First up I've not heard back re the EL Panel yet so that is still on hold...

Anyway, you know when you have one of those days where your head really isn't right, and you know everything's going to go wrong? And then it does, but you keep ploughing on anyway? Yep, today was one of those days

Lets start with a moan! Ordered 2 of these Monsoon temperature sensors and both came without rubber o-rings. Not just they weren't pre fitted, they were non existent. Good job I had some spares!

Then screwed one in and the thread is that tight I actually had to use pliers to remove it. Hardly screaming 'quality product' so lets just hope it actually works once fitted.

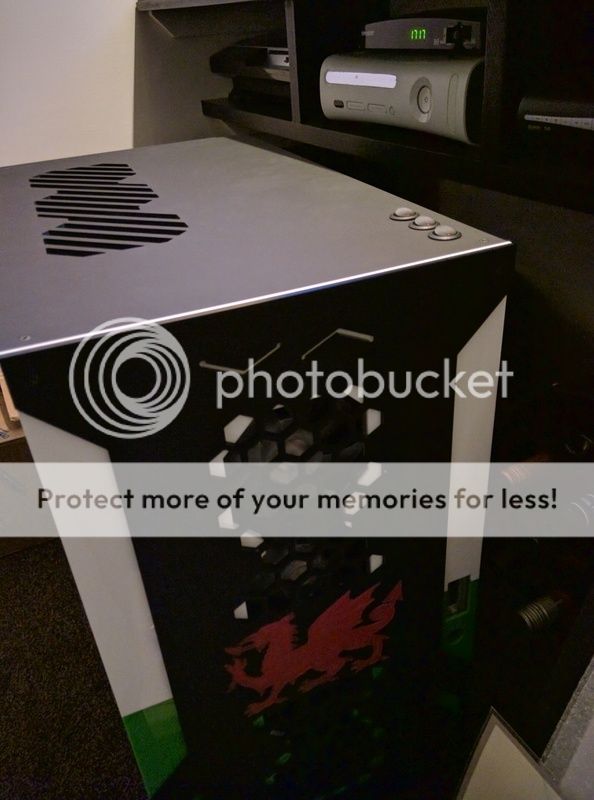

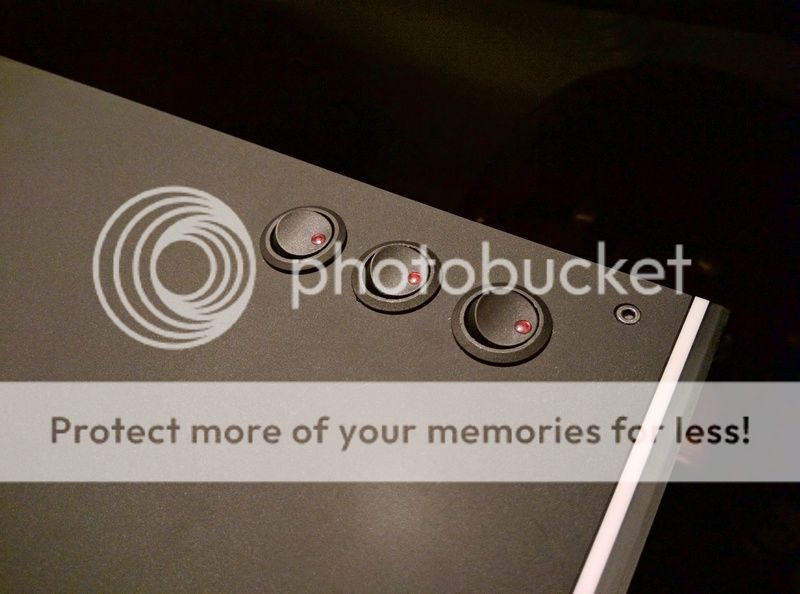

Better news: It points in the right direction!

