wires required - and then put those wires into some 2x12 shells. The extensions are available in 12cm or 30cm but at £12.30 each plus £8 shipping, plus the 2x12 shells off ebay and the male-to-male pin headers, you're getting to silly money for a cable! Much cheaper to crimp your own....if a little soul-destroying.

Associate

- Joined

- 20 Sep 2009

- Posts

- 99

Very cool!

Thanks. Have to get round to sleeving the ATX wiring yet...but have got a bit distracted by the pursuit of audio that doesn't have half the channels missing (old Logitech surround system with blown centre channels). Cables finally arrived so I think we may now have appropriately overkill sound too

Associate

- Joined

- 25 Aug 2013

- Posts

- 392

I think I would have definitely gone mad by now. You have way more resolve when it comes to this sort of fine work than I do.

Thanks Frank. You're only assuming I've not gone mad....truth is I've just been doing it quietly!

At the moment I'm thinking that I may get the ATX sleeving done and call it done....and then do the conversion to integrated acrylic work as a separate project.

At the moment I'm thinking that I may get the ATX sleeving done and call it done....and then do the conversion to integrated acrylic work as a separate project.

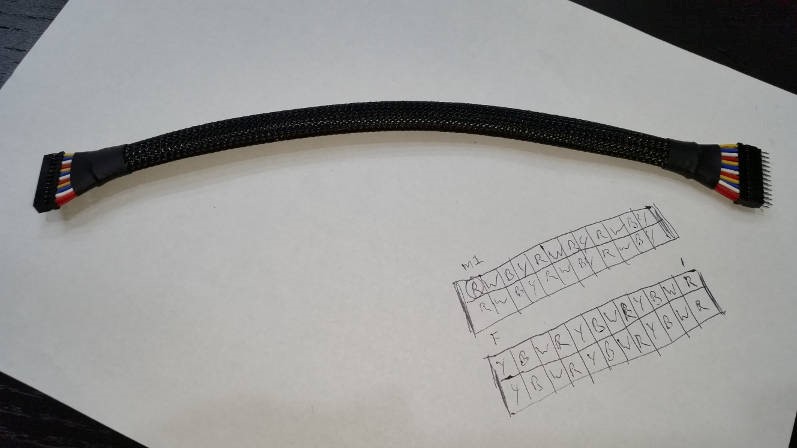

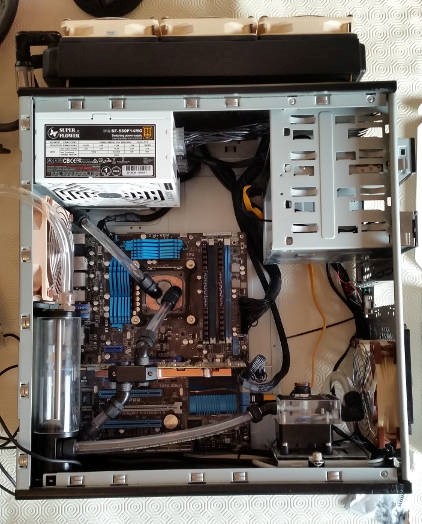

Happy new year all. Tiny update for you. Still haven't sleeved the ATX cable. Not been very well over Christmas and still haven't shaken the cough yet. That and it works without it so haven't gathered the enthusiasm yet. So what news then? Well, I've been rebuilding my wife's PC into my old watercooled case. Gives her what I thought was a graphics card upgrade*, larger SSD and it's quieter for me! Plan was that I would just rebuild with the existing parts and wouldn't need to buy anything. Well, yu can guess how well that went! Had to flip the top rad so the fittings were pointing upwards - not as neat but easier to bleed - which needed more 90s. Few more random fittings to facilitate replacing as much of the 10/8 with 13/10 as possible - front with some stiff flexible tube (could get kicked) straightened with hot water (70°C) and rear with a length of 12mm acrylic which was straight despite my best earlier aborted efforts at bending. Did a spot more cable tying and soldered the speaker back on after this shot but it gives an idea. Side panel which would be blocking the view of the table has a QDC bulkhead to connect to output of the pump, 8 Alphacool Cape Cora passive rads and then feeds the top rad via another QDC - so the panel is removable.

