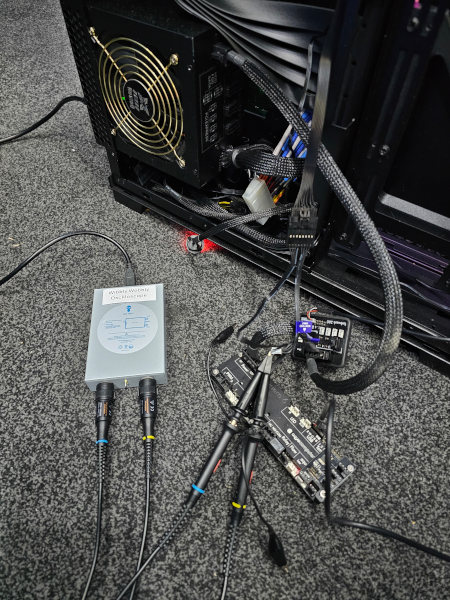

Wibbly Wobbly USB Oscilloscope is surely the official product description. And should be if it's not.

I've been around looking in from time to time, but never had the brain space to usefully comment still don't tbh, sat here in the new house for 12 hours waiting for a fridge that nobody wants to give me tracking data for, whilst nothing is getting done at the old house.

still don't tbh, sat here in the new house for 12 hours waiting for a fridge that nobody wants to give me tracking data for, whilst nothing is getting done at the old house.

Putting the big res in the middle of the distro has done a great job of separating the two halves so all of my concerns and brain wrangling to try and suggest some kind of symmetry in the tube runs is n longer needed.

Does the D5 NEXT work upside down though?

I've been around looking in from time to time, but never had the brain space to usefully comment

still don't tbh, sat here in the new house for 12 hours waiting for a fridge that nobody wants to give me tracking data for, whilst nothing is getting done at the old house.

still don't tbh, sat here in the new house for 12 hours waiting for a fridge that nobody wants to give me tracking data for, whilst nothing is getting done at the old house.Putting the big res in the middle of the distro has done a great job of separating the two halves so all of my concerns and brain wrangling to try and suggest some kind of symmetry in the tube runs is n longer needed.

Does the D5 NEXT work upside down though?

Last edited:

Hey, I'm not pessimistic, I work in IT....we call it "experience"!

Hey, I'm not pessimistic, I work in IT....we call it "experience"!