Mayhems Aurora? Yeah, it's a 'show coolant' and not to be used long term 'cos the particles in it can do nasty things to the impellor in your pump. Looks pretty though. Did you see JR23's Oil Black with silver Aurora in? End of this post:

http://forums.overclockers.co.uk/showpost.php?p=30075837&postcount=15

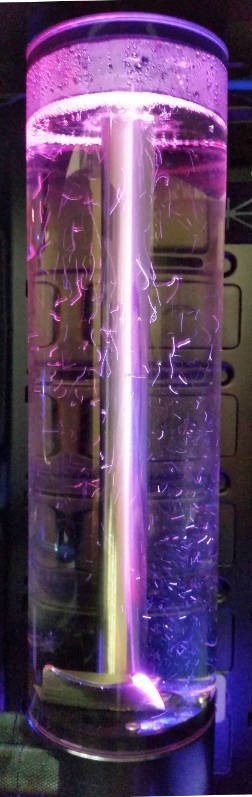

Well, res is back in. Giving the fountain effect a try. Not really going to know the outcome until the sidewall bubbles have had a chance to dissipate. Certainly at full pump speed with the ports off to fill, it sounds like an aquarium!

The pump speed now seems to need balancing so that below 200 l/h the water doesn't hit the surface hard enough to trap any bubbles. Above about 220 l/h the bubbles get dragged into the pump. Currently got it around 210 so will see what happens.

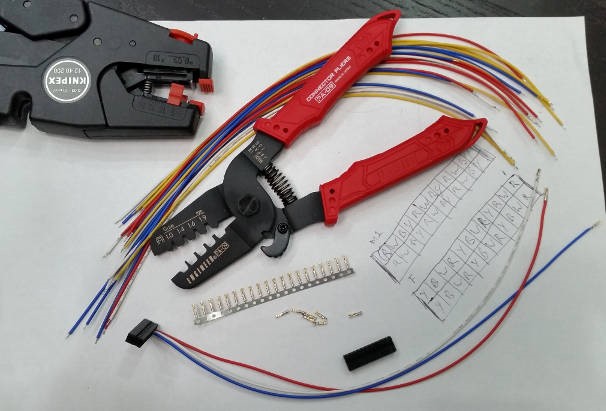

Thoroughly tested the replacement MPS fill-level sensor and it properly read changing levels up and down as I filled the res. Accurate to the top after calibrating it near the bottom too. Plugged the old module into a spare cable with no res attached and it's reading a raw pressure of about 800 whereas the working one was reading something like 300-400 for a full res. That would be why it was saying the res was 100% full when it was 100% all over the carpet then!

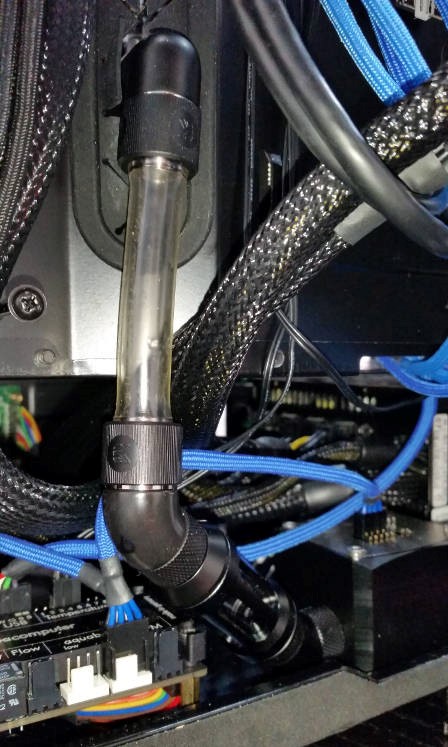

Couple of bad pics for you while I had stuff in bits. Will take pics of the updated res with dynamic bubbles once the static bubbles have gone - as is, it just looks the same as the last pic.

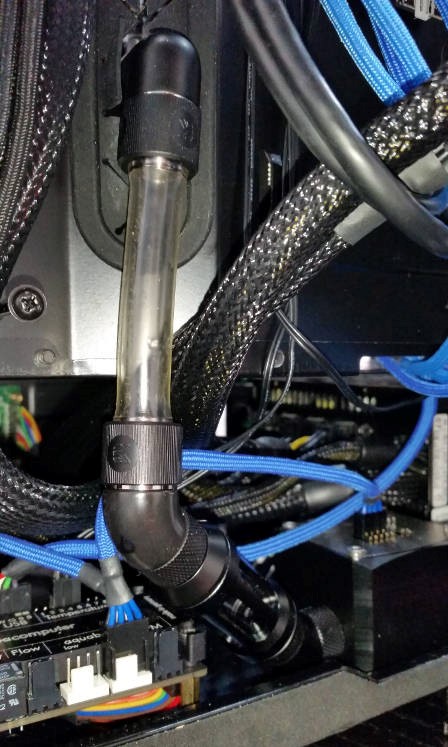

Flow meter to filter to res return via the new 60° fitting.

Same thing but with the wiring back in place. Tidy

They look very much like a Barrow fitting; diamond knurling on the rotary and matt black with no logo on the top. Will see if it's any good when it gets here.

They look very much like a Barrow fitting; diamond knurling on the rotary and matt black with no logo on the top. Will see if it's any good when it gets here.

It could be that there was a mechanical strain that caused this but it didn't show if that's the case.

It could be that there was a mechanical strain that caused this but it didn't show if that's the case.