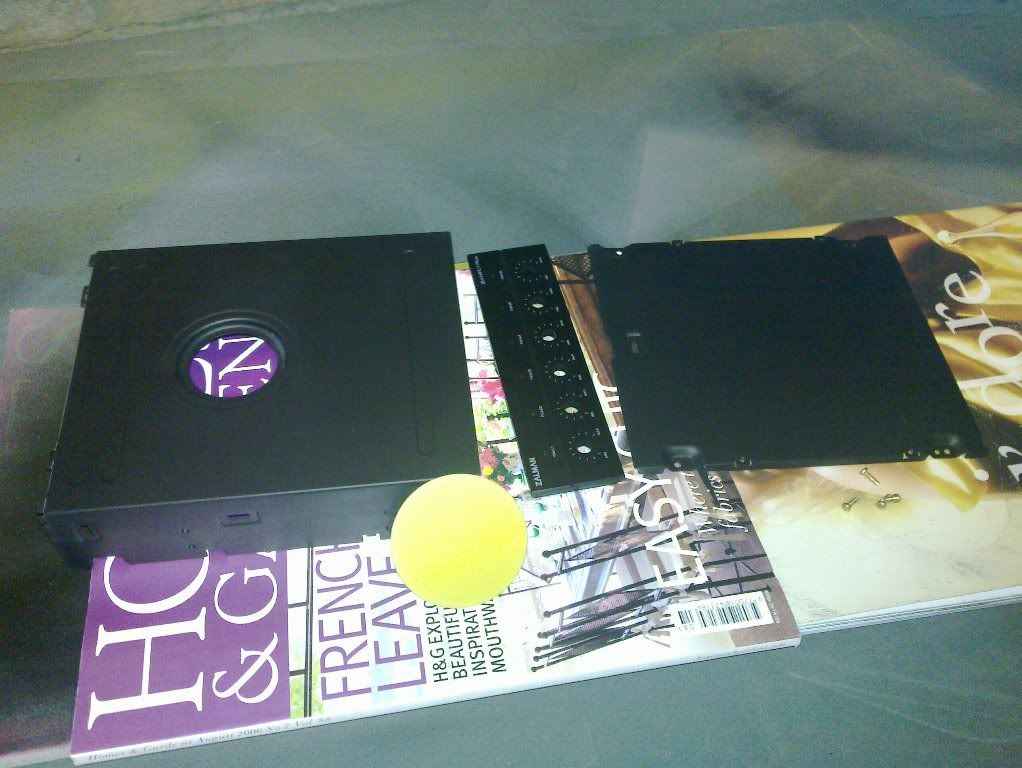

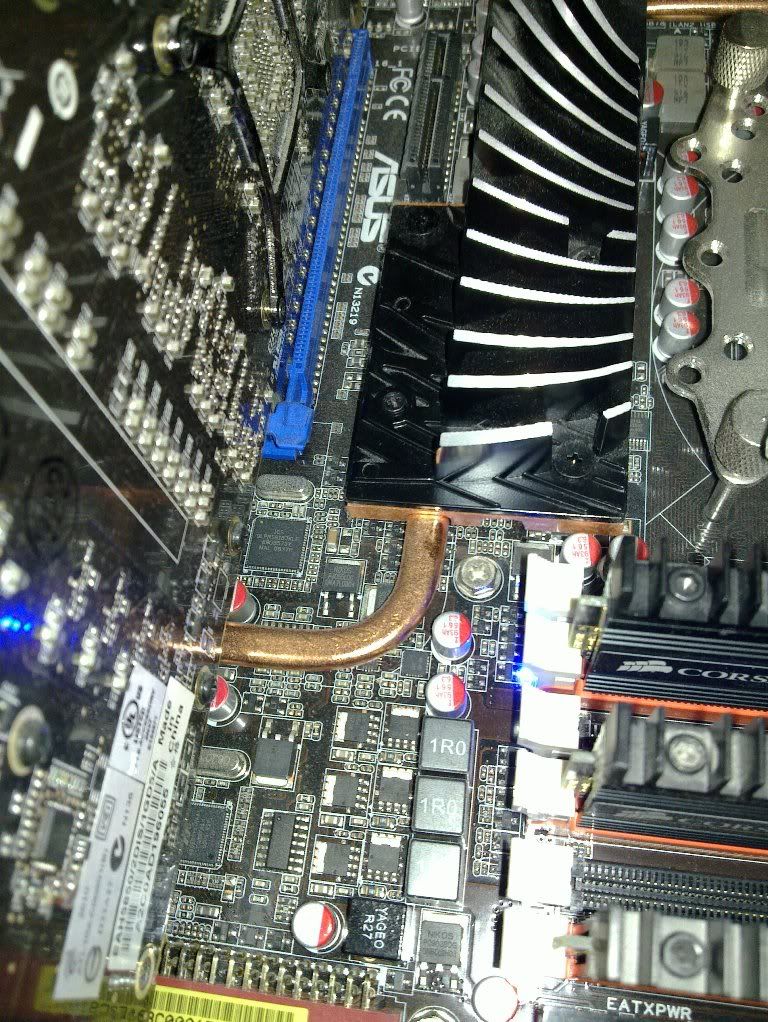

I've taken the arch section off of the Skelly in order to prepare for the installation of the CPU block and to enable me to access some of the other fans in the system to braid them and link to the new fan controller.

