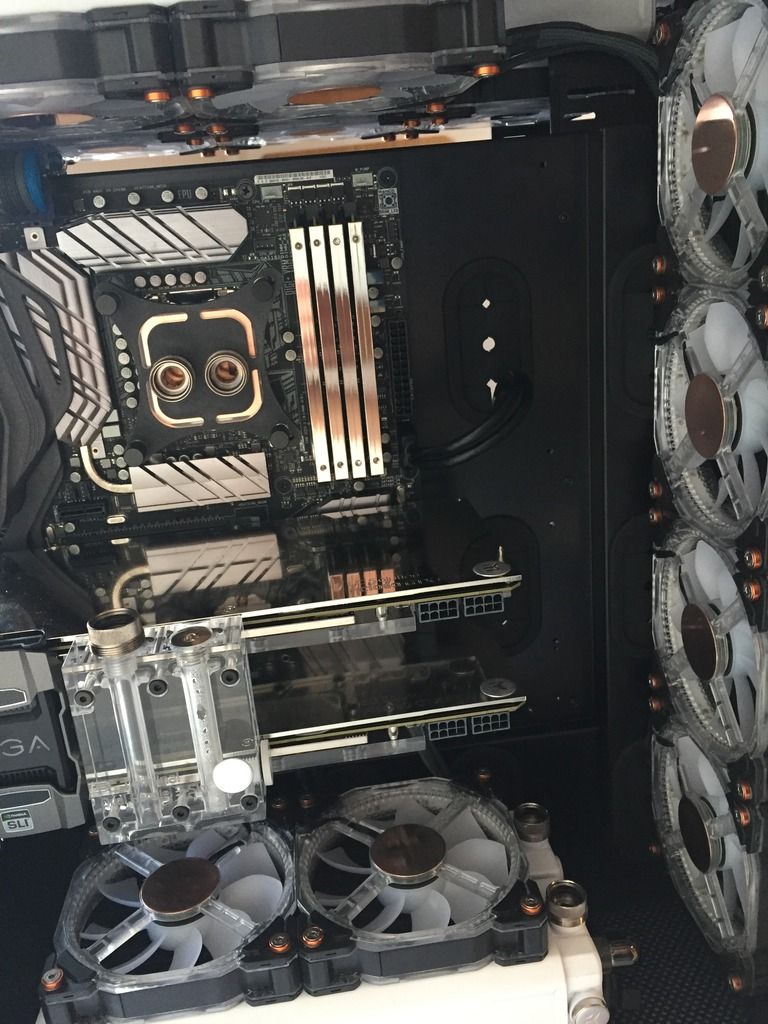

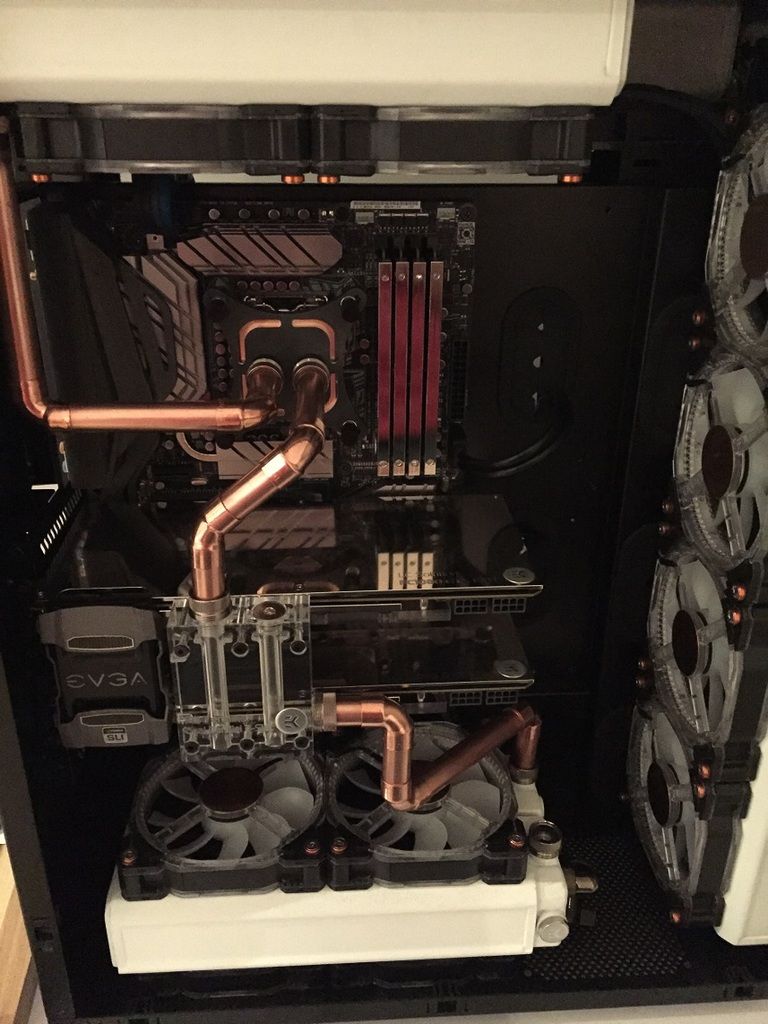

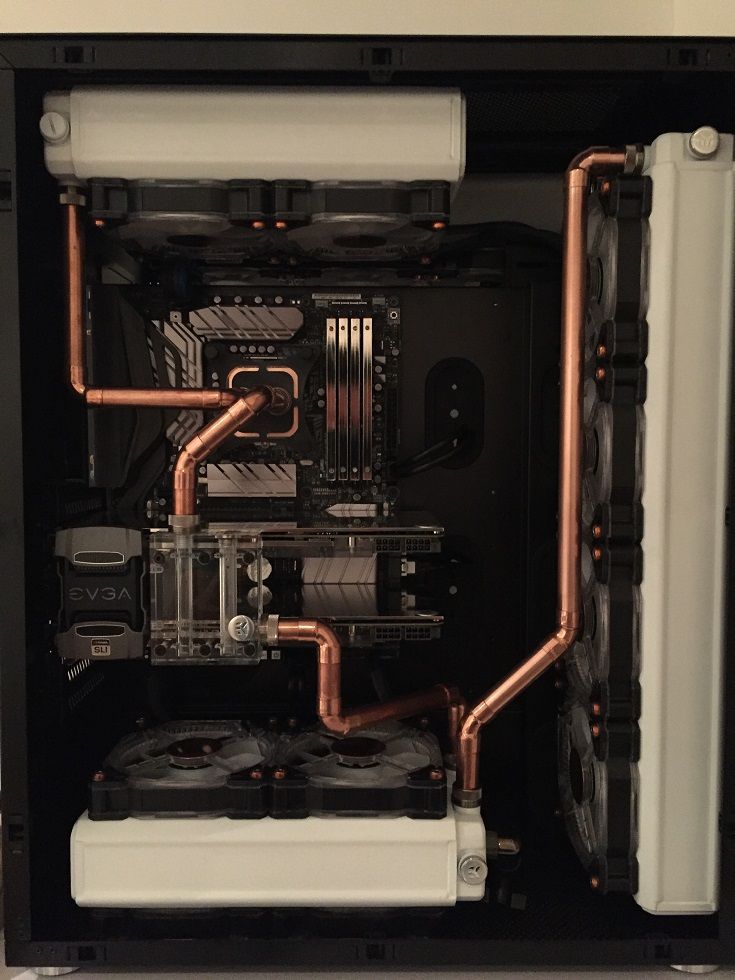