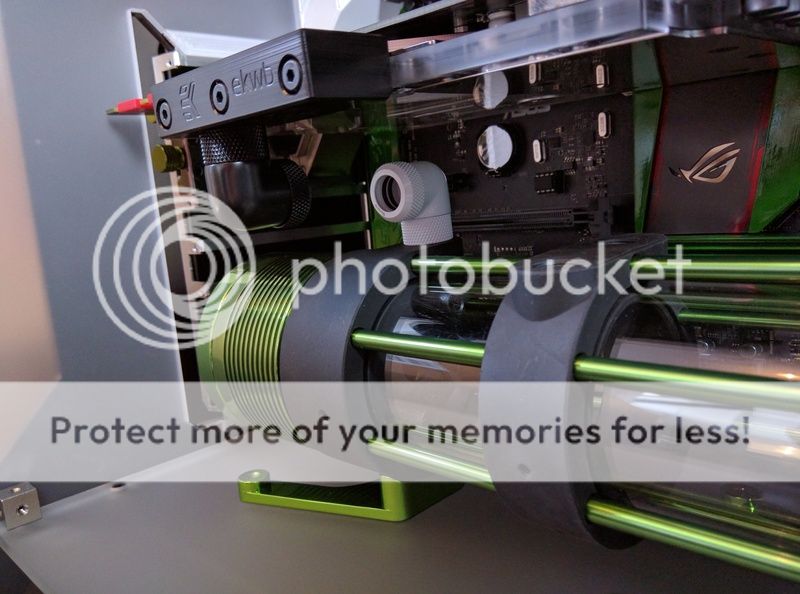

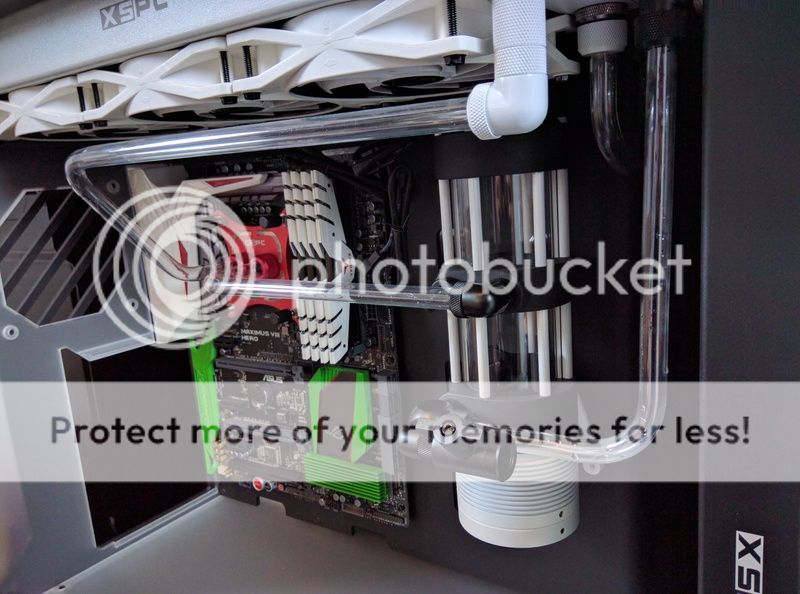

So onto the loop. Firstly I re did the small piece joining the 2 radiators so it (in my eyes at least) looks better. Then changed the CPU > reservoir so it A) looked straight and B) went into the other port on the res. Reasoning? To hide the temperature sensor and cable

Finally I got the last section done, but unfortunately it's not perfect by a long way as I was getting massively frustrated by then

Not too bad, and as you may have noticed I also added a draining valve. Looks fugly but worth spoiling the looks a little for the hassle it removes later on

The new, smoother, loop. May shorten it a bit so it doesn't drop down quite so low.

Sensor hidden, tap added

Fairly happy with how it looks but might still change a few things...

