- Joined

- 25 Aug 2013

- Posts

- 392

A minor update: The new PCIe Riser arrived!

This one is from "Adapter World" and is sold as a Gen 3 16x shielded, flexible riser. I was expecting (from the picture online) it to be that awful medical grey they normally are, but I opened it to find the shielding on the outside which looks perfect for the build!

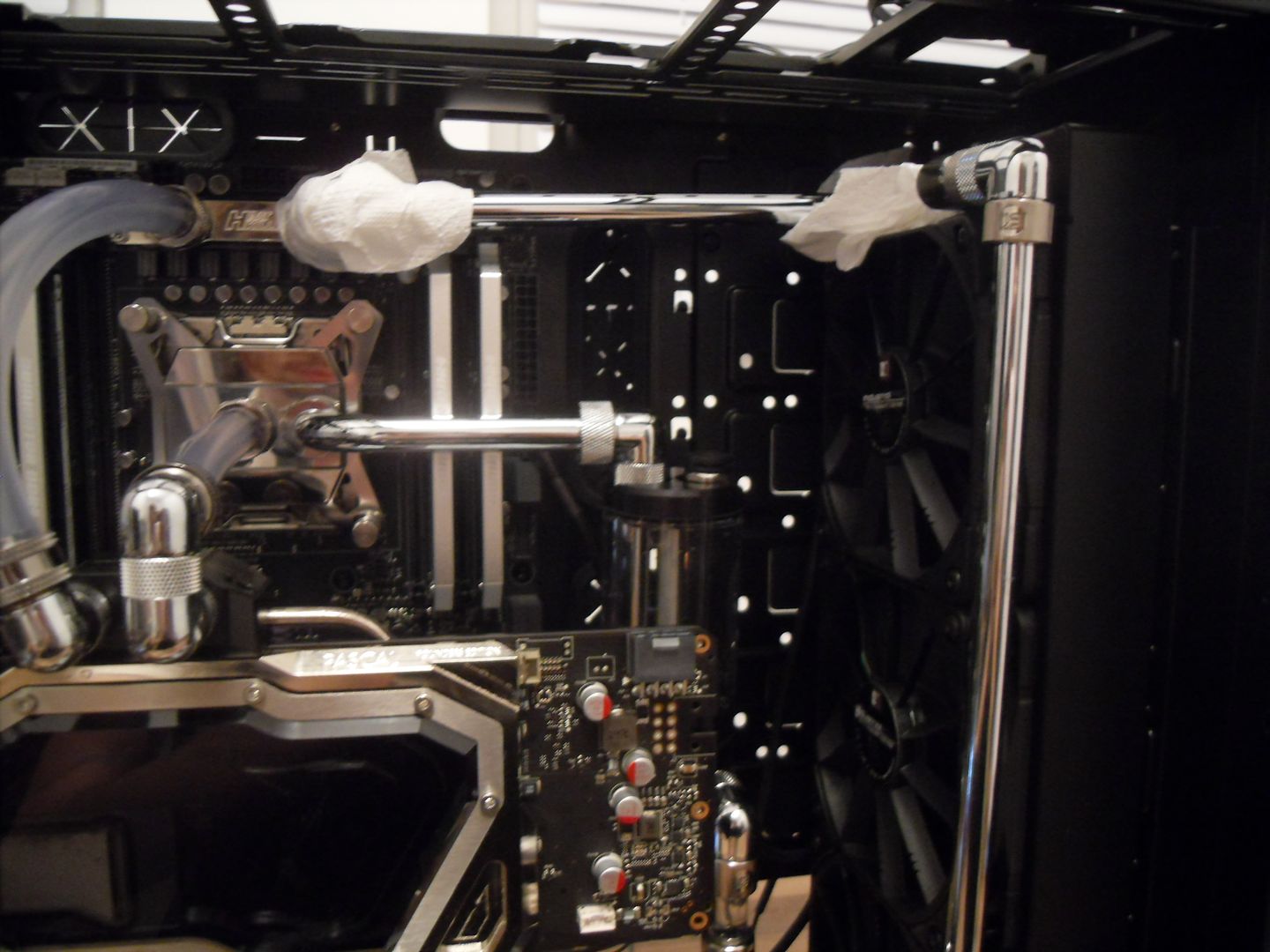

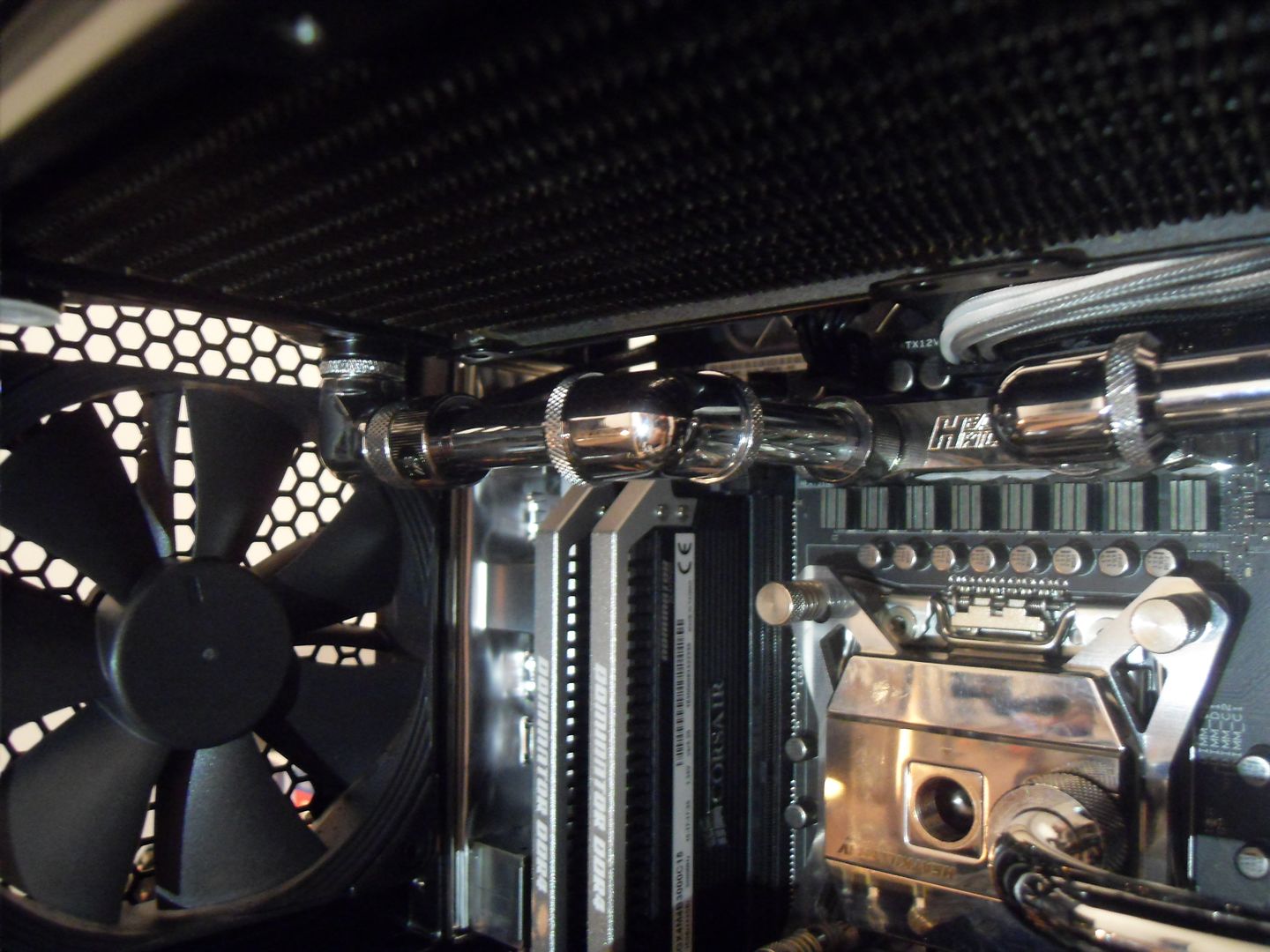

I had to test it, so I used flexible tubing to complete my loop and plugged my old SSD to get things booted.

The riser was plugged into the 3rd 16x slot on my motherboard and immediately booted up no problem. Downside is that apparently my 3rd slot is only 8x, but that shouldn't make a difference and it with be in the 4th slot when the build is complete which is 16x.

I had ran Firestrike Ultra when I was tested my component and wrote down the results to compare. With the riser in the 8x slot I got a slightly higher score than compared without the riser in a 16x slot, but this is probably because the GPU is watercooled and therefore able to stably boost higher.

What this does show is that my performance probably won't be effected by the riser and that it works fine, so I am very happy!

This one is from "Adapter World" and is sold as a Gen 3 16x shielded, flexible riser. I was expecting (from the picture online) it to be that awful medical grey they normally are, but I opened it to find the shielding on the outside which looks perfect for the build!

I had to test it, so I used flexible tubing to complete my loop and plugged my old SSD to get things booted.

The riser was plugged into the 3rd 16x slot on my motherboard and immediately booted up no problem. Downside is that apparently my 3rd slot is only 8x, but that shouldn't make a difference and it with be in the 4th slot when the build is complete which is 16x.

I had ran Firestrike Ultra when I was tested my component and wrote down the results to compare. With the riser in the 8x slot I got a slightly higher score than compared without the riser in a 16x slot, but this is probably because the GPU is watercooled and therefore able to stably boost higher.

What this does show is that my performance probably won't be effected by the riser and that it works fine, so I am very happy!

. so the completion of this project will have to be postponed to the week of the 26th of this month so I'd sub to get updated when I start again.

. so the completion of this project will have to be postponed to the week of the 26th of this month so I'd sub to get updated when I start again.