OK so tonight I ordered the last parts

Firstly I ordered some more chainguns (god damn you OCUK and your prices !)

Four obs.

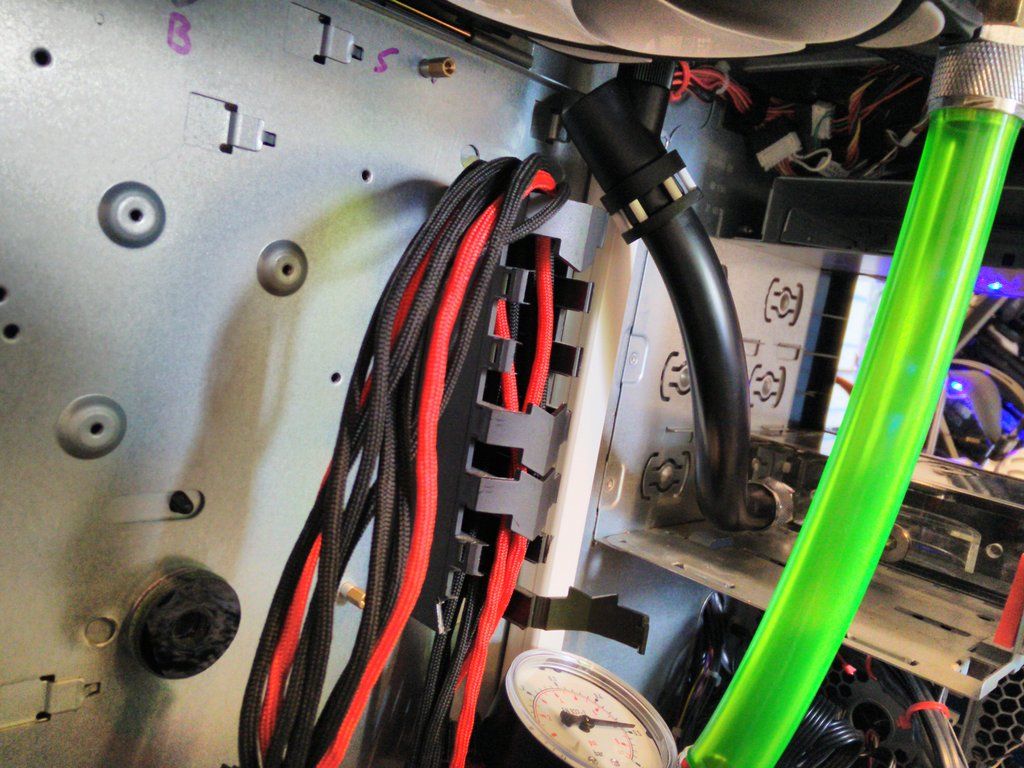

Hands down these are easily the best fittings I have used yet. The chaingun design is also handy, because you can get your fingers into the poles in order to tighten them meaning they need no tools and because they are so huge they are also easy to tighten up fully without removing your skin.

I got a new res cap (it's a brand new res but I stole the cap from it to put on my dual bay res)

Thanks for finding that G !

OK now for the block it will either be like this.

Or like this.

Basically I bought it used from the bay of fleas. I paid £25. Apparently the guy has loads and is selling them off cheap. It may have a couple of marks on it but nothing that I don't think I can polish out etc. Not sure why I went for a high end block tbh? maybe because it will be here sooner etc. Either way whether I get the clear one I requested or a black one it doesn't really matter too much

