Sorry for lack of activity, just waiting for my fittings to arrive at present.

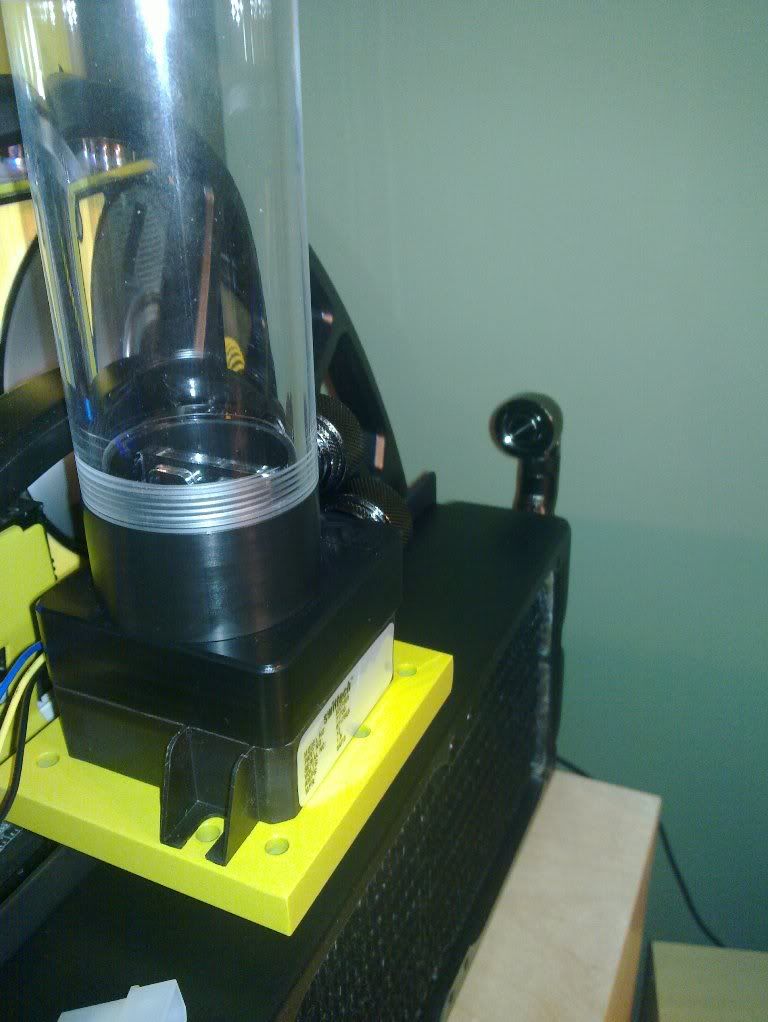

Was originally going for clear tubing and yellow fluid but think the yellow might look like pee (anyone know a good strong yellow fluid?).

if not the above then Black tubing with Black dye, or possibly even clear fluid

(are the dyes really that bad for the health of the loop?)

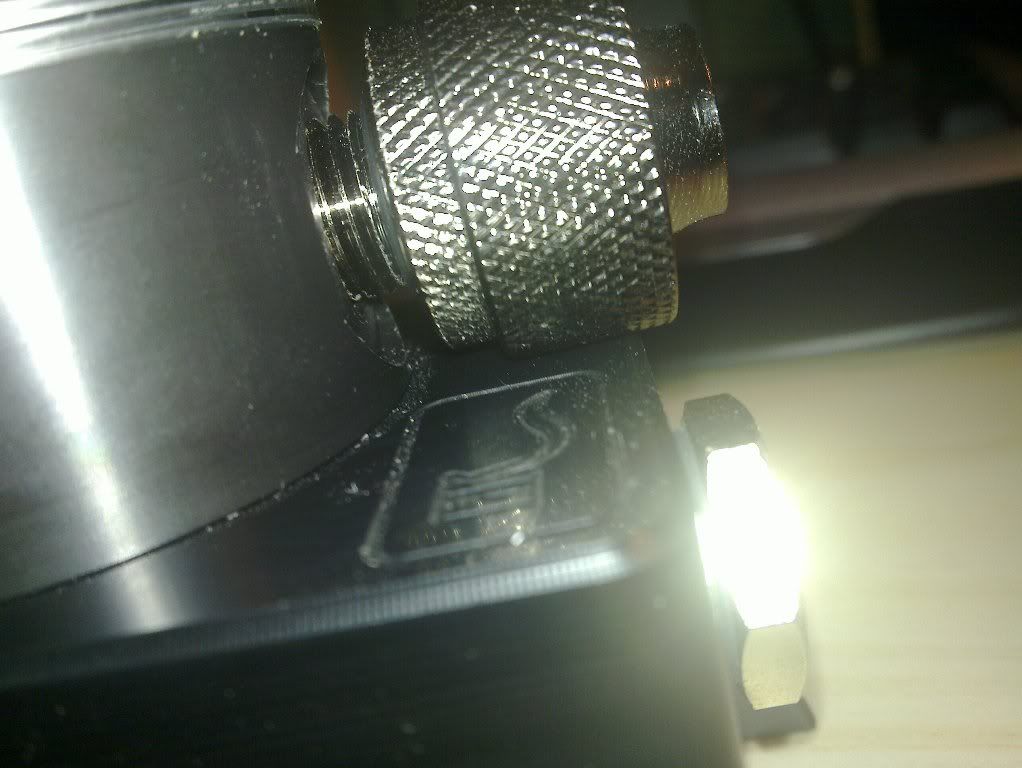

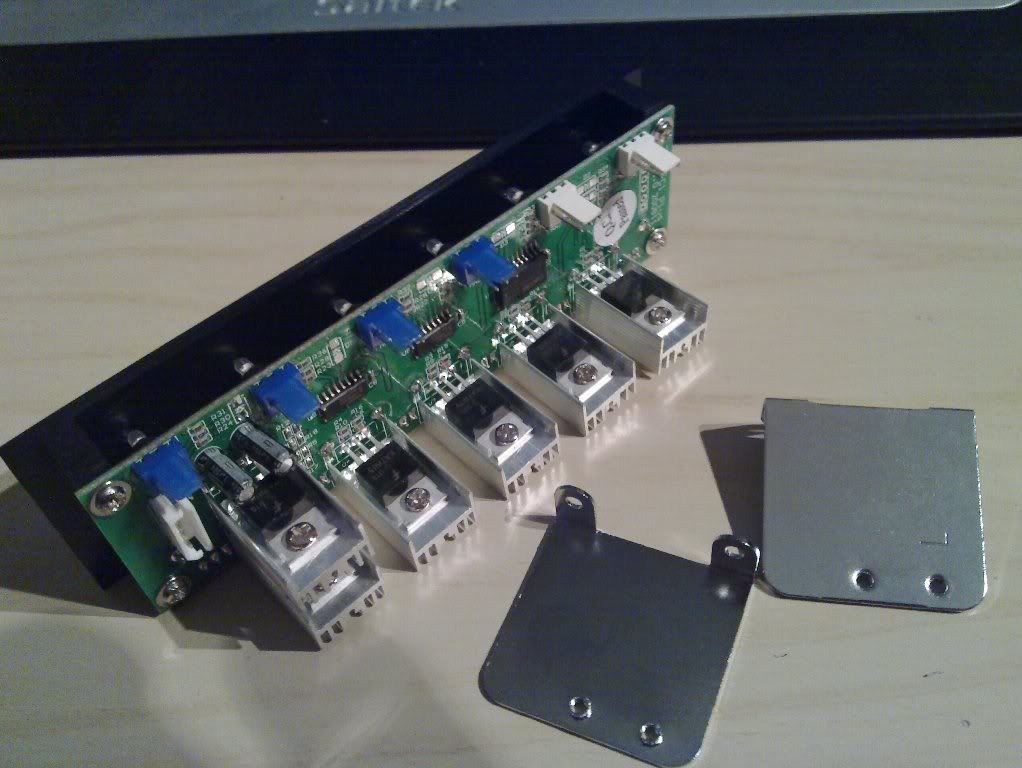

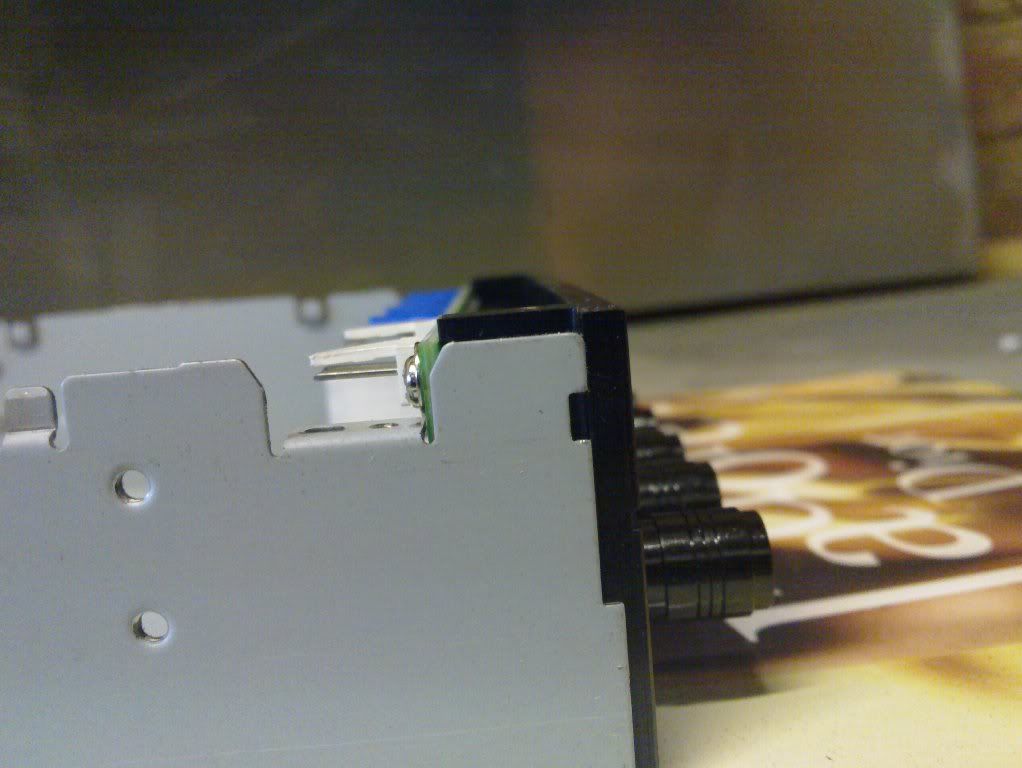

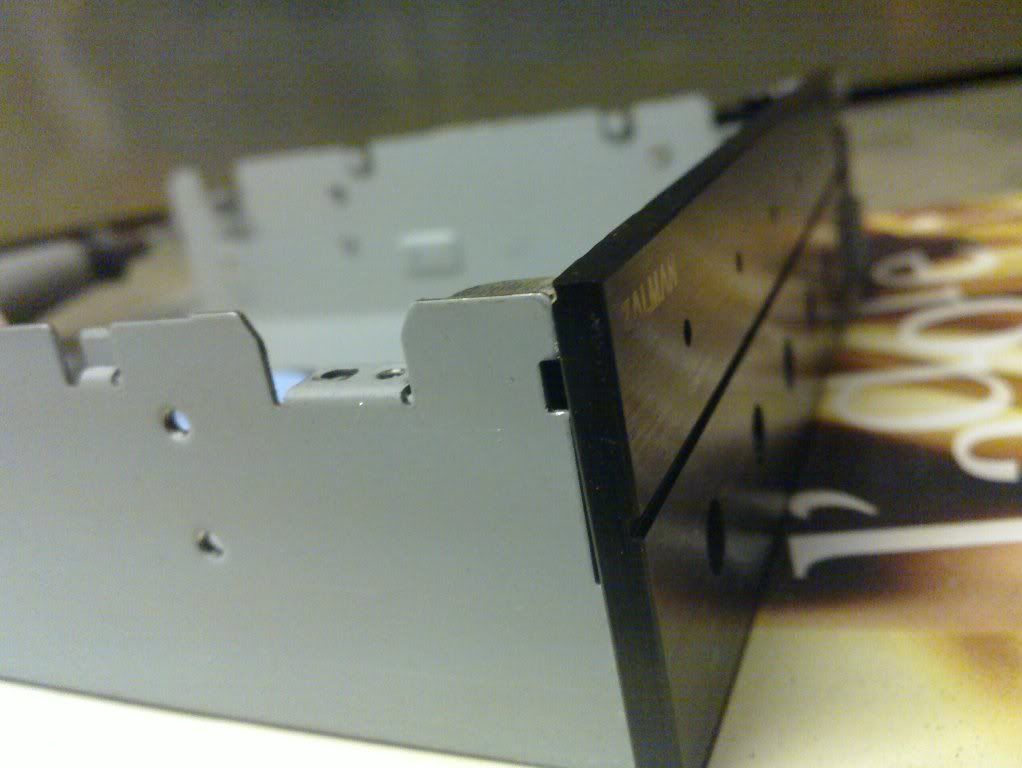

Meanwhile a few night shots of the case.

Was originally going for clear tubing and yellow fluid but think the yellow might look like pee (anyone know a good strong yellow fluid?).

if not the above then Black tubing with Black dye, or possibly even clear fluid

(are the dyes really that bad for the health of the loop?)

Meanwhile a few night shots of the case.