*Watercooled GTX 580 is better than passive cooled 720. This is true but she had three monitors and the 580 will only do two. Found a USB to VGA adaptor that was good enough for a small analogue-only screen.

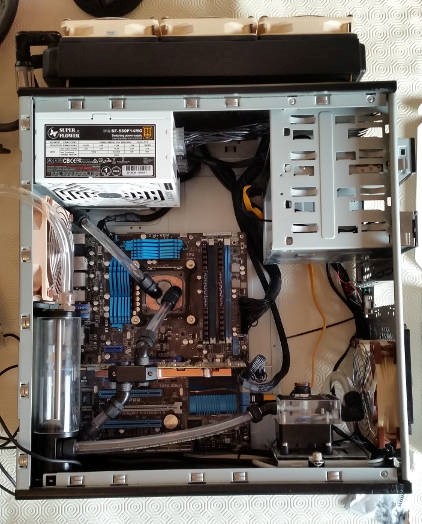

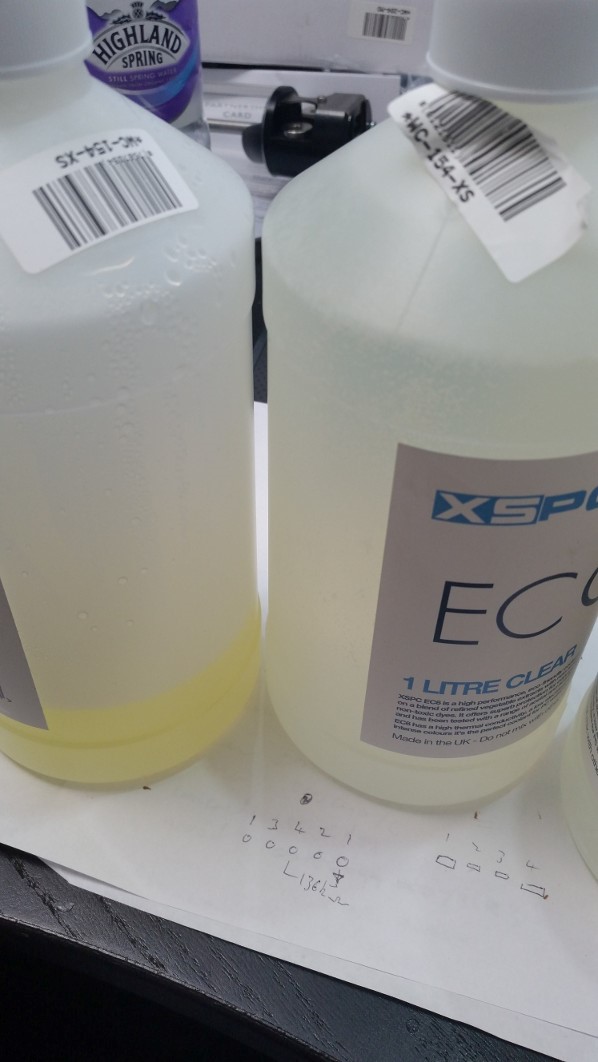

How does this affect my machine? Well I ordered two new bottles of XSPC clear EC6 coolant since the ones if over-ordered in preparation were already in use replacing those that are soaked into my carpet! The new ones were clear and the old ones were quite yellow:

Spoke to XSPC and they say this can happen if exposed to direct sunlight. Not harmful but not pretty. Neither I nor OCUK can see how this could have happened but XSPC have kindly organised some replacements through OCUK. So soon it should stop looking like someone's relieved themselves in my res!

*Watercooled GTX 580 is better than passive cooled 720. This is true but she had three monitors and the 580 will only do two. Found a USB to VGA adaptor that was good enough for a small analogue-only screen.

How does this affect my machine? Well I ordered two new bottles of XSPC clear EC6 coolant since the ones if over-ordered in preparation were already in use replacing those that are soaked into my carpet! The new ones were clear and the old ones were quite yellow:

Spoke to XSPC and they say this can happen if exposed to direct sunlight. Not harmful but not pretty. Neither I nor OCUK can see how this could have happened but XSPC have kindly organised some replacements through OCUK. So soon it should stop looking like someone's relieved themselves in my res!

Looks like you managed to turn a relatively simple job into a complete rebuild. Top work mate

Haha looking good though, certainly not the simplest case to watercool that's for sure with the PSU and drive bays right where you'd usually mount the radiator & reservoir. You really must be a sucker for punishment with the jobs you take on! Hope the reward was something shiny to go inside Silent Overkill

That's an interesting one with the coolant, never realised sunlight could do that to it. Still, if it is that sensitive to sunlight maybe XSPC should think about using a non-transparent plastic for the bottle...

Haha looking good though, certainly not the simplest case to watercool that's for sure with the PSU and drive bays right where you'd usually mount the radiator & reservoir. You really must be a sucker for punishment with the jobs you take on! Hope the reward was something shiny to go inside Silent Overkill

That's an interesting one with the coolant, never realised sunlight could do that to it. Still, if it is that sensitive to sunlight maybe XSPC should think about using a non-transparent plastic for the bottle...

Looks like you managed to turn a relatively simple job into a complete rebuild. Top work mate

I can complicate - nay, over-complicate anything! T'is my special ability!....well, that and procrastination

Haha looking good though, certainly not the simplest case to watercool that's for sure with the PSU and drive bays right where you'd usually mount the radiator & reservoir.

Yeah, awkward but

You really must be a sucker for punishment with the jobs you take on! Hope the reward was something shiny to go inside Silent Overkill

Yeah, you'd think. No, the only reward will be the avoidance of "Why has my PC stopped working? Why does it hate me?!" when the 120GB SSD filled its last gig. Only issue is the occasional "I can't find <app>!?" as I did a clean install onto a 240GB PCI-E SSD - I do spoil her

Seemed like the easy option given that her docs, desktop etc will just be handled by folder redirection.

Seemed like the easy option given that her docs, desktop etc will just be handled by folder redirection.That's an interesting one with the coolant, never realised sunlight could do that to it. Still, if it is that sensitive to sunlight maybe XSPC should think about using a non-transparent plastic for the bottle...

A good solution to the problem if we can demonstrate that it is the cause. Given that OCUK say their stock room is no tanning salon, it was boxed for transit and that I had it stored (sealed) in a closed black cupboard, I can't help but think maybe something else caused it. I was half convinced the new bottles had got yellower overnight...but I think that was just different light and a nats of paranoia

That does sound more than a little dodgy if the liquid has been stored in the dark and still turned yellow. You'd think after all the years people have been watercooling someone would have made a decent coolant by now, but judging by all the issues people are still having with colour disappearing, blocks clocking with gunk etc it looks like distilled water is still the 'safe' option...

Do you never get tempted to just give up and order a more sensible case? Not sure where you got your patience from but wish you could send me some!

That's one of the main problems I face when fixing PC's for others: "Why's it so slow? It never used to be" "No mate, it didn't. But when it was new it didn't have 498GB of the 500GB HDD filled with 'start on boot' junk programs..." "BUT THERE'S STILL SPACE, WHY IS IT SLOW?!" *Face, meet desk*

Best one yet mind was when a mate couldn't understand why Firefox took an age to open. Turned out every time he wanted to look at a new website he opened a new tab, all without ever closing one... Moral of the story? Stick to building your own PC mate, it's far less stressful and far more rewarding!

Do you never get tempted to just give up and order a more sensible case? Not sure where you got your patience from but wish you could send me some!

