You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IC-DIAMOND RESULTS THread

- Thread starter frostdragon

- Start date

More options

Thread starter's postsOk, so I have done temps tests with my previous TIM Noctua NT-H1 and then with the IC Diamond 24c.

Unfortunately, my PC has decided to play up and I can't OC at all without BSODing, so temps are done at stock

For me there wasn't much of a difference with IC Diamond, however this is at stock volts. There might be a bigger difference with an overclock, with higher volts causing higher temps. But without being able to test OC results I can not say for sure.

I would like to thank you guys for sending me the tube of IC Diamond though and even though I only saw a small difference I would definitely buy it over all the TIM I have used previously.

I want to do my GPU as well but non of my screwdrivers fit the screws on my card, as soon as I get one that does I will replace the TIM with the IC Diamond and report back with temps.

Ambient temp for all was ~20*c

Noctua NT-H1 Idle

Noctua NT-H1 load

IC Diamond Idle

IC Diamond Load

Unfortunately, my PC has decided to play up and I can't OC at all without BSODing, so temps are done at stock

For me there wasn't much of a difference with IC Diamond, however this is at stock volts. There might be a bigger difference with an overclock, with higher volts causing higher temps. But without being able to test OC results I can not say for sure.

I would like to thank you guys for sending me the tube of IC Diamond though and even though I only saw a small difference I would definitely buy it over all the TIM I have used previously.

I want to do my GPU as well but non of my screwdrivers fit the screws on my card, as soon as I get one that does I will replace the TIM with the IC Diamond and report back with temps.

Ambient temp for all was ~20*c

Noctua NT-H1 Idle

Noctua NT-H1 load

IC Diamond Idle

IC Diamond Load

Last edited:

- Joined

- 17 Mar 2014

- Posts

- 241

Ok, so I have done temps tests with my previous TIM Noctua NT-H1 and then with the IC Diamond 24c.

Unfortunately, my PC has decided to play up and I can't OC at all without BSODing, so temps are done at stock

For me there wasn't much of a difference with IC Diamond, however this is at stock volts. There might be a bigger difference with an overclock, with higher volts causing higher temps. But without being able to test OC results I can not say for sure.

I would like to thank you guys for sending me the tube of IC Diamond though and even though I only saw a small difference I would definitely buy it over all the TIM I have used previously.

I want to do my GPU as well but non of my screwdrivers fit the screws on my card, as soon as I get one that does I will replace the TIM with the IC Diamond and report back with temps.

Ambient temp for all was ~20*c

Noctua NT-H1 Idle

Noctua NT-H1 load

IC Diamond Idle

IC Diamond Load

Hey there and THANK you for the results. I trust you are running on air and not a waterblock?

Interesting results there, however I have the noctua product and whilst it is VERY VERY good for performance I have seen greater results. Having said this with almost 5c differential between the cores I think there is a issue with the CPU IHS. Essentially one should see at MOST 2-3c difference between all cores at MOST.

Can you please show us on how you applied the paste?

If you have further issues we are willing to send you some test paper in order to have a look at that IHS.

Regards

Christopher

Hey there and THANK you for the results. I trust you are running on air and not a waterblock?

Interesting results there, however I have the noctua product and whilst it is VERY VERY good for performance I have seen greater results. Having said this with almost 5c differential between the cores I think there is a issue with the CPU IHS. Essentially one should see at MOST 2-3c difference between all cores at MOST.

Can you please show us on how you applied the paste?

If you have further issues we are willing to send you some test paper in order to have a look at that IHS.

Regards

Christopher

I used the application method recommended here

http://www.innovationcooling.com/application.html

I'm using a corsair H100 with a i5 2500k. My cores have always been a few *c apart from each other, my one core can be up to 10*c hotter than the others.

I will try another application tomorrow and see if I can get better results.

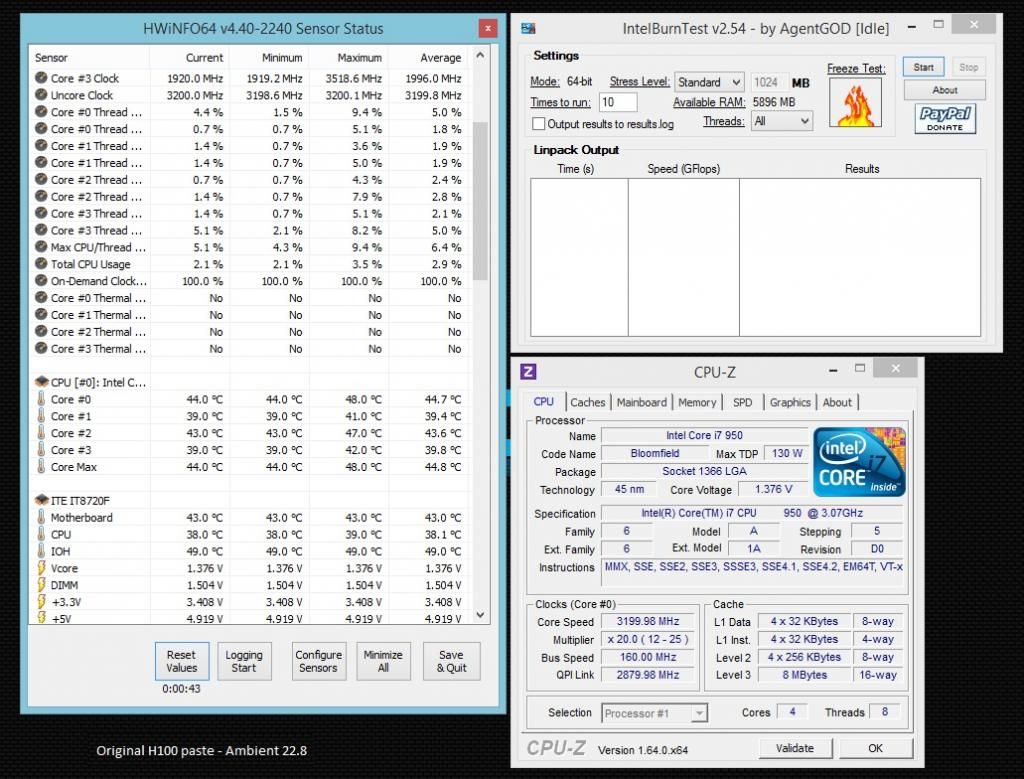

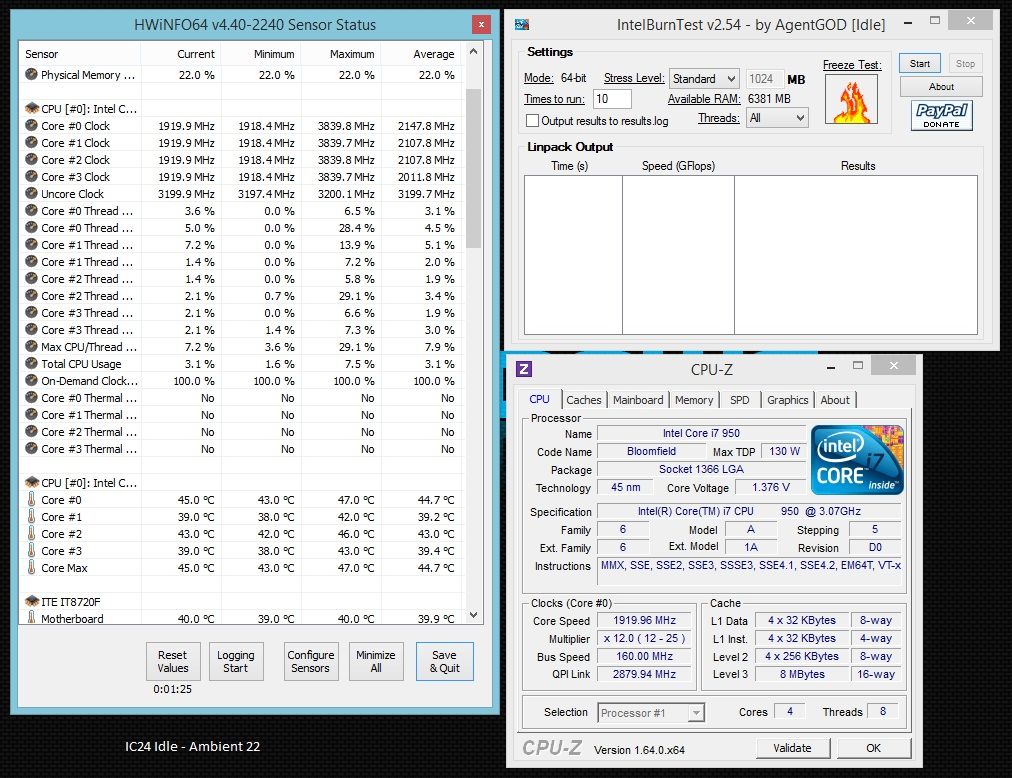

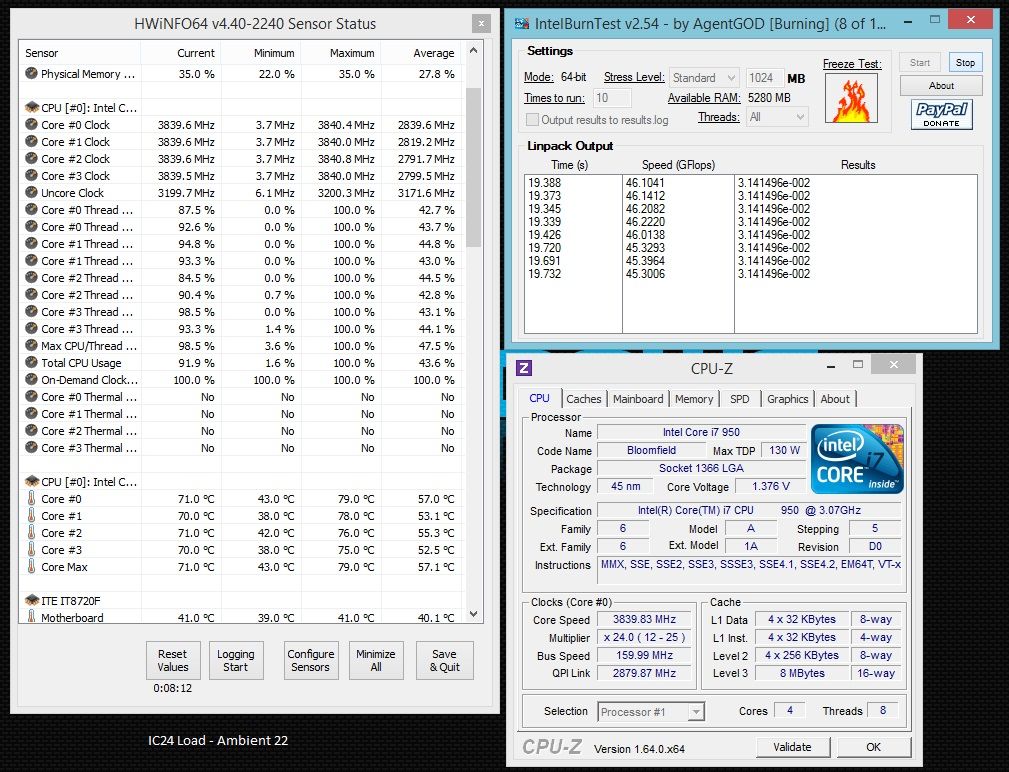

Here are some screenshots, ambient was pretty much the same for all tests.

My original paste was the standard stuff pre-applied to the H100 AIO.

I'm getting pretty much the same temps, not much different at all. I followed the instructions on the website to apply the paste. The amount they tell you to use is more than I would normally use.

H100 Idle

H100 Load

IC24 Idle

IC24 Load

My original paste was the standard stuff pre-applied to the H100 AIO.

I'm getting pretty much the same temps, not much different at all. I followed the instructions on the website to apply the paste. The amount they tell you to use is more than I would normally use.

H100 Idle

H100 Load

IC24 Idle

IC24 Load

Soldato

- Joined

- 29 Dec 2009

- Posts

- 7,369

Just wanted to check how much paste everybody is using?

I think I might've put too much on.. It's performing worse than MX-4 at the mo. 70'c load as opposed to 60-63'c with MX-4

I think I might've put too much on.. It's performing worse than MX-4 at the mo. 70'c load as opposed to 60-63'c with MX-4

Associate

- Joined

- 7 Dec 2010

- Posts

- 223

Just wanted to check how much paste everybody is using?

