You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project Dianoga

- Thread starter ALXAndy

- Start date

More options

Thread starter's postsIronic that the o-rings on the barbs you didn't want match your colour scheme! I'm with you on disliking barbs though. Compression fittings are much neater and less fiddly.

Aye and it will probably be even more ironic that I only end up needing two

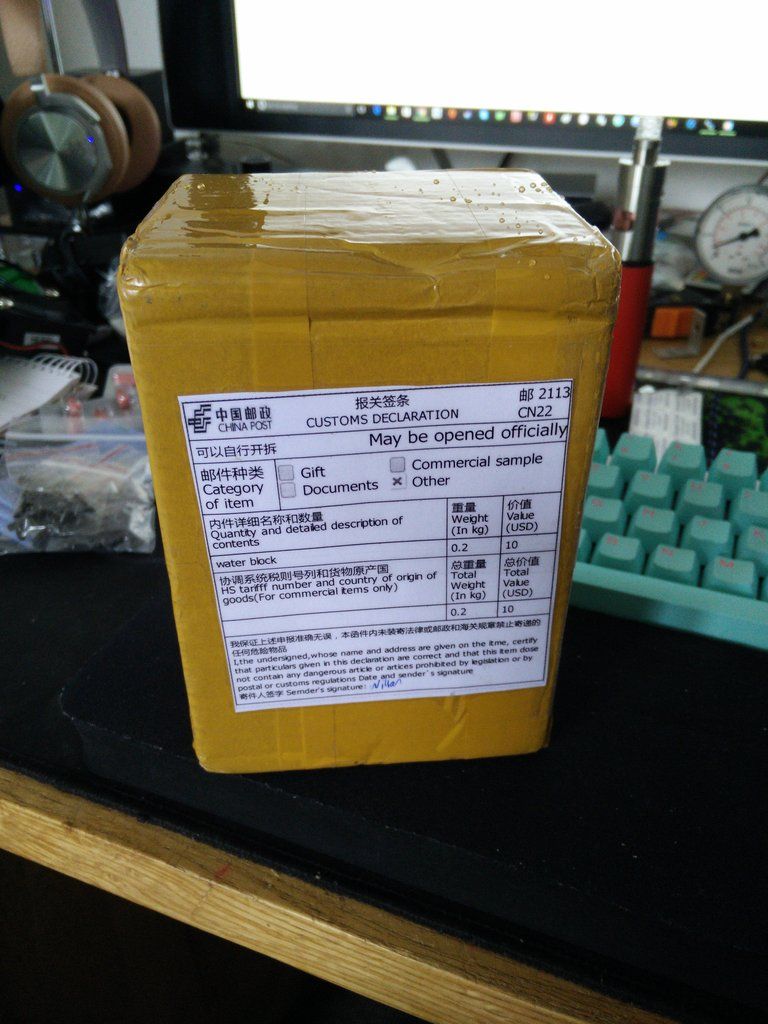

I think I'm covered on the rest. Forgot to mention that I got two other parcels today. One contained the fittings I needed to use the ball valve.

And the other contained about 200 M3 bolts in black. These are what I am supposed to be using to hold the huge mobo plate down with etc. They are black button type.

Must say it's kinda fun assembling water cooling parts. Kinda like Lego. I guess that's why a lot of people enjoy water cooling, and not because they have had to work themselves ragged forcing a ten year old case to do what it wasn't supposed to

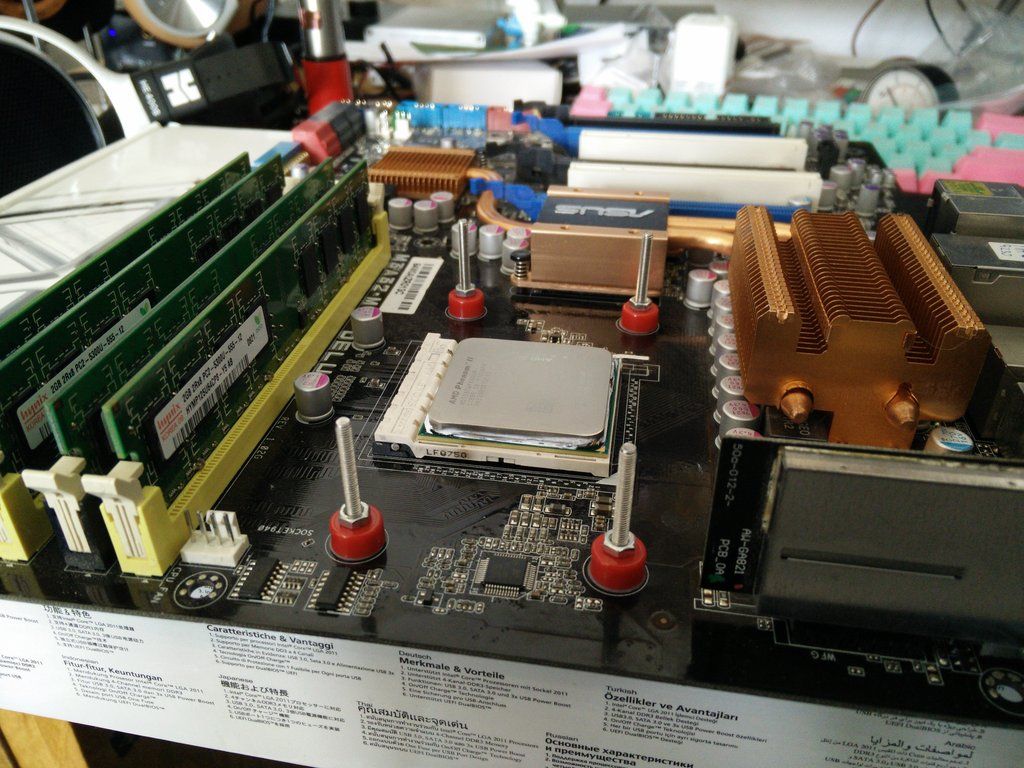

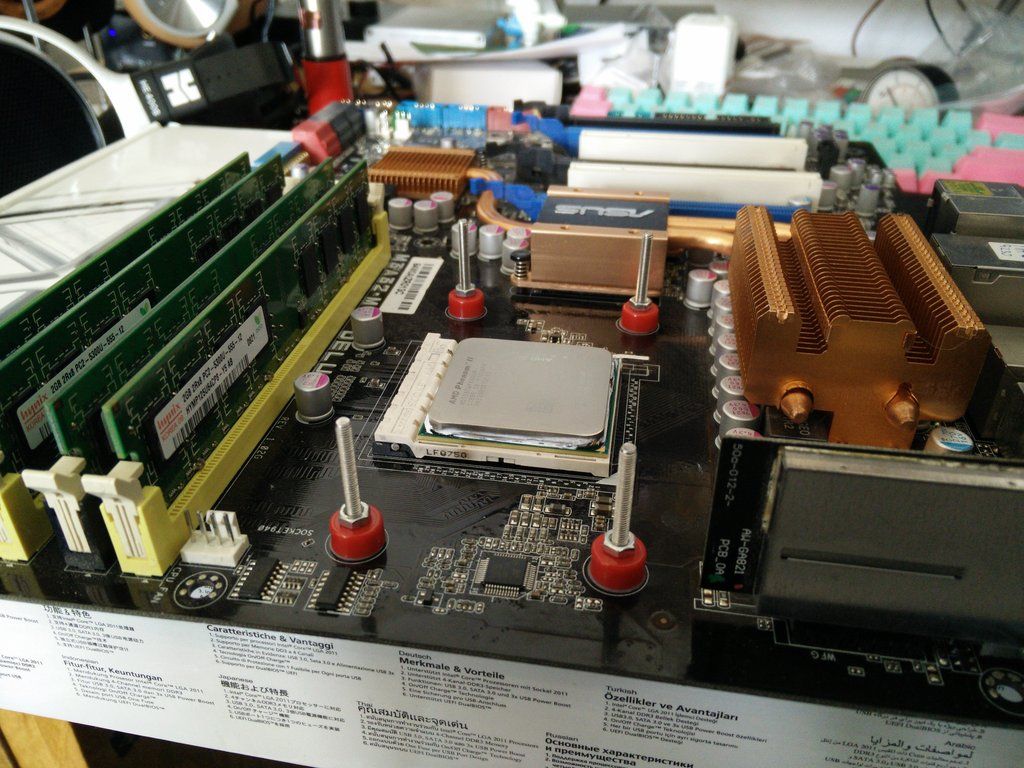

So earlier I got the board out and test fitted both the GPU and the NIC cards. I did this so that I could get exact actual measurements for the board parts I need to make.