Looks great, well done

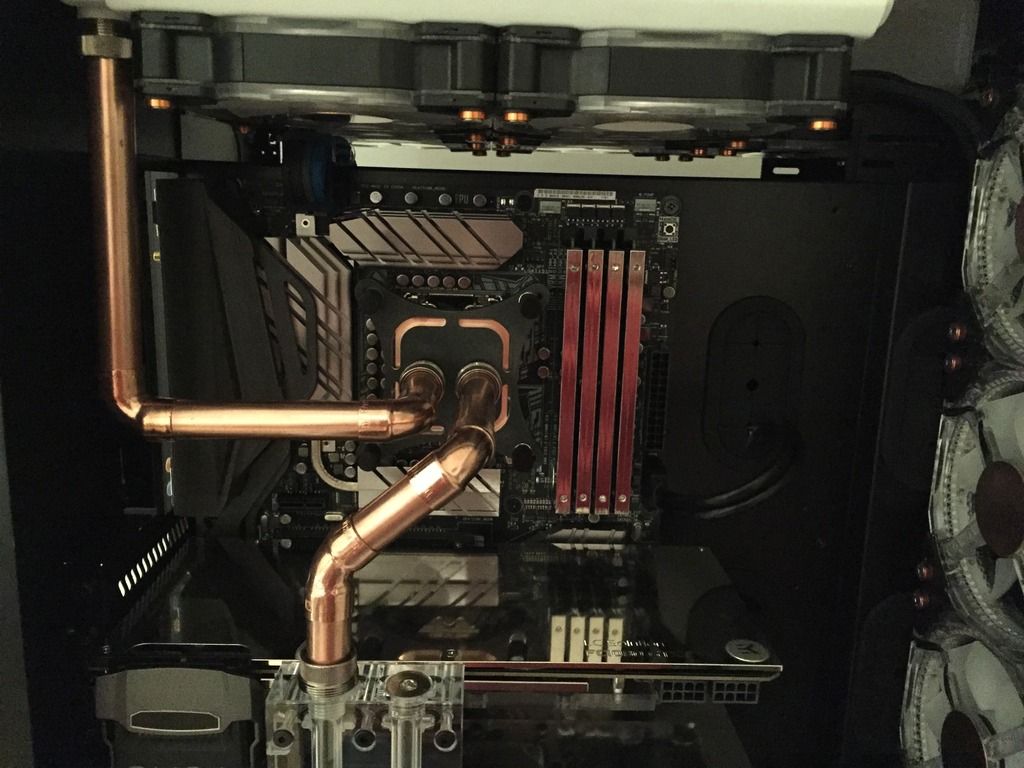

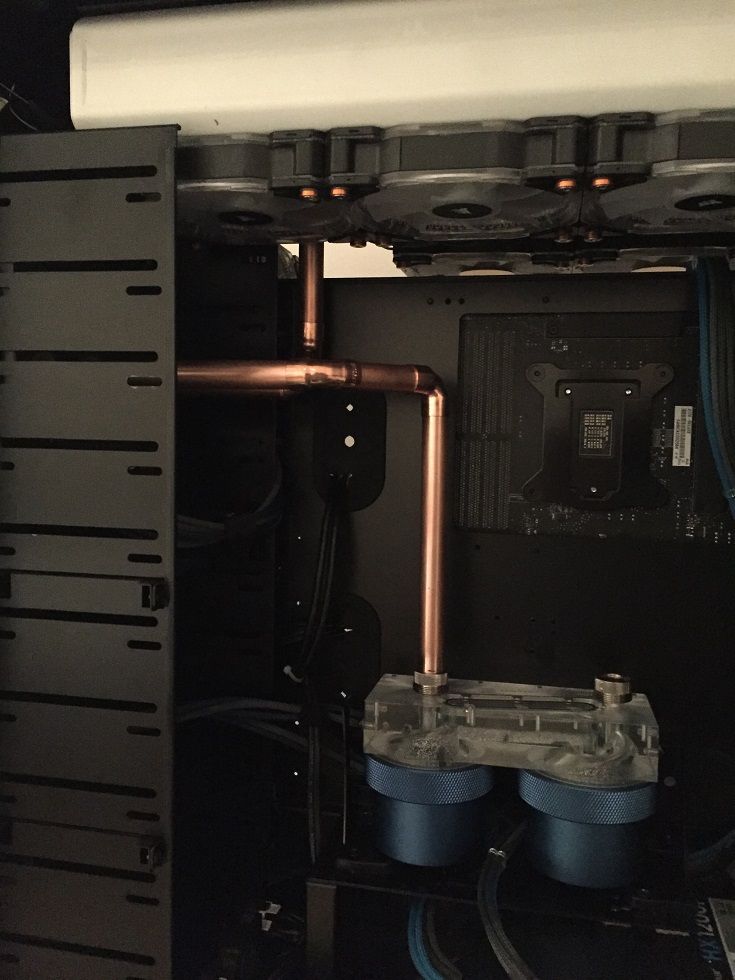

Why thank you, although there still seems to always be more to do! Most nervous about the copper tube i'm about to get started on