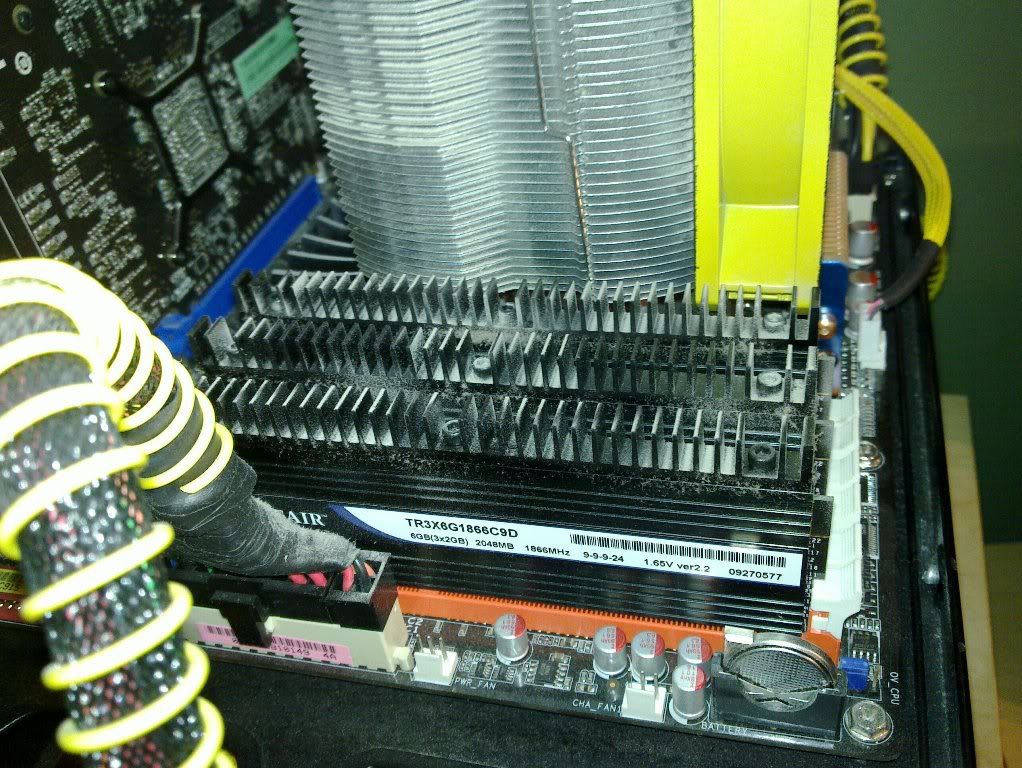

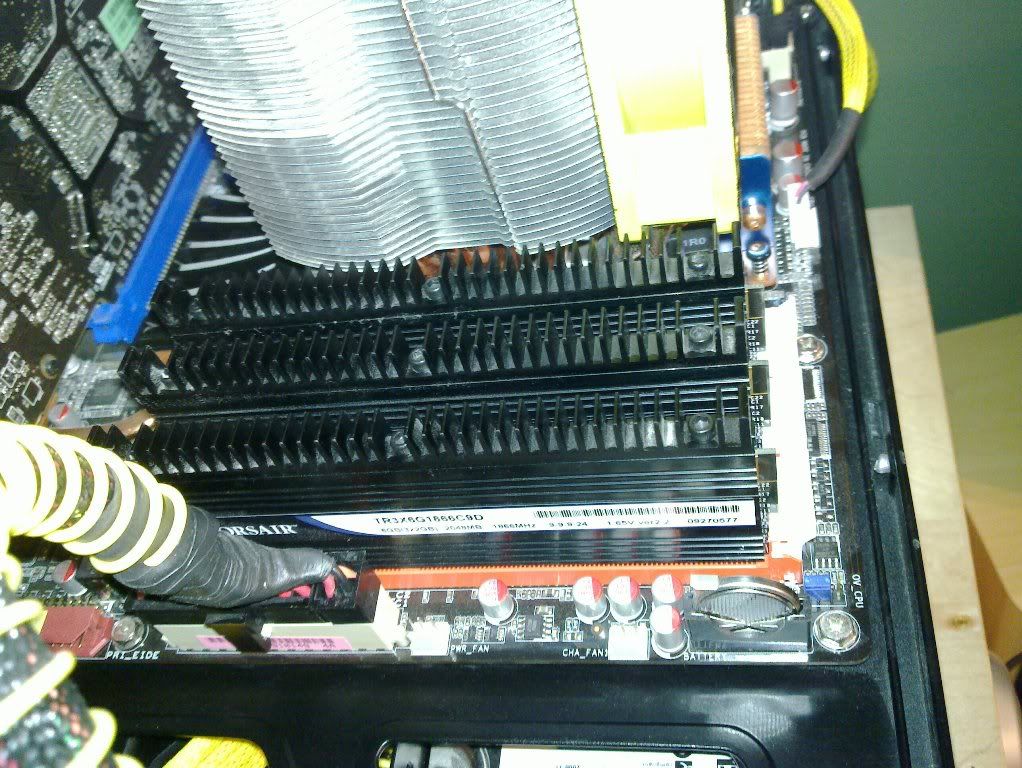

It just happens to be exactly a year since I finished the original Skeleton build so what does a year of dust look like on this case??? I deliberately haven't gone near it with anything to remove dust before now, wanting to see what the build up would be, bearing in mind that we've had builders in for 3 months knocking walls down and plastering and sawing and drilling and the like

So what does it look like.... Pretty much the same as any case really.

The PCB is pretty good, as is the GPU as they are directly under the big top fan.

Dust has gathered in "dead areas " as it would in any case, but was particularly bad behind the RAM cooler fans and the HDD fans.