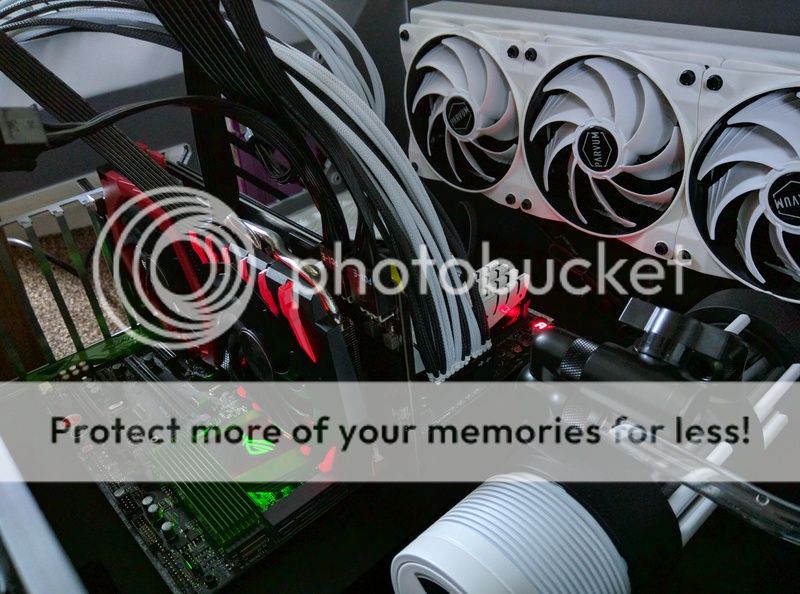

And that's when I should have called it a day as my head really wasn't good by then... But I didn't. I wanted to refit the old CPU cooler and install the GPU to test.

So what exactly did my extremely sleep deprived and

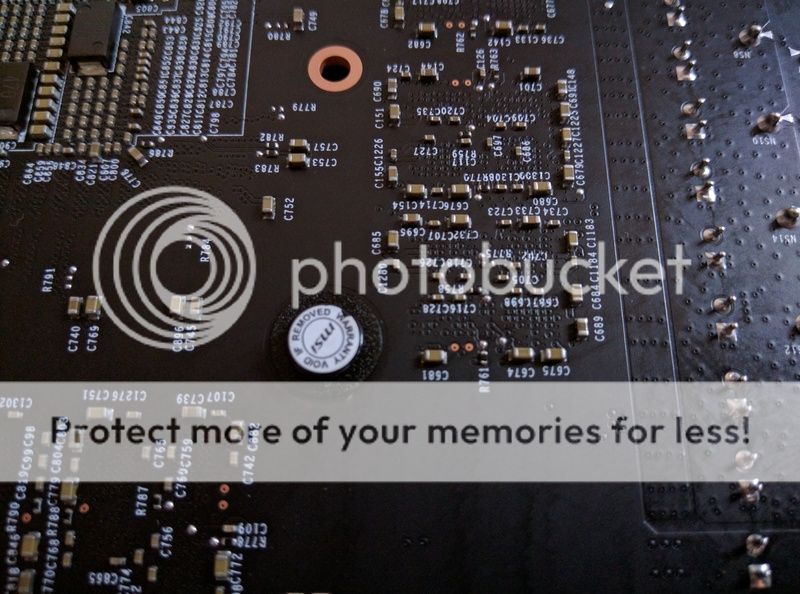

****ed off mood end up doing to the build I hear you ask? Well it damn near cost me a £200+ motherboard. How? Well, after removing the CPU cooler I cleaned the CPU up, chucked a pea of paste on and attempted to install the crap cooler, but the pile of junk wouldn't 'click' into the motherboard. So I removed it again... Dripping a nice glob of thermal paste over both the motherboard and RAM.

But wait, that's not so bad! It got worse. Removed the CPU so I could clean it up properly and in a

****ed off mood I was rushing about a bit and yep, snagged a couple of the motherboard CPU pins with some kitchen roll, bending them up and to one side...

