Not a problem, just wasn't sure if I was more clueless than I was aware!

Looks good by the way.

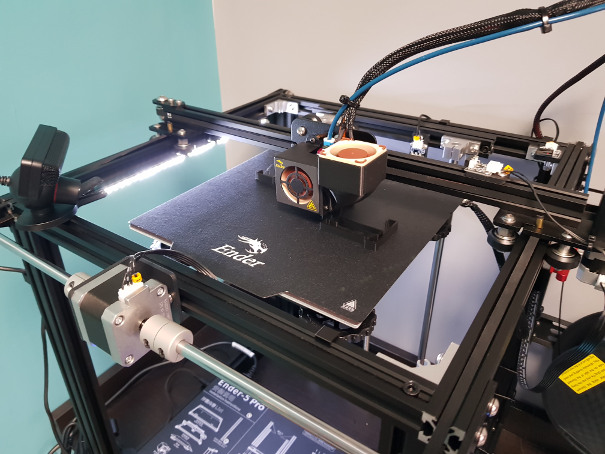

Having bought an Ender 5 Pro on the grounds that I wanted to be able to use it and didn't want to be replacing parts of it straight away or printing upgrades to it.....I've dismantled, modded and upgraded it.

The fans in the control box I changed already but now I've done the hot end fans too. The joy, of course, being to make sure that the duct doesn't crash if the head moves full scale.

I've also made and printed some brackets to hold that light strip you can see - they just clip into the bottom slot of the 2020 extrusion - and I've added a toggle switch to turn on/off a jack socket that feeds them off the same 12V buck convertor that runs the fans.

The layer fan isn't totally quiet but that's mainly due to the fact that it's running off a really poor PWM implementation. I believe I could turn up the frequency of the PWM by modding the firmware.....but I'm not sure I'm there yet! It's a lot quieter than it was already.

The other thing that may not be obvious is that I've rebuilt it bass ackwards. This allows the Y-axis motor to be at the front instead of the back. Flipping it means that 0,0 is still in the back right corner. This means I can push it back far enough that it will fit on the work surface (39.5cm deep - nominally 40) without the front feet falling off the front. Previously I had to have a couple of planks under the feet to extend the surface....not the best of looks!

Web cam is now also mounted on a 4mm shaft that fits in the corner bracket much like the Y-axis stop does.

Looks good by the way.

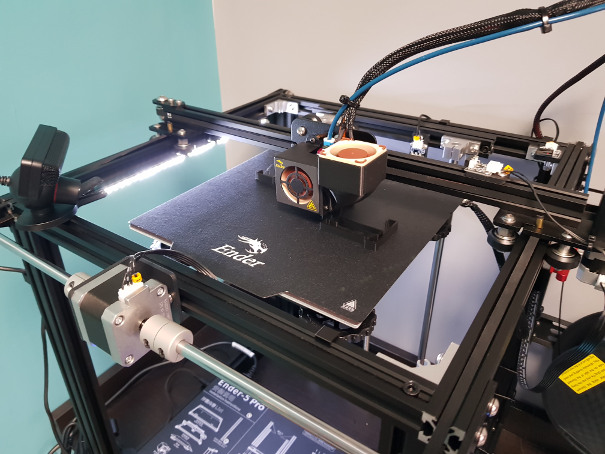

Having bought an Ender 5 Pro on the grounds that I wanted to be able to use it and didn't want to be replacing parts of it straight away or printing upgrades to it.....I've dismantled, modded and upgraded it.

The fans in the control box I changed already but now I've done the hot end fans too. The joy, of course, being to make sure that the duct doesn't crash if the head moves full scale.

I've also made and printed some brackets to hold that light strip you can see - they just clip into the bottom slot of the 2020 extrusion - and I've added a toggle switch to turn on/off a jack socket that feeds them off the same 12V buck convertor that runs the fans.

The layer fan isn't totally quiet but that's mainly due to the fact that it's running off a really poor PWM implementation. I believe I could turn up the frequency of the PWM by modding the firmware.....but I'm not sure I'm there yet! It's a lot quieter than it was already.

The other thing that may not be obvious is that I've rebuilt it bass ackwards. This allows the Y-axis motor to be at the front instead of the back. Flipping it means that 0,0 is still in the back right corner. This means I can push it back far enough that it will fit on the work surface (39.5cm deep - nominally 40) without the front feet falling off the front. Previously I had to have a couple of planks under the feet to extend the surface....not the best of looks!

Web cam is now also mounted on a 4mm shaft that fits in the corner bracket much like the Y-axis stop does.

Some filler stuff stuff to make some rough patches and some textures where im going to put some rust and stuff, but yea coming together:

Some filler stuff stuff to make some rough patches and some textures where im going to put some rust and stuff, but yea coming together:

Today I am printing more parts for my mini nuke! So far she is looking the bomb!

Today I am printing more parts for my mini nuke! So far she is looking the bomb!