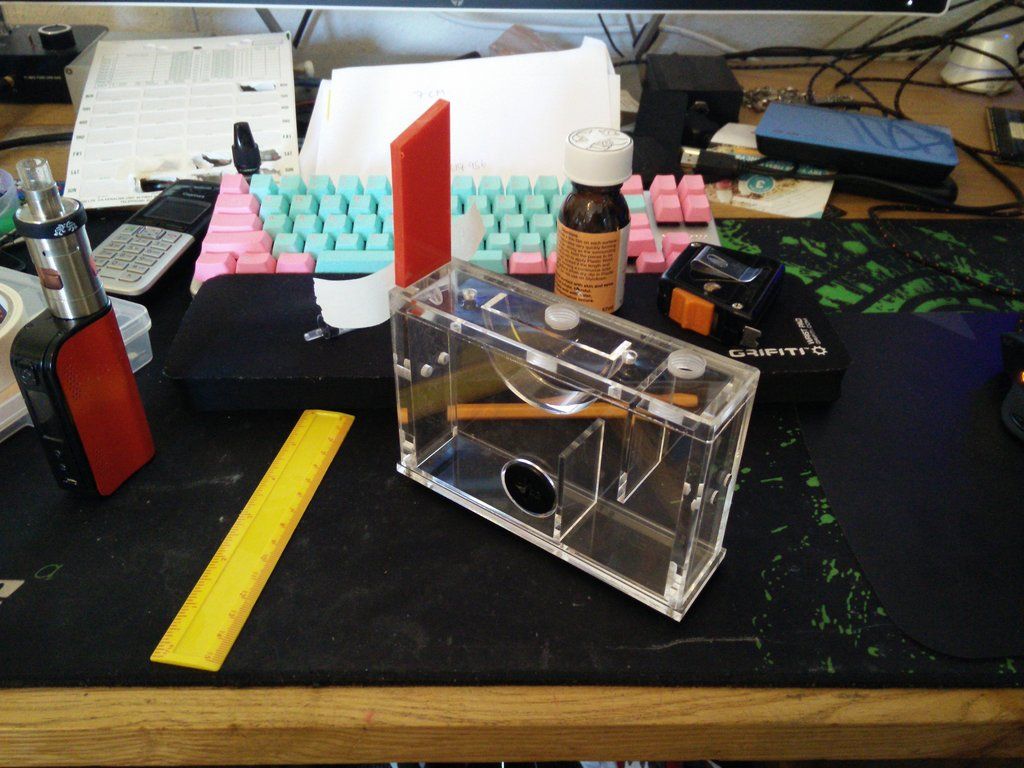

I got one of these.

Which I was worrying about at first because this res has no spare ports (unlike my dual bay res) but then I remembered I bought these.

The first of which goes near the pump, so instead of capping it with a cap to turn 90' I will just put the temp probe in

I ordered an A3 sheet of black 3mm.

Because Gareth was wrong, I don't have a stash, honestly*

I also ordered plenty of silver brushed alu vinyl (for the floor and inside) and some brushed black alu vinyl (for the two bays I need to fill in the front of the rig). Of course I will be custom making a front panel cover that will hold the temp sensor etc.

* I'm lying really and he was right. But it's all pukey colours like yellow and orange and purple etc. I cba painting it so I ordered some in black, which seems to go faster.

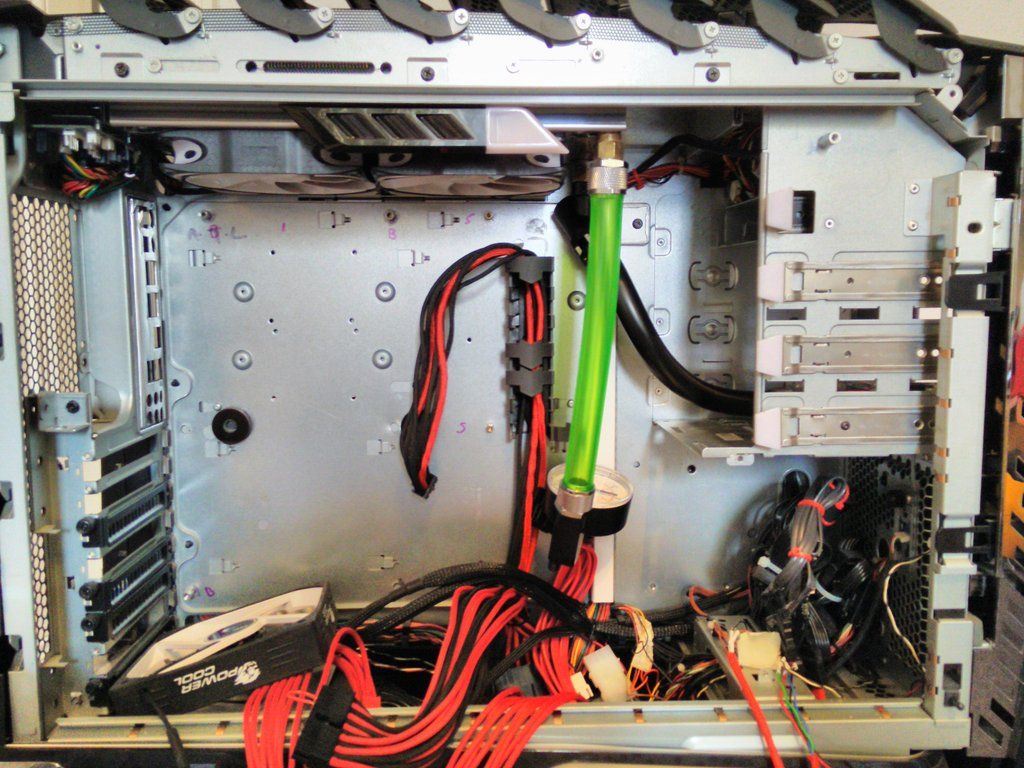

I forgot I had the carrier in, what a *****.

I forgot I had the carrier in, what a *****.