Soldato

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

I started this project some time ago with only one three hour slot a week put aside

to work on the build. To be honest that's not fare on the reader, so now I'm nearly finished

I'm rewriting it into 3 sections.

1) Clean Installation.

2) Loop Evolution

3) Enclosed Colouration.

All three have their own separate intertwined stories and reasons within by build.

And over the time it's taken me to finish, the bias of the three has shifted more

than once. But enough of the waffle here's where i am now.

Case: Lian Li S80B

Motherboard:GA-P45T-EXTREME

CPU: E8200ES

Ram: 4Gb G.Skill Ripjaw

PSU: Yestico 550-FL (Fanless)

GPU: Sapphire 3870 (blue pcb)

Boot drive: 2 x samsung slc ssd's RAID

Data drive: WD Black

Media drive: Seagate Barracuda

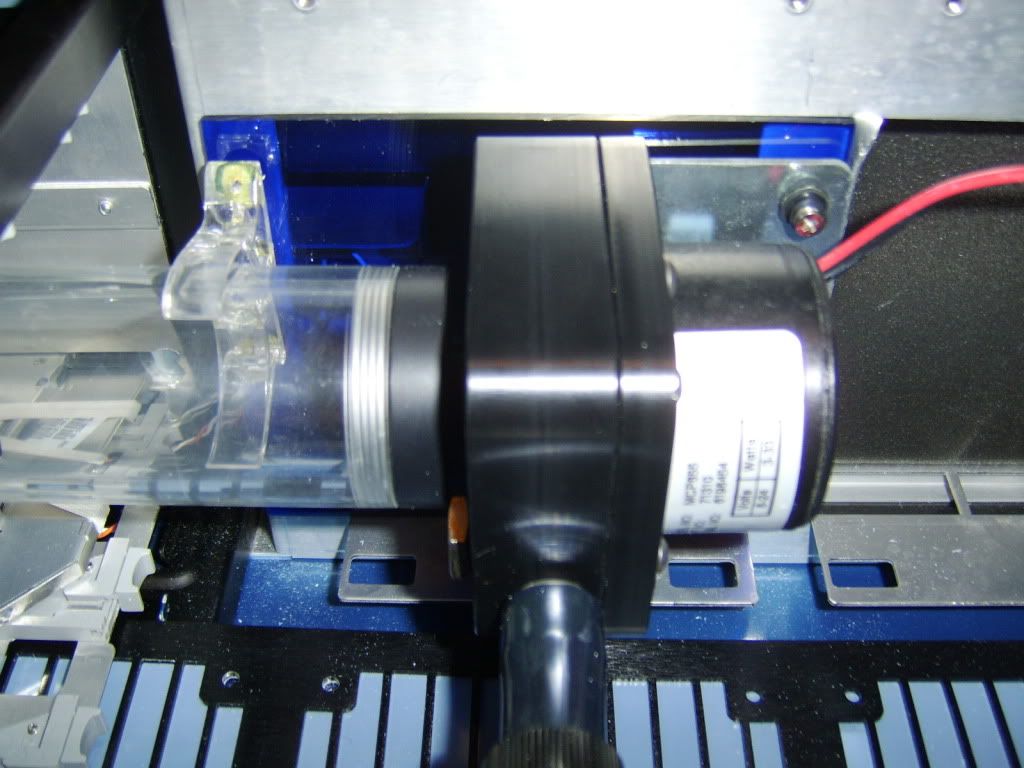

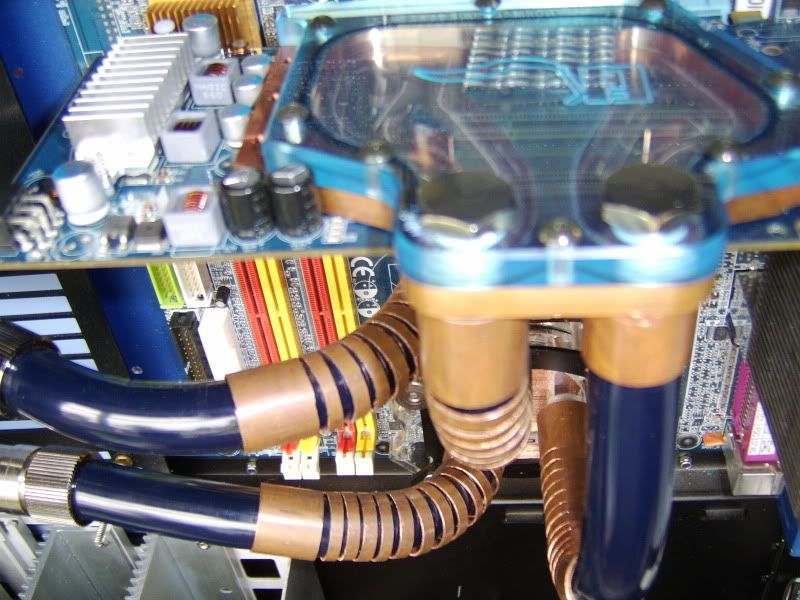

Pump: D5 with EK rev2 X-Top

Block: Xspc Edge with EK top supreme top plate

Block: EK full cover 3870 blue edition

Block: EK NB

Rad: Thermochill PA120.3

Tube: Feser black UV

Barbs: Primochill ghost (1/2 inch metal version)

QC's: Koolance VL4 (extreme flow)