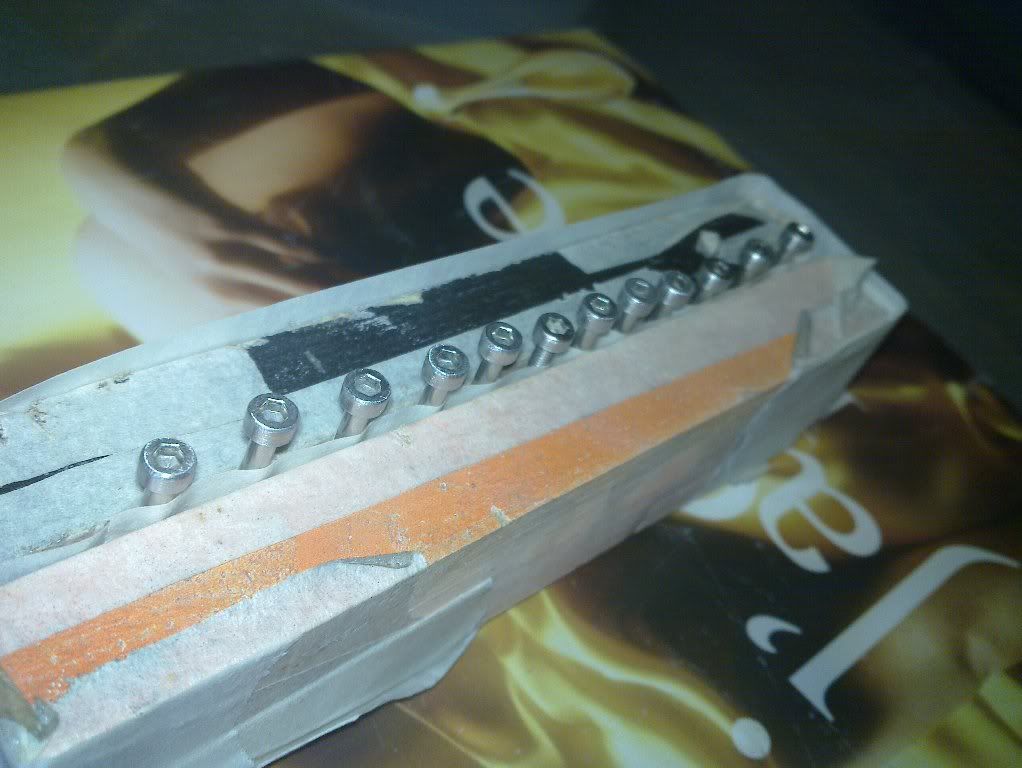

Fortunately I've found this great stuff that is excellent for getting rid of dust, It molds into all the nooks and crannies, doesn't leave a residue and does not generate static. You just dab it on and it picks up the dust, fold it over and dab it on again and repeat etc. it also feels really disgusting, but in a Goooood way!!!! The feel reminds me a bit of silly putty.

RAM de dusted 9the white you can see is from the flash.

All is fine, de dusted and working well.

Please excuse the wall paper. I took this picture while my wife was logged in to her desktop, so it's showing her wall paper. I'll have a word with her and make sure it doesn't happen again.