You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Window To Wales

- Thread starter OJ46

- Start date

More options

Thread starter's postsStrangely the panel is from EL Wirecraft, the same seller as the smaller, noisy panel was, so can only assume I either got unlucky first time round or they use cheaper spec drivers for the tiny panels.

Having looked into it this morning it seems to be the same company as EL PanelAndTape, who deblow used for Project TRON. Just hoping they'll make me a custom sized panel for the floor now, but as the website states min order of 5-10 units I won't be holding my breath on that one... Unless I could get deblow to have a word and say he needs it for TRON

Haha the HDD light on the Evolv ATX is bad enough, think if the dragon was wired up like that I'd have an epileptic fit before Windows had loaded

Having looked into it this morning it seems to be the same company as EL PanelAndTape, who deblow used for Project TRON. Just hoping they'll make me a custom sized panel for the floor now, but as the website states min order of 5-10 units I won't be holding my breath on that one... Unless I could get deblow to have a word and say he needs it for TRON

Haha the HDD light on the Evolv ATX is bad enough, think if the dragon was wired up like that I'd have an epileptic fit before Windows had loaded

Shame it's all or nothing, otherwise you could light the legs in sequence and have it look like the dragon was running when the disk was accessed

It's a good job we don't both contribute silly/expensive/time-consuming ideas to each other's projects or we'd never get anything done!

It's a good job we don't both contribute silly/expensive/time-consuming ideas to each other's projects or we'd never get anything done!

Haha now there's an idea for when I build his M-ATX brother!

But it's so much more fun when it's other people that have to do the work...! It's always good to hear other peoples ideas though mate, might add more work but if it improves the finished build I'm happy to hear as many daft ideas you can think of

But it's so much more fun when it's other people that have to do the work...! It's always good to hear other peoples ideas though mate, might add more work but if it improves the finished build I'm happy to hear as many daft ideas you can think of

Cheers mate, can't wait to get the top loop done so I can fire it up properly. Just need a 1080 to go in it then...

About time you pulled your finger out

No 1080Ti, can't help you with the 1080

Haha just figuring out where the runs are going to go now mate... All going well apart from linking the 2 radiators which is giving me brain ache!

As Nvidia are looking like they're going to wait until I've bought a 1080 before releasing the Ti version I may as well just go for it, so waiting for OcUK to put the MSI Gaming X on sale then that order button will be clicked so hard the mouse will never work again

As Nvidia are looking like they're going to wait until I've bought a 1080 before releasing the Ti version I may as well just go for it, so waiting for OcUK to put the MSI Gaming X on sale then that order button will be clicked so hard the mouse will never work again

Another couple of small deliveries yesterday, including these... Erm... Ring extenders?

Does slightly alter the look of the pump housing, but still a far better option than whacking a bloody great hole in the bottom like I was planning on doing!

Then a couple more parcels arrived, including some switches, a fill port from EK and some rocking horse ****: Yes, it's an Aquaero 6 LT!

Not long after that a MASSIVE delivery arrived from the guys at Aqua Computer...

What do you think this contains? A pair of Aquaero's? Half dozen D5 pumps? Couple of GPU blocks?

Nope, it's a pair of Aquabus cables

Should have some 90° fittings and a couple of other bits coming today, then I can finally get the one reservoir mounted and the top loop done

Does slightly alter the look of the pump housing, but still a far better option than whacking a bloody great hole in the bottom like I was planning on doing!

Then a couple more parcels arrived, including some switches, a fill port from EK and some rocking horse ****: Yes, it's an Aquaero 6 LT!

Not long after that a MASSIVE delivery arrived from the guys at Aqua Computer...

What do you think this contains? A pair of Aquaero's? Half dozen D5 pumps? Couple of GPU blocks?

Nope, it's a pair of Aquabus cables

Should have some 90° fittings and a couple of other bits coming today, then I can finally get the one reservoir mounted and the top loop done

Looks like Aqua Computer have been learning from HP. Good job you didn't order just one cable or you might have had a pallet turn up!

What are the ring extenders for and why would you be putting big holes in things without them? Sure it makes sense, just don't follow.

A 6 LT...so they're not just myth then! Rip that ugly sticker off it and get it heatsinked! Do enjoy cutting the fiddly-sized thermal pads to size, won't you!

Do enjoy cutting the fiddly-sized thermal pads to size, won't you!

What are the ring extenders for and why would you be putting big holes in things without them? Sure it makes sense, just don't follow.

A 6 LT...so they're not just myth then! Rip that ugly sticker off it and get it heatsinked!

Do enjoy cutting the fiddly-sized thermal pads to size, won't you!

