More madness

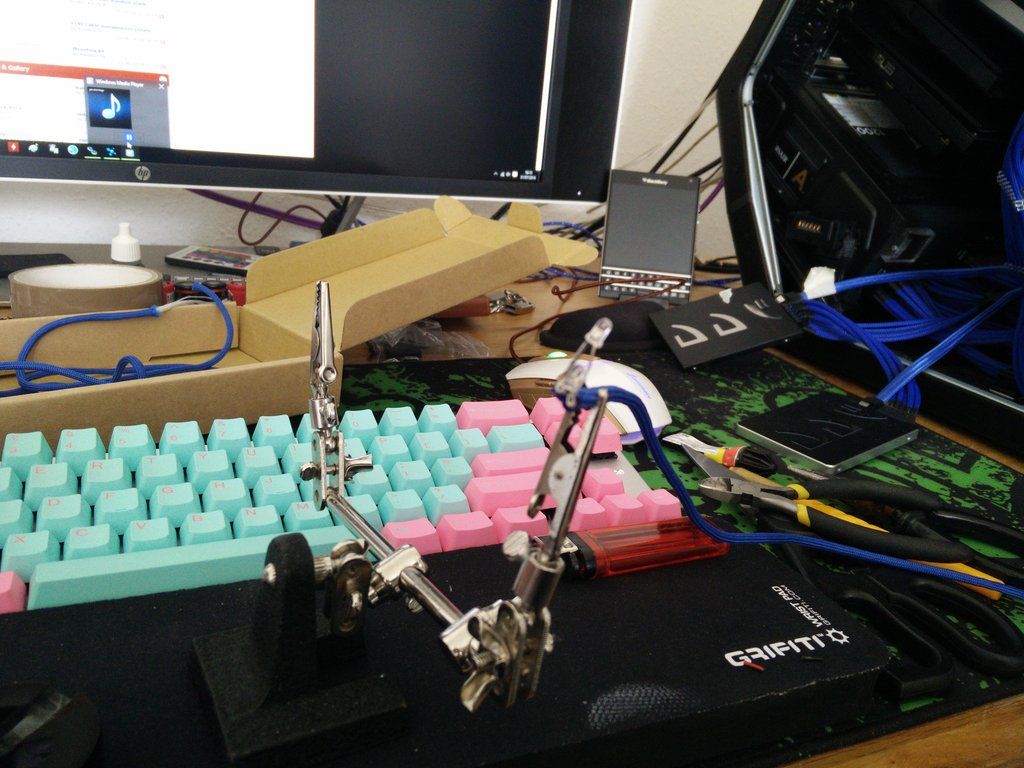

As I mentioned earlier in the build log I really wanted to go for detail. So that means pretty much that I would like some really fine details on the build as well as just the boxes and covers.