Clean installation

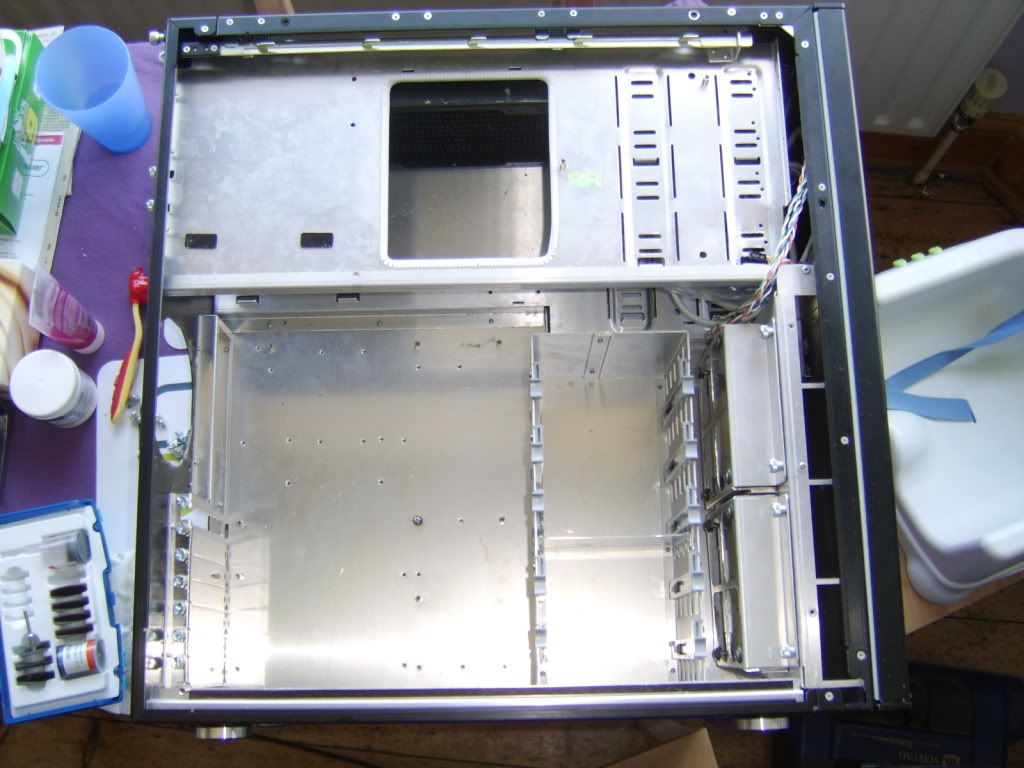

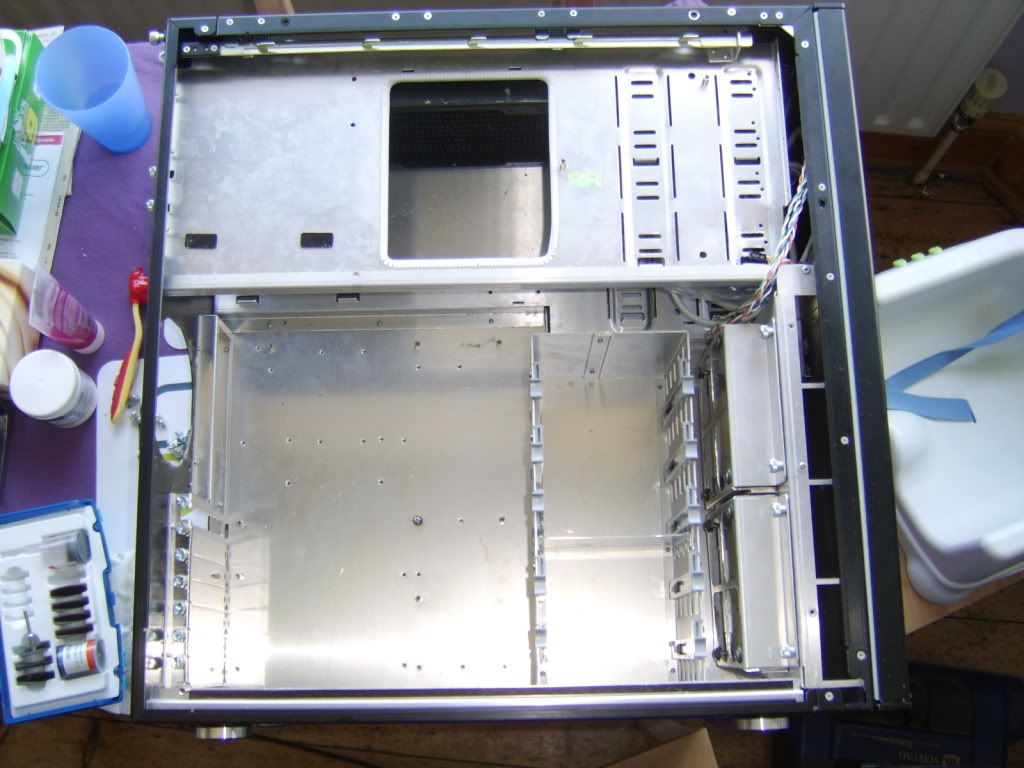

The S50 is a large case without much room. And very little cable management.

It is equipped with three 120mm fan spaces which is rare for a case of this age.