I think I might've put too much on.. It's performing worse than MX-4 at the mo. 70'c load as opposed to 60-63'c with MX-4

Better to put more than not enough- Excess just squishes out till/or if you have enough pressure to reach the average particle size or aka your bond line thickness (BLT)

more likely than not something to do with sink contact

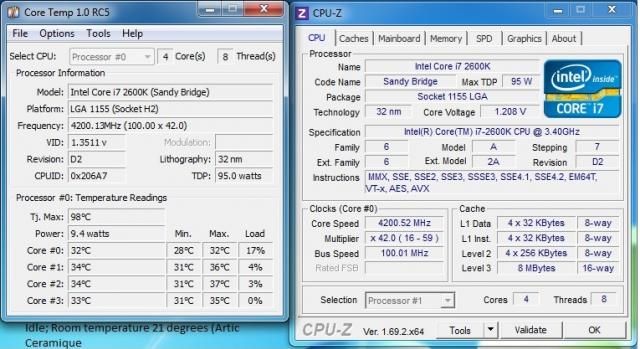

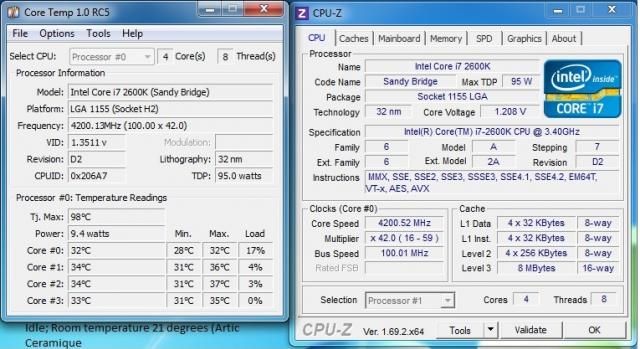

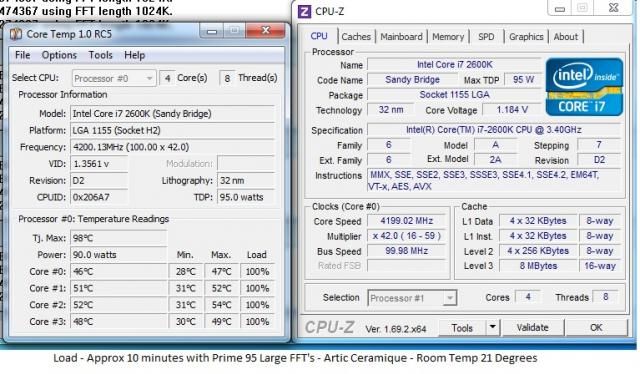

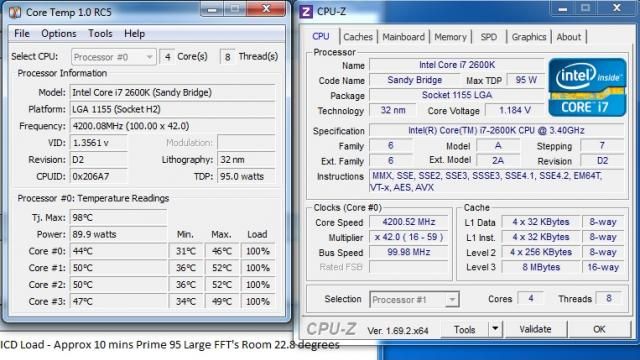

Hi Guys.

Sorry its taken me so long to post results, the reason I have taken such time is to try and make this as fair a test as possible - When I did my idle temps, my ambient room temp was around 21 degrees, the last week or so my room temp has been 25+ and not representative of the temperatures achieved by this paste.

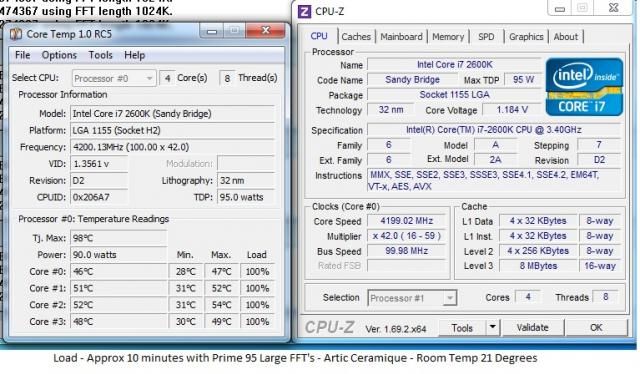

I used Prime 95, and large FFT's to load up my CPU core on both instances, and ran for approx 10 mins both occasions to attain consistency.

I have averaged out my temps for ease of reading.

------------------------------------------------------------------------------------

I-7 2600K, 4.2ghz @ 1.2v, EK Supreme HF CPU Block, AX360, D5,

Before Compound: Artic Ceramique

Ambient Temp: 21 Degrees

Idle Temp: 33 Degrees

Load Temp: 49 Degrees (10 minutes of Prime Large FFT's)

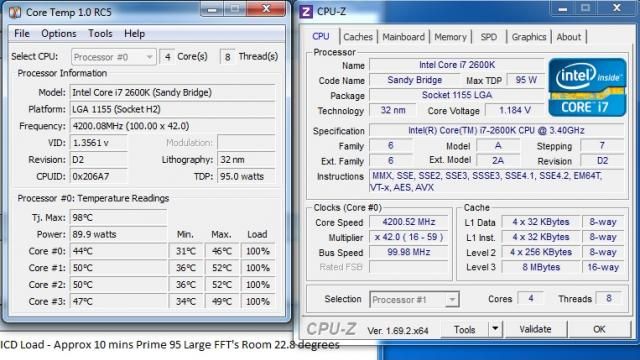

ICD/Perihelion

Ambient Temp:22.5

Idle Temp: 33.25

Load Temp:48.75

-------------------------------------------------------------------------------------------

Idle (Old paste)

Load (Old Paste)

ICD Idle

ICD Load

The ICD, wasn't particularly difficult to work with - I re-seated my CPU 3 times to ensure consistency, and the quantity used is without doubt essential to getting good temps.

All things considered, the ICD has made a difference of around 1-2 degrees (When the Ambient has been taken into consideration), and the difference is consistent with what others have been reporting, in so far as loaded temps are where the biggest gains are seen.

Thanks to Chris (Frostdragon) for the generous offer, and opportunity to test this Thermal Compound, I will use it again for sure.

Thanks,

-Vinny-

Sorry its taken me so long to post results, the reason I have taken such time is to try and make this as fair a test as possible - When I did my idle temps, my ambient room temp was around 21 degrees, the last week or so my room temp has been 25+ and not representative of the temperatures achieved by this paste.

I used Prime 95, and large FFT's to load up my CPU core on both instances, and ran for approx 10 mins both occasions to attain consistency.

I have averaged out my temps for ease of reading.

------------------------------------------------------------------------------------

I-7 2600K, 4.2ghz @ 1.2v, EK Supreme HF CPU Block, AX360, D5,

Before Compound: Artic Ceramique

Ambient Temp: 21 Degrees

Idle Temp: 33 Degrees

Load Temp: 49 Degrees (10 minutes of Prime Large FFT's)

ICD/Perihelion

Ambient Temp:22.5

Idle Temp: 33.25

Load Temp:48.75

-------------------------------------------------------------------------------------------

Idle (Old paste)

Load (Old Paste)

ICD Idle

ICD Load

The ICD, wasn't particularly difficult to work with - I re-seated my CPU 3 times to ensure consistency, and the quantity used is without doubt essential to getting good temps.

All things considered, the ICD has made a difference of around 1-2 degrees (When the Ambient has been taken into consideration), and the difference is consistent with what others have been reporting, in so far as loaded temps are where the biggest gains are seen.

Thanks to Chris (Frostdragon) for the generous offer, and opportunity to test this Thermal Compound, I will use it again for sure.

Thanks,

-Vinny-

- Joined

- 17 Mar 2014

- Posts

- 241

Well after fighting to get my cooler off and breaking off one of the mounting pins i now have some test results. Im happy with the results and reckon they might be even better if my cooler was held on with all four pins not just three!

Q6600 @ 3.45 ghz , 1.49v, arctic freezer 7 pro cooler.

Old paste was MX-4

Room temp 21c

Idle 46, 45, 42, 43

Load 95c+ on all cores before OCCT shut the stress test down in less than 5 min!

IC Diamond

Room temp 21c

Idle 40, 39, 37, 37

Load 72, 72, 69, 69

Over 20c drop in load temps!

Admittedly the paste was due a change but the load temps are still 10-15c lower than when i first built the system.

Paste was easy to apply after gentle armpit warming and i will definitely be using this on my new build.

Well after fighting to get my cooler off and breaking off one of the mounting pins i now have some test results. Im happy with the results and reckon they might be even better if my cooler was held on with all four pins not just three!

Q6600 @ 3.45 ghz , 1.49v, arctic freezer 7 pro cooler.

Old paste was MX-4

Room temp 21c

Idle 46, 45, 42, 43

Load 95c+ on all cores before OCCT shut the stress test down in less than 5 min!

IC Diamond

Room temp 21c

Idle 40, 39, 37, 37

Load 72, 72, 69, 69

Over 20c drop in load temps!

Admittedly the paste was due a change but the load temps are still 10-15c lower than when i first built the system.

Paste was easy to apply after gentle armpit warming and i will definitely be using this on my new build.

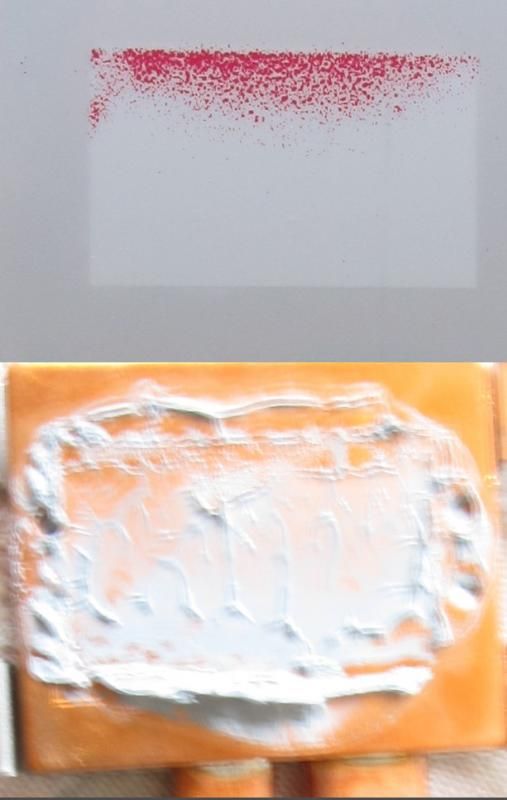

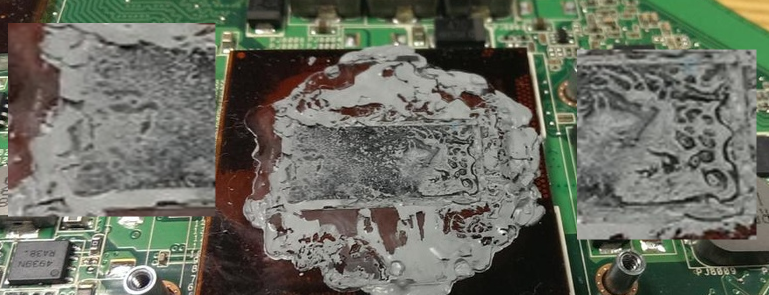

Hello there, with reference to the massive temperature differential you received. Whilst we are pleased with the performance of our product, we must also be honest and attribute much of the difference with the idea that possibly you have had thermal paste failure from your last compound.

When a thermal paste failure occurs is for the reason that the liquid in the product has evaporated and the compound itself has expanded OUT of the actual contact area. This is in effect a VOID in the aforementioned area and thus performance loss. This is even more of an issue in higher heat environments such as a LAPTOP/Notebook or a graphics card.

Note the dry compound on this asus ATI card

Please note: the two dark scratch lines were done by my finger nail as the compound was actually DRY. THe lighter one on the lower part of the GPU core is a void. In addition one can see

This is part of our message to consumers and pro-overclockers is that PERFORMANCE is only one half the equation and RELIABLITY is the next part. With some pastes one has to re-apply the TIM after a year in order to counter the perofmance loss as the liquid is simply evaporated. This then creates the void as seen above.

With ICD the reliability and performance over time is MUCH greater (subject to adequate contact and pressure)

Hope this helps.

Regards

Frost Dragon

Last edited:

- Joined

- 17 Mar 2014

- Posts

- 241

Here are my CPU results:

- 3570k @ 4.5GHz, 1.25v

- GTX 770

- Fractal Define R3

- TRUE Cooler + Scythe Gentle Typhoon

Ambient temps for both results: 23.5c

Before:

Old paste, probably not in best condition at this point and needed reapplying.

After

Followed instructions (small pearl in middle)

Conclusions:

Apologies for forgetting to do idle temps, imo they are not very important to see anyway. At load using Prime95, the new paste knocked off roughly 6-7c over all the cores - big results, and this is directly after install. Will likely do my GTX770 in the next few days, too. Thanks to Frostdragon for sending the paste!

Good old 'Tried, Tested and True' IC-Diamond!'

These are the kind of results we have come to expect, the more wattage that is put through the CPU, the gap differential widens!

Reliable tried and tested

Frost Dragon

Soldato

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

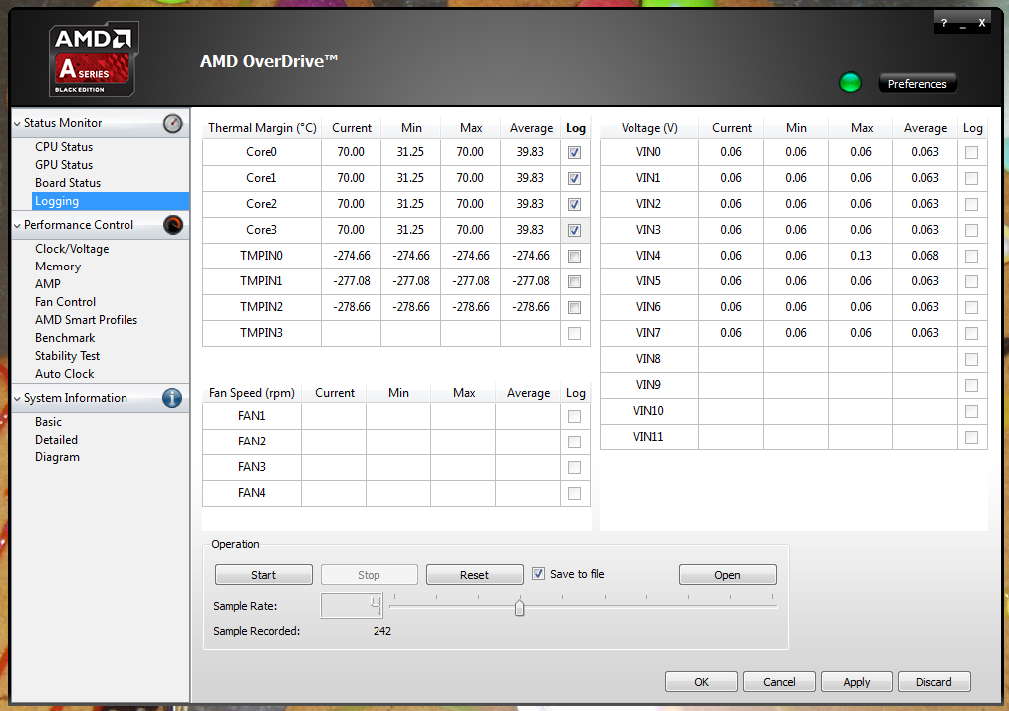

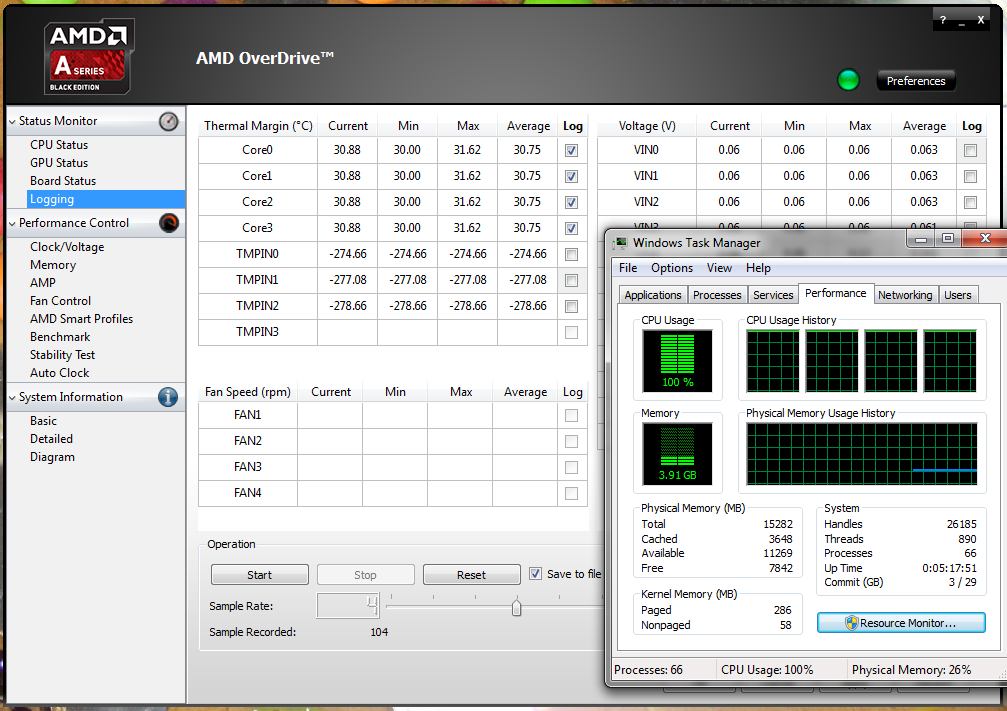

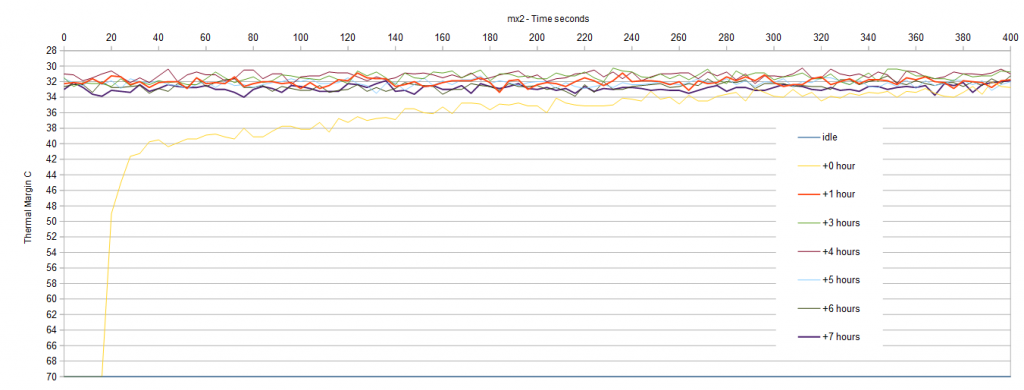

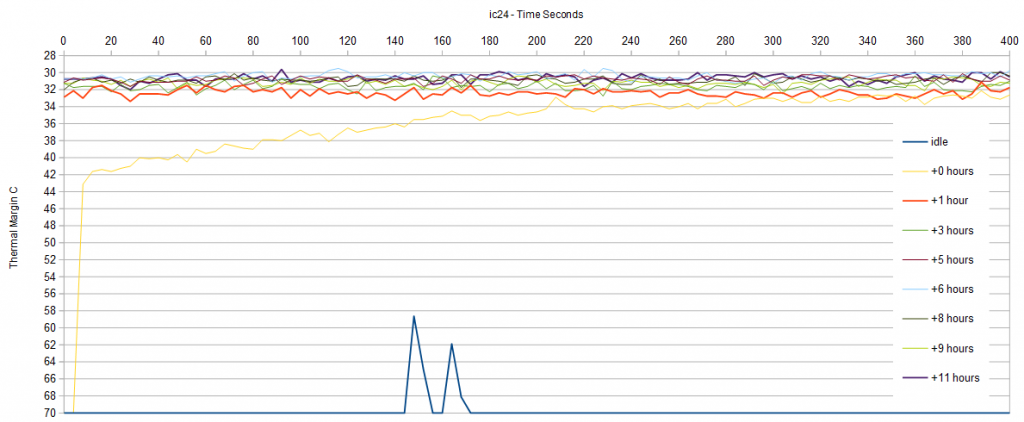

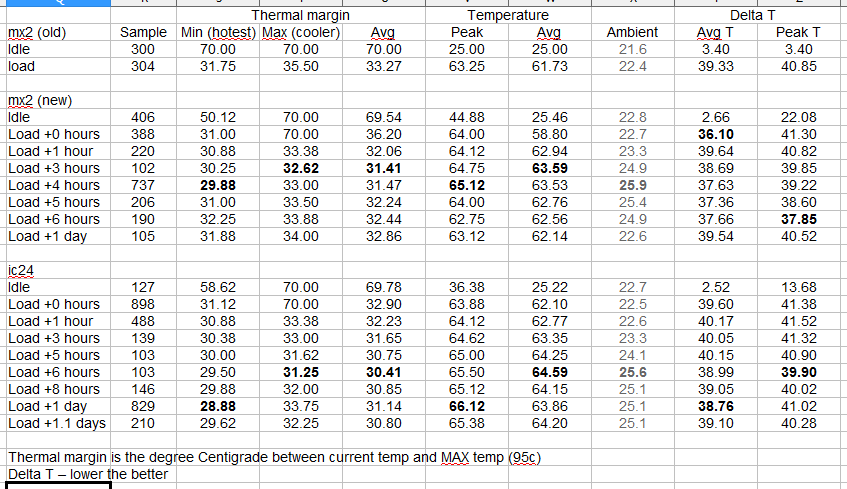

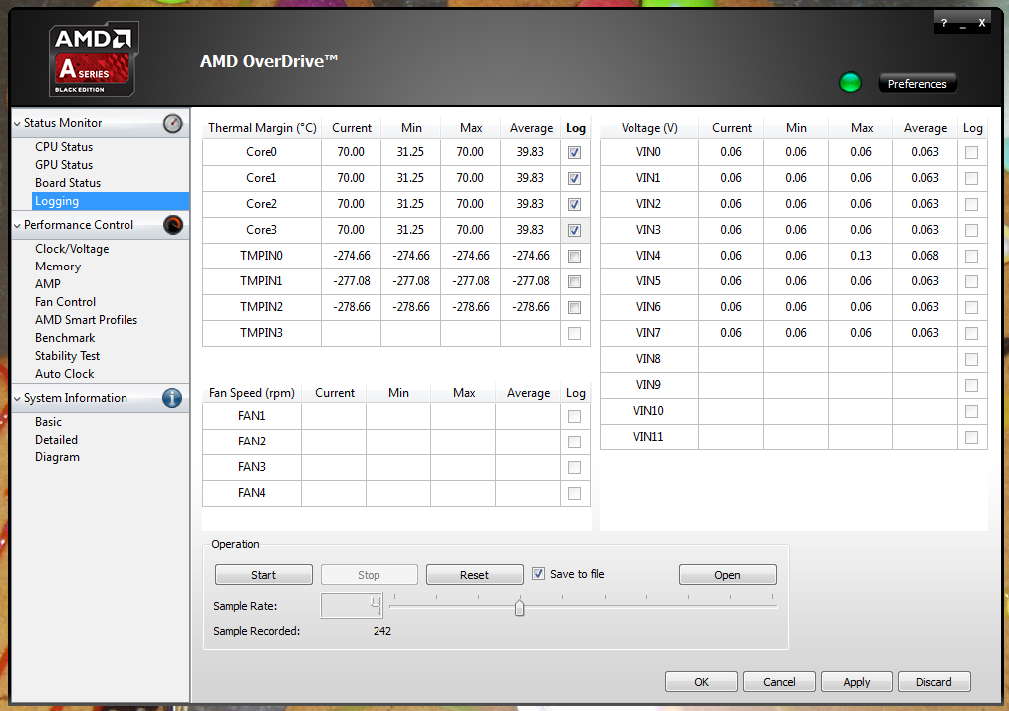

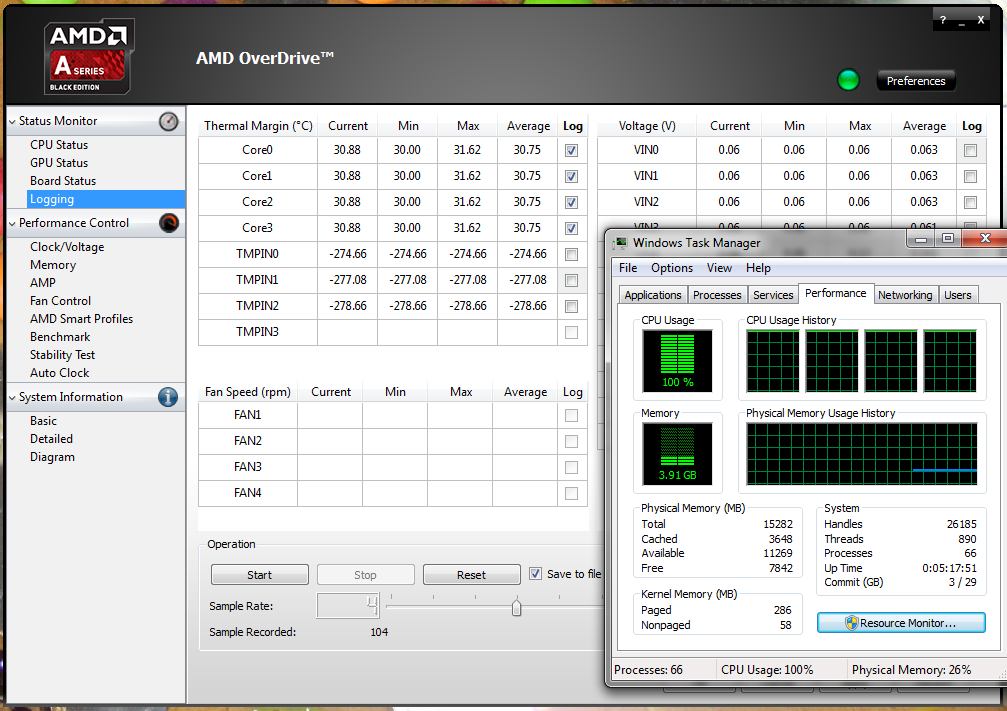

5800k (trinity) Cooled by a NH-U12F with a TY-140 @ 7volts

As AMD overdrive reports thermal margin (not actual temps) on APU's I've used this.

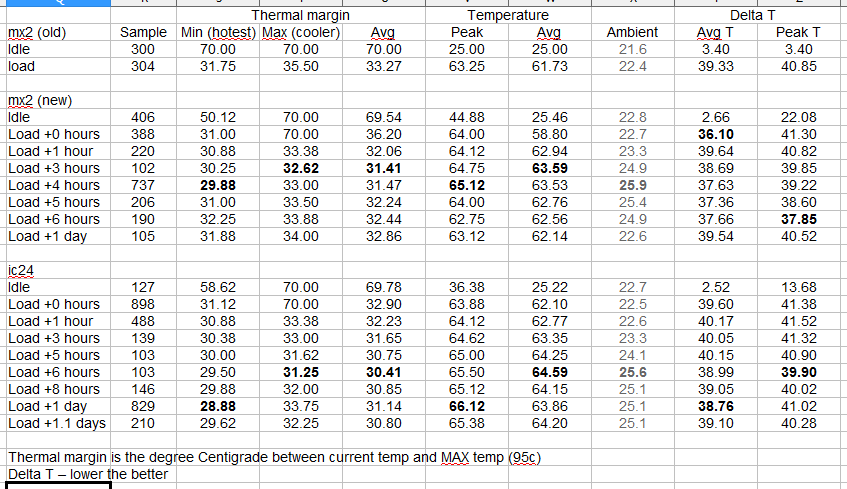

I've converted it in the table of results based on a 95c throttle, typical screen shots below.

MX2 at 6 hours

ICD at 5 hours

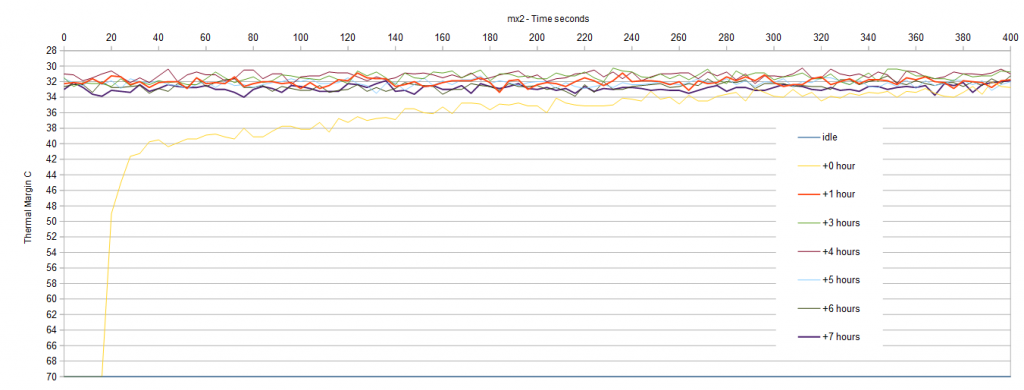

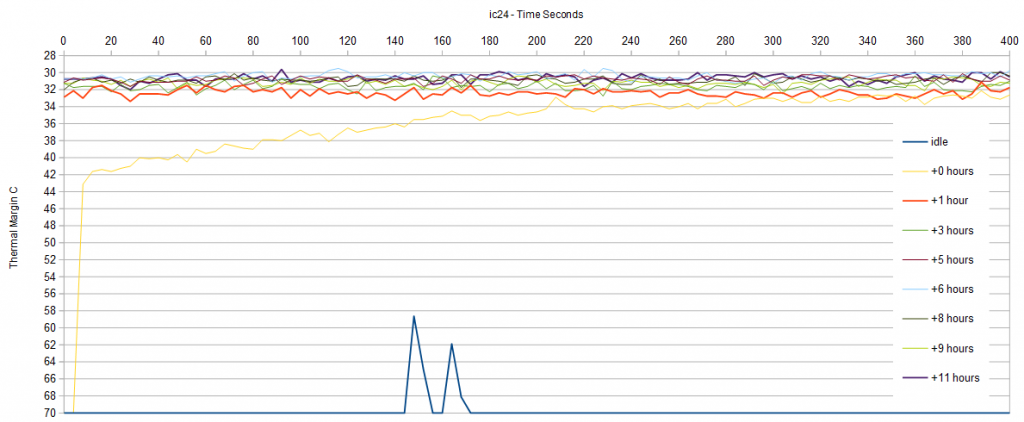

Consecutive 100 sample grab of Raw data show in graph form

Most samples were larger, but 100 (or 400 seconds) make a neat graph)

MX2 (as you would expect)

ICD (looks like it getter worst - but ambients temps rose)

Table of results

Clear drop in ICD delta T from 41.5ish to 40ish after 5 hours of full load temps.

New application of MX2 is better that 6 month old application

No 2-3c drop in temps that other have reported.

As AMD overdrive reports thermal margin (not actual temps) on APU's I've used this.

I've converted it in the table of results based on a 95c throttle, typical screen shots below.

MX2 at 6 hours

ICD at 5 hours

Consecutive 100 sample grab of Raw data show in graph form

Most samples were larger, but 100 (or 400 seconds) make a neat graph)

MX2 (as you would expect)

ICD (looks like it getter worst - but ambients temps rose)

Table of results

Clear drop in ICD delta T from 41.5ish to 40ish after 5 hours of full load temps.

New application of MX2 is better that 6 month old application

No 2-3c drop in temps that other have reported.

Last edited:

Associate

- Joined

- 7 Dec 2010

- Posts

- 223

hi ive been using ic for about a while now, ive been using it on my old gtx 680's since they were released, also on my old i7 920 since release, what i wanted to know was how long will it last also how often to replace it.

thanks

ricky

Depends

Results will vary with avg. temperature loads but is more critically dependent on the quality of the contact and pressure.

What happens in a light contact situation is that the compound in contact is overly stressed as at those limited points of contact transferring most of the heat through those points.

With full contact the heat transfer is spread over a wider area so hence less stressed.

Below user example is a notebook failure of MX-4 which lasted 6 months after replacing the stock compound which lasted only four months. ICD then applied and after a year of light use failed.

Another user with + 60% contact has four years ICD on a notebook with no change. So C/P as well as average heat load are the primary limiting factors.

Interesting that the stock paste impression matches the C/P paper impression.

Contact here is only about 20% hence the early failure

You can see the processor line edge at the top and where the paste is thin matches the contact paper area showing the same contact.

From the thickness of the paste I would guess a gap of about .003 -.005 on the far edge. Likely the sink is flat but has a little convex bow in the heat pipe when installed.

Holding tolerances on multiple bends and twists is problematic for the manufacturer, just the nature of the beast.

Like any liquid it follows the path of least resistance hence the accumulation opposite the contact side.

MX4 at 6 months from same user/laptop, note the void formation

The process of reliability here is that with a tight particle distribution along with decent pressure/contact you create an airtight "Gasket" type seal retarding liquid loss and preventing oil oxidation and then increasing the life of the application. This is combined low liquid content (high bulk Loading) eliminating void formation with pump out and bake out type failures

An example of this Gasket type seal can be noted in an example provided where the end user introduced a copper slug to increase C/P on a notebook and the result is after 9 months use.

Note in the contact area the compound is still liquid while the compound exterior to the joint shows signs of ageing.

Last edited:

Associate

- Joined

- 7 Dec 2010

- Posts

- 223

Generally when you observe thermal compound comparisons you will sometimes note little difference between results due to mitigating factors that tend to homogenize the results.

We have had this tested a number of times by end users as can be observed in the chart below with IC Diamond compared with a variety of compounds. Observe in the chart below Data Point# 4 the average surface area of these IHS's was around 1.7 inches. So @ . 09 in. contact area and 38 lbs. pressure there was no measured temperature difference at that C/P combination between compounds.

The difference then between individual user compound test results can be noted as differences in C/P and also pretty well explains why on some HW sites where most results are only within a degree or two.

For comparison here are MX 2 tests vs IC Diamond taken by end users on multiple forums as there seems to be some number of MX users on this forum and so makes a familiar comparison.

We have had this tested a number of times by end users as can be observed in the chart below with IC Diamond compared with a variety of compounds. Observe in the chart below Data Point# 4 the average surface area of these IHS's was around 1.7 inches. So @ . 09 in. contact area and 38 lbs. pressure there was no measured temperature difference at that C/P combination between compounds.

The difference then between individual user compound test results can be noted as differences in C/P and also pretty well explains why on some HW sites where most results are only within a degree or two.

Contact And Force Charts - In the two charts below from selected test data you will note that when contact area increases temperatures drop and when force increases temperatures also drop, the two parameters are inextricably linked to performance.

For comparison here are MX 2 tests vs IC Diamond taken by end users on multiple forums as there seems to be some number of MX users on this forum and so makes a familiar comparison.

Here are some results on my main pc.

i5-3570k-4.3GHz

GTX 570 (looking to upgrade soon lol)

Bitfenix Prodigy

With stock paste.

With ICD24 paste

Now on to the Gainward GTX 570 Phantom

Stock paste that shipped with the card

With ICD24 paste

Ambient temps were maintained throughout the tests at 24c.

Also will have some more results posted of laptop and htpc later on next week when I find some time to do so! Thanks again frostdragon

i5-3570k-4.3GHz

GTX 570 (looking to upgrade soon lol)

Bitfenix Prodigy

With stock paste.

Idle: 34 35 34 36

Load: 70 71 73 74

Load: 70 71 73 74

With ICD24 paste

Idle: 32 34 33 34

Load: 67 69 71 73

Load: 67 69 71 73

Now on to the Gainward GTX 570 Phantom

Stock paste that shipped with the card

Idle:38

Load:68

Load:68

With ICD24 paste

Idle:34

Load:66

Load:66

Ambient temps were maintained throughout the tests at 24c.

Also will have some more results posted of laptop and htpc later on next week when I find some time to do so! Thanks again frostdragon

Got my paste today, However they said it was missing 20p postage so i had to pay the 20p and then £1 handling fee by Royal Mail lol.

So stupid.

Photo here: https://www.dropbox.com/s/1mnirv1rmf1dl8n/2014-06-07 12.28.36.jpg

Will do some tests soon.

Same as me then.

Still a tube of IC Diamond for £1.20 is a bit of a bargain.

Sadly at the moment I'm only able to snatch the odd 5mins to myself at the moment, certainly not enough time to spend a day testing. Unfortunately I'm trying to squeeze 18 months of wedding planning into 8 weeks. The wedding is for my sister and her fiance and extenuating circumstances have forced them to bring the wedding forward so I've been drafted in.

I will endeavor to put an afternoon aside soon to get it done but I can't make a promise

A placeholder here just to let you know I have done a rebuild and used MX-4 on one Titan and IC-Diamond on the other, as well as IC-Diamond on the 3930K. I am letting the paste settle, as I only finished the build on Friday but will be giving a full review after some proper testing tomorrow. Just to say, so far so good for the IC-Diamond

All water cooled for reference.

Also had to pay £1.20 but I am not fussed about that

All water cooled for reference.

Also had to pay £1.20 but I am not fussed about that

I have now done some full testing on my system and benched 2 games with some before and after results. I am running a pair of Titans coupled with a 3930K and for the purpose of testing, all settings were on 1.38V for the CPU (4.6Ghz) and 1.3V for each of the Titans. Previously, Arctic Silver was used on both GPUs and CPU. My ambients before were 23c and todays testing was 24c, so slightly warmer.

Here is my results on Batman Arkham Origins from before I redid the TIM.

And here is my results with the CPU and top GPU being on IC-Diamond and the bottom GPU is on MX-4.

And these are the results for Tomb Raider.

Arctic Silver 5 on everything

And again with the CPU and top GPU on IC-Diamond and the bottom GPU on MX-4

As you can see, there is a 7 degree difference on the GPUs in Batman Arkham Origins, with temps being hotter and the ambients being cooler than before switching to IC-Diamond. The difference between top GPU and bottom GPU is now only 4 degrees. The CPU is 8 degrees cooler than before as well. Very impressive.

The same is also true with Tomb Raider and you can clearly see the difference in temps. 43c and 51c was the previous temperatures but when switched to the IC-Diamond, temps dropped to 39c and 42c. This is outstanding and the CPU has gone from 57c to 34c. Remember that all the tests were done under the same conditions and the ambients were slightly warmer (if only by 1c) before on Arctic Silver 5.

I have also heard great things about MX-4, so hence my reasoning for testing it on the bottom GPU but I can safely say I will be using IC-Diamond from now on. Great stuff. If I had a griped with it, it would be the thickness of the paste and it isn't the easiest to spread but for results, it is unmatched.

Here is my results on Batman Arkham Origins from before I redid the TIM.

And here is my results with the CPU and top GPU being on IC-Diamond and the bottom GPU is on MX-4.

And these are the results for Tomb Raider.

Arctic Silver 5 on everything

And again with the CPU and top GPU on IC-Diamond and the bottom GPU on MX-4

As you can see, there is a 7 degree difference on the GPUs in Batman Arkham Origins, with temps being hotter and the ambients being cooler than before switching to IC-Diamond. The difference between top GPU and bottom GPU is now only 4 degrees. The CPU is 8 degrees cooler than before as well. Very impressive.

The same is also true with Tomb Raider and you can clearly see the difference in temps. 43c and 51c was the previous temperatures but when switched to the IC-Diamond, temps dropped to 39c and 42c. This is outstanding and the CPU has gone from 57c to 34c. Remember that all the tests were done under the same conditions and the ambients were slightly warmer (if only by 1c) before on Arctic Silver 5.

I have also heard great things about MX-4, so hence my reasoning for testing it on the bottom GPU but I can safely say I will be using IC-Diamond from now on. Great stuff. If I had a griped with it, it would be the thickness of the paste and it isn't the easiest to spread but for results, it is unmatched.

Permabanned

- Joined

- 19 Jul 2012

- Posts

- 4,722

- Location

- Buckinghamshire

Hey greg. I bought some IC Diamond 24k in dec, but haven't used it. Been using MX-4 for CPU. IC Diamond isnt conductive is it? Also I use a little grain size blob on cpu and let the heat spread the paste? Whats the best for IC Diamond? Grain size blob or do I spread paste?

Cheers mate

Cheers mate

Last edited: