Man of Honour

- Joined

- 5 Jun 2003

- Posts

- 91,648

- Location

- Falling...

I already had 170-200mm so only needed it to top up and/or plug the gaps that was needed. If you have nothing then 200mm is bare minimum.Yeah that's the stuff. Although I think I've got the 200mm stuff in the basket at the moment. I'm trying to work out the best value by m2 but it's like a GCSE maths problem as they're all different thicknesses and lengths lol.

Just plug the values in excel and work out £ /sqm for each roll, and then multiply it by the number of sqm.

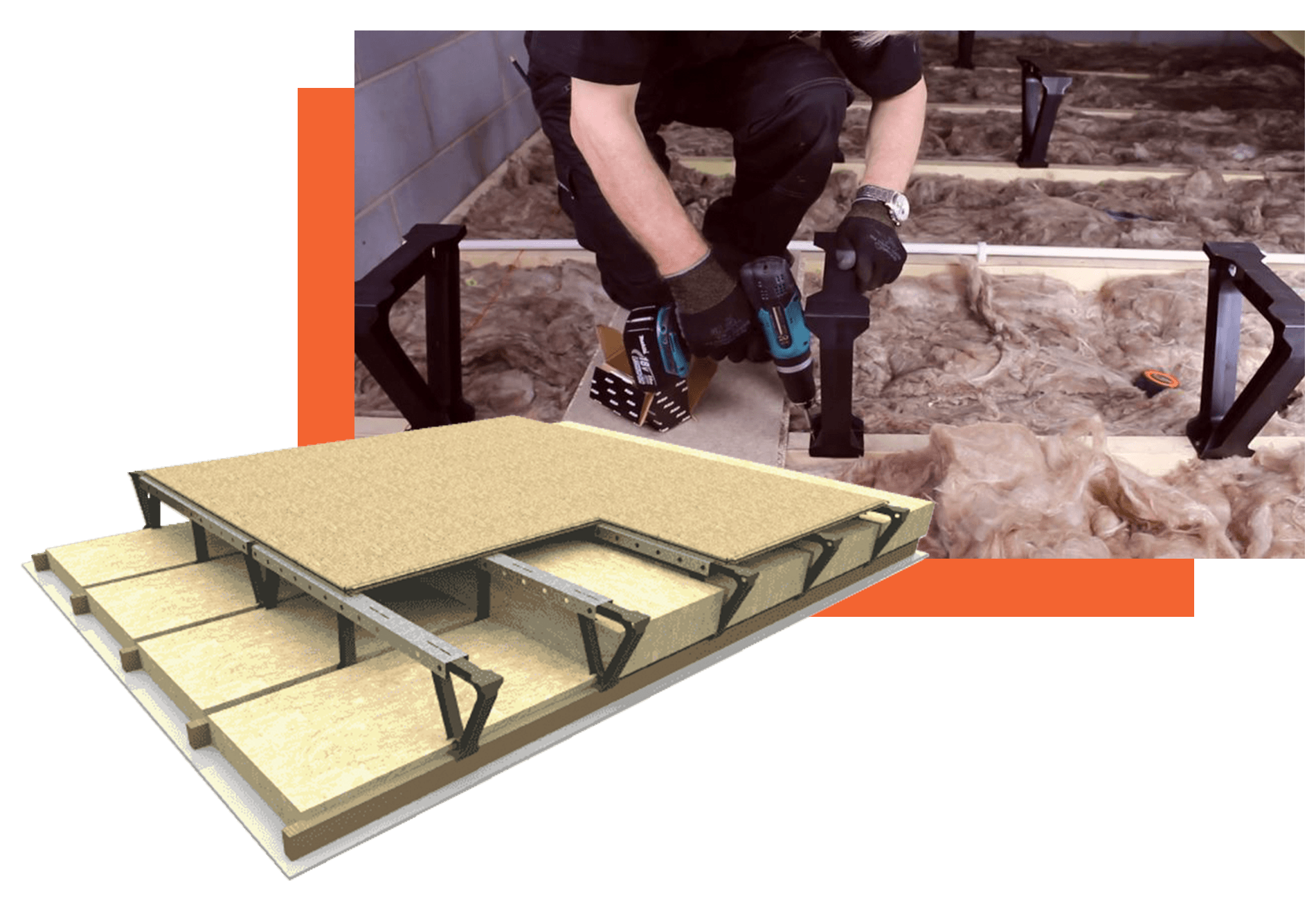

. Also surprised they don't lay the boards in a brick-like pattern for added strength, perhaps to save on cutting boards or to see where the beams are?

. Also surprised they don't lay the boards in a brick-like pattern for added strength, perhaps to save on cutting boards or to see where the beams are?