But its sound reduction features all use up space. The double box takes 40mm off its width.

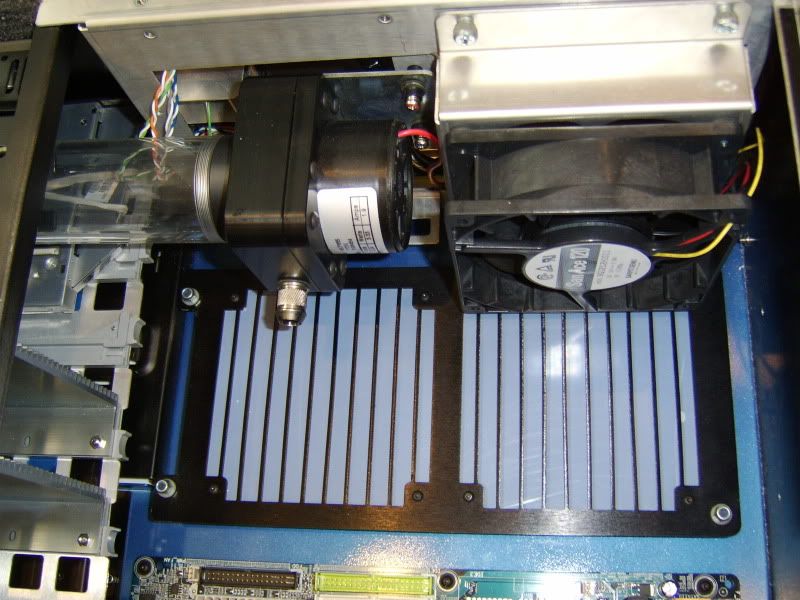

And the enormous void above the psu is just crying out to have a 120.2 or larger rad installed.

However if a triple is used then you lose optical bays. At lease two is not three of the four.