So that was fun! After shouting '

****' so many times the neighbours probably thought the entire series of Father Ted was on TV I bent them back as straight as I could, installed the CPU & cooler and held my breath... THANK

**** FOR THAT, IT LIVES!!

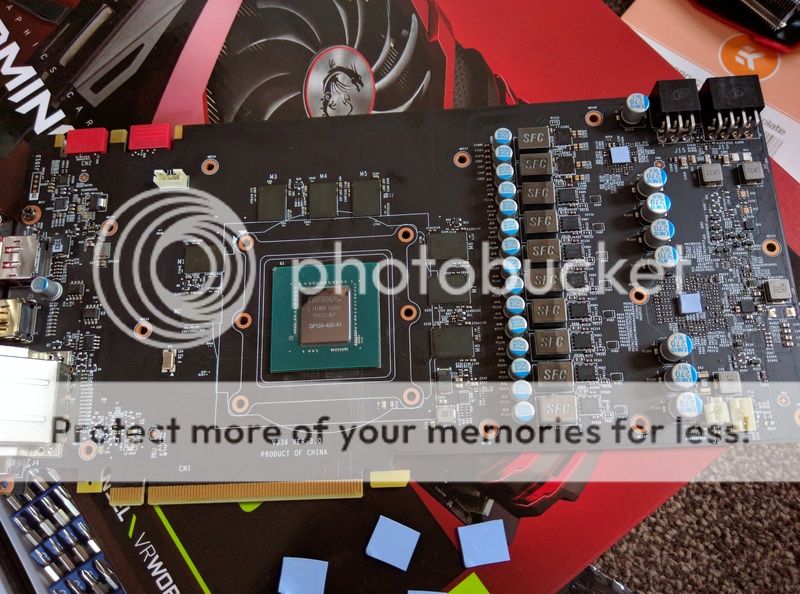

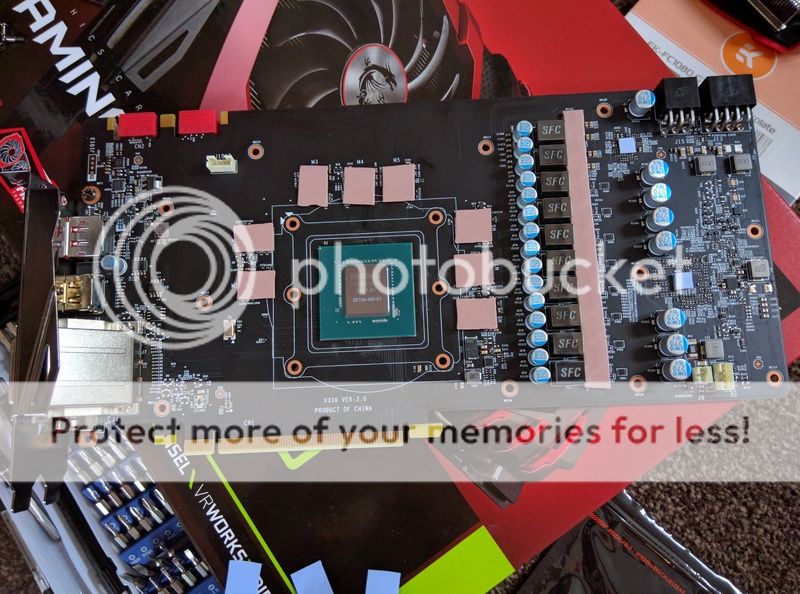

Finally got around to trying out the GPU and happy to say it worked like a charm. Not pretty, but I'll take 'working' for now...

Installed the drivers and 3Dmark etc to stress it and all appears OK, so will give it one more thrashing when I get 10 minutes just to double check and then it will be put under water. That's it for now folks, I'm off to chill with a bucket full of our home made wine and some crap TV

It does look like they've just screwed a 5mm male to male extender into it too. I know, I know, it's almost exactly what I said I wanted but I'm still not happy. Isn't that always the story?! At least they have the sense to realise there is a need for it. Cheers for pointing it out.

It does look like they've just screwed a 5mm male to male extender into it too. I know, I know, it's almost exactly what I said I wanted but I'm still not happy. Isn't that always the story?! At least they have the sense to realise there is a need for it. Cheers for pointing it out.