Do enjoy cutting the fiddly-sized thermal pads to size, won't you!

Last edited:

Nice to see those Monsoon ring extenders in the flesh. I only found out about them a couple of days ago, and was wondering how they looked in a real build.

Same here, was just about to drill a great hole in the bottom when I went on OcUK to order something else and stumbled across them... Very lucky timing! I'm happy with how they look, certainly tidier than smacking a big hole in the housing

Looks like Aqua Computer have been learning from HP. Good job you didn't order just one cable or you might have had a pallet turn up!

What are the ring extenders for and why would you be putting big holes in things without them? Sure it makes sense, just don't follow.

A 6 LT...so they're not just myth then! Rip that ugly sticker off it and get it heatsinked!Do enjoy cutting the fiddly-sized thermal pads to size, won't you!

At least now I can see why the postage was about 3 times the cost of the cables lol

The extenders are so you can fit the Aquabus cable mate, not enough room between the back of the pump and the housing without it

Oh yes, certainly took long enough to find one in stock! Will have to rip the screen off the other one now so they're the same... As irritating as fitting thermal pads can be I'm definitely going to enjoy that more than bending the PETG

Cheers mate, just fancied something a little different to the usual EK ones

Anyways, some good news: I actually got something done today! Then back to the more usual news: MOAR PROBLEMS

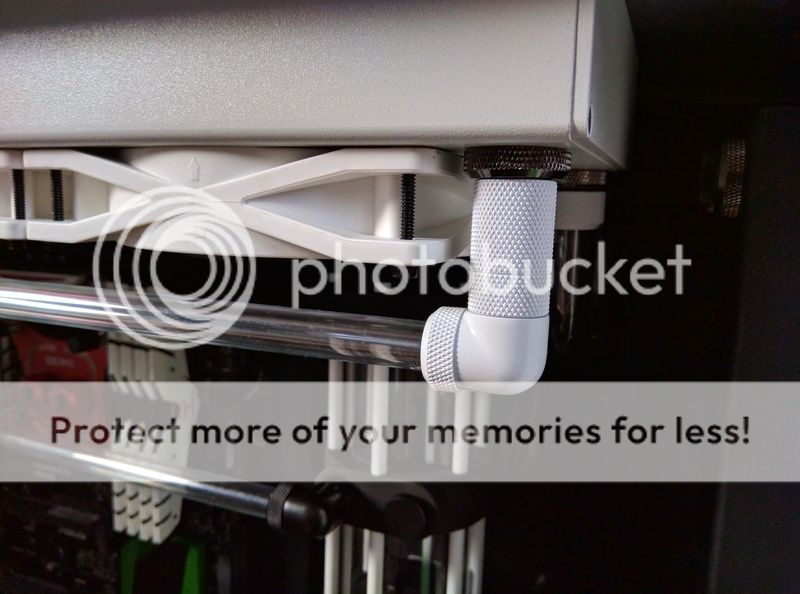

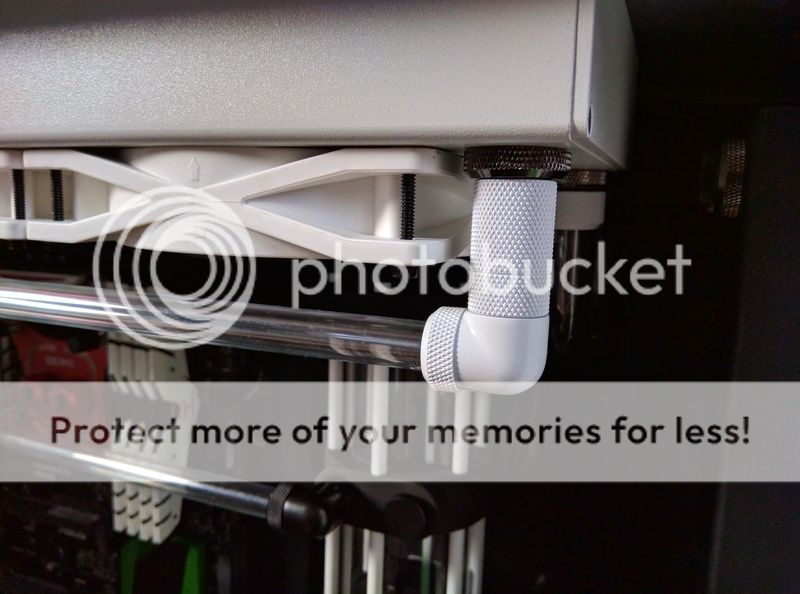

First up the progress... Can ya tell what it is yet?

Yep, the reservoir is in so time to crack on

Mmmmm, pipes... Not happy with the run from CPU to reservoir though so will be redoing that one.