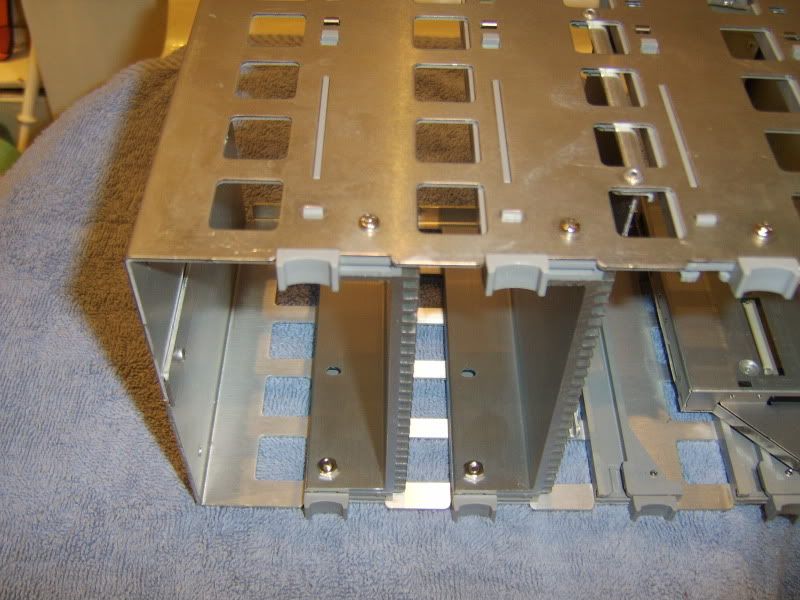

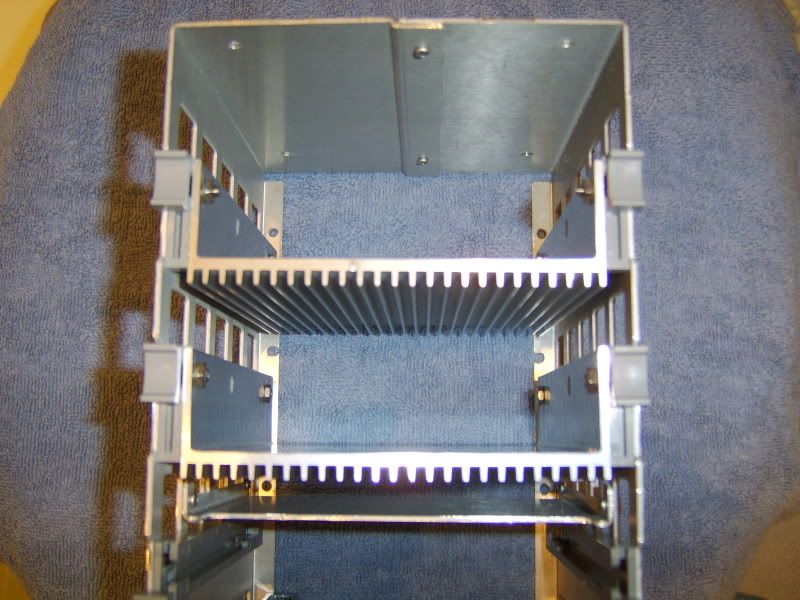

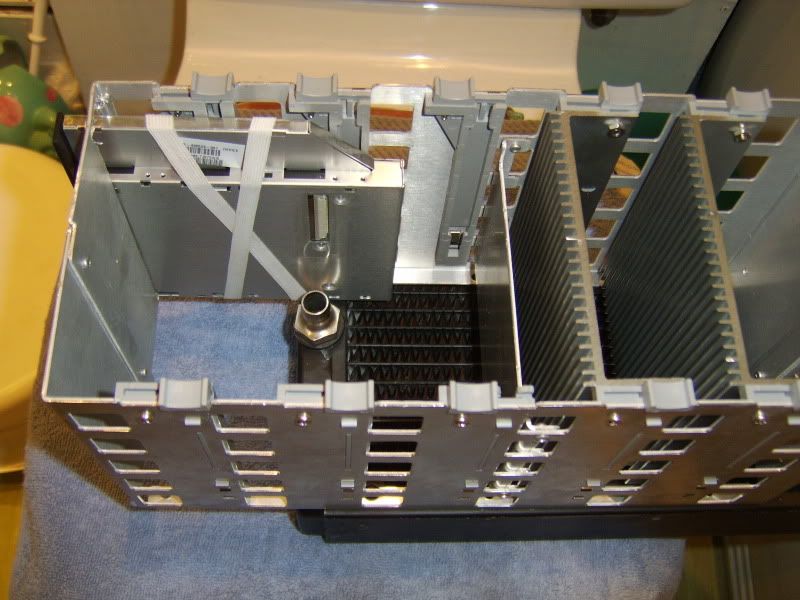

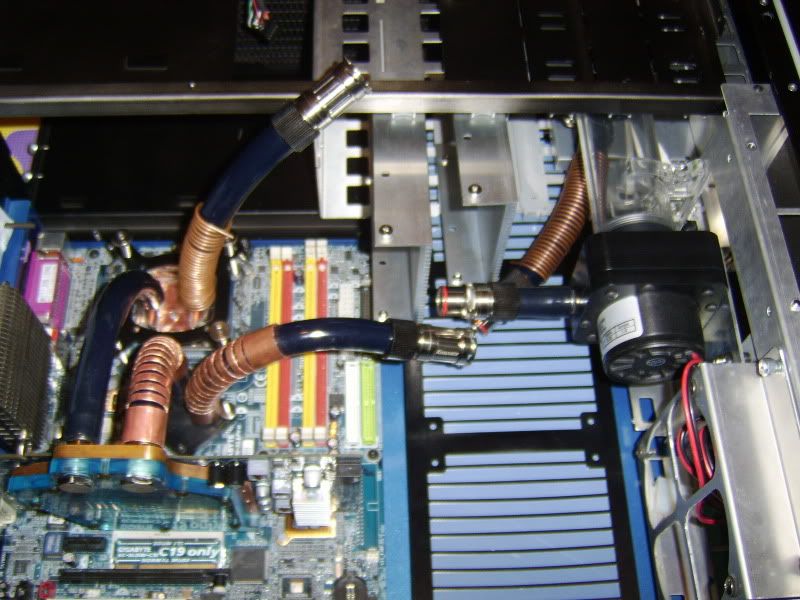

internal panels removed to show internals and PA in roof

Striped down

I couldn't not have a dvd drive and a normal one just would fit with my loop layout what ever i did,

but it was then that i considered a slimline laptop drive. This would fit if mounted with the tray vertical, like a wii.

[image coming soon]