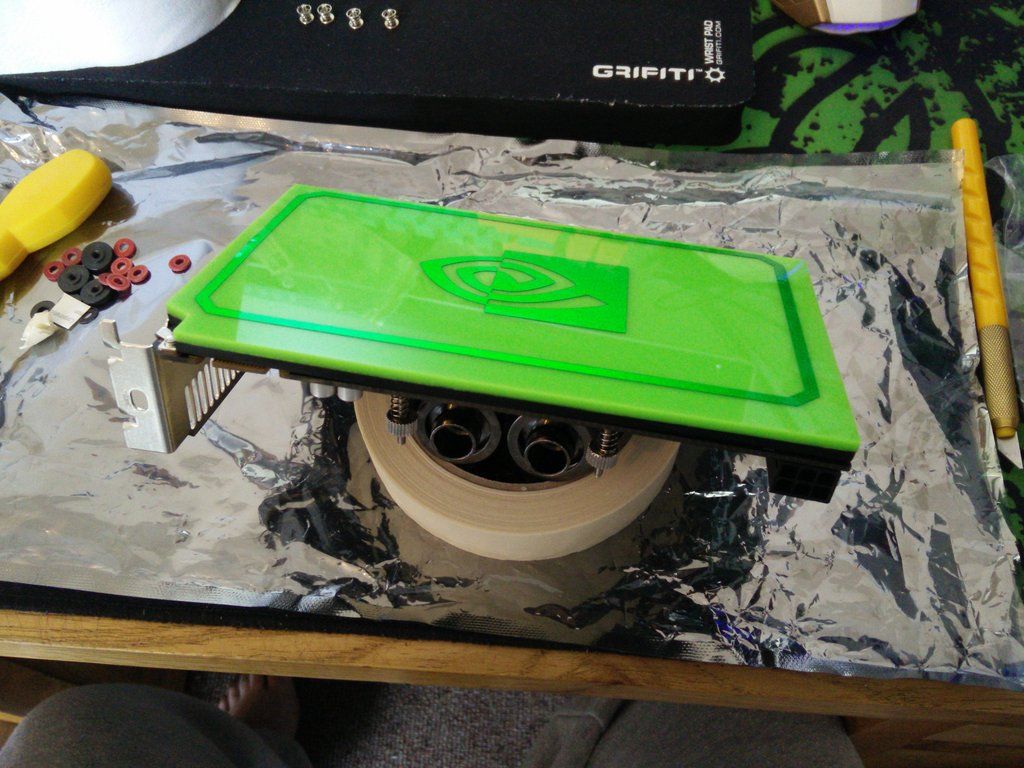

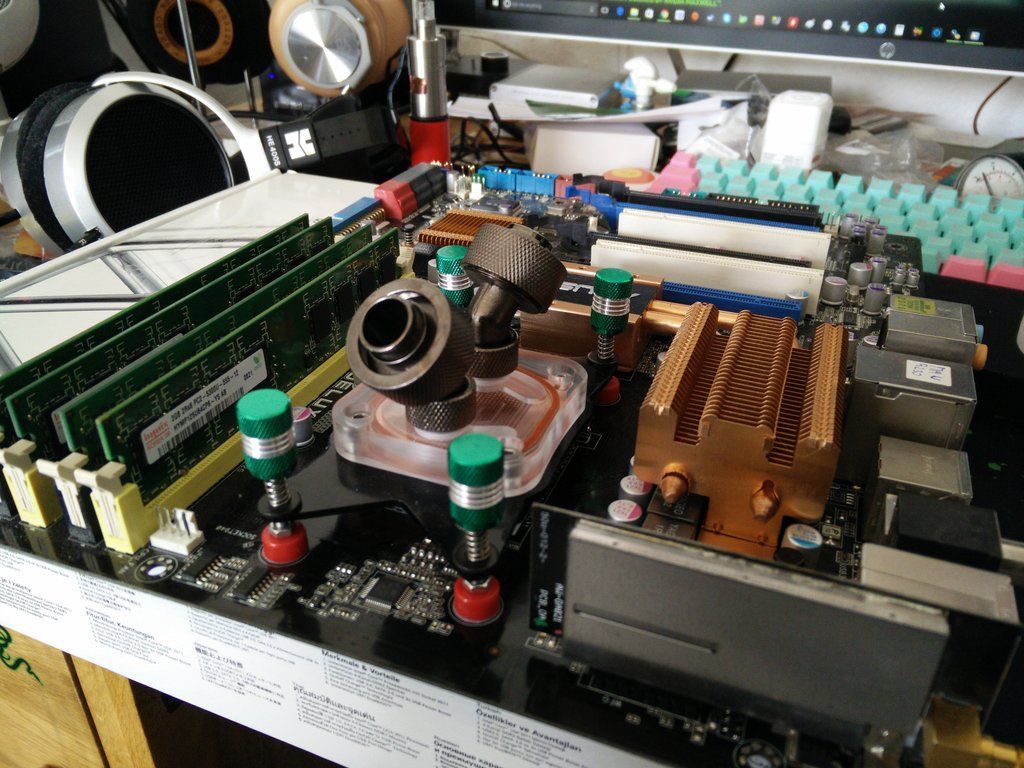

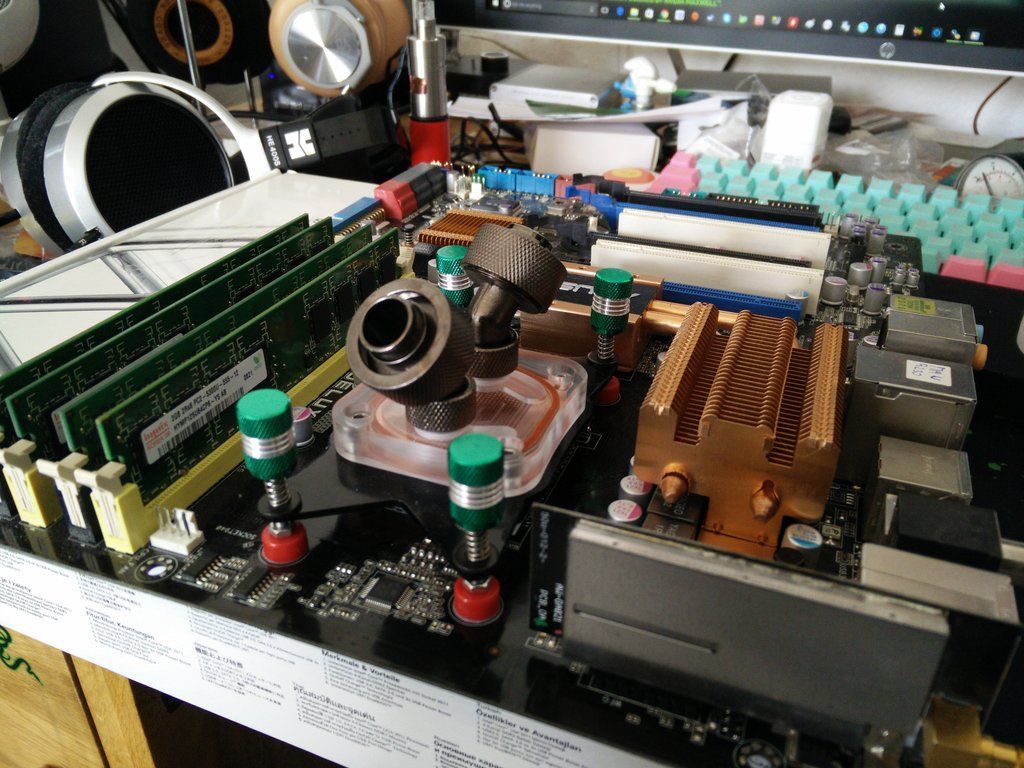

I then decided it was finally time to fit the CPU block. I did this by robbing half of the mech from a Noctua air cooler (the back plate and red bits) and used the bolts that came with the water block and bolted them straight through like this.

And fitted.

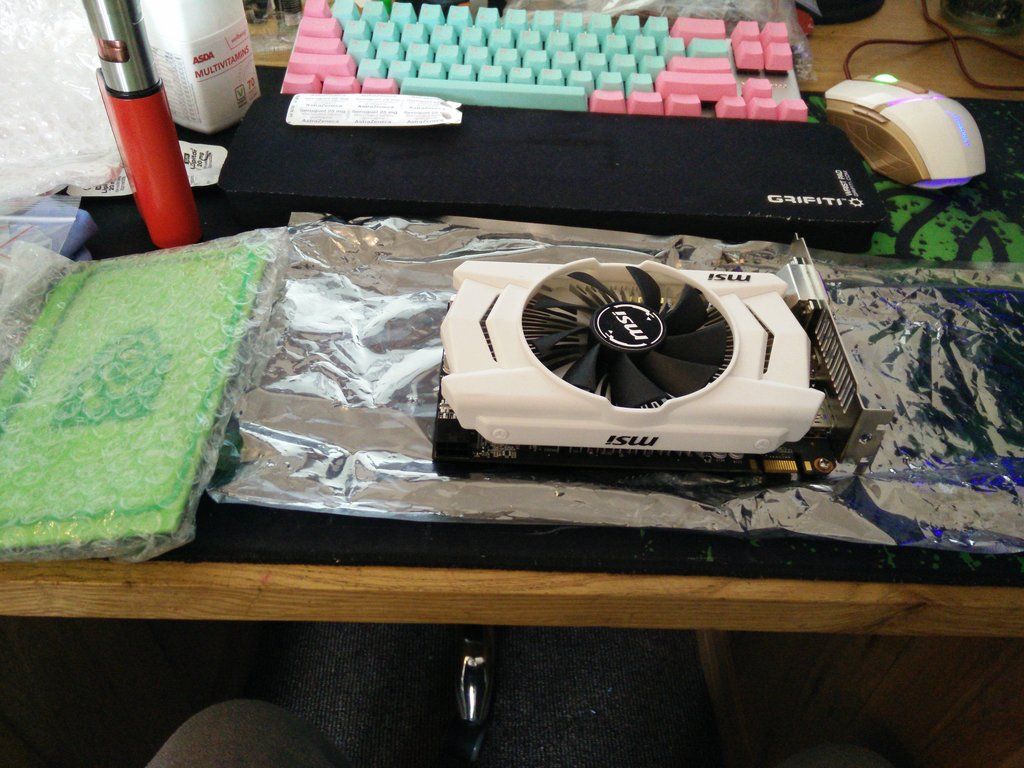

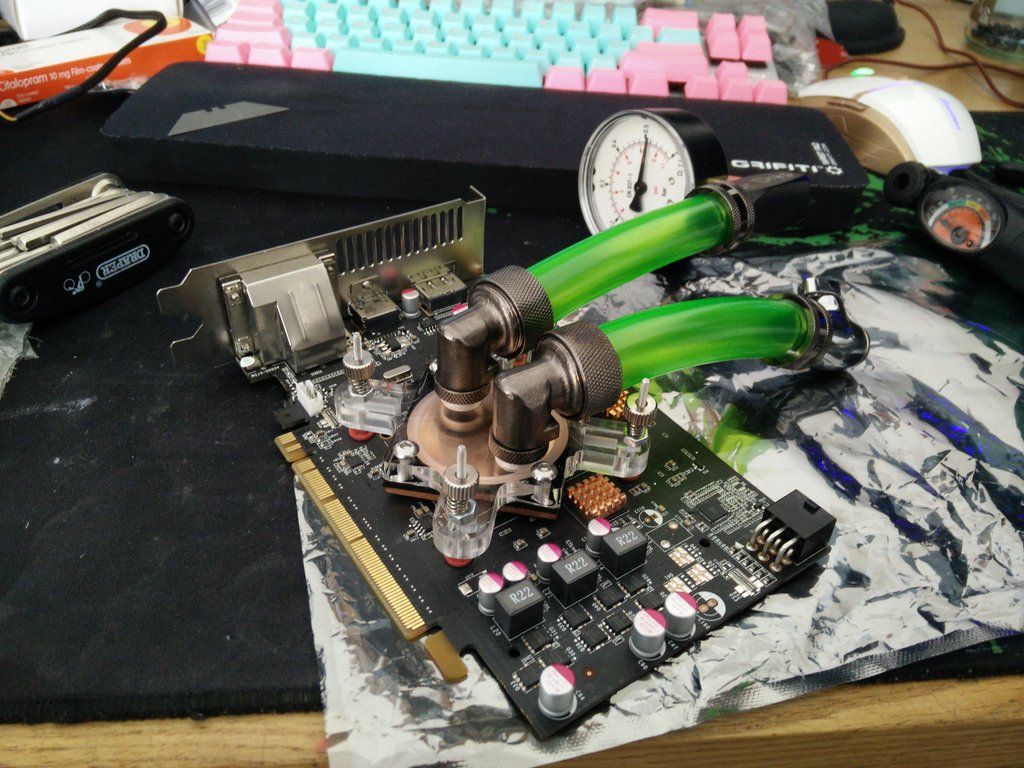

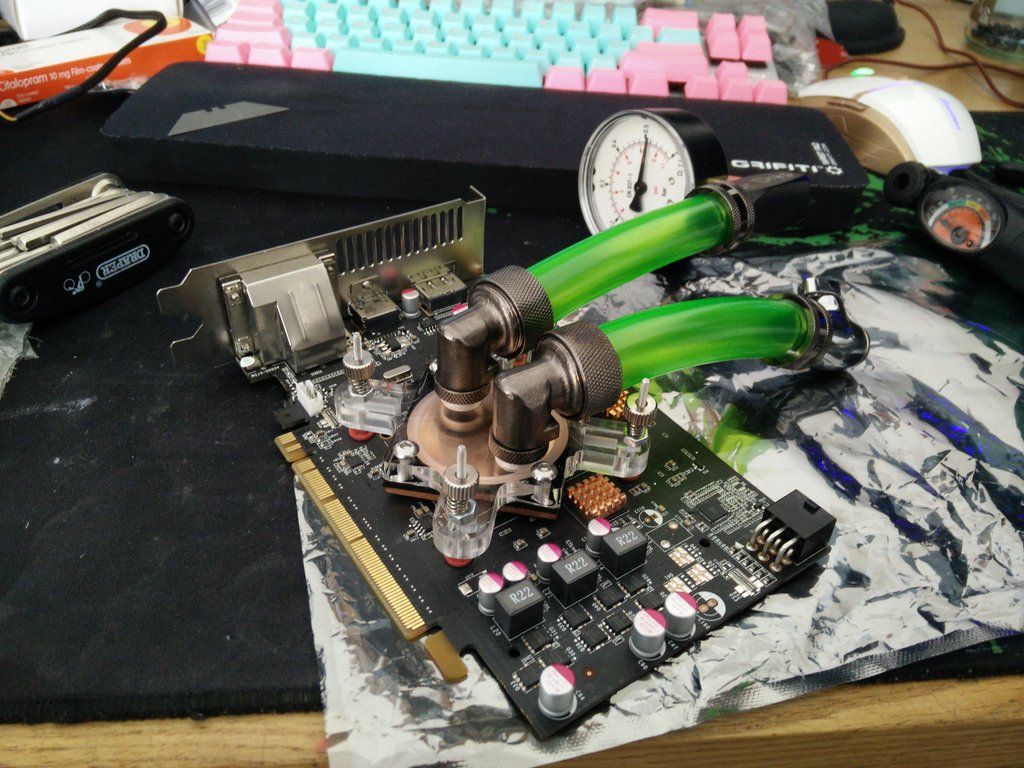

I also decided to pressure test the GPU with Dr Drop. This turned out to be a nightmare, with it just peeing air straight out. Then I realised that you really do need to tighten up the compression fittings all the way. This pic was taken when I still had a leak. I had to tighten them more so that you could not see any thread at all.

