You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project: Hush! - updated 26/12/23

- Thread starter Monkey Puzzle

- Start date

More options

Thread starter's postsdude i want more pics!!!! - subscribed

yeah i got to admit, i am getting pic withdrawels with this one too

Didn't have time to read all the posts, but I noticed in a previous post, that you had trouble bending the microbore pipe cleanly.

You can use a pipe bending spring for this, for example here

You will be able to get nice tight bends using a spring.

Note: If you use pipe cutters on the microbore, you probably wont be able to insert the spring, as the cutters push the ends in.

Use something like a junior hacksaw to cut the pipe, and finish of with a fine file (nail file), if you want to use a bending spring.

One other tip, if you have'nt used a bending spring before, slightly over bend on the angle you need to start with and then bend back to the angle you need. This makes it much easier to remove the spring after bending.

HTH

You can use a pipe bending spring for this, for example here

You will be able to get nice tight bends using a spring.

Note: If you use pipe cutters on the microbore, you probably wont be able to insert the spring, as the cutters push the ends in.

Use something like a junior hacksaw to cut the pipe, and finish of with a fine file (nail file), if you want to use a bending spring.

One other tip, if you have'nt used a bending spring before, slightly over bend on the angle you need to start with and then bend back to the angle you need. This makes it much easier to remove the spring after bending.

HTH

Last edited:

Associate

- Joined

- 9 May 2007

- Posts

- 827

holy crap i was going to make my own radiator untill i saw this 0.0!!

Anyone know of a place I can get lots of cheap, relatively strong acid? Not sure where to get it and any regulations - was told by a car bits shop that they can't sell battery acid (~35% sulphuric acid) these days. I could probably make do with distilled vinegar but it'll be expensive for the amount I need and take a long time as it's weak.

have you thought of heading down the scrap yard and enmptying out some batterys? im sure the scrappy wont mind you having the old batteries to drain, at a price of course. even a diluted amount will be stronger than vinigar

That was a very detailed reply, thank you man. I'm studying engineering, but fluid dynamics is not my strong point. I'm very glad you've run the numbers on it before starting manufacture, any estimates for the heat it can dissipate?

Getting flux up to temperature in 6 minutes shouldn't be a problem, whack the oven up to full temperature until it finishes warming up, then swiftly put the copper into it. If it doesnt fit then no luck though, which is a shame. I hope the blowtorch works out for you.

Bit more ambitious, and in several ways a quite stupid idea, but you could heat it electrically. Mains ac will make things quite hot. I succeeded in welding a small piece of aluminium with it before the circuit breaker went. Mains ac hurts mind, and passing current through a large copper block will be considered unsafe.

Regardless I look forward to the next update

Getting flux up to temperature in 6 minutes shouldn't be a problem, whack the oven up to full temperature until it finishes warming up, then swiftly put the copper into it. If it doesnt fit then no luck though, which is a shame. I hope the blowtorch works out for you.

Bit more ambitious, and in several ways a quite stupid idea, but you could heat it electrically. Mains ac will make things quite hot. I succeeded in welding a small piece of aluminium with it before the circuit breaker went. Mains ac hurts mind, and passing current through a large copper block will be considered unsafe.

Regardless I look forward to the next update

I am becoming more intrigued on how the soldering is going to be done as it looks to me that getting all those plates to line up and pressed into place is going to be a very tricky job, which will get harder as you put more plates on and the thing stiffens up, unless everything is absoutely dimensionally **** on. Have you considered making the holes in the plate a fair bit larger to make fitting easier, then using copper washers to bridge the gap? You could offer a plate up to the tubes, clamp it up, put the washers on, draw round each washer, take everything off, solder the washers to the plate in the exact same position, so that when you offer up the plate again it should be tailored to the tubes. Just have to use washers which have a inner hole dia close to the tube OD. With the plate in place solder the washers to the tubes, the washers may well unsolder themselves form the plate while you do the second solder run but if you clamp the plate and do them one at a time it shouldn't matter. Then repeat this for the next plate.

