There's an absolute ton of it tbh dude. With it all pulled out I have filled a PSU box. It has a control board with switches for RGB, or, if you were super loaded an electronic PIC board that you could change the lighting on.

This was 2006, so it does make me smile now that people are going crazy for RGB controllable lighting all of a sudden

Thing is, mixing up the primary colours comes out weird. So I always stuck with green or blue or red.

/boring geek mode. The latest case (the Triad) has active lighting that interacts with certain games. So for example if I am playing Dying Light and I fall from a decent height the case flashes red as you hit the ground. When you turn on your flashlight at night the case turns white. When you kill a zombie it flashes green.

I never even noticed it at first. My 2008 did it too and I thought it was busted lmao. I remember playing Metro Last Light and the lights kept changing to white and purple etc, I figured there was a short somewhere.

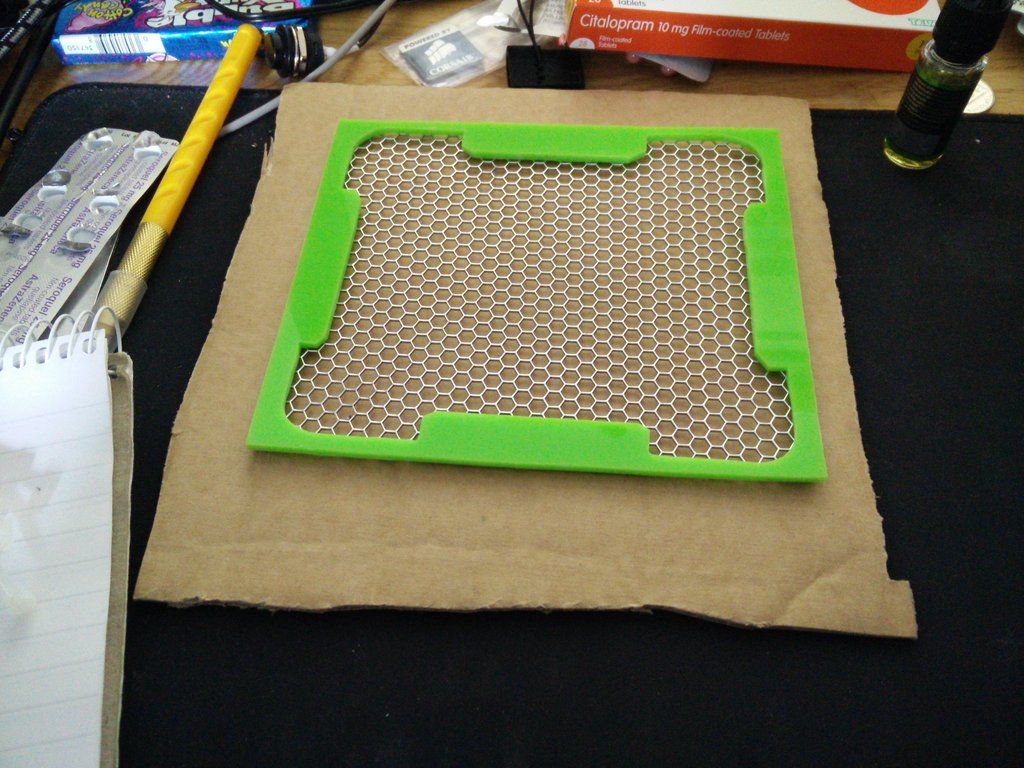

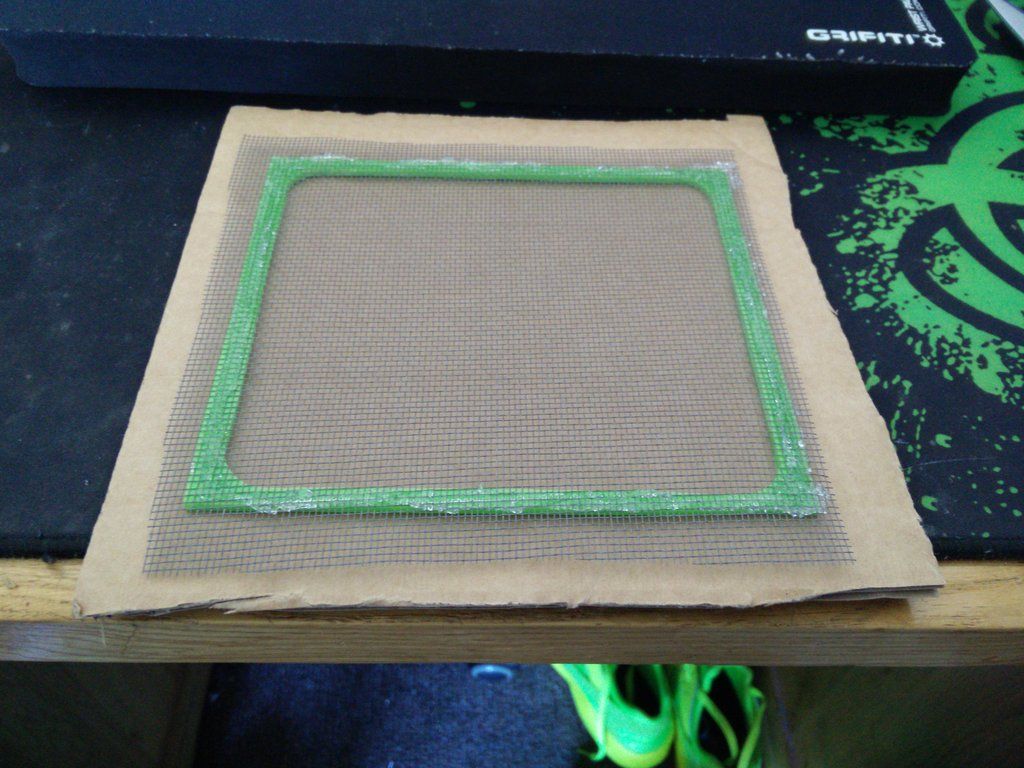

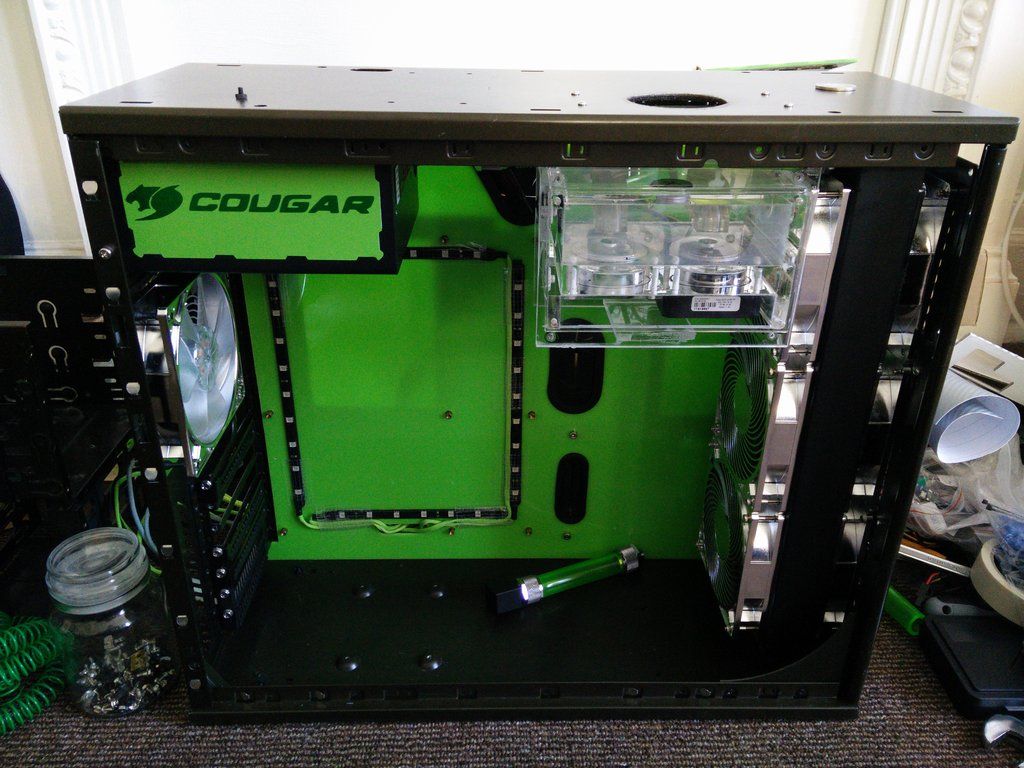

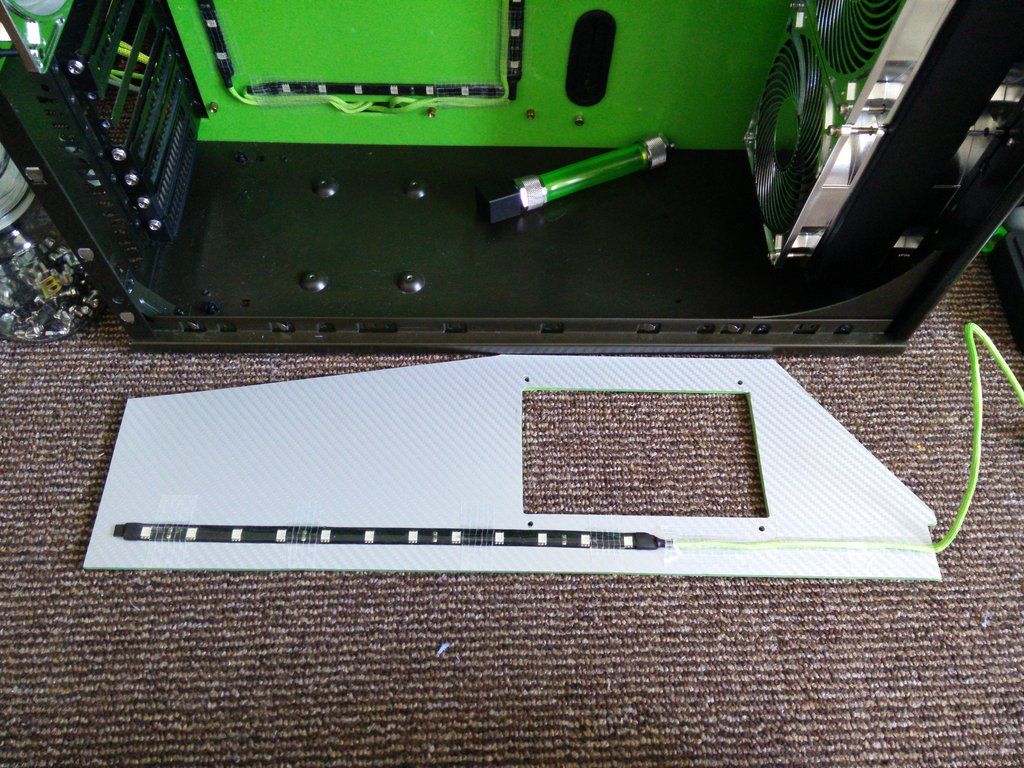

/Update. I just made the two parts for the front cover panel. They are cut, one will be getting mesh and the other a dust filter.

This was 2006, so it does make me smile now that people are going crazy for RGB controllable lighting all of a sudden

Thing is, mixing up the primary colours comes out weird. So I always stuck with green or blue or red.

/boring geek mode. The latest case (the Triad) has active lighting that interacts with certain games. So for example if I am playing Dying Light and I fall from a decent height the case flashes red as you hit the ground. When you turn on your flashlight at night the case turns white. When you kill a zombie it flashes green.

I never even noticed it at first. My 2008 did it too and I thought it was busted lmao. I remember playing Metro Last Light and the lights kept changing to white and purple etc, I figured there was a short somewhere.

/Update. I just made the two parts for the front cover panel. They are cut, one will be getting mesh and the other a dust filter.