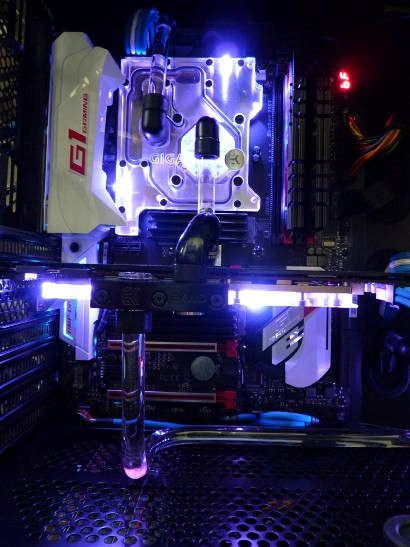

Ok, some sleeving has been done at last.

A shiny new USB cable for the Aquaero to the motherboard. Gets rid of the mile and a half of slack but does lose the shielding on the USB cable. So far no problem but it is only about twenty odd centimetres long.

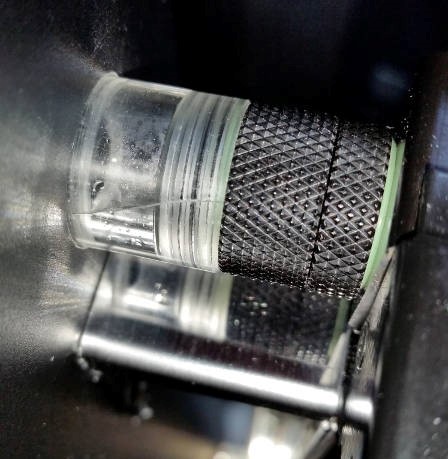

Shortened and sleeved the cables on the front case fans. I did think about buying some overly expensive fans to replace these (I quite like the look of the new Corsair ML140's) but to be honest, these aren't that bad and I've got three of them sitting in my pile-o'-fans

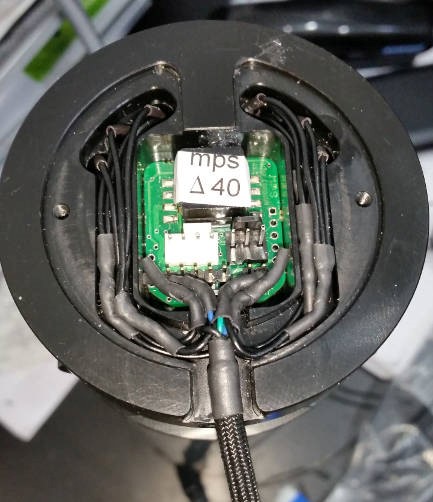

And lastly (for the moment) a three-way fan splitter. Currently I only need two so the third is just blanked off. I'm still debating putting a rear fan in for exhaust but I don't think I really need it; it's only the SSDs, the pumps and the memory that are really dumping any heat inside the case and I can feel some air coming out the back of the case with the front fans on low.

A shiny new USB cable for the Aquaero to the motherboard. Gets rid of the mile and a half of slack but does lose the shielding on the USB cable. So far no problem but it is only about twenty odd centimetres long.

Shortened and sleeved the cables on the front case fans. I did think about buying some overly expensive fans to replace these (I quite like the look of the new Corsair ML140's) but to be honest, these aren't that bad and I've got three of them sitting in my pile-o'-fans

And lastly (for the moment) a three-way fan splitter. Currently I only need two so the third is just blanked off. I'm still debating putting a rear fan in for exhaust but I don't think I really need it; it's only the SSDs, the pumps and the memory that are really dumping any heat inside the case and I can feel some air coming out the back of the case with the front fans on low.

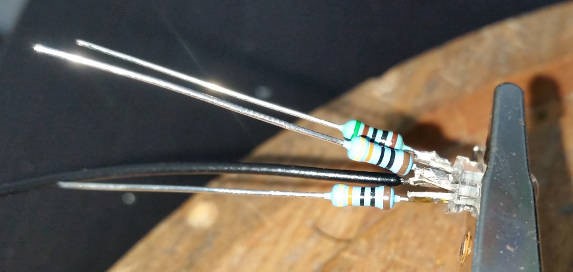

no damage it seems, just trying to scare me. Couple of 4.8mm holes for the 5mm LEDs but in different places to the existing 3mm holes as it seemed to light it up better.

no damage it seems, just trying to scare me. Couple of 4.8mm holes for the 5mm LEDs but in different places to the existing 3mm holes as it seemed to light it up better.