at JonJ's mains AC idea! In words of Sergeant Wilson "Do you really think that's wise sir?"

at JonJ's mains AC idea! In words of Sergeant Wilson "Do you really think that's wise sir?"

edit: Just thought how my idea could be improved. Why not fabricate your own squaure washers using the flat plate you already have. Cut the plate into squares, coat one side with flux and seed with solder so you have a square of copper with a film of solder on one side. Then drill a suitable hole in each washer. Pre-soldering each washer removes to need to put the loose washer on and draw round it, you should just be able to put the pre-soldered washer on the cooling plate as positioned on the tubes, and blast it with your blow torch. The solder may even run around the tubes as well, though it will probably still be necessary to put an additional ring around each tube. The key benefit of this is you can enlarge the holes in your cooling plates so that they will be more forgiving to any measurement errors.

at JonJ's mains AC idea! In words of Sergeant Wilson "Do you really think that's wise sir?"

at JonJ's mains AC idea! In words of Sergeant Wilson "Do you really think that's wise sir?"edit: Just thought how my idea could be improved. Why not fabricate your own squaure washers using the flat plate you already have. Cut the plate into squares, coat one side with flux and seed with solder so you have a square of copper with a film of solder on one side. Then drill a suitable hole in each washer. Pre-soldering each washer removes to need to put the loose washer on and draw round it, you should just be able to put the pre-soldered washer on the cooling plate as positioned on the tubes, and blast it with your blow torch. The solder may even run around the tubes as well, though it will probably still be necessary to put an additional ring around each tube. The key benefit of this is you can enlarge the holes in your cooling plates so that they will be more forgiving to any measurement errors.

Last edited:

- Joined

- 13 Mar 2006

- Posts

- 6,712

have you thought of heading down the scrap yard and enmptying out some batterys? im sure the scrappy wont mind you having the old batteries to drain, at a price of course. even a diluted amount will be stronger than vinigar

A cunning plan - I'll look into it - using a vinegar/harpic power plus mix atm I had leftover from earlier - seems to do the job but leaves the copper a very slightly bluey-pink..

That was a very detailed reply, thank you man. I'm studying engineering, but fluid dynamics is not my strong point. I'm very glad you've run the numbers on it before starting manufacture, any estimates for the heat it can dissipate?

Not entirely sure tbh - the best-case scenario from the simulator gives stupidly high heat dissipation (500W+ for a 0.5C delta T) which I'm not entirely sure is just from assumptions made in the model which by adapting it I've violated.

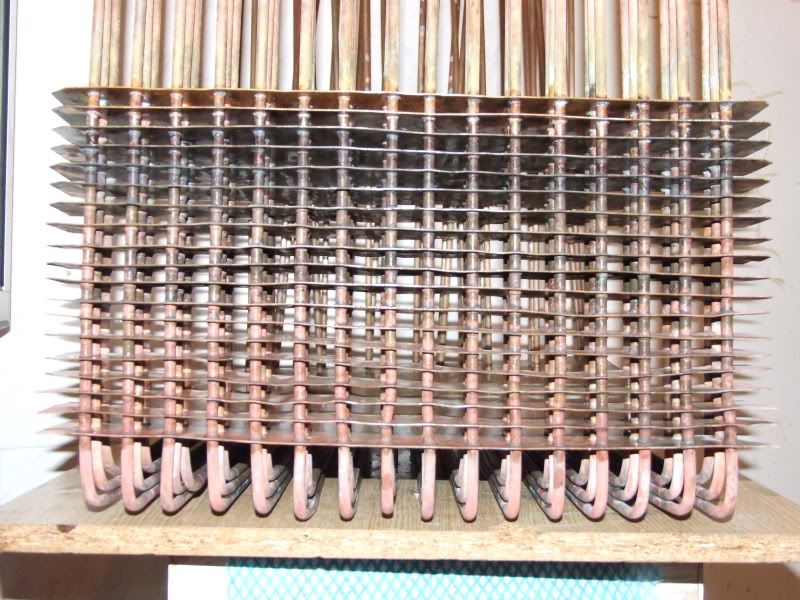

Worst case (modelling the combined 48 x 6mm x ~0.9mm (=~800mm^2 ish) pipe-to-heatfin surface area, with the surface area the heatfins would make with the hotplate at the end in the model (50mm x 0.9mm x 2 = 90mm^2) gives around 300W for a 10C delta T. It should hopefully perform much better than that, despite lowered performance from largely tin solder (the solder has a thermal conductivity around a quarter that of copper).

Getting flux up to temperature in 6 minutes shouldn't be a problem, whack the oven up to full temperature until it finishes warming up, then swiftly put the copper into it. If it doesnt fit then no luck though, which is a shame. I hope the blowtorch works out for you.

Bit more ambitious, and in several ways a quite stupid idea, but you could heat it electrically. Mains ac will make things quite hot. I succeeded in welding a small piece of aluminium with it before the circuit breaker went. Mains ac hurts mind, and passing current through a large copper block will be considered unsafe.

Regardless I look forward to the next update

Lol, I had considered this, but then my sense took over. I have a feeling there's no way on earth that the current would be high enough - copper's not the best resistor in the world!

I also considered sealing off the tube ends and superheating water, but it would have inevitably ended with a "hai guys, I just blinded myself with highly pressurised steam" post.

I also looked into a soldering clamp tool called a hotdog2 that uses an electrical heating element and clamps around the bit of tube you're soldering, but it didn't seem to do 6mm and costs about £100, plus it's meant to go around the outside of pipe fittings being soldered, which mine aren't, so it would probably get gunked up with burnt flux etc.

Anyhow, the blowtorch seems to be working okay - gets up to temperature without too much trouble.

It's a painfully slow process of putting the heatfins on, deoxidising etc.

It's a painfully slow process of putting the heatfins on, deoxidising etc.

I am becoming more intrigued on how the soldering is going to be done as it looks to me that getting all those plates to line up and pressed into place is going to be a very tricky job, which will get harder as you put more plates on and the thing stiffens up, unless everything is absoutely dimensionally **** on. Have you considered making the holes in the plate a fair bit larger to make fitting easier, then using copper washers to bridge the gap? You could offer a plate up to the tubes, clamp it up, put the washers on, draw round each washer, take everything off, solder the washers to the plate in the exact same position, so that when you offer up the plate again it should be tailored to the tubes. Just have to use washers which have a inner hole dia close to the tube OD. With the plate in place solder the washers to the tubes, the washers may well unsolder themselves form the plate while you do the second solder run but if you clamp the plate and do them one at a time it shouldn't matter. Then repeat this for the next plate.

at JonJ's mains AC idea! In words of Sergeant Wilson "Do you really think that's wise sir?"

edit: Just thought how my idea could be improved. Why not fabricate your own squaure washers using the flat plate you already have. Cut the plate into squares, coat one side with flux and seed with solder so you have a square of copper with a film of solder on one side. Then drill a suitable hole in each washer. Pre-soldering each washer removes to need to put the loose washer on and draw round it, you should just be able to put the pre-soldered washer on the cooling plate as positioned on the tubes, and blast it with your blow torch. The solder may even run around the tubes as well, though it will probably still be necessary to put an additional ring around each tube. The key benefit of this is you can enlarge the holes in your cooling plates so that they will be more forgiving to any measurement errors.

Thanks for the suggestion, but it sounds rather fiddly. I'm using 9mm thick wooden spacers atm, which seem to work okay - I'll do an update later with pics.

Last edited:

- Joined

- 13 Mar 2006

- Posts

- 6,712

UPDATE 1

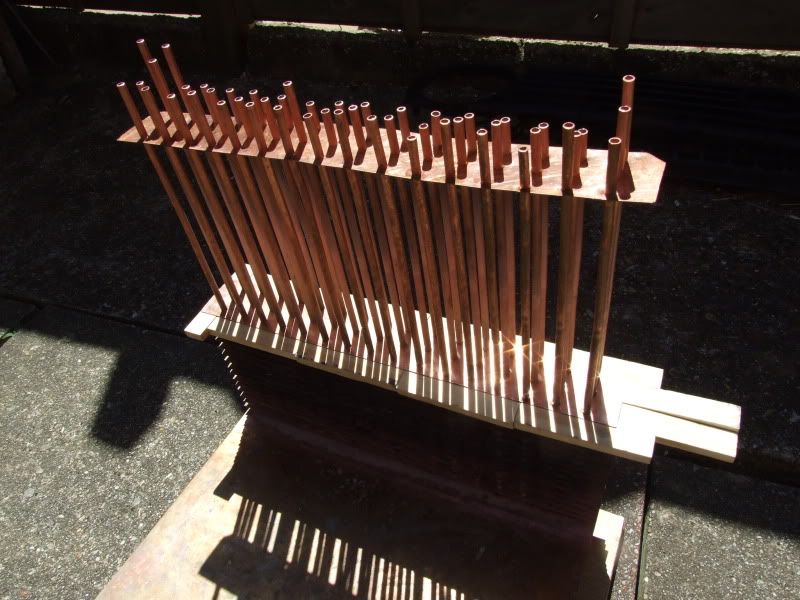

Roughly how the removable motherboard tray will sit (looks a little tighter height-wise than it will be due to the top pipes being a little bent down atm). The PSU will sit behind at the bottom, fan facing down.

A sheet of 2mm styrene that was lying around:

Heatgun:

Bending:

A quick and dirty tray to bath it in. So quick and dirty that it leaked , so it has an outer box lined with plastic sheet a mattress came in - now it's in the styrene tray to avoid cutting up the plastic lining:

, so it has an outer box lined with plastic sheet a mattress came in - now it's in the styrene tray to avoid cutting up the plastic lining:

Deoxidising:

Shiny:

Making solder slinkies.

After cutting to solder rings - not sure how many are in the bag, probably a thousand or so.

Blowtorch - gets up to temperature okay.

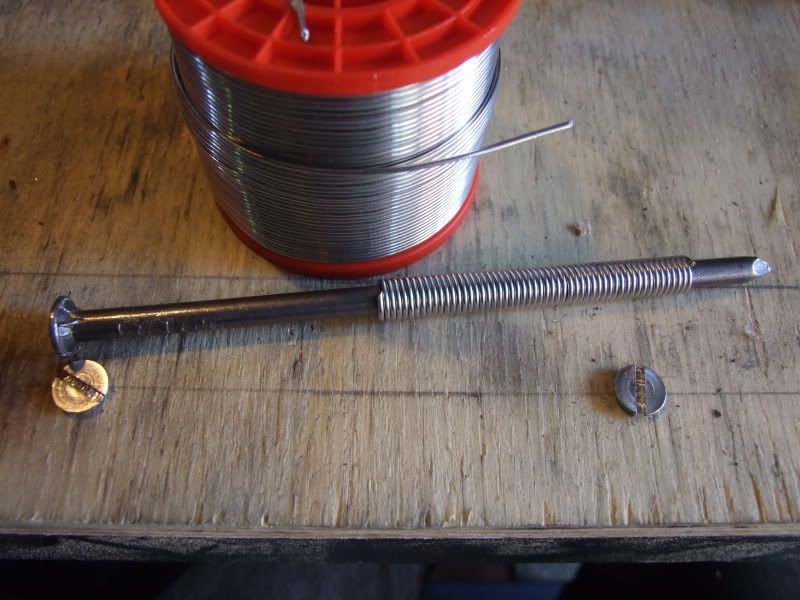

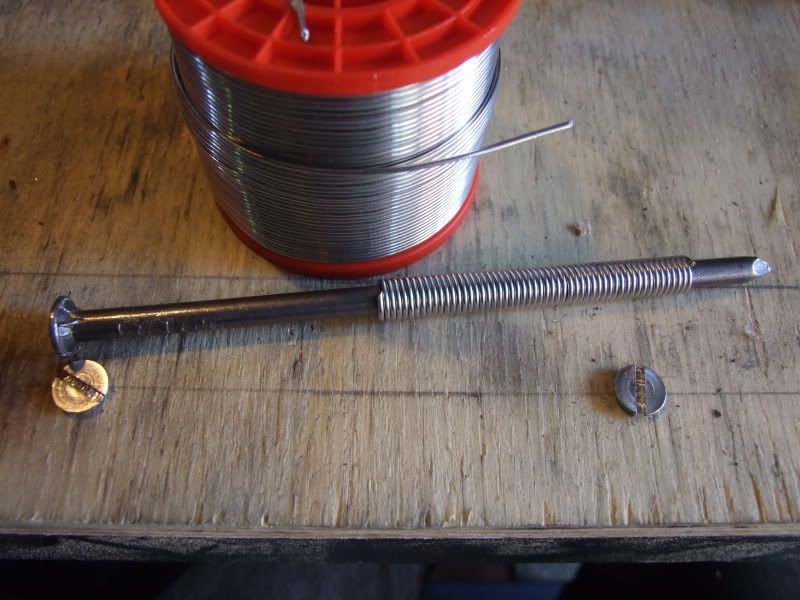

Various bits for putting fins on and soldering:

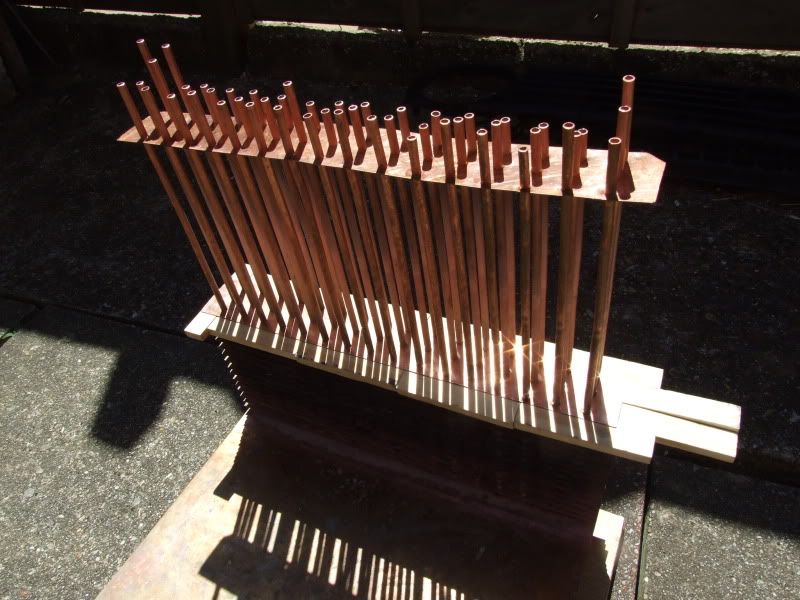

Fin in place with 9mm thick wooden spacers for straightening the fins (they need to be hammered gently into place and deform a little in the process)

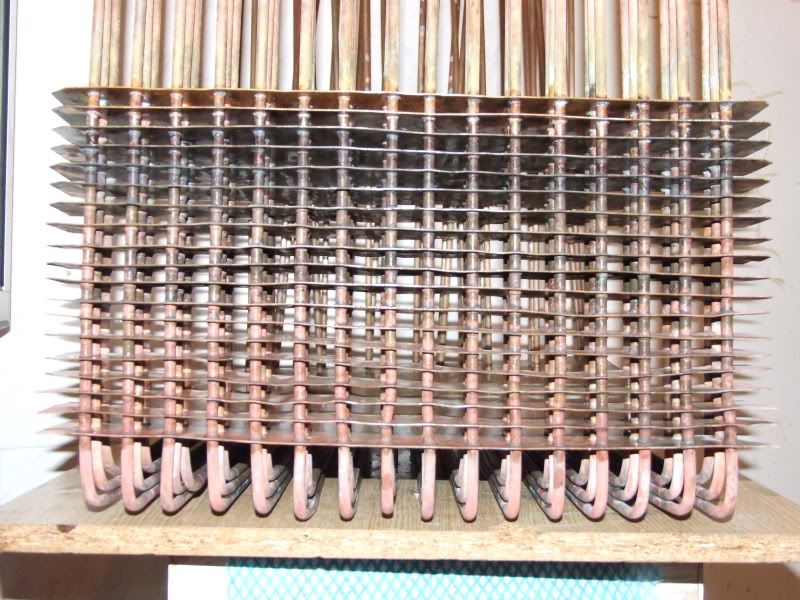

Solder rings put around the pipes - it's quicker to put them on like this, with a fin above, near the pipe ends, as it made putting the fins on a lot quicker.

Solder rings after tightening with needl-nosed pliers (surprisingly quick and easy).

A freshly soldered fin on top: The fins are a bit rainbow coloured from scale slowly being removed by the weak acid bath - hopefully it'll all go - the bottom fins are quite pink. It was pretty disconcerting to see the shiny copper scale up and get covered with burnt flux, as it didn't seem to get removed at first. I'm a bit concerned about the acid possibly attacking the solder joints - I may switch to cleaning it only at the end when all in place and using a fine wire brush to clean the pipe before soldering.

Unfortunately I couldn't correct the bend that got pushed too far through (3rd from the left at the bottom). A few of the first fins are a little bent as well, though they'll be mostly out of sight behind the motherboard tray.

A few of the first fins are a little bent as well, though they'll be mostly out of sight behind the motherboard tray.

Roughly how the removable motherboard tray will sit (looks a little tighter height-wise than it will be due to the top pipes being a little bent down atm). The PSU will sit behind at the bottom, fan facing down.

A sheet of 2mm styrene that was lying around:

Heatgun:

Bending:

A quick and dirty tray to bath it in. So quick and dirty that it leaked

, so it has an outer box lined with plastic sheet a mattress came in - now it's in the styrene tray to avoid cutting up the plastic lining:

, so it has an outer box lined with plastic sheet a mattress came in - now it's in the styrene tray to avoid cutting up the plastic lining:

Deoxidising:

Shiny:

Making solder slinkies.

After cutting to solder rings - not sure how many are in the bag, probably a thousand or so.

Blowtorch - gets up to temperature okay.

Various bits for putting fins on and soldering:

Fin in place with 9mm thick wooden spacers for straightening the fins (they need to be hammered gently into place and deform a little in the process)

Solder rings put around the pipes - it's quicker to put them on like this, with a fin above, near the pipe ends, as it made putting the fins on a lot quicker.

Solder rings after tightening with needl-nosed pliers (surprisingly quick and easy).

A freshly soldered fin on top: The fins are a bit rainbow coloured from scale slowly being removed by the weak acid bath - hopefully it'll all go - the bottom fins are quite pink. It was pretty disconcerting to see the shiny copper scale up and get covered with burnt flux, as it didn't seem to get removed at first. I'm a bit concerned about the acid possibly attacking the solder joints - I may switch to cleaning it only at the end when all in place and using a fine wire brush to clean the pipe before soldering.

Unfortunately I couldn't correct the bend that got pushed too far through (3rd from the left at the bottom).

A few of the first fins are a little bent as well, though they'll be mostly out of sight behind the motherboard tray.

A few of the first fins are a little bent as well, though they'll be mostly out of sight behind the motherboard tray.

Soldato

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

lemon juice is another cheap strong acid.

Also Hydrogen Peroxide plus heat works wonders - but does take hours

Really looks the business - keep up the good work

Also Hydrogen Peroxide plus heat works wonders - but does take hours

Really looks the business - keep up the good work