Work on this project's been delayed as I need tools etc to make progress and I live and work away from it, so only get a chance to work on it when I come back to my folks place. An update from a few hours ago would probably suggest it's not dead!

???

Im glad its all coming together for you Tom, was starting to worry the lack of updates was cause my parts hadnt worked out.

Nah, just that my friend was ill over xmas so couldn't cut them until after the new year, and I'm back fora week to try and get it finished. Thanks again for making the cutting plans Ben.

Just got back from Robin's - took everyhting over to hiis to tidy up the plates with the slits in and cut the steps on the back of them for the 1/8" thick 1.5" x 1.5" aluminium angle upright legs to sit flush prior to putting countersunk allen-head screws in.

Sadly in trying to cut one of the steps in the back of the plate on his lathe it mangled the step, so he's going to remill a new plate, and cutting the steps took longer than expected; so they didn't get finished this evening. So I've left the plates and a blank one with him to do. Sadly it's probably not going o get done before I go back on Sunday.

When that's done I'll need to countersink, drill and tap a LOT of 6mm long m4 screws and bolts, cut a slit for a slot-loading optical drive, a PSU and a laptop optical drive bracket/holder, a few small cuts for the motherboard tray and also a USB/esata/firewire panel and a hole for a bulgin vandal power switch.

Very frustrating not to be able to do the drilling etc tonight- had hoped to get it completed or damn near by this Sunday.

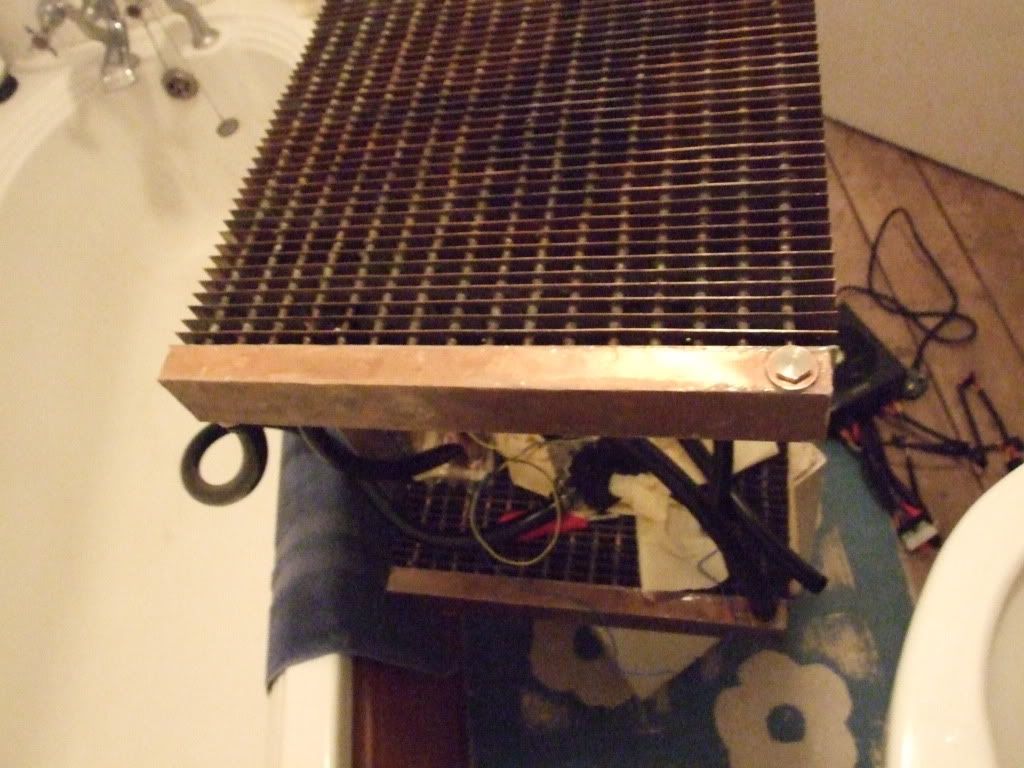

if anyone has access to martins flowrate calculator I'd be really interested to see how that compares to the restriction of something like a pa120.3.

if anyone has access to martins flowrate calculator I'd be really interested to see how that compares to the restriction of something like a pa120.3.

but then stuck with it and must say you are a very skilled engineer

but then stuck with it and must say you are a very skilled engineer

I completely forgot about it

I completely forgot about it

I completely forgot about it