That's one of the main problems I face when fixing PC's for others: "Why's it so slow? It never used to be" "No mate, it didn't. But when it was new it didn't have 498GB of the 500GB HDD filled with 'start on boot' junk programs..." "BUT THERE'S STILL SPACE, WHY IS IT SLOW?!" *Face, meet desk*

Best one yet mind was when a mate couldn't understand why Firefox took an age to open. Turned out every time he wanted to look at a new website he opened a new tab, all without ever closing one... Moral of the story? Stick to building your own PC mate, it's far less stressful and far more rewarding!

Associate

- Joined

- 23 Sep 2009

- Posts

- 782

- Location

- London

That's an interesting one with the coolant, never realised sunlight could do that to it. Still, if it is that sensitive to sunlight maybe XSPC should think about using a non-transparent plastic for the bottle...

The coolant probably reacted with the plastic when heat and sunlight are added into the mix! Similar to plasticizer in some tubing.

A certain youtube watercooling enthusiast also reported this issue but with Mayhem's, I recall it was reacting with the tubing, so if it was stored in the dark, it might have reacted with the bottle. Bad batch, contaminated fluid, bad plastic in the bottle, who knows!

Last edited:

Do you never get tempted to just give up and order a more sensible case? Not sure where you got your patience from but wish you could send me some!

That's one of the main problems I face when fixing PC's for others: "Why's it so slow? It never used to be" "No mate, it didn't. But when it was new it didn't have 498GB of the 500GB HDD filled with 'start on boot' junk programs..." "BUT THERE'S STILL SPACE, WHY IS IT SLOW?!" *Face, meet desk*

Well, yes...that's why I rebuilt mine in an Evolv ATX. Nice and clean, no drive bays needed to be Dremeled out, PSU at the bottom where it should be (never liked the heavy bit at the top, makes it less stable). Only issue with the case is airflow to internal rads...but that wasn't going to be an issue for me

Patience is variable and is often insufficient to complete what started off looking like a small, easy job!

Turned down a paid custom-build recently for just that reason. They wanted to build a "super-computer" for gaming....with a budget of a whole £1000 (max). I could just see disappointment in the spec and ongoing support issues. Sent them to OCUK....you're welcome...and, sorry guys

At least OCUKs support burden would be limited to the hardware rather than anything from "I don't know how to use a mouse..."

At least OCUKs support burden would be limited to the hardware rather than anything from "I don't know how to use a mouse..."Harpss1ngh: I think in the Mayhems case it was specifically their XT1 concentrate and not the similarly named pre-mixed X1. The XT1 has glycol (either ethylene or propylene, I forget) and that isn't tolerated well by the PVC in some tubing. The EC6 doesn't declare glycols in its Material Safety DataSheet (MSDS) so as far as I'm aware, this shouldn't be the problem. Could be a different reaction though. The bottles were sealed so it shouldn't be anything atmospheric affecting them. Temperature was consistent (office is on a thermostat 24x7 - cheaper to keep it at temp rather than heating it up from cold every morning), so assuming the bottle isn't gas-permeable, logically it can only be either light, reaction with the bottle's plastic or some form of degradation within itself. Will chuck the new stuff in when it turns up and see what happens. Glad I fitted a drain now! Will post pics of the res before and after for comparison once OCUK receive the stock to ship out.

if it is that sensitive to sunlight maybe XSPC should think about using a non-transparent plastic for the bottle...

The OJ doth work in mysterious ways! For lo, no sooner had he said it than it was done!

New bottles turned up and instead of a semi-transparent clear plastic, they're an opaque white plastic. Presumably UV-proof (or whatever it is in the sunlight that discolours it) and possibly a different plastic. Both old and new are HDPE so doesn't look like they've changed the plastic, just the colour.

Drain time tomorrow - work permitting. Also, my office seems to be being watercooled* so that may disrupt things.

*Mono-pitch flat roof with skylights. One used to leak but was repaired...unless it rains heavily it appears. Had some drops hit the top of the empty alu case...but can't find any wet patch on the ceiling