An almost elegant solution to an annoyingly awkward problem.

More pics...

I know, should have been a bend etc etc but sorry, tried that and prefer this as it looks neater

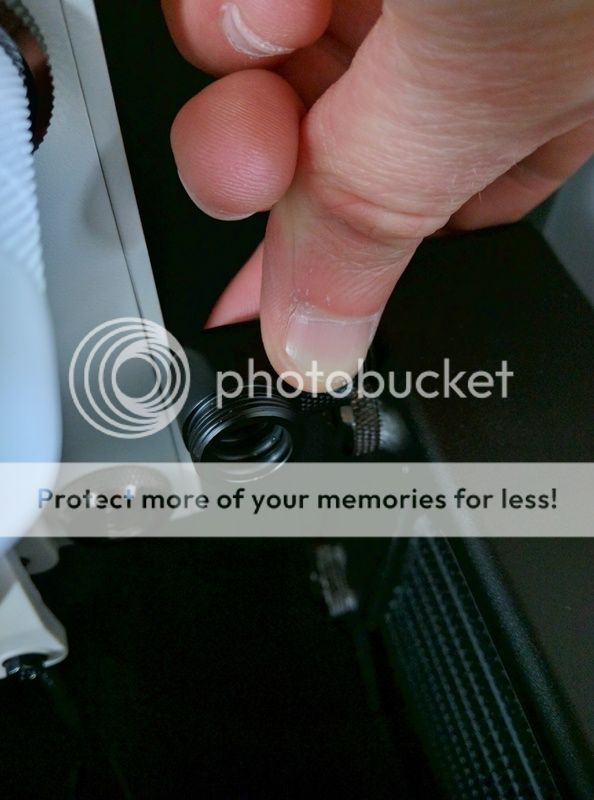

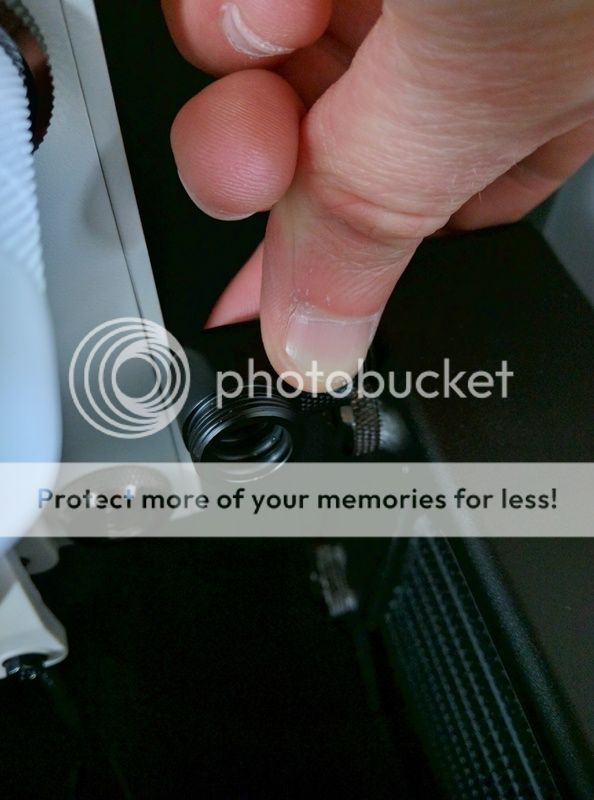

Now to the problem... Bet you can guess what it is with a 2 second glance at the picture below:

CORRECT! The 90° fitting doesn't... Erm... Fit!

As it's less than the thickness of the cover panel out I'm thinking the simplest solution would be to cut a piece out of the white radiator cover... Thoughts?

As per usual any ideas / thoughts / criticisms / verbal abuse is more than welcome

Anyways, some good news: I actually got something done today! Then back to the more usual news: MOAR PROBLEMS

First up the progress... Can ya tell what it is yet?

Yep, the reservoir is in so time to crack on

Mmmmm, pipes... Not happy with the run from CPU to reservoir though so will be redoing that one.

An almost elegant solution to an annoyingly awkward problem.

More pics...

I know, should have been a bend etc etc but sorry, tried that and prefer this as it looks neater

Now to the problem... Bet you can guess what it is with a 2 second glance at the picture below:

CORRECT! The 90° fitting doesn't... Erm... Fit!

As it's less than the thickness of the cover panel out I'm thinking the simplest solution would be to cut a piece out of the white radiator cover... Thoughts?

As per usual any ideas / thoughts / criticisms / verbal abuse is more than welcome

Mmmmm, pipes... Not happy with the run from CPU to reservoir though so will be redoing that one.

