Just starting a thread for my first water cooled build.

Progress will be gradual as work and fatigue interfere!

As for the name Blackbox II, my Dad always used to call my PC 'the blackbox' so this build is an evolution on that theme.

The theme is carbon fibre, silver metal and white illumination highlights, including motherboard backlighting. I am going for a clean look that also performs well, something that Dad would be proud of!

So forgive me build addicts, as I take my time with this one

700D

Sans grommets:

Standoffs came off with some needle nose pliers:

All off:

What do we have here?! A tube...:

3m Carbon Di-Noc vinyl emerges:

More:

Stock 140mm fans removed:

PCI slot covers plates removed:

Ready for cutting with a scalpel:

The exposed and cut to shape film:

In situ:

Too big as planned:

Picture of the back:

Spot the motherboard! This case is BIG but getting used to it..:

Some access points cut out, I stopped myself there as I realised I didn't necessarily have to cut them ALL out and could have created a cleaner look potentially, oh well no deal, too late now, hopefully i'll need to use them all:

Box of toys:

Test fitting the bottom piece:

That's all for now, I have more pics but will do another uploading session tomorrow. Night

Progress will be gradual as work and fatigue interfere!

As for the name Blackbox II, my Dad always used to call my PC 'the blackbox' so this build is an evolution on that theme.

The theme is carbon fibre, silver metal and white illumination highlights, including motherboard backlighting. I am going for a clean look that also performs well, something that Dad would be proud of!

So forgive me build addicts, as I take my time with this one

700D

Sans grommets:

Standoffs came off with some needle nose pliers:

All off:

What do we have here?! A tube...:

3m Carbon Di-Noc vinyl emerges:

More:

Stock 140mm fans removed:

PCI slot covers plates removed:

Ready for cutting with a scalpel:

The exposed and cut to shape film:

In situ:

Too big as planned:

Picture of the back:

Spot the motherboard! This case is BIG but getting used to it..:

Some access points cut out, I stopped myself there as I realised I didn't necessarily have to cut them ALL out and could have created a cleaner look potentially, oh well no deal, too late now, hopefully i'll need to use them all:

Box of toys:

Test fitting the bottom piece:

That's all for now, I have more pics but will do another uploading session tomorrow. Night

Last edited:

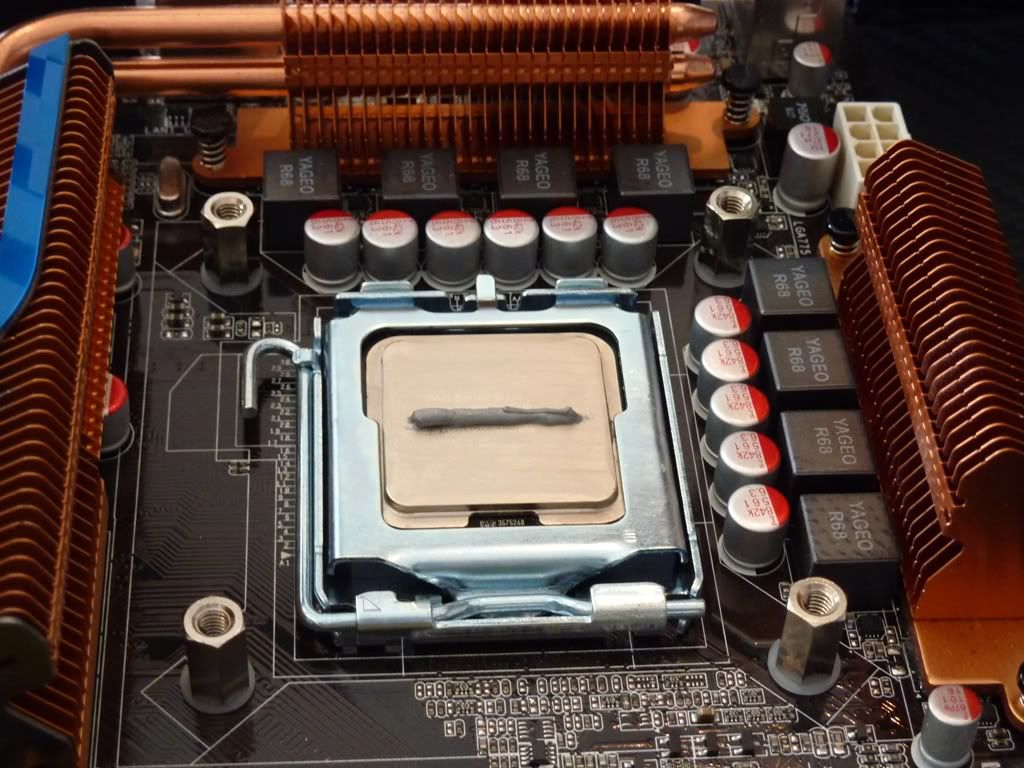

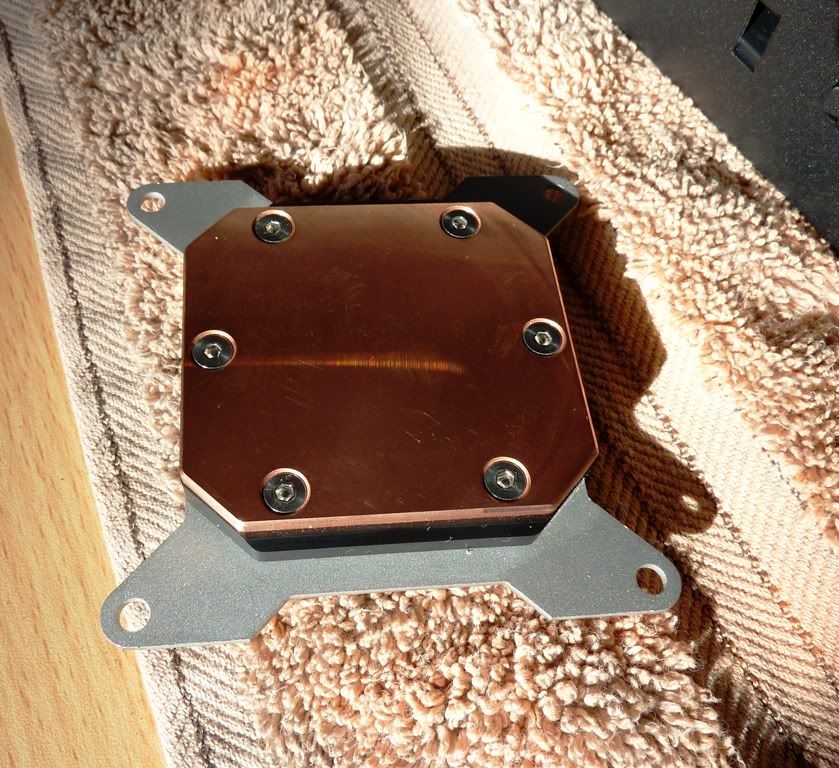

Didn't plan this so well...

Didn't plan this so well...