Looks great, well done

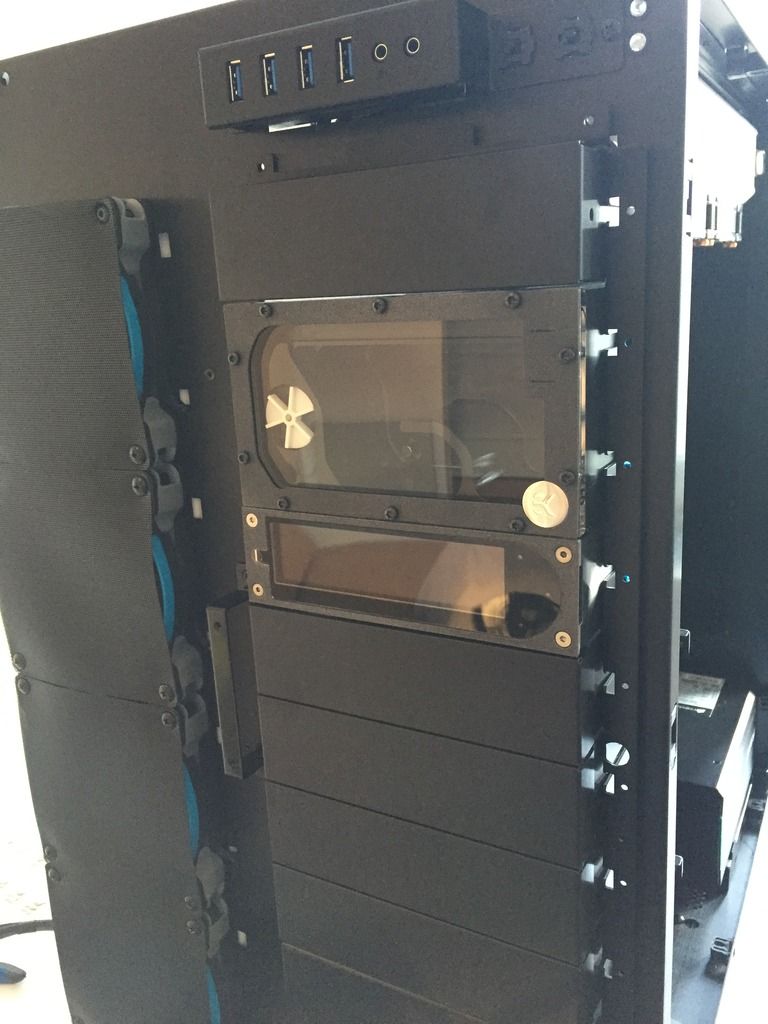

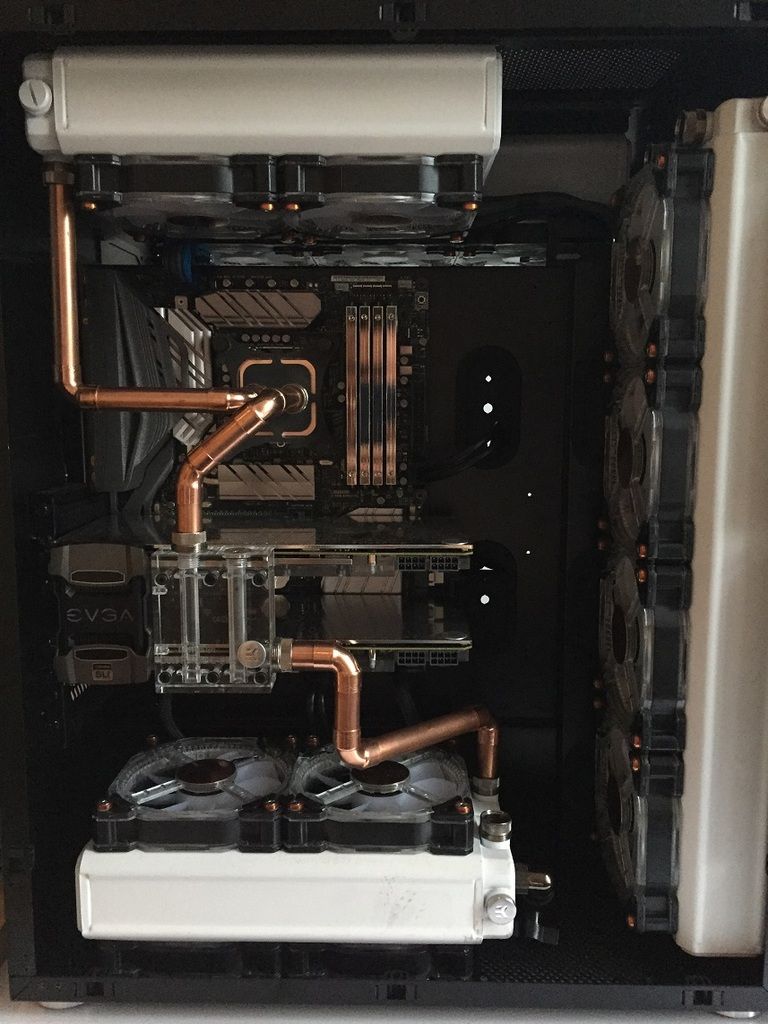

All that building and rebuilding has paid off, looking slick mate! Only shame is those pumps being hidden away on the PSU side, might have to go all redneck again and build Lian Li D80000

Good luck....and if we see you with one arm more developed than the other, we'll know it's from polishing your pipe

That looks great! Loved the blue touch to it at the start

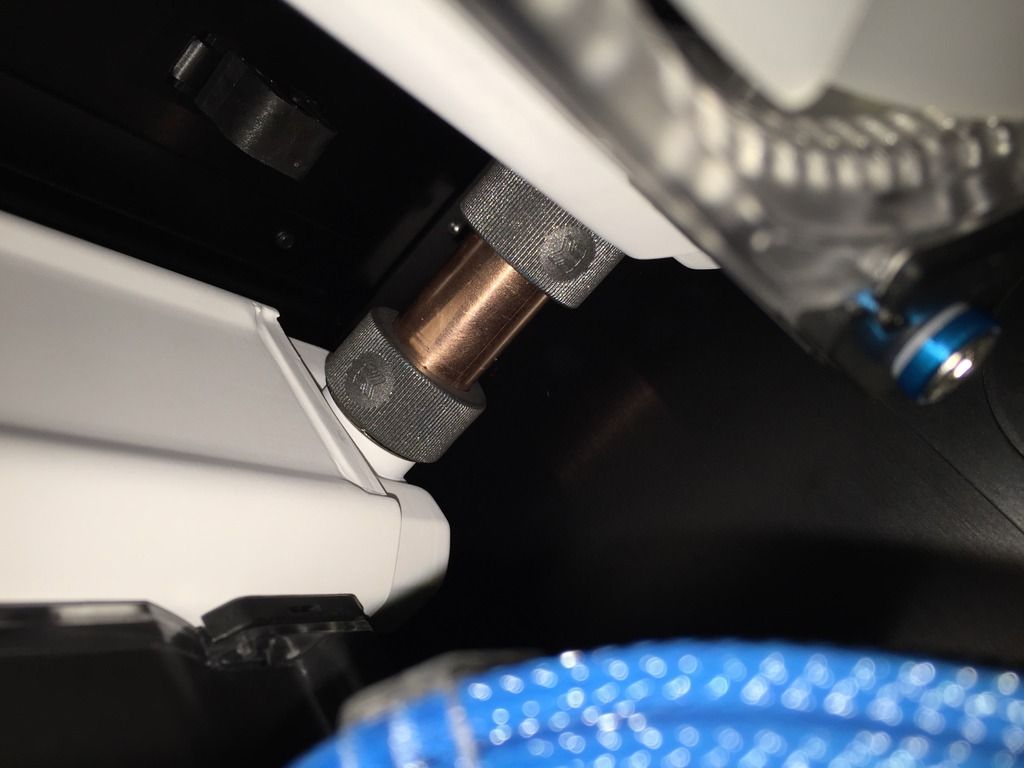

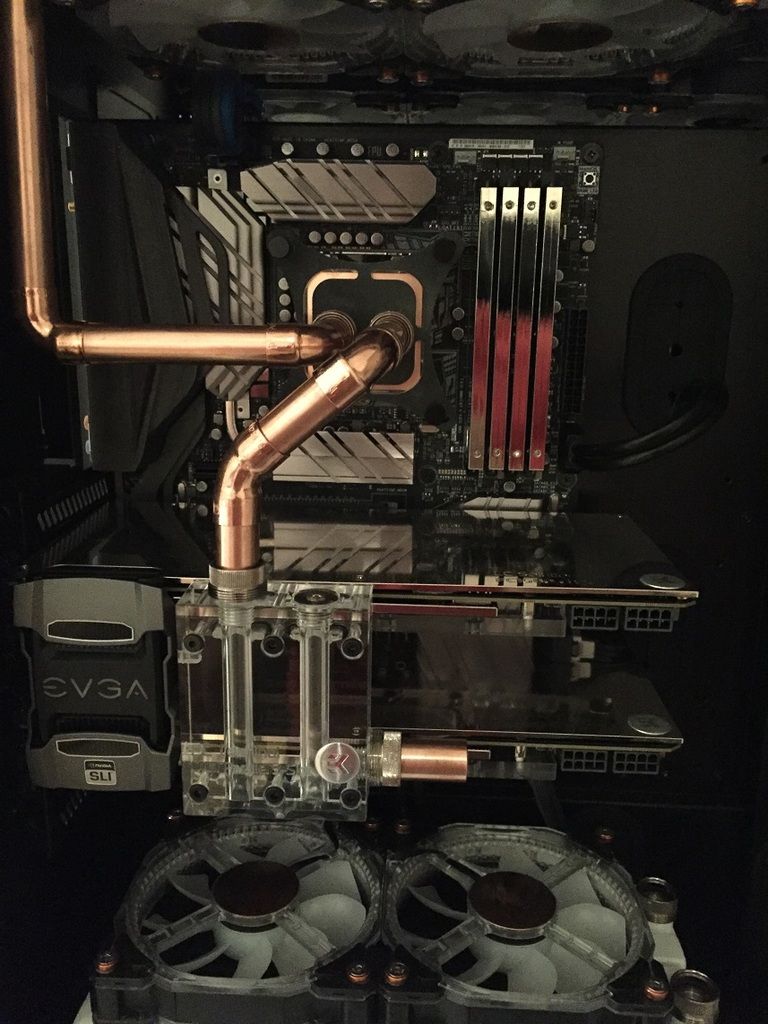

Echo the above. Copper discs look gorgeous !

Looking sweet mate, loving the copper discs over the fan stickers. Classy touch

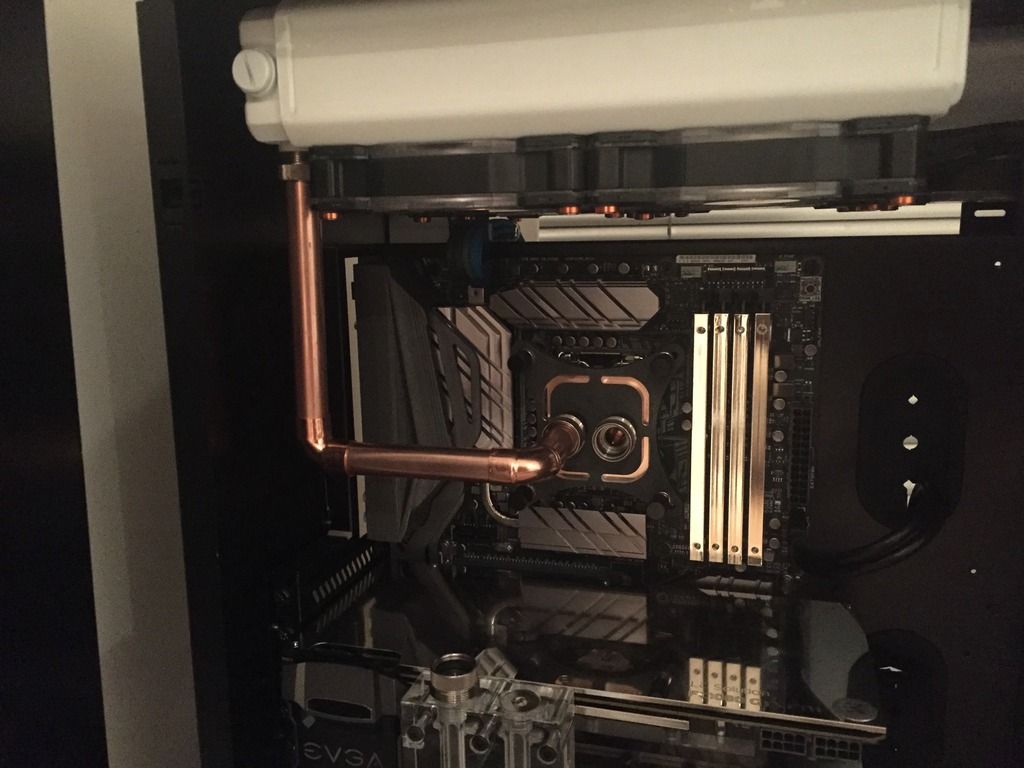

I say solder copper bends on or just use petg mate

Providing you proper clean out the inner of the copper after soldering surly it will be fine.

Hmm, interesting product. Only question is whether it would react with the coolant. It's good for drinking water which implies it doesn't leach out or dissolve. It also doesn't mention that you can't use it on central heating pipes which may have Fernox or similar anti-corrosion/sludge additives so that's promising. Their website makes my eyes bleed though

Nor should you get the sort of pressure exerted on it by water-hammer - and by that I mean specifically when you get water flowing at full mains pressure suddenly being shut off. Our old washing machine used to do it, you'd hear the water get shut off when the pipework vibrated with the sudden change. Suck it and see I think. Should avoid the problem of having solder showing through and ruining the look.

Looks good. If it's not a rude question, why have you connected the pipe to the top port of the front rad instead of the front port? Doesn't make any difference in the scheme of things; would just save you a 90. Or have I just missed the point and the pipe is left too long for the moment?

Extra rad ports seem to be damned handy for drains! Plus it probably lets you go neatly sideways across the top to the res I'm guessing.

Looks superb man. I've not been around much but you've made some excellent progress

Top work mate, looking good. Hope the Just-For Copper works and doesn't react with the coolant, will make life a hell of a lot easier than soldering every single join!