You know, I could have sworn I posted more details somewhere...but I can't find them either

So, I printed what confirmed my suspicion that this would fit (remarkably difficult to find reliable dimensions of these things!):

Marsgizmo Filament Bunker v3. There are plenty of remixes and so on but this seems to be the original.

There's also a video with an idea about making them upside-down that might be of interest:

The containers I used I'm not sure if I can post a link but search for "Skroam 4 Piece Plastic Storage Containers" and you'll find them. They're the 4 litre size and they have the three grooves for a handle rather than the deep inset handle that reduces the width of the container significantly.

Edit: I think the octagonal shape of the opening on the top panel is also a giveaway of the correct type.

So far, most of my containers read either 10% or 14%. I think this is the lowest they read. I've got one at 19% and a roll of PETG that I hate (cardboard spool that gave me no end of grief) that's sitting at 26% even after drying it twice.

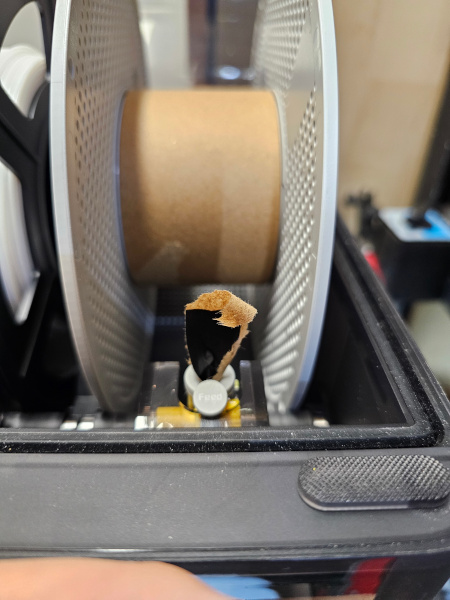

Rather than make holes in all of mine, I printed a plug for one of the spouts and put a tube in that:

Help yourself to the

step file if you're using the same containers. I've got the Fusion 360 model if that more helpful...but it's one of those that's evolved during the design process so it's not a masterpiece of concise design

Edit: Another option is to design directly for the octagonal opening as there is more of a seal there. You might be able to start from the design in the video and modify from there if that's the way you want to go.

The inserts are PC4-M10 pneumatic push connectors by the way.... although it's worth noting that if you're designing a model with the thread included, it's NOT an M10 thread but a G1/8 which is a BSPP series thread (in Fusion it's under BSPP Pipe threads).