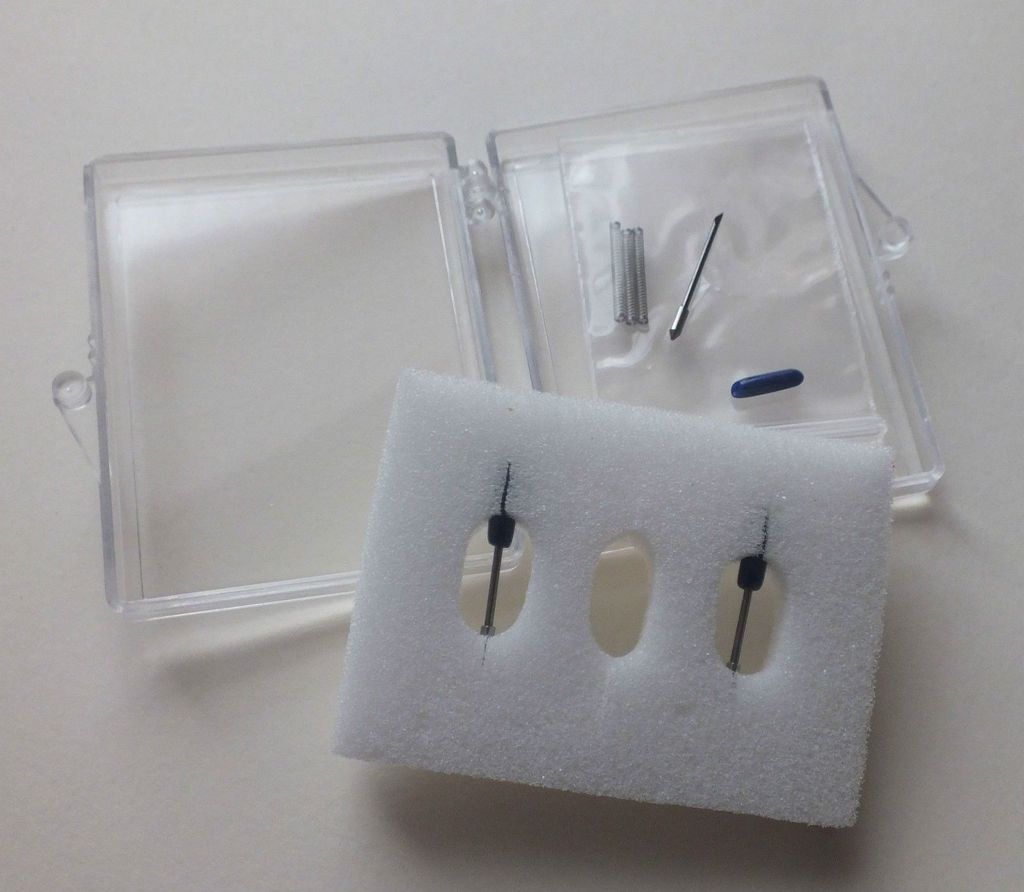

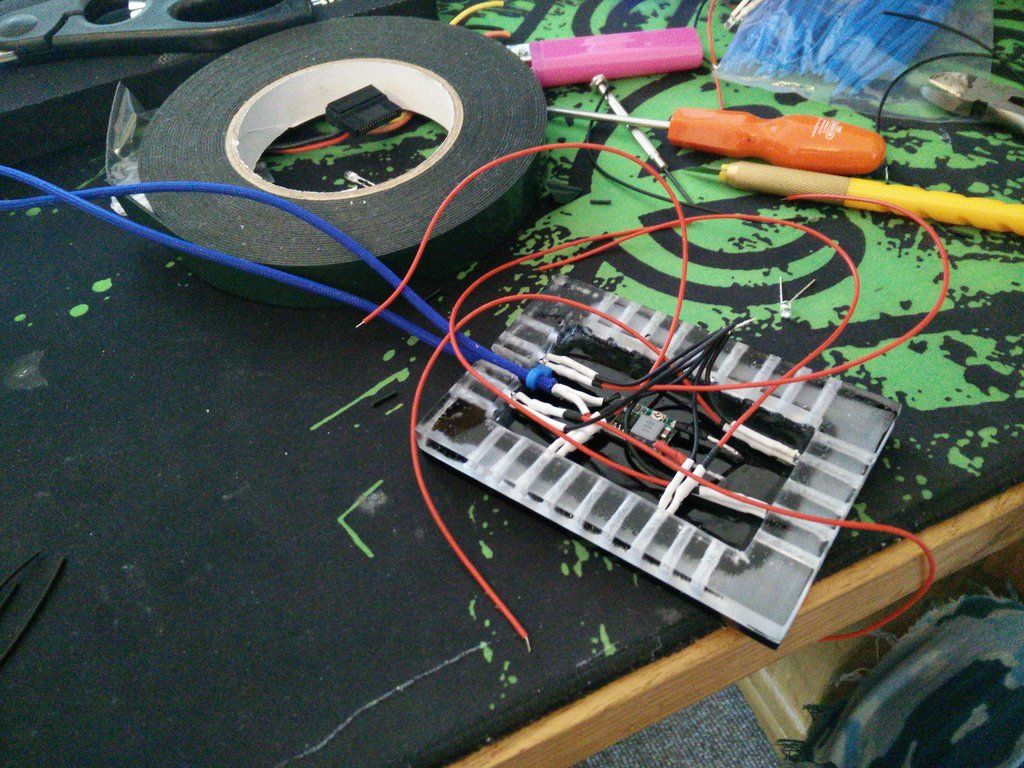

OK so pretty much everything is here now. I am still waiting on some blue tint but that may not even end up getting used.

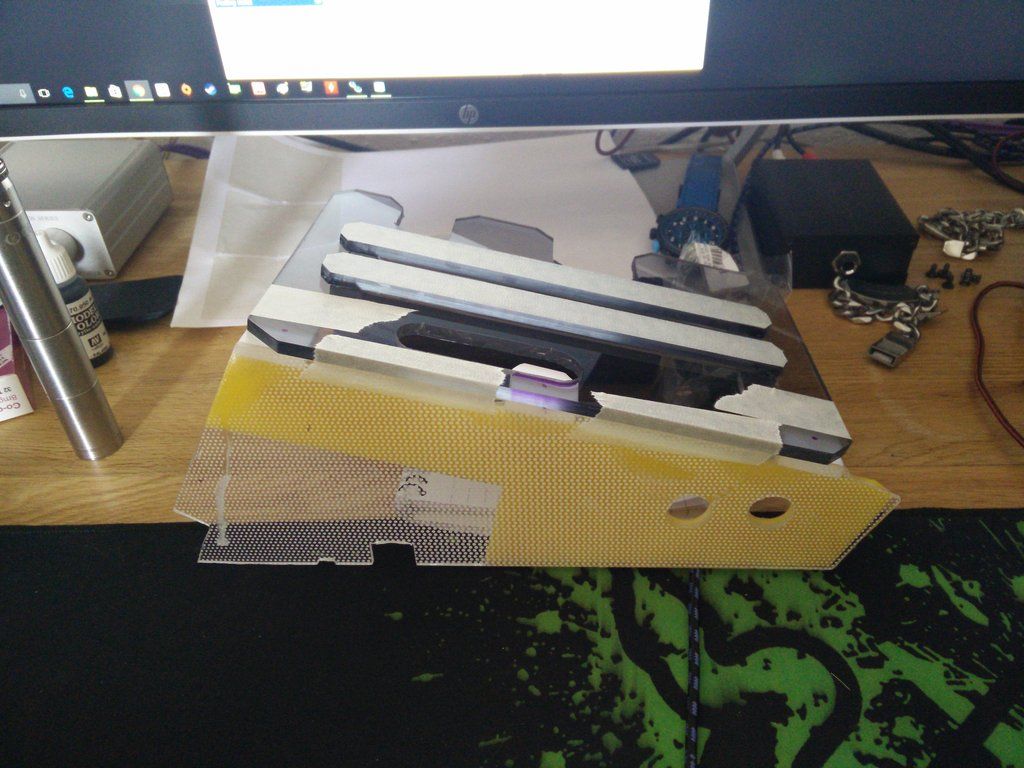

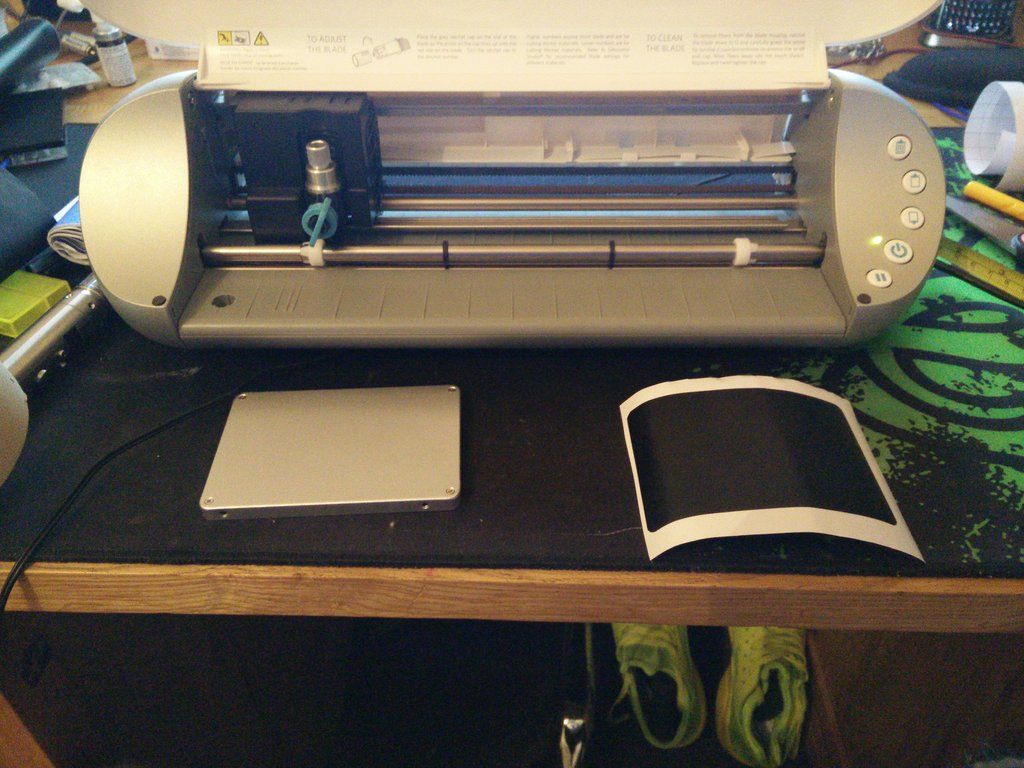

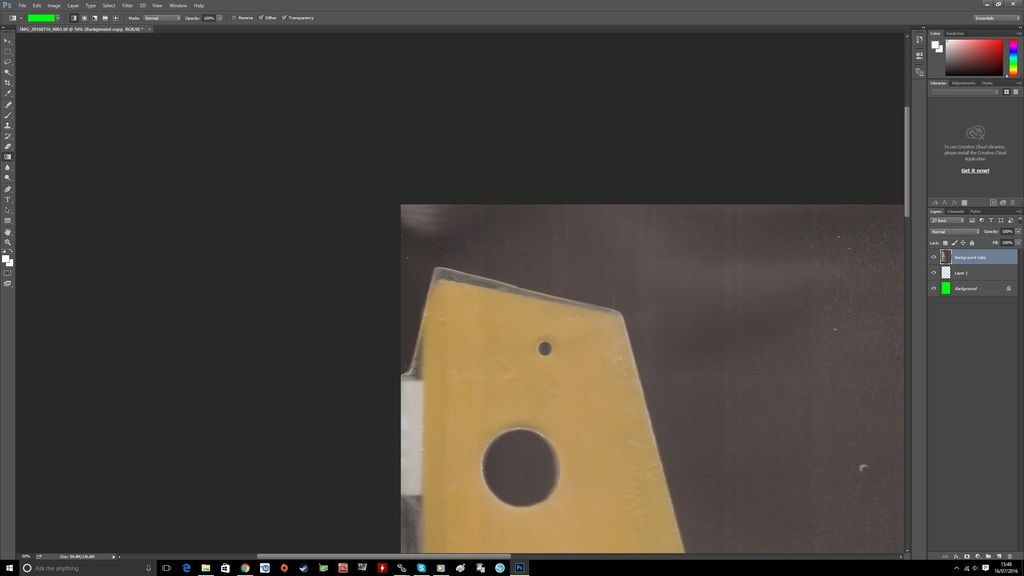

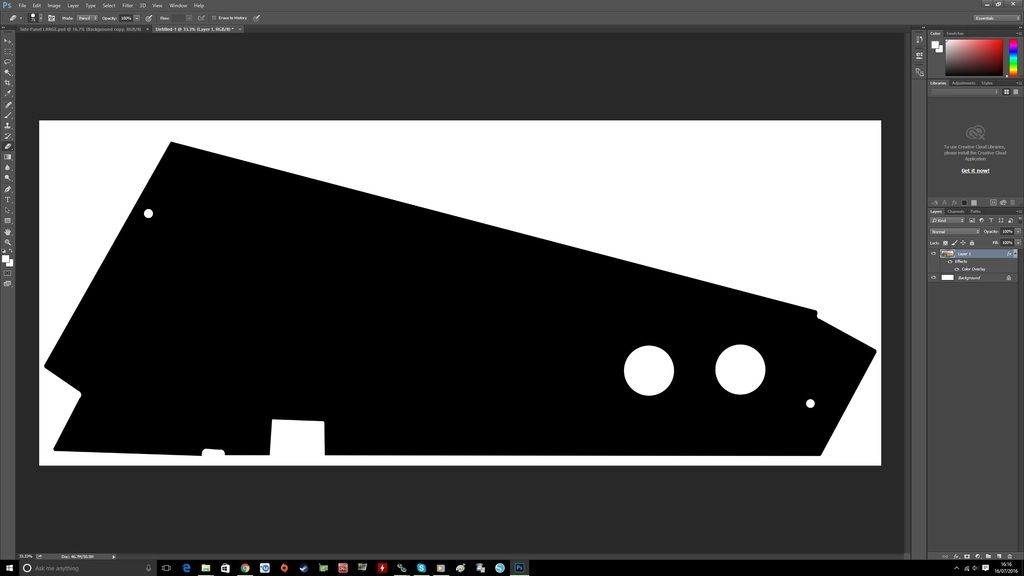

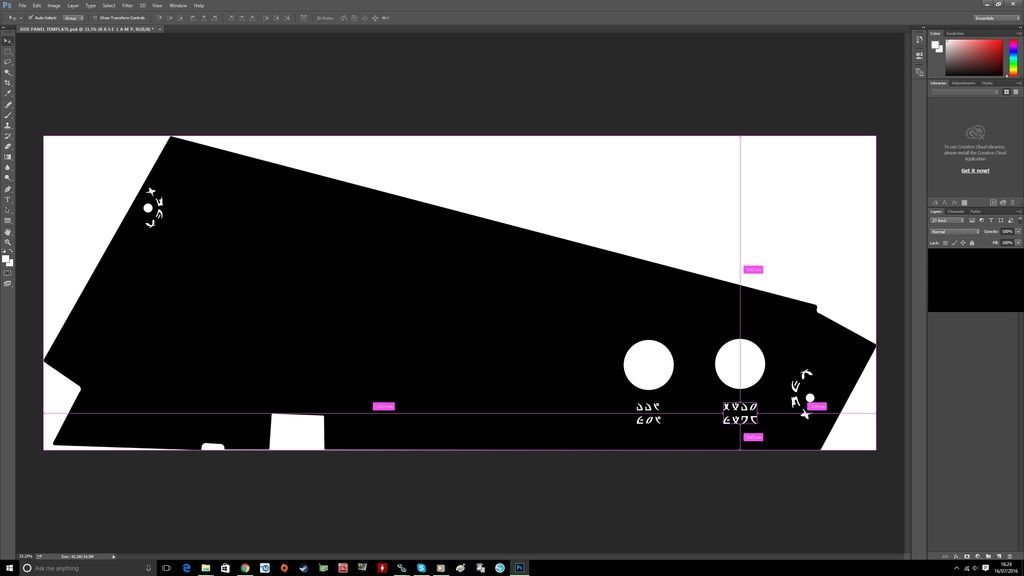

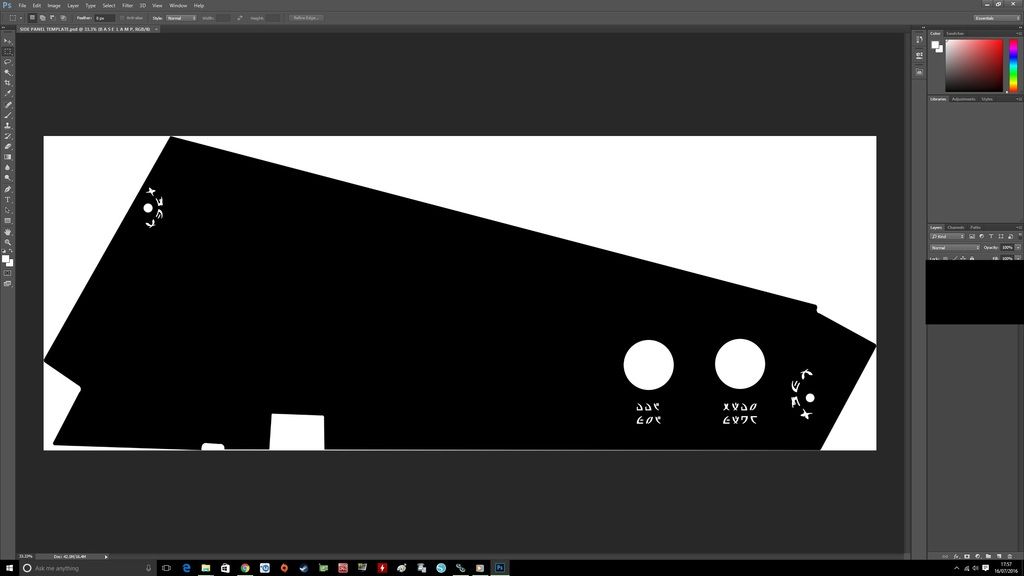

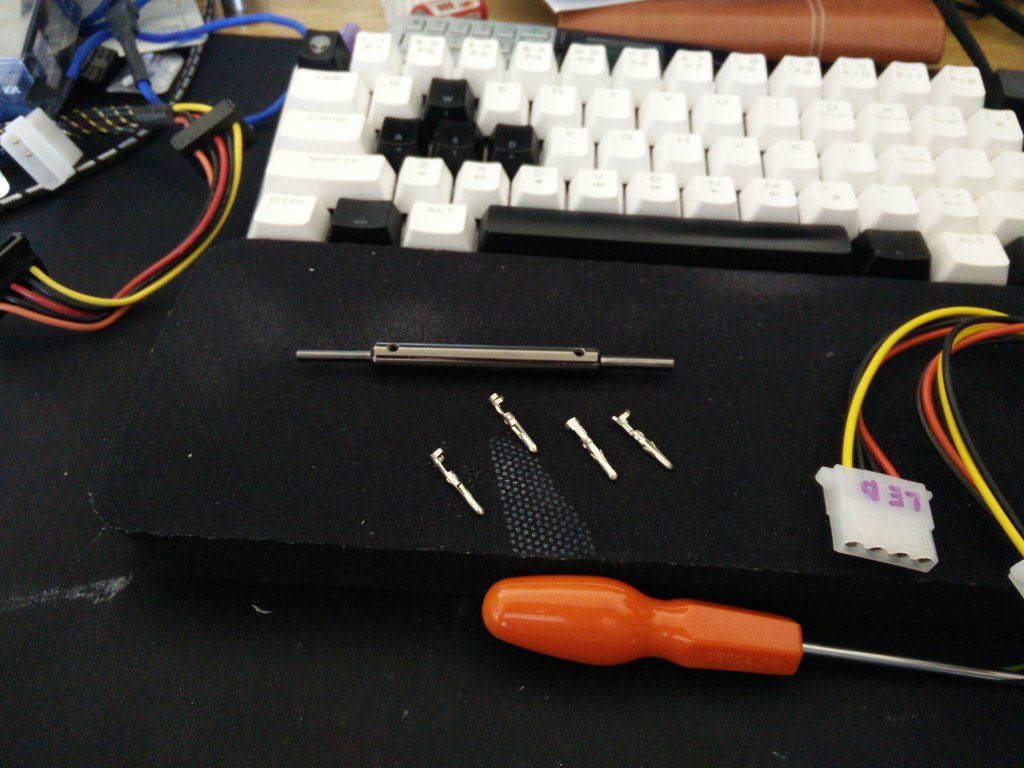

Today the vandal switches arrived from HK (£3.80 the pair, they're four times that EACH from UK vendors) and they're pretty snazzy. So I could finally cut the holes into the side panel to hold the switches. However, I had been very nervous about this because the outer skin is made from plexi glass and not acrylic. It tends to crack and split extremely easily. Thankfully though it was one of those jobs that just worked first time - phew, I'd put hours into that panel !

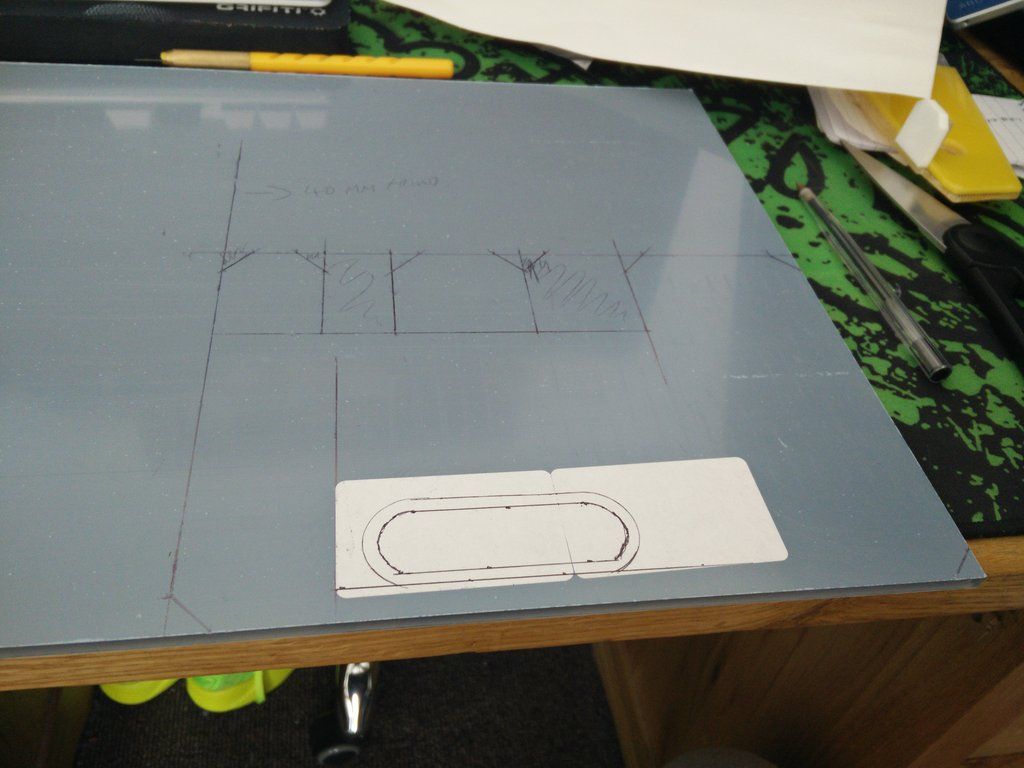

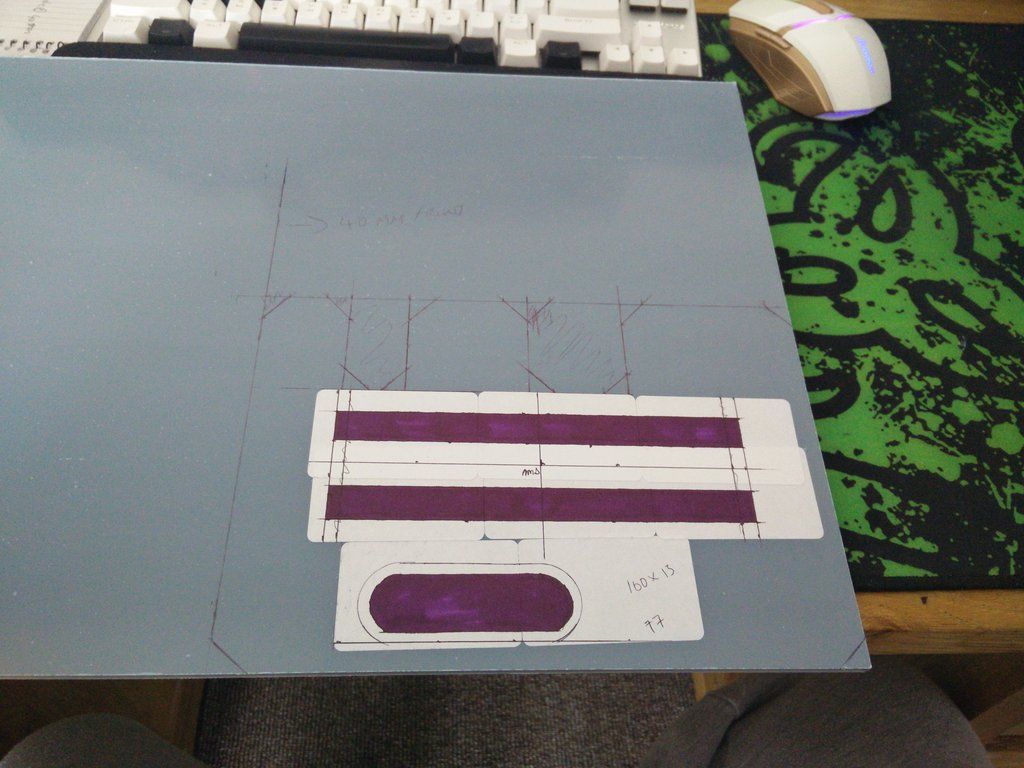

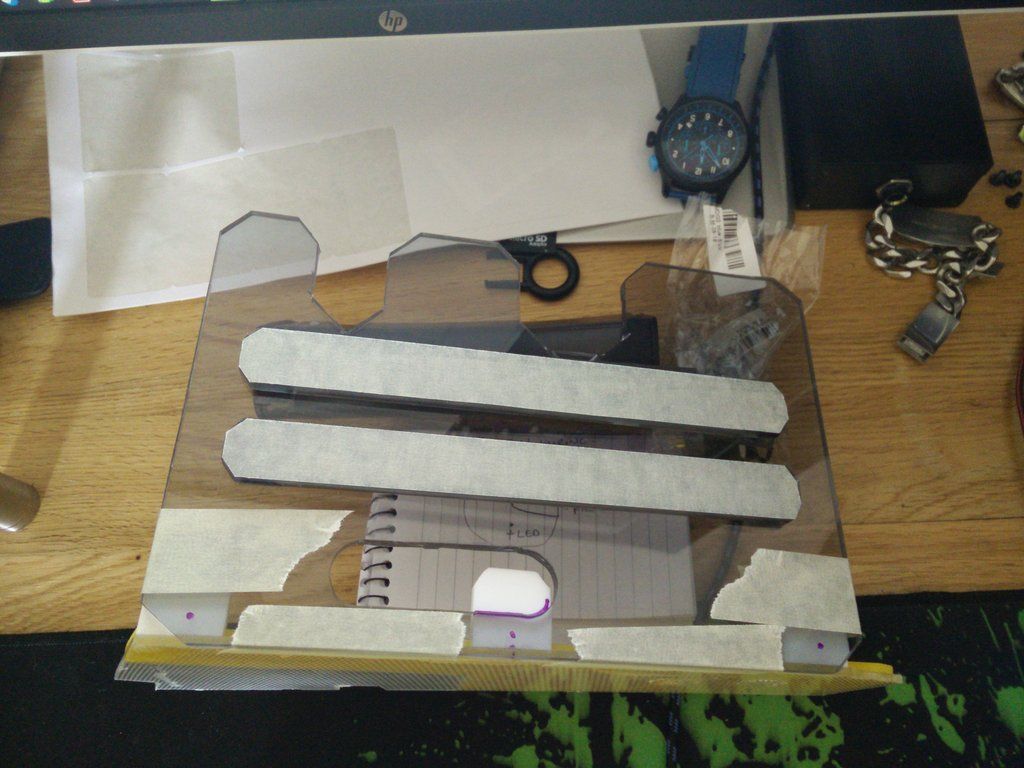

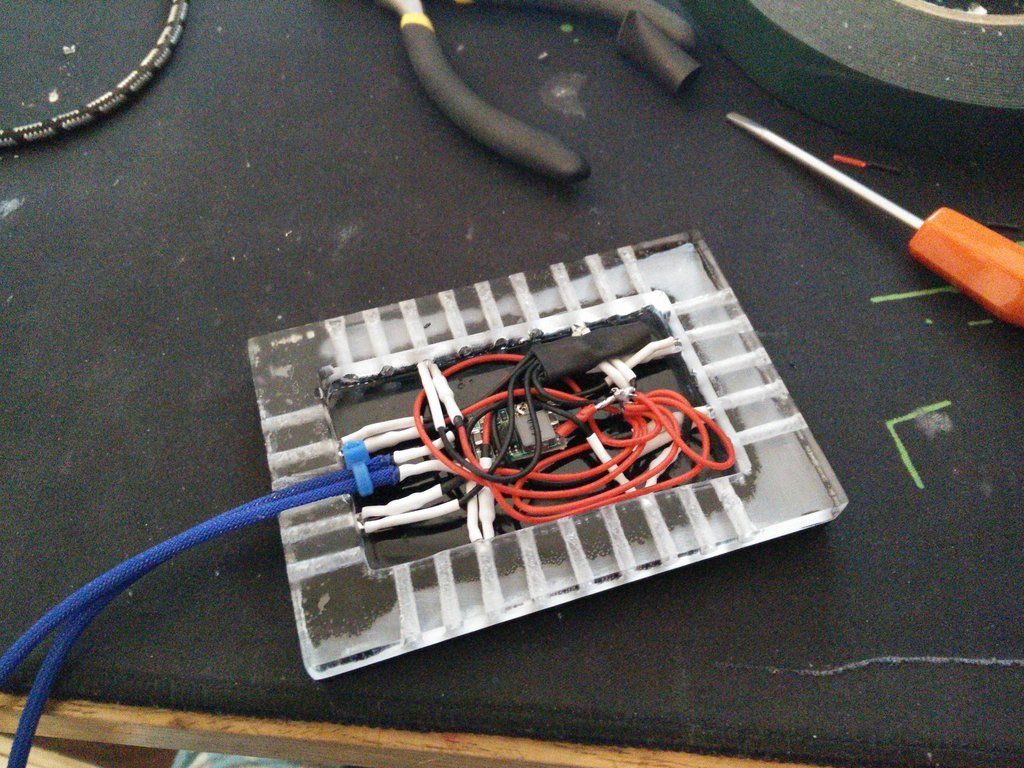

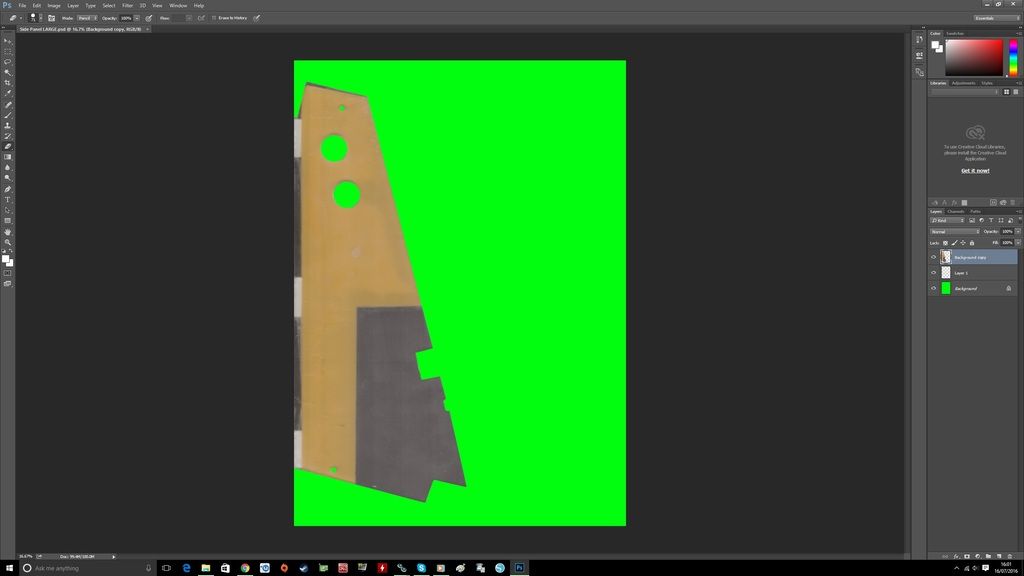

As you can see the final struts have also been cut and welded on. It should now be able to carry the quite heavy top panel without anything breaking off.

Here are the switches in situ.

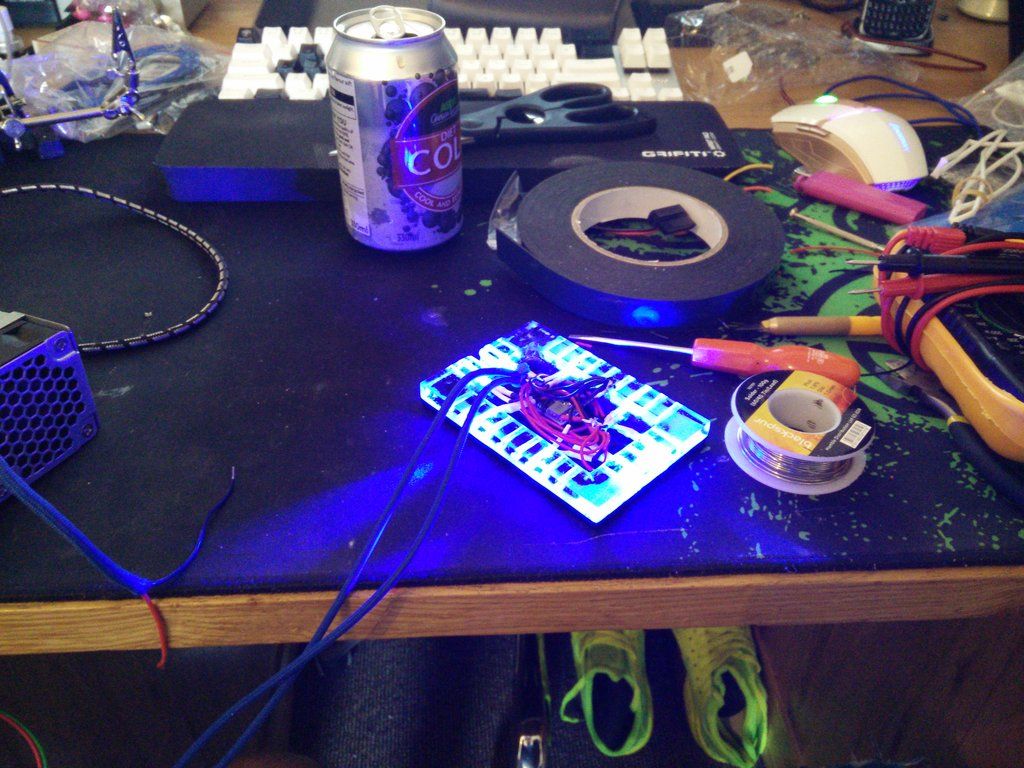

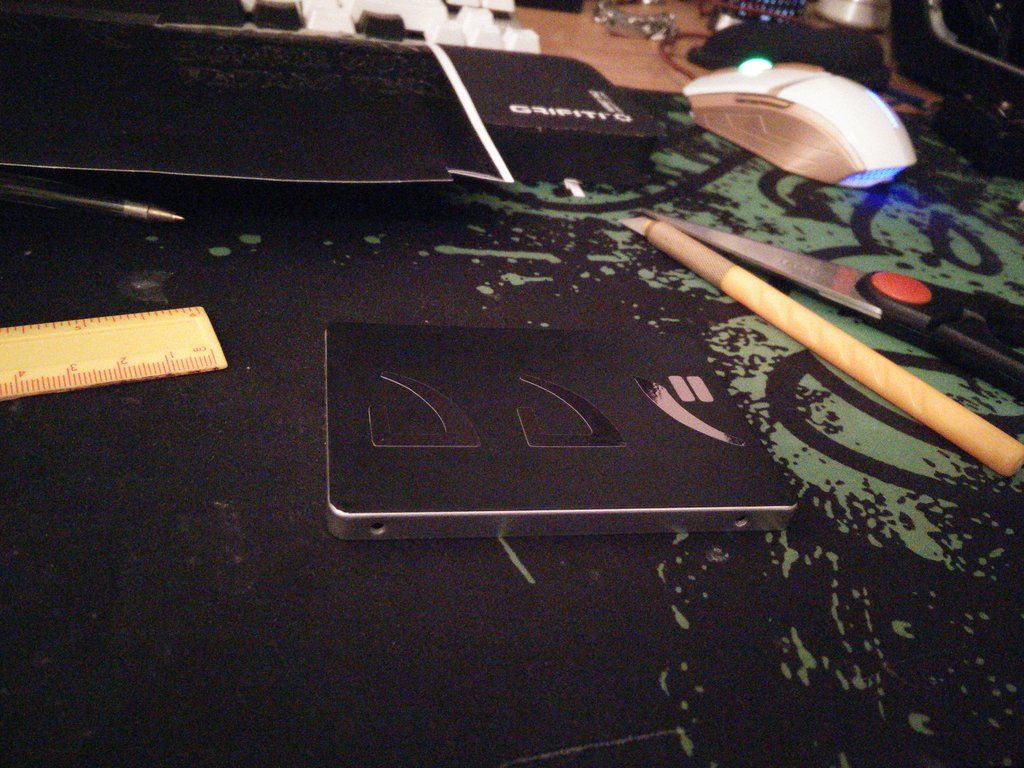

They light up too, very happy with those ! and of course the finished SSD-UFO.

Today the vandal switches arrived from HK (£3.80 the pair, they're four times that EACH from UK vendors) and they're pretty snazzy. So I could finally cut the holes into the side panel to hold the switches. However, I had been very nervous about this because the outer skin is made from plexi glass and not acrylic. It tends to crack and split extremely easily. Thankfully though it was one of those jobs that just worked first time - phew, I'd put hours into that panel !

As you can see the final struts have also been cut and welded on. It should now be able to carry the quite heavy top panel without anything breaking off.

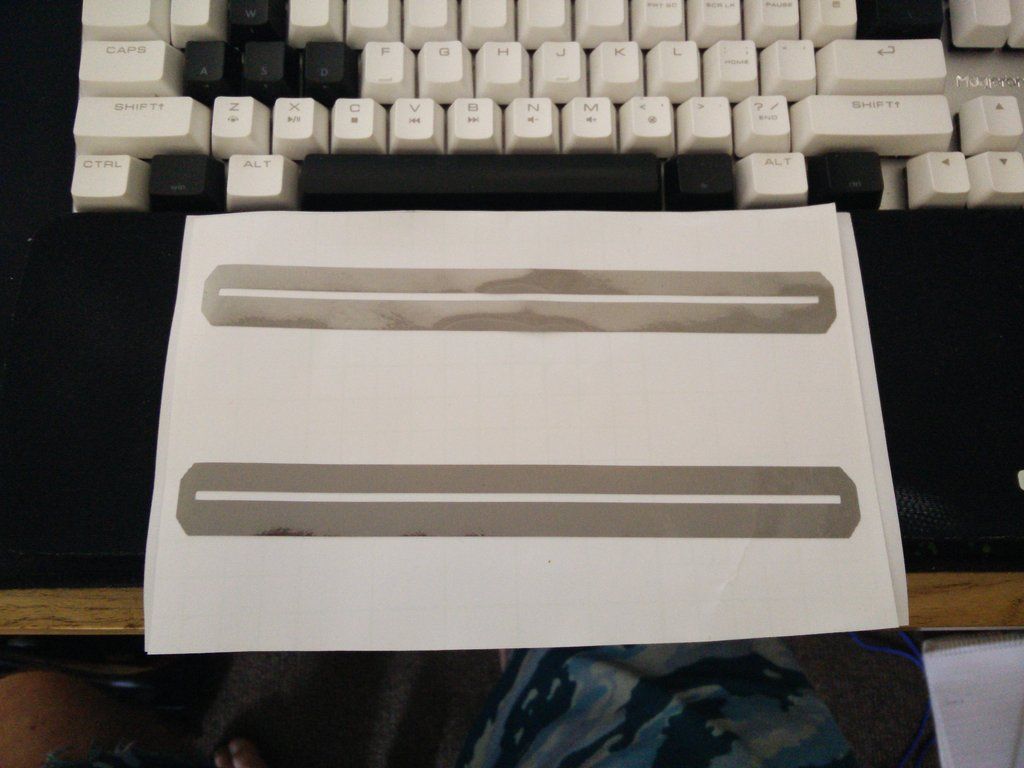

Here are the switches in situ.

They light up too, very happy with those ! and of course the finished SSD-UFO.

at least I found out after one!

at least I found out after one!