Looks good in principle, probably just needs 'sharpening' - seems to slope a bit but a bit more length on the cpu arm should get it right. I found it next to impossible to get the bend exactly where I wanted so I did the bend and then trimmed the ends to length once I'd offered it up and measured it.

Analmostelegant solution to an annoyingly awkward problem.

Fixed that for you

I know, should have been a bend etc etc but sorry, tried that and prefer this as it looks neater

Didn't notice it until you pointed it out. Agree with you though.

Now to the problem... Bet you can guess what it is with a 2 second glance at the picture below:

CORRECT! The 90° fitting doesn't... Erm... Fit!

As it's less than the thickness of the cover panel out I'm thinking the simplest solution would be to cut a piece out of the white radiator cover... Thoughts?

As per usual any ideas / thoughts / criticisms / verbal abuse is more than welcome

Hmm. You could roll the dice and try a non-rotary 90° fitting. Barrow a Matte Black 90 Degree Male To Female Fitting that might fit. Could end up pointing in completely the wrong direction but if it works...

Doesn't help the above problem but have you considered re-routing the cpu to top rad pipe thusly: go from the other rad port, 90 down, 90 left running acrossthe space between the rad and then 90 down, 90 into CPU? Entirely aesthetic but would mean the views of the rad wasn't impinged.

Potentially though a non-rotary 90 that wasn't quite pointing in the right direction could get you from the top white rad port to the impinged black rad port.

There's a knurled thread on the black rad port. Does that unscrew and is it a G1/4 thread underneath? Would the rotary 90° fitting connect directly to that and solve the problem?

Soldato

- Joined

- 1 Dec 2015

- Posts

- 18,512

non- rotary but get 2/3 different brands as they might start the thread at different positions .

Looks good in principle, probably just needs 'sharpening' - seems to slope a bit but a bit more length on the cpu arm should get it right. I found it next to impossible to get the bend exactly where I wanted so I did the bend and then trimmed the ends to length once I'd offered it up and measured it.

Yeah that's exactly it mate. Did that run before I'd done the radiator > CPU and it looked perfect, but as soon as I'd done the other one I realised I'd cut the CPU end about 5mm short... D'Oh!

I found the easiest way was to offer the mandrel up to the pipe exactly where the bend needed to go, then put a tiny bit of tape to mark where the end of the mandrel is. The fact where even talking about this kind of shows it wasn't exactly fool proof though.

Fixed that for you

I do wish there was a nicer way of joining the 2 rads but the amount they're out of line by makes everything else I thought of fail or look messy, so this was my last attempt at something tolerable before it went for a flight through a window! Guess as a bonus it would have given new meaning to the build name

Didn't notice it until you pointed it out. Agree with you though.

When I tried it with a bend it just looked too big a radius, too close to the fitting and also pushed the pipe a bit further from the radiator. Didn't look bad but not really 'neat' enough for the look I was after

Hmm. You could roll the dice and try a non-rotary 90° fitting. Barrow a Matte Black 90 Degree Male To Female Fitting that might fit. Could end up pointing in completely the wrong direction but if it works...

Now THAT is a good shout cheers mate, hadn't even thought of that!

Am I right in thinking that if I ordered a few of them the threads would be started in different places, so would likely all end up pointing in different directions?

Doesn't help the above problem but have you considered re-routing the cpu to top rad pipe thusly: go from the other rad port, 90 down, 90 left running acrossthe space between the rad and then 90 down, 90 into CPU? Entirely aesthetic but would mean the views of the rad wasn't impinged.

Potentially though a non-rotary 90 that wasn't quite pointing in the right direction could get you from the top white rad port to the impinged black rad port.

I did mock up quite a few different layouts including flipping the top rad around, using different ports etc but always found myself coming back to this one. Didn't want to use a 90° fitting on the CPU block so that killed quite a few layouts off straight away, but ended up going with this one as it leaves the CPU looking good and I think the 3 horizontal runs should, if I get them straight, look tidy! Also liked the idea of having the return to the centre of the reservoir. No real reason I just like being different / awkward

There's a knurled thread on the black rad port. Does that unscrew and is it a G1/4 thread underneath? Would the rotary 90° fitting connect directly to that and solve the problem?

Unfortunately not, but thankfully there's no need now you've solved my brain ache with non rotaries

Will get on the 'bay now and order some non rotary 90°s! Won't be here until next week so guess there'll be no more updates until then

non- rotary but get 2/3 different brands as they might start the thread at different positions .

Ah, so if I ordered a few Barrow 90°s they'd all be started in the same place? Bugger. Guess I'll just order the one then and hope!