Got a little bit more done Saturday afternoon, finally got the spring, shock & hub etc off but ruined one of the ball joints in the process, they are cheap to replace so it's no real worry and i want to polybush the car anyway so i'm sure more old suspension components are going to break in the process.

Anyway, i got the inside of the suspension turret all back to bare metal and only found a bit of surface corrosion in a few small areas, it came off pretty easily but it was a bit awkward to get to all of it, once back to bare metal and I was happy all rust is removed I gave it a lick of etching primer.

You can see at the very top of the picture there is a small piece of metal missing from the turret housing, it appears to have been melted there when someone has replaced the triangular strengthening plate in the past and they have welded it in.

I know in this pic I missed a bit but I made sure it was covered afterwards.

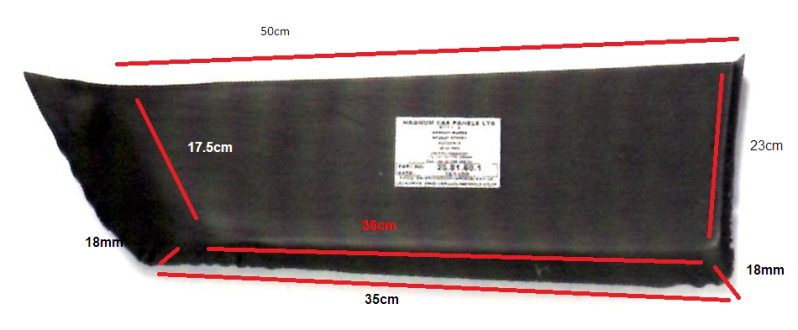

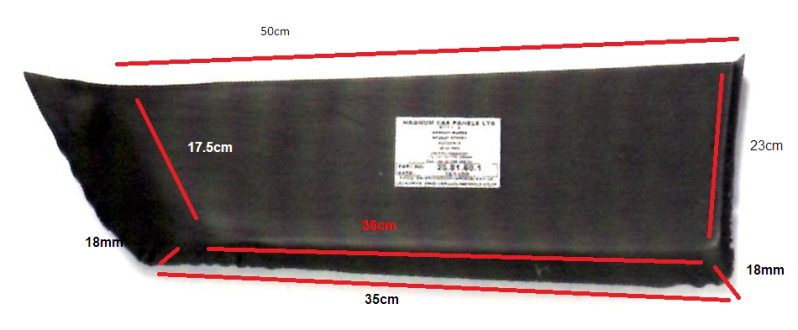

And for Lopez, i took those measurements but they are probably not 100% accurate as the rear end of the panel is curved and i wasn't sure how far into the curve you wanted measuring.

If you want to draw lines on the very bottom pic and re-post it i'd probably be able to get something more accurate for you.

Anyway, i got the inside of the suspension turret all back to bare metal and only found a bit of surface corrosion in a few small areas, it came off pretty easily but it was a bit awkward to get to all of it, once back to bare metal and I was happy all rust is removed I gave it a lick of etching primer.

You can see at the very top of the picture there is a small piece of metal missing from the turret housing, it appears to have been melted there when someone has replaced the triangular strengthening plate in the past and they have welded it in.

I know in this pic I missed a bit but I made sure it was covered afterwards.

And for Lopez, i took those measurements but they are probably not 100% accurate as the rear end of the panel is curved and i wasn't sure how far into the curve you wanted measuring.

If you want to draw lines on the very bottom pic and re-post it i'd probably be able to get something more accurate for you.

. I have taken yours & Jonny69's advise and got a few 1mm cutting discs, tried to get Makita ones but they didn't have any in stock. They are indeed much nicer to cut with, the grinder has not tried to launch itself accross the garage yet which is nice, but I haven't done any proper cutting today, i just feel a bit worried about them shattering as they seem so flimsy.

. I have taken yours & Jonny69's advise and got a few 1mm cutting discs, tried to get Makita ones but they didn't have any in stock. They are indeed much nicer to cut with, the grinder has not tried to launch itself accross the garage yet which is nice, but I haven't done any proper cutting today, i just feel a bit worried about them shattering as they seem so flimsy.