I'm kinda mad at myself because I'm praying I haven't killed the GPU. I took it apart again after and repasted it and couldn't see any damage so yeah, hopeful

I also built up the ball valve.

I tell you what XSPC fittings kick the crap out of those other ones I have. They're so easy to tighten.

However, I realised after (when fiddling around) that if you moisten the hose it's then far easier to tighten the fittings. It's also going to be easier to fit the hose, then fit the fittings. The fittings are easily done up hand tight.

I then decided it was finally time to fit the CPU block. I did this by robbing half of the mech from a Noctua air cooler (the back plate and red bits) and used the bolts that came with the water block and bolted them straight through like this.

And fitted.

I also decided to pressure test the GPU with Dr Drop. This turned out to be a nightmare, with it just peeing air straight out. Then I realised that you really do need to tighten up the compression fittings all the way. This pic was taken when I still had a leak. I had to tighten them more so that you could not see any thread at all.

I'm kinda mad at myself because I'm praying I haven't killed the GPU. I took it apart again after and repasted it and couldn't see any damage so yeah, hopeful

I also built up the ball valve.

I tell you what XSPC fittings kick the crap out of those other ones I have. They're so easy to tighten.

However, I realised after (when fiddling around) that if you moisten the hose it's then far easier to tighten the fittings. It's also going to be easier to fit the hose, then fit the fittings. The fittings are easily done up hand tight.

Normally you don't have to tighten the compression rings that much. The barb makes the seal and the ring stops it from pulling off.....but in ghetto-fabulous territory, you could be seeing why there's a price difference. You might also find that if your tubing is hard, rather than a bit squishy, it may need encouraging to seal against the barb.

One thing to watch out for with the XSPC fittings. If they're the coin style ones that have a slot cut across the barb so you can tighten it with a coin, apparently they also cut a slot across the G1/4 thread and it can trash the thread in an acrylic block. Just worth a check - not going to harm a metal thread like your ball valve though.

One thing to watch out for with the XSPC fittings. If they're the coin style ones that have a slot cut across the barb so you can tighten it with a coin, apparently they also cut a slot across the G1/4 thread and it can trash the thread in an acrylic block. Just worth a check - not going to harm a metal thread like your ball valve though.

So for today's work log I am going to show you what you need (apart from a good steady pair of hands and good eyes) to cut acrylic almost perfectly.

Let's first start with what you need. Firstly you want these.

Obviously you need a rotary tool. You then want one of these.

They are called "snakes" and Silverline does a good one pretty cheaply. You then want these. After years of cutting acrylic I have found these to be the best.

25MM Diamond coated blades. Again from Silverline and should cost about a fiver. I am on my second to last one and I bought them four years ago. They last *ages*.

You then want a clean dust pan and brush, one you will only use for this. The reason is you are going to want to sweep the powder and bits off of yourself and using a dirty one sucks.

OK, so those are the basics. As I said with the blades they are the best. No ifs, no buts. Anything else I have used has cabbaged the edges. These things glide through like a hot knife through butter. The snake is needed because a Dremel is like writing with a chisel, the snake turns that chisel into a pen.