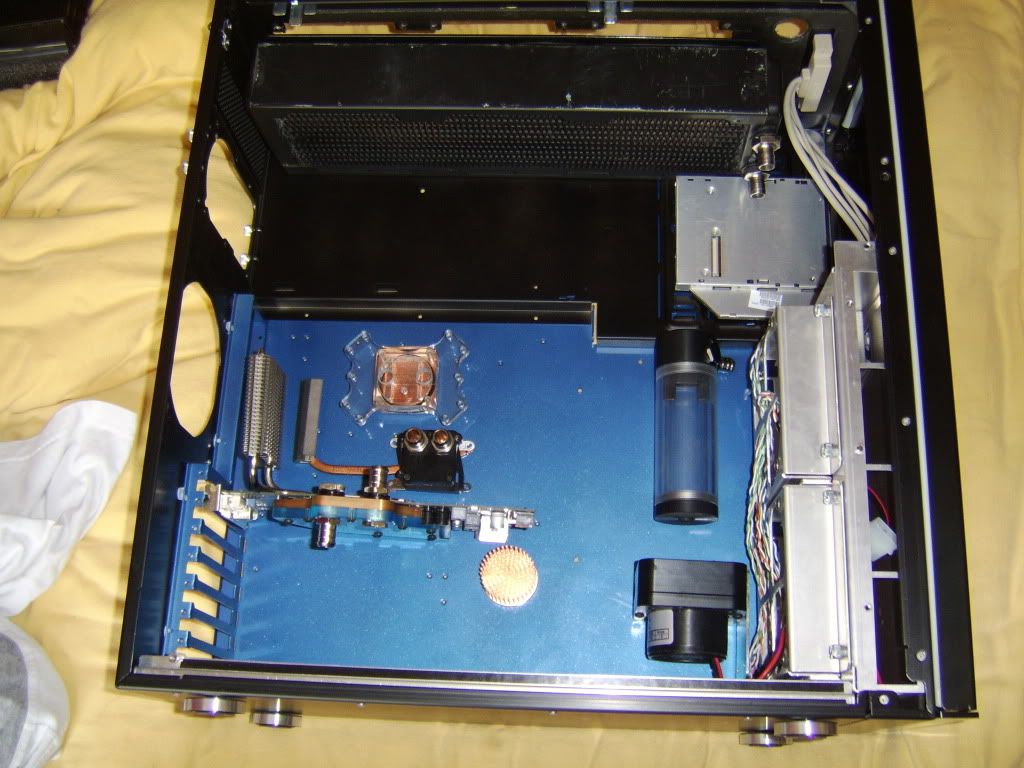

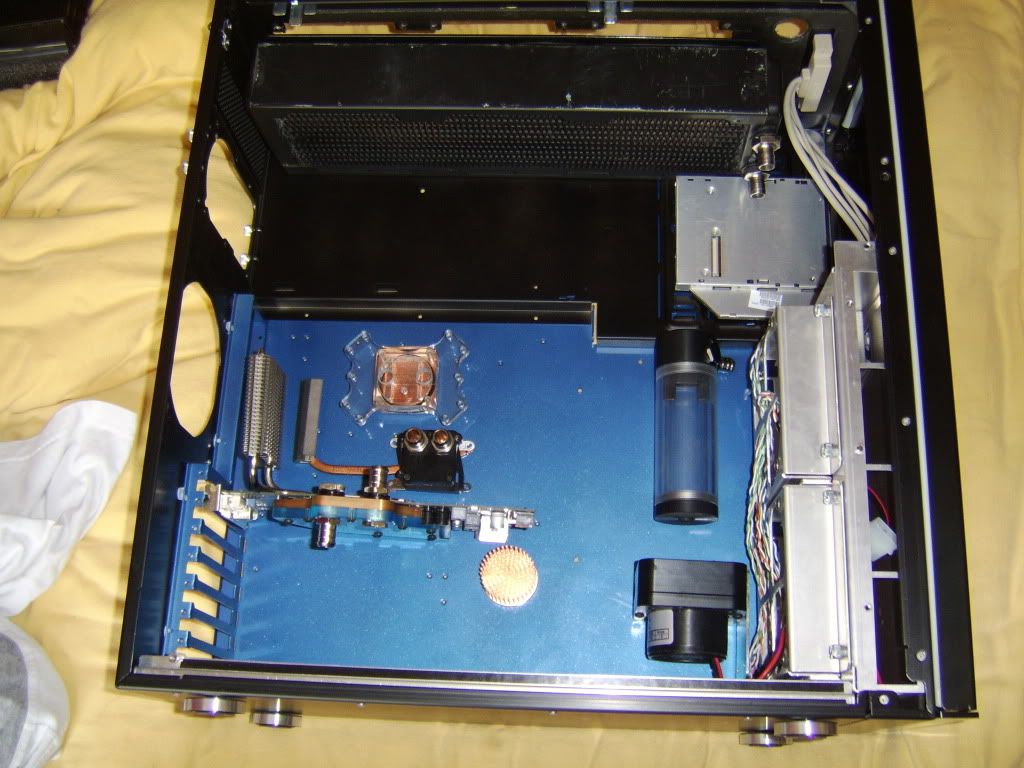

My first option was to use some foam and bungee it to the side.

This worked, but as the design progressed this changed into it being mounted into the hdd rack

in it's now location. This was moved early on to improve air and water flow.

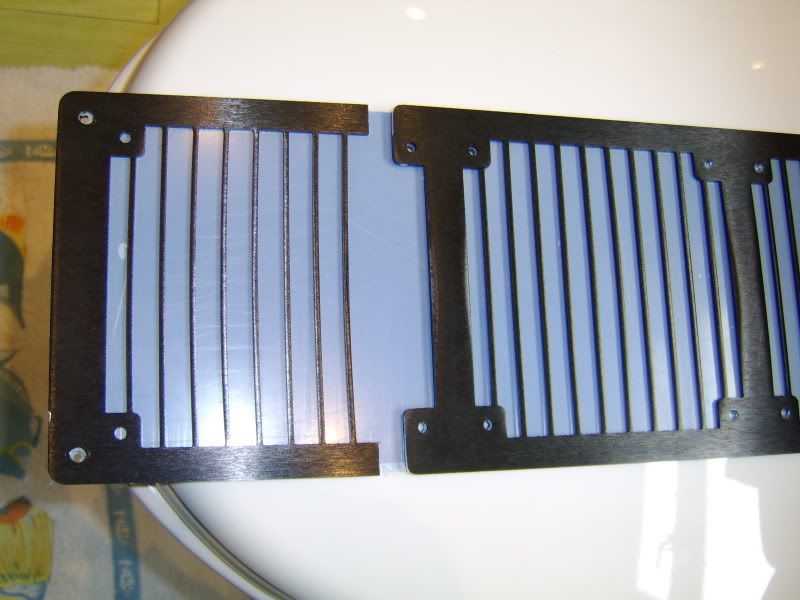

Early mock up

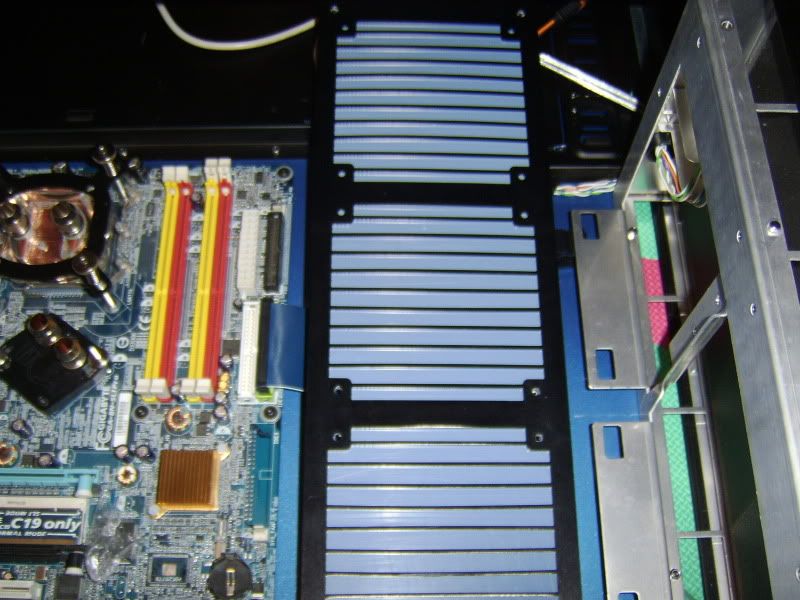

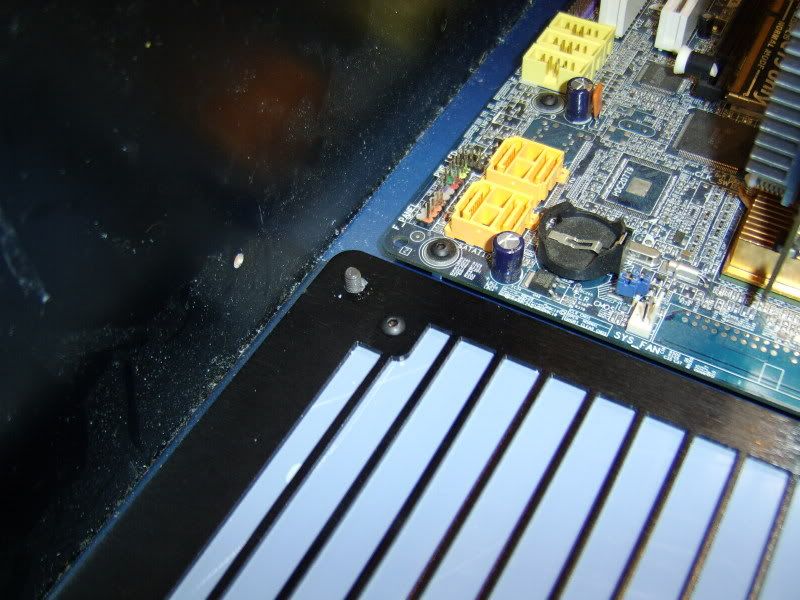

after painting case reasembled with nylock nuts and button head allen bolts

to work on the build. To be honest that's not fare on the reader, so now I'm nearly finished

I'm rewriting it into 3 sections.

1) Clean Installation.

2) Loop Evolution

3) Enclosed Colouration.

All three have their own separate intertwined stories and reasons within by build.

And over the time it's taken me to finish, the bias of the three has shifted more

than once. But enough of the waffle here's where i am now.

Case: Lian Li S80B

Motherboard:GA-P45T-EXTREME

CPU: E8200ES

Ram: 4Gb G.Skill Ripjaw

PSU: Yestico 550-FL (Fanless)

GPU: Sapphire 3870 (blue pcb)

Boot drive: 2 x samsung slc ssd's RAID

Data drive: WD Black

Media drive: Seagate Barracuda

Pump: D5 with EK rev2 X-Top

Block: Xspc Edge with EK top supreme top plate

Block: EK full cover 3870 blue edition

Block: EK NB

Rad: Thermochill PA120.3

Tube: Feser black UV

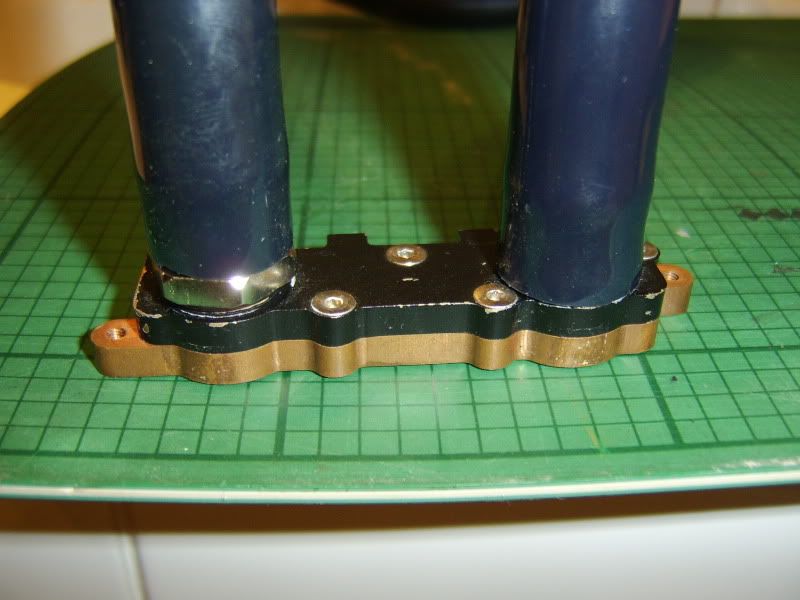

Barbs: Primochill ghost (1/2 inch metal version)

QC's: Koolance VL4 (extreme flow)

Clean installation

The S50 is a large case without much room. And very little cable management.

It is equipped with three 120mm fan spaces which is rare for a case of this age.

But its sound reduction features all use up space. The double box takes 40mm off its width.

And the enormous void above the psu is just crying out to have a 120.2 or larger rad installed.

However if a triple is used then you lose optical bays. At lease two is not three of the four.

internal panels removed to show internals and PA in roof

Striped down

I couldn't not have a dvd drive and a normal one just would fit with my loop layout what ever i did,

but it was then that i considered a slimline laptop drive. This would fit if mounted with the tray vertical, like a wii.

[image coming soon]

My first option was to use some foam and bungee it to the side.

This worked, but as the design progressed this changed into it being mounted into the hdd rack

in it's now location. This was moved early on to improve air and water flow.

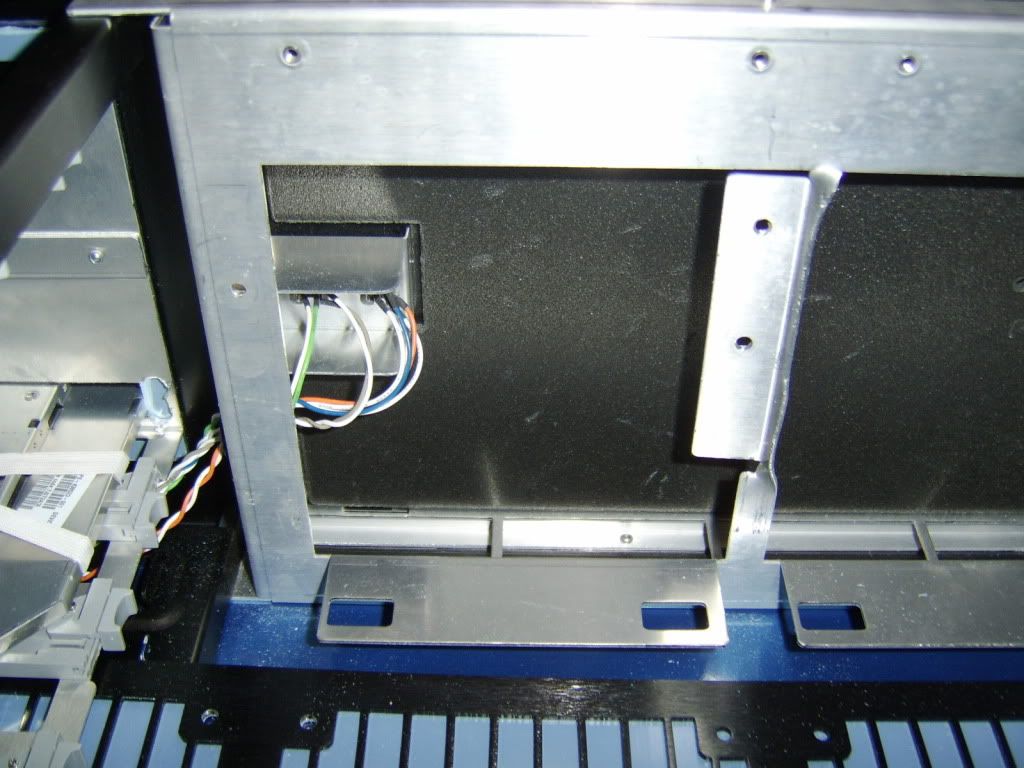

Early mock up

after painting case reasembled with nylock nuts and button head allen bolts

Last edited: