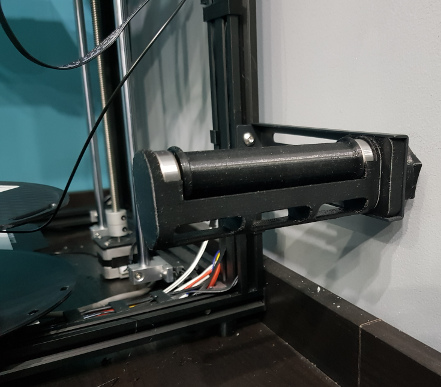

At the risk of talking to myself, I thought I'd update. When I made this I simply modelled some holes in each end of the part and then ran a reamer through them and made some stub shafts out of aluminium to take the bearings. I wasn't careful enough making sure I reamed the holes concentric to the part so the stub shafts weren't perfectly inline with the roller. That means that as the roller rotated the distance between the top edges of the bearings got longer and shorter. There wasn't any space in the holder for that so mostly the spool just slid round the spindle rather than the spindle rotating in the bearings. I reprinted the spindle with a 12mm through-hole down the centre and then reamed it to size (holes come out undersize on my printer currently) with a cheap import reamer - not really sharp enough when compared to the smaller ones I have that are of decent quality. Made a full length shaft that was around 12mm in the middle (had taper issues with my lathe at the time) and had 8mm diameter ends for the bearings. Used my swing press (that's an overly fancy term for a hammer when you don't have the right equipment to press it in properly) to push the shaft into the spindle, set the bearings on the end and now it turns quite nicely.

When I printed the 1st replacement spindle, there were several lines in the print that didn't look right and I thought they looked like weak points....snap....I was right. I think it was caused by the fact that on this spindle the very end of the filament sticks through a hole (to retain it) into the centre of the spindle. Better ones have this go into a space that isn't right in the middle where the spool spins about. This got hung up on the arm because it didn't have a spindle in it and I think meant that each layer that came about when the tail of the filament got stuck on the holder, under extruded enough that there was no strength there. 2nd one was better (with the old spindle back in place) but didn't look perfect. Wasn't sure it was going to survive the reaming to be honest - sharper reamer would have been a lot better.

) rolled off the printer as a first print. I told him I wasn't spending £22 on a spool of orange just so he could have a penguin! ....but £7 ain't so bad. So in true rod-for-my-own-back style, we now have parts in black, white, orange and red queued to print.

) rolled off the printer as a first print. I told him I wasn't spending £22 on a spool of orange just so he could have a penguin! ....but £7 ain't so bad. So in true rod-for-my-own-back style, we now have parts in black, white, orange and red queued to print.