Soldato

- Joined

- 19 Oct 2002

- Posts

- 18,505

- Location

- Shakespeare’s County

Its basically the same principals then as polishing and porting the intake and exhaust ports no? To increase the airflow and reduce air turbulence?

Thats focus'ed on getting air out of the engine, the exhaust manifold on a turbo should really be focus'ed on getting more fresh air INTO the engine.

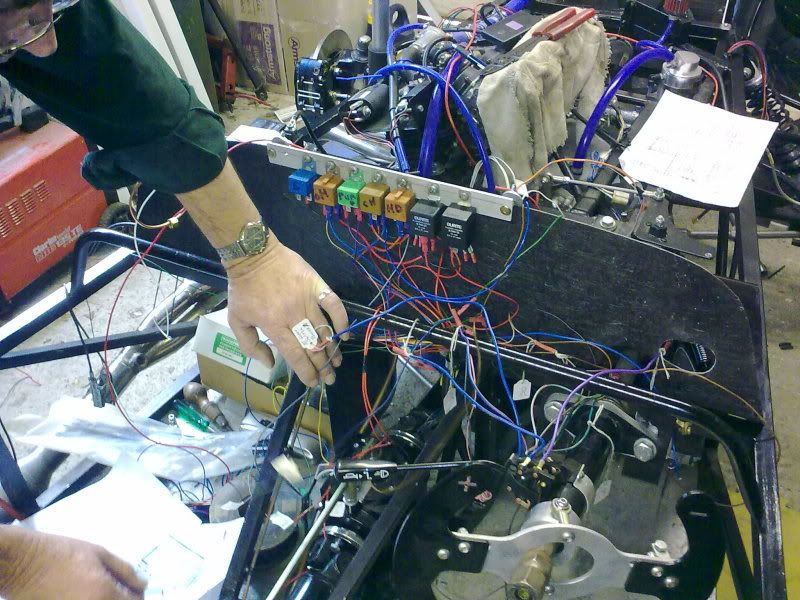

Spent a fun 2 hours driving round the industrial estate trying to find the correct pitch bolts to mate the cradle to the engine block lol

Spent a fun 2 hours driving round the industrial estate trying to find the correct pitch bolts to mate the cradle to the engine block lol