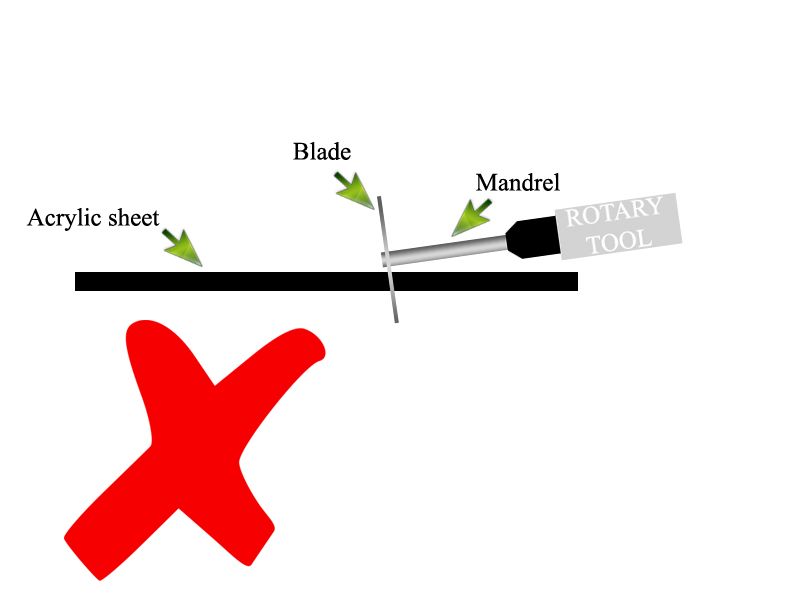

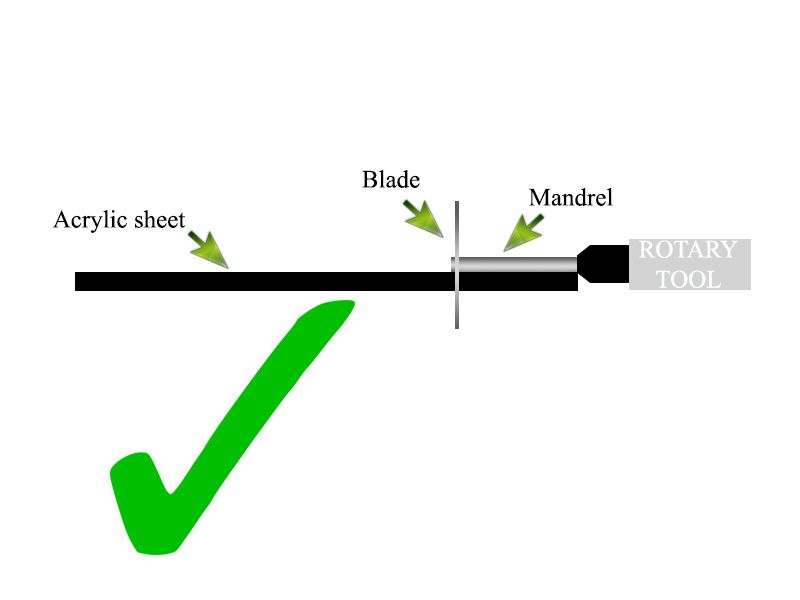

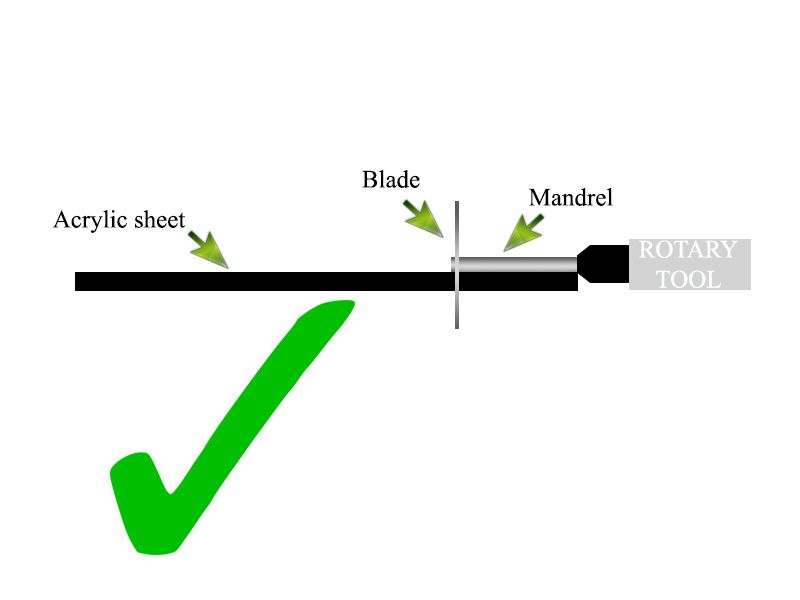

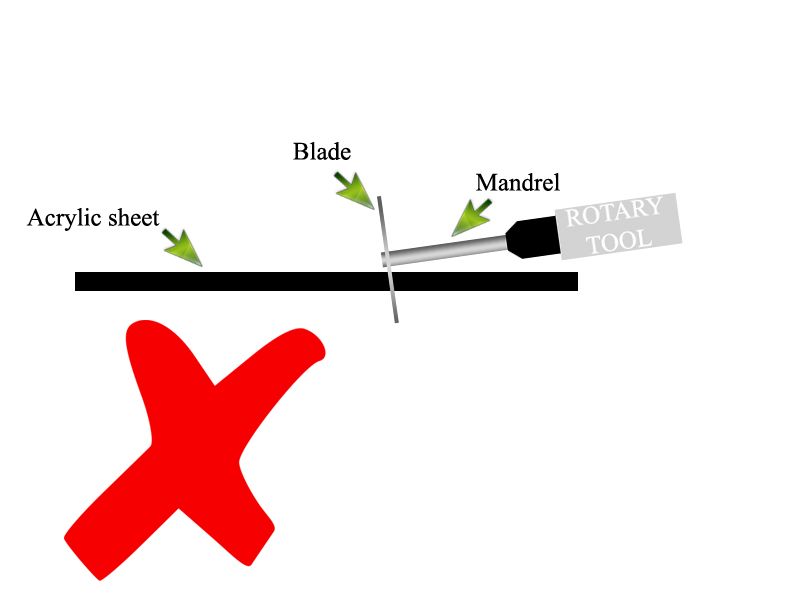

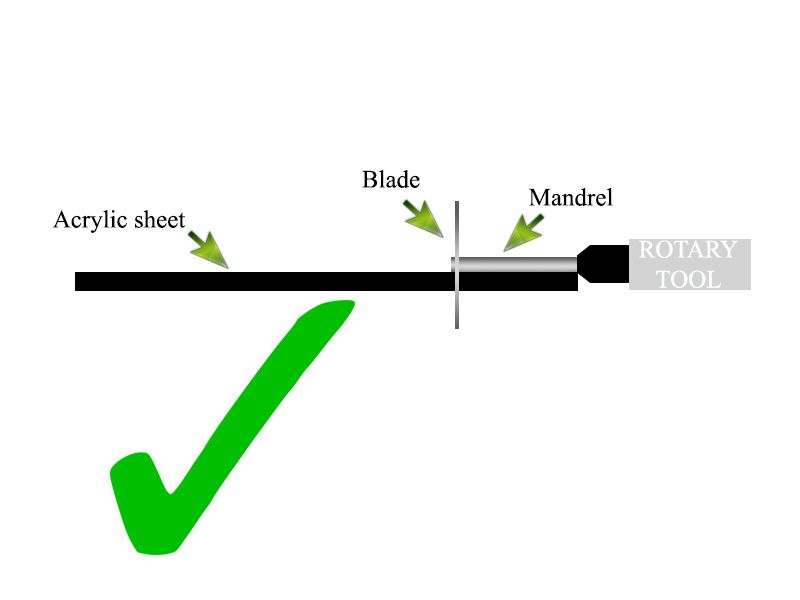

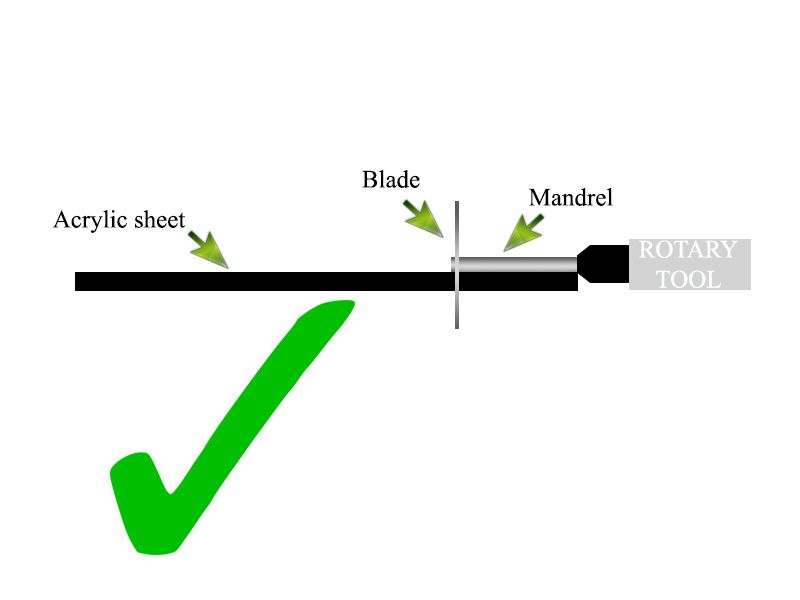

OK, so take a look at these two pics. These are "Acrylic cutting 101" pretty much summed up.

And the correct way.

OK so as you can see if you go in at an angle (which you almost certainly will due to the relatively short mandrel) you will end up with a wavy sloped edge. There is no getting around this unless you rough cut all of your pieces and then cut them again with about 5mm over hang. This way you can put the blade in straight on the edge (as there won't be enough material around your cut edges to foul the tool itself) and cut nice straight lines.

The only down side to this method is that the screw on the end of the mandrel that holds the blade in will scar the edges of your piece. However, this is where I offer two pieces of advice.

1. If the part you are cutting is the same both ways (IE you can flip it over and it will be the same) then it's OK.

2. If the part is not the same flipped over then you need to print your stencil (or mark it out with a ruler and pen) flipped. This way the scar edge will become the back when you turn it over.

I have tried practically everything I can think of to stop this scarring but even two layers of duct tape was not enough. That screw spins fast and gets really hot, melting straight through any tape or protection. I even tried lining up an alu sheet with the piece but the screw jammed and sheered off.

I also do not recommend trying to keep the screw off the edge. If you do then the blade will likely snag and come out as you are cutting.

OK, so step one - Design.

Step two - Stick down or mark out with pen and ruler.

Noting that I have left around at least 1CM or 10MM between each piece so I can rough cut and then final cut.

This is the bit you should be using. It is good for 3mm and 5mm acrylic.

And the diamond coating.

And here you can see me rough cutting each piece the "wrong" way. It's the only way you can cut them now, and you correct it later.

Here they all are rough cut. Put as many pieces as you can along a good edge, that saves you a cut basically.

And now you use this method, as the blade can now go in straight as there is not enough edge material to foul the tool or chuck.

Finish cut.

Then sand. This part is not rocket science, you need a flat surface and a sheet of paper. I am using 600 alu oxide here as it is very strong and lasts. The trick of course is to put the piece down as upright as possible and then just start pushing and pulling back and forth.

*Note. If you are cutting small angled edges like I am then be very careful when sanding them as it's very easy to wee them up and make them look different sizes. Once you mis shape one you will be chasing your tail on all of them trying to make them look the same again.

Here are my cut pieces sanded. I will edge polish them later with finer wet sandpaper.

And done. Note, I have left the back side covering on so I know which side to put the decals on. They are also all different sizes, each corresponds to a design so I will know what decals to put where.

Unfortunately I am all out of green metallic and am waiting on an order I placed at the weekend. Should be here tomorrow, then I will do a "how to use a plotter 101"

Be good.

Let's first start with what you need. Firstly you want these.

Obviously you need a rotary tool. You then want one of these.

They are called "snakes" and Silverline does a good one pretty cheaply. You then want these. After years of cutting acrylic I have found these to be the best.

25MM Diamond coated blades. Again from Silverline and should cost about a fiver. I am on my second to last one and I bought them four years ago. They last *ages*.

You then want a clean dust pan and brush, one you will only use for this. The reason is you are going to want to sweep the powder and bits off of yourself and using a dirty one sucks.

OK, so those are the basics. As I said with the blades they are the best. No ifs, no buts. Anything else I have used has cabbaged the edges. These things glide through like a hot knife through butter. The snake is needed because a Dremel is like writing with a chisel, the snake turns that chisel into a pen.

OK, so take a look at these two pics. These are "Acrylic cutting 101" pretty much summed up.

And the correct way.

OK so as you can see if you go in at an angle (which you almost certainly will due to the relatively short mandrel) you will end up with a wavy sloped edge. There is no getting around this unless you rough cut all of your pieces and then cut them again with about 5mm over hang. This way you can put the blade in straight on the edge (as there won't be enough material around your cut edges to foul the tool itself) and cut nice straight lines.

The only down side to this method is that the screw on the end of the mandrel that holds the blade in will scar the edges of your piece. However, this is where I offer two pieces of advice.

1. If the part you are cutting is the same both ways (IE you can flip it over and it will be the same) then it's OK.

2. If the part is not the same flipped over then you need to print your stencil (or mark it out with a ruler and pen) flipped. This way the scar edge will become the back when you turn it over.

I have tried practically everything I can think of to stop this scarring but even two layers of duct tape was not enough. That screw spins fast and gets really hot, melting straight through any tape or protection. I even tried lining up an alu sheet with the piece but the screw jammed and sheered off.

I also do not recommend trying to keep the screw off the edge. If you do then the blade will likely snag and come out as you are cutting.

OK, so step one - Design.

Step two - Stick down or mark out with pen and ruler.

Noting that I have left around at least 1CM or 10MM between each piece so I can rough cut and then final cut.

This is the bit you should be using. It is good for 3mm and 5mm acrylic.

And the diamond coating.

And here you can see me rough cutting each piece the "wrong" way. It's the only way you can cut them now, and you correct it later.

Here they all are rough cut. Put as many pieces as you can along a good edge, that saves you a cut basically.

And now you use this method, as the blade can now go in straight as there is not enough edge material to foul the tool or chuck.

Finish cut.

Then sand. This part is not rocket science, you need a flat surface and a sheet of paper. I am using 600 alu oxide here as it is very strong and lasts. The trick of course is to put the piece down as upright as possible and then just start pushing and pulling back and forth.

*Note. If you are cutting small angled edges like I am then be very careful when sanding them as it's very easy to wee them up and make them look different sizes. Once you mis shape one you will be chasing your tail on all of them trying to make them look the same again.

Here are my cut pieces sanded. I will edge polish them later with finer wet sandpaper.

And done. Note, I have left the back side covering on so I know which side to put the decals on. They are also all different sizes, each corresponds to a design so I will know what decals to put where.

Unfortunately I am all out of green metallic and am waiting on an order I placed at the weekend. Should be here tomorrow, then I will do a "how to use a plotter 101"

Be good.

To stop your screw-burn (there's ointment for that!  ) Could you put a thin piece of scrap acrylic next to the cut so that it holds the shaft of the mandrel up from the surface but parallel? It would lift the screw clear of the surface but maintain the square edge.

) Could you put a thin piece of scrap acrylic next to the cut so that it holds the shaft of the mandrel up from the surface but parallel? It would lift the screw clear of the surface but maintain the square edge.

Alternatively, a piece of thin scrap acrylic over the cut to do the same thing but also protect the edges of your vinyl a bit during the cut?

) Could you put a thin piece of scrap acrylic next to the cut so that it holds the shaft of the mandrel up from the surface but parallel? It would lift the screw clear of the surface but maintain the square edge.

) Could you put a thin piece of scrap acrylic next to the cut so that it holds the shaft of the mandrel up from the surface but parallel? It would lift the screw clear of the surface but maintain the square edge. Alternatively, a piece of thin scrap acrylic over the cut to do the same thing but also protect the edges of your vinyl a bit during the cut?

To stop your screw-burn (there's ointment for that!) Could you put a thin piece of scrap acrylic next to the cut so that it holds the shaft of the mandrel up from the surface but parallel? It would lift the screw clear of the surface but maintain the square edge.

Alternatively, a piece of thin scrap acrylic over the cut to do the same thing but also protect the edges of your vinyl a bit during the cut?

You could try yes. TBH though there's not really any point, unless you need both sides of the piece on display. Obviously you just put the scarred piece scar side down and you never see it

Just thought it might save you the hassle of having to mirror everything - or if you're using clear acrylic.

You would need a piece of acrylic with a perfectly cut straight edge. Sadly the bit would trash it so in theory you would need one for every cut you make.

Once that bit spins up anything plastic acrylic or perspex you put near it disintegrates.

Check this pic.

That's after one cut lol. That's why you need a very steady hand, because that bit literally flies through acrylic. If the edges weren't as covered as they are (about 7mm across the bit) then you could probably save the straight piece.

Thanks to a frightfully good piece of fortune the board parts are done

It turned out that when I trashed the entire first set of vinyl* I had created a lot of scraps. It was difficult, because they were all odd shapes and some not even wide enough to fit the plotter, but I just glued those ones down to paper and then removed the blade and did a "dry cut" to make sure I was located correctly

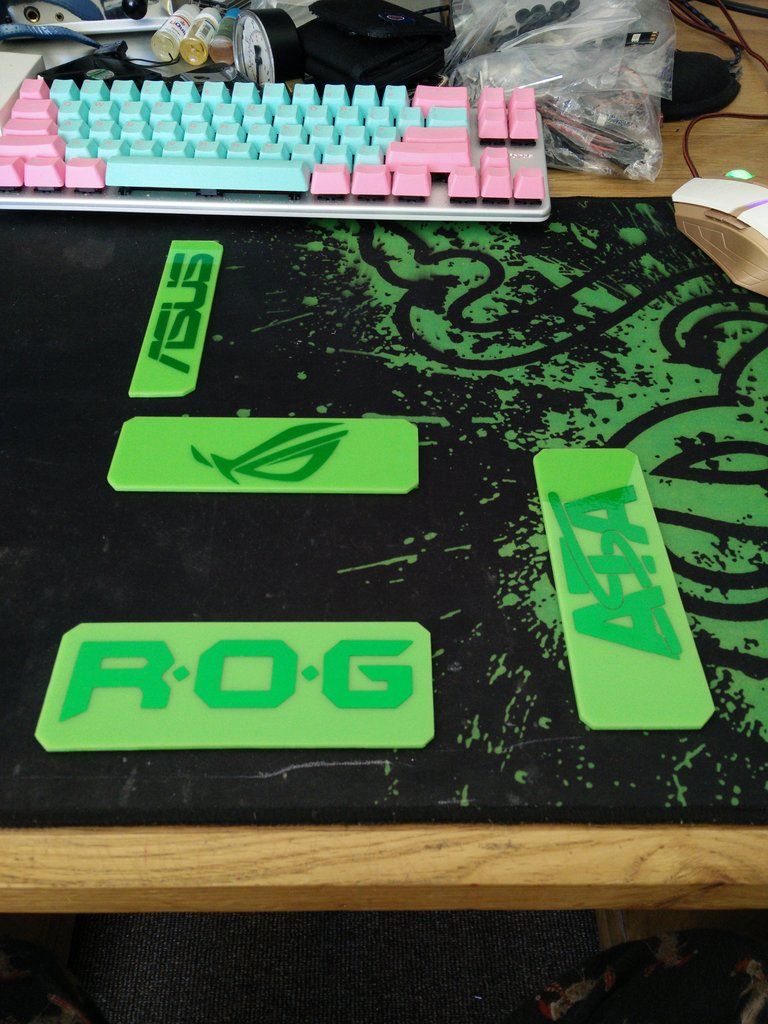

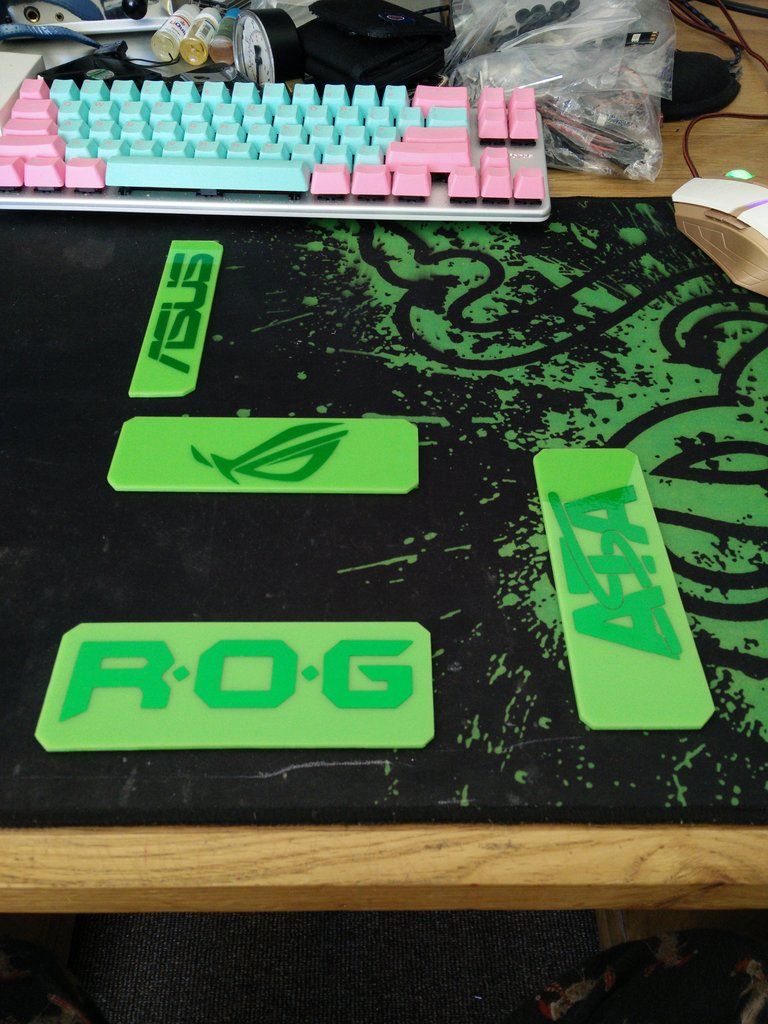

They're all finished now then. I've laid them out so you can build a picture in your mind

I'm not done yet though so I won't fit them yet.

* When the first set of vinyl arrived it looked scratched and dirty. I complained to the seller who sent me a replacement straight away. However, I then realised that it wasn't damaged because it had a protective layer over it that you need to peel off. Sadly I did not realise this and trashed about 3/4 of it cutting stuff that was not cut deep enough, ruining the vinyl. This was what I had stored in a box so I'm very glad for it now

It turned out that when I trashed the entire first set of vinyl* I had created a lot of scraps. It was difficult, because they were all odd shapes and some not even wide enough to fit the plotter, but I just glued those ones down to paper and then removed the blade and did a "dry cut" to make sure I was located correctly

They're all finished now then. I've laid them out so you can build a picture in your mind

I'm not done yet though so I won't fit them yet.

* When the first set of vinyl arrived it looked scratched and dirty. I complained to the seller who sent me a replacement straight away. However, I then realised that it wasn't damaged because it had a protective layer over it that you need to peel off. Sadly I did not realise this and trashed about 3/4 of it cutting stuff that was not cut deep enough, ruining the vinyl. This was what I had stored in a box so I'm very glad for it now

Few simple jobs on for today. I got up pretty early so I decided it was time to do some more wiring and soldering etc. Hopefully I will be done with that soon. So here's what I started with. A simple Molex splitter.

I have plenty of female ends but no black males left (ok joke away )

)

TBH nearly all of the wiring will be hidden in the right side panel any way so tbh if I wasn't so fussy I wouldn't even bother. Problem is I will see it and it would annoy me. I test fitted the cover panels onto the motherboard last night and they all fit nicely. Talk about transform a board ! However I had already sort of decided that I had over done the branding so now they look like this.

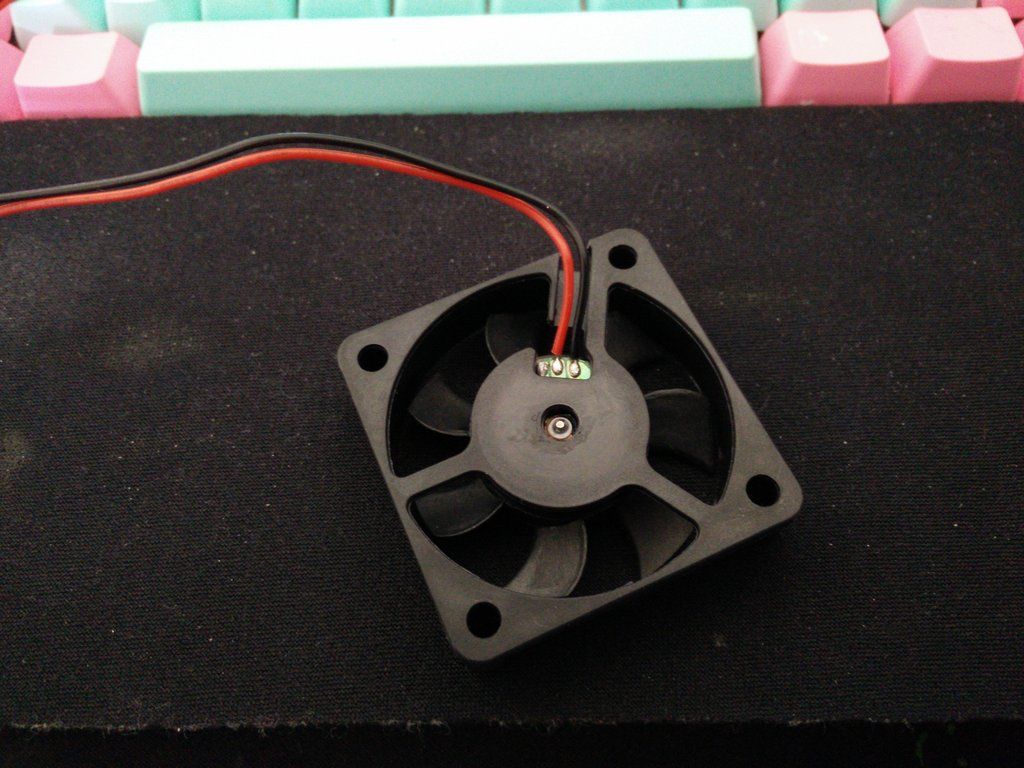

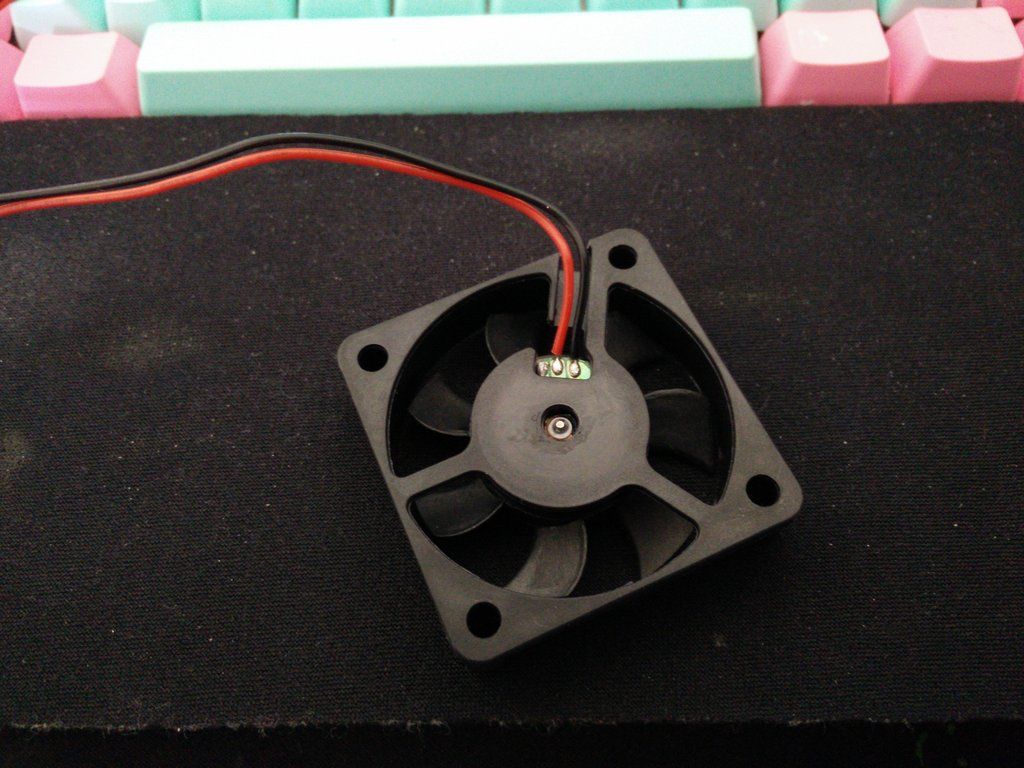

These too came today.

SATA cable for the show SSD and 50mm plain black fan. I was poking around on the bay the other day, typed in "50mm fan" trying to find a green one and this came up for 99p delivered on clearance. Sod's law the doorbell went once I had literally packed all of the braiding stuff away. Doh. I will get that extended and braided today. I will probably run it at 5v.

I have plenty of female ends but no black males left (ok joke away

)

)

TBH nearly all of the wiring will be hidden in the right side panel any way so tbh if I wasn't so fussy I wouldn't even bother. Problem is I will see it and it would annoy me. I test fitted the cover panels onto the motherboard last night and they all fit nicely. Talk about transform a board ! However I had already sort of decided that I had over done the branding so now they look like this.

These too came today.

SATA cable for the show SSD and 50mm plain black fan. I was poking around on the bay the other day, typed in "50mm fan" trying to find a green one and this came up for 99p delivered on clearance. Sod's law the doorbell went once I had literally packed all of the braiding stuff away. Doh. I will get that extended and braided today. I will probably run it at 5v.

50mm? It'll be quieter at 0V!

Braided cables look good. 3mm paracord rather than 550?

Are you soldering onto pinned stubs or re-crimping harvested pins? Just curious how you went about getting two wires into one pin - I went with the dubious method of stripping too much insulation so that you crimp both sets of wings over the pair of wire rather than one set on wire and one set on the insulation. Scrap that, I've just spotted the pre-made cable you've sleeved. Open eyes before opening mouth  *sigh*

*sigh*

Might have to see how your covers look and whether the idea is pinchable. The bios debug display is bright red and clashes with most other lighting - maybe that's why people go for red lighting themes! I think a hinged cover (it's a useful display when you need it!) might be the way to go.

Braided cables look good. 3mm paracord rather than 550?

*sigh*

*sigh* Might have to see how your covers look and whether the idea is pinchable. The bios debug display is bright red and clashes with most other lighting - maybe that's why people go for red lighting themes! I think a hinged cover (it's a useful display when you need it!) might be the way to go.

Last edited:

The best method to use on unsightly lights and so on is just cover them with black vinyl/tape.

My RAIDR used to have a small white panel in it that said RAIDR and it lit up red when I started the rig. First of all it broke the almost invisible lines of all of my PCIE cards (that I had painstakingly took apart and painted the edges of the PCBs etc) and secondly it was red, so looked utterly out of place.

I just took it apart and covered the white panel with black, red light be gone.

I wish I could remove the fan completely tbh. Sadly it is what holds the inner fins in and just a plate would look a bit gash. I would also need to make three plates and weld them all together, way too much mucking around.

The board covers look great. Thankfully a PCI slot (white) sticks up higher than any other so that is the perfect anchor point to hold them down. I will need to cut off the locking mechs on the PCIE slots though as they are even higher.

So I just extended the fan wires to 50cm so I can run it into the back of the case where it will meet a male fan connector - 5v molex male.

This is why I need so many splitters, and yeah, that one was an old one I bought years ago. I've done three or four so far and I had them all here from other builds so I have just replaced the connectors with black ones up until today when I ran out.

Sadly molex connectors in black are stupid money, and cost about three times as much as a cheap splitter. I may paint them black or just wrap them in black tape or something.

My RAIDR used to have a small white panel in it that said RAIDR and it lit up red when I started the rig. First of all it broke the almost invisible lines of all of my PCIE cards (that I had painstakingly took apart and painted the edges of the PCBs etc) and secondly it was red, so looked utterly out of place.

I just took it apart and covered the white panel with black, red light be gone.

I wish I could remove the fan completely tbh. Sadly it is what holds the inner fins in and just a plate would look a bit gash. I would also need to make three plates and weld them all together, way too much mucking around.

The board covers look great. Thankfully a PCI slot (white) sticks up higher than any other so that is the perfect anchor point to hold them down. I will need to cut off the locking mechs on the PCIE slots though as they are even higher.

So I just extended the fan wires to 50cm so I can run it into the back of the case where it will meet a male fan connector - 5v molex male.

This is why I need so many splitters, and yeah, that one was an old one I bought years ago. I've done three or four so far and I had them all here from other builds so I have just replaced the connectors with black ones up until today when I ran out.

Sadly molex connectors in black are stupid money, and cost about three times as much as a cheap splitter. I may paint them black or just wrap them in black tape or something.

The best method to use on unsightly lights and so on is just cover them with black vinyl/tape.

Duct Tape! Good plan

/me wanders off to the shed sharpening his cowboy spurs on the way

Oh btw sorry mate missed a question.

It's not 550 Paracord. It's not even measured etc I just buy it for like £3.50 for 100ft.

I prefer the cheap stuff though. It's easier to stretch, melts easier and fits the plugs far easier. With 550 I used to have to use a small screwdriver to ram the pins in sometimes.

It's not 550 Paracord. It's not even measured etc I just buy it for like £3.50 for 100ft.

I prefer the cheap stuff though. It's easier to stretch, melts easier and fits the plugs far easier. With 550 I used to have to use a small screwdriver to ram the pins in sometimes.

Your pic seems to suggest it's 3mm which could make it Paracord 425 Type II (Google is my friend!)

Yeah I'm not using that dude. Too fiddly and the weave is pretty loose, meaning it's easy to shove the wire threader through the side. It looks gorgeous when you do get it on mind but yeah, far too fiddly and annoying and the weave does not match the other paracord I have.

I only used it on a molex extension you won't see, then resorted back to my stash

I only used it on a molex extension you won't see, then resorted back to my stash

Last update for today. Firstly I desoldered the very short wires on the 50mm fan and soldered on a 50cm cable.

Then of course I braided it and made it Molex compliant etc.

OK so motherboard before.

Motherboard after. Notes - it's not finished by any means. The plates are not even on straight as they are not aligned with the cards going in ETC ETC.

One thing annoying me now is the copper. However, I have this at my disposal so the next time I set the booth up I could well blow the whole thing over.

Note - when I say whole thing I mean the cooling assembly, not the board.

So the power switch arrived ages and ages ago and I have been meaning to poke/buzz (test for the switch continuity/send voltage into it) it so I could find the pinouts for the switch and pins for the LED. That's one problem with ordering from China you never get instructions. I bought these a few days back and fitted PCIE male pins to them so I can connect them into the PSU to give me a hot and cold probe.

19mm power switch.

Thar she blows.

And thanks to some good advice I have now ordered this.

And these.

Then of course I braided it and made it Molex compliant etc.

OK so motherboard before.

Motherboard after. Notes - it's not finished by any means. The plates are not even on straight as they are not aligned with the cards going in ETC ETC.

One thing annoying me now is the copper. However, I have this at my disposal so the next time I set the booth up I could well blow the whole thing over.

Note - when I say whole thing I mean the cooling assembly, not the board.

So the power switch arrived ages and ages ago and I have been meaning to poke/buzz (test for the switch continuity/send voltage into it) it so I could find the pinouts for the switch and pins for the LED. That's one problem with ordering from China you never get instructions. I bought these a few days back and fitted PCIE male pins to them so I can connect them into the PSU to give me a hot and cold probe.

19mm power switch.

Thar she blows.

And thanks to some good advice I have now ordered this.

And these.