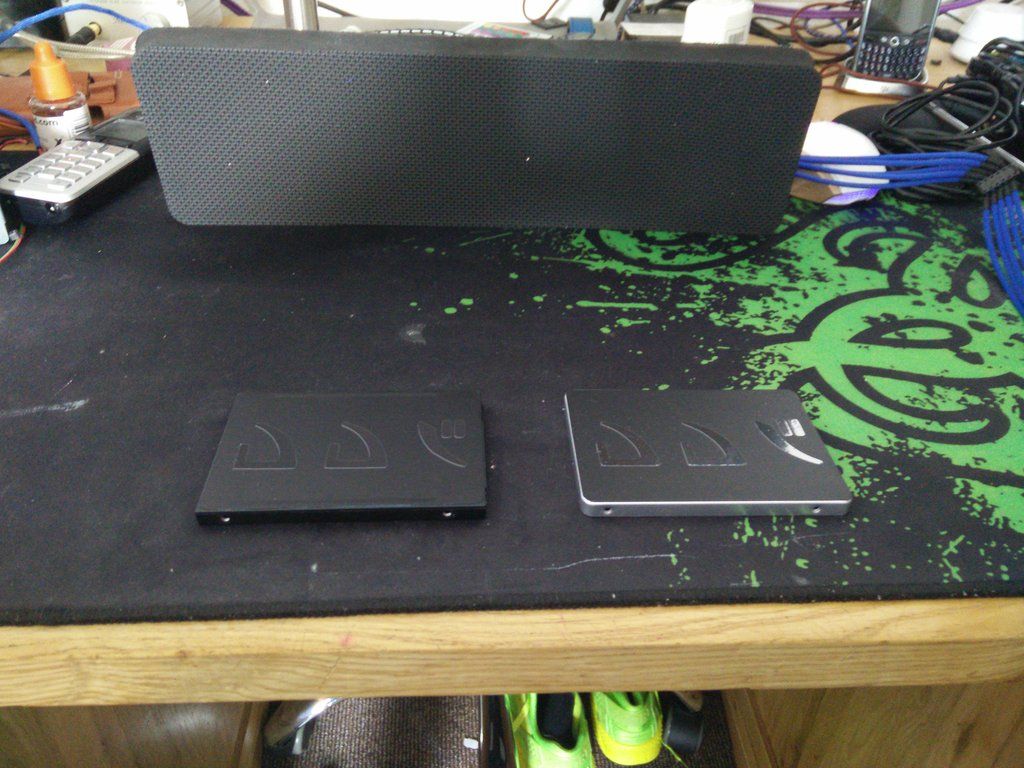

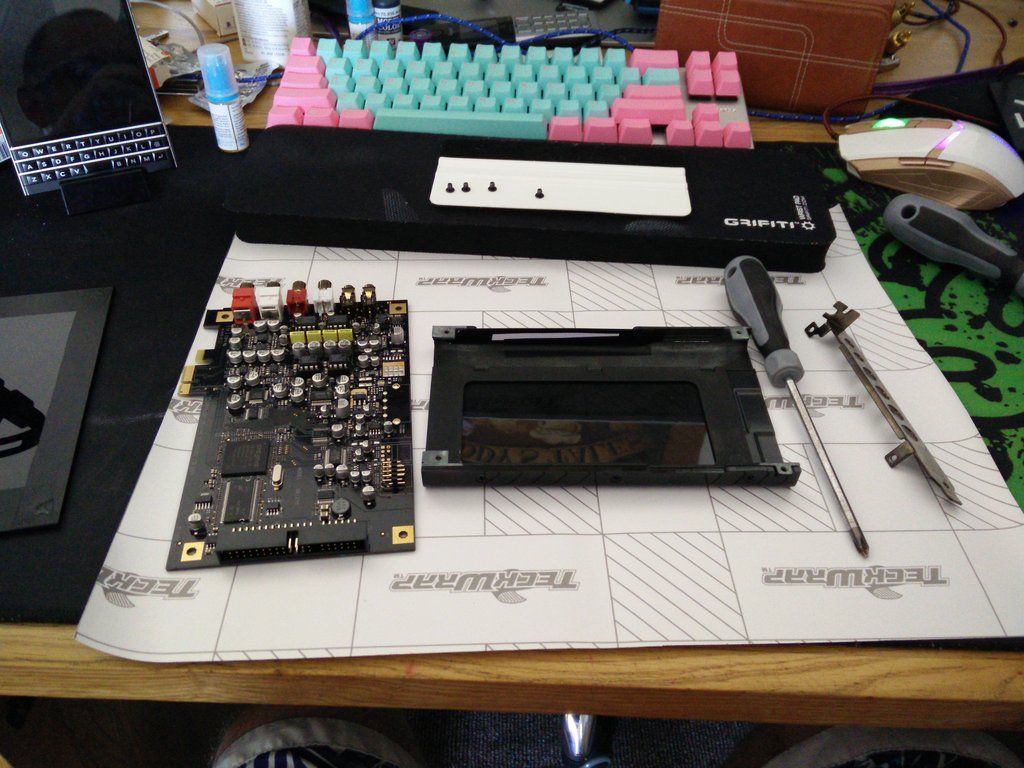

So I was walking down the hallway earlier and spotted this in one of my junk boxes (fans, wiring, fan grills etc).

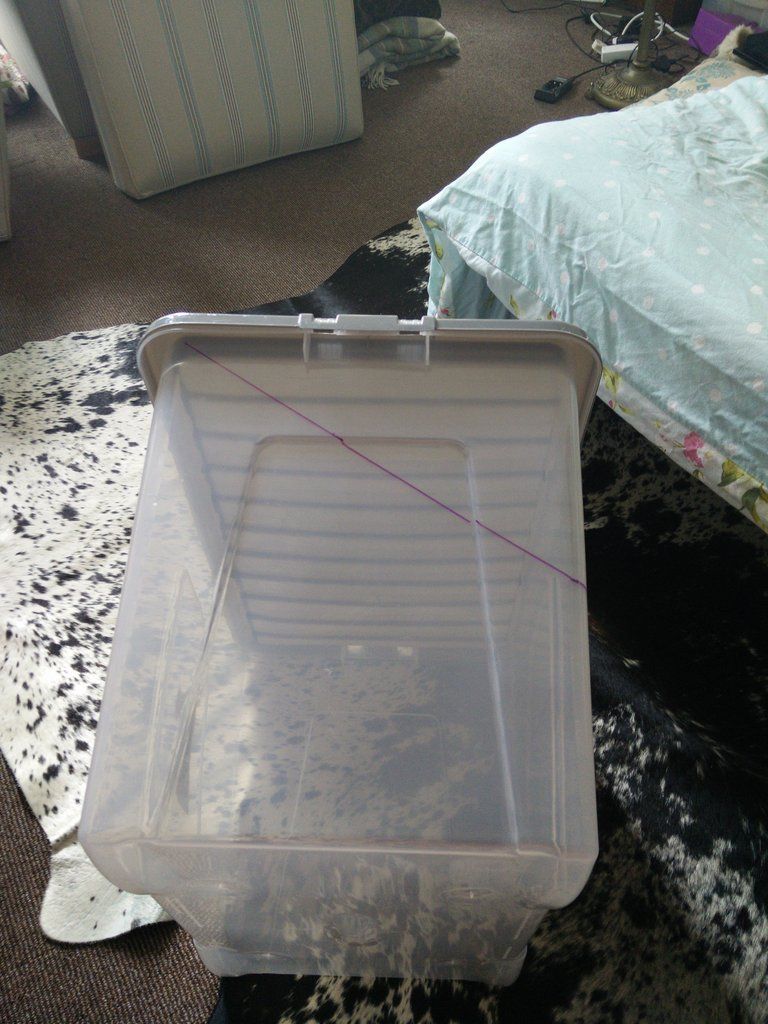

Now I have a lot of fans. And I mean,

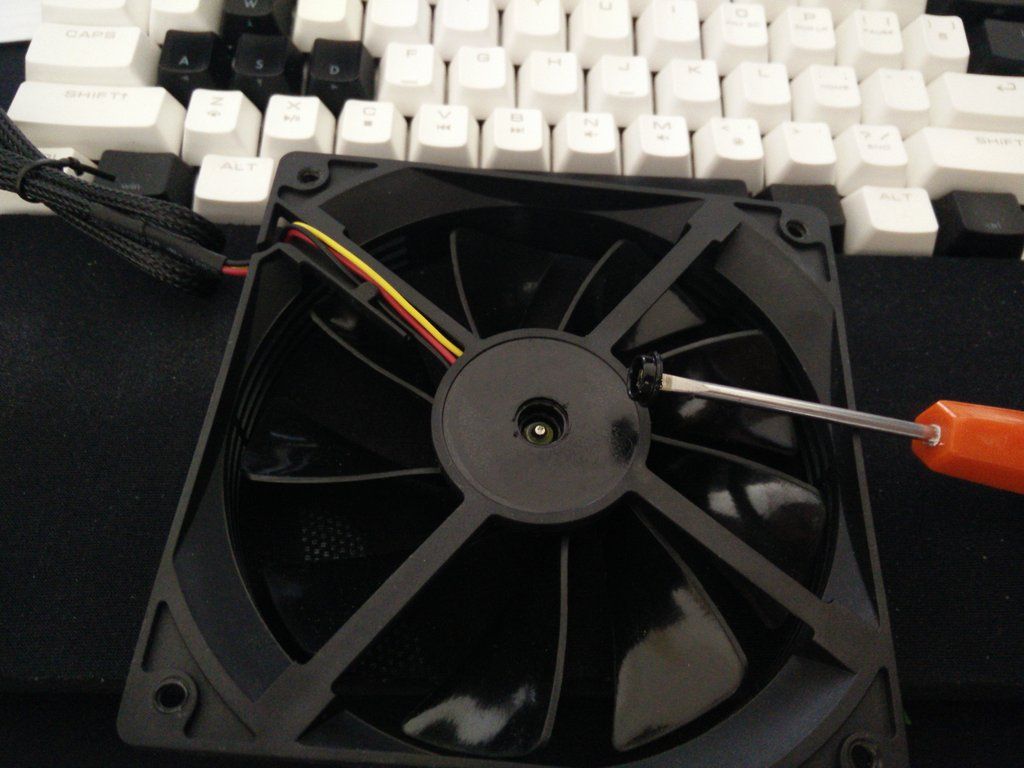

a lot. Some were from rigs I no longer own (or no longer even exist) and some were for projects that never got started and so on. This is a Xigmatek one way 120mm fan that I picked up in a sale for about £3. I remember ordering about five of them with big plans and ended up only using a few for a few weeks. You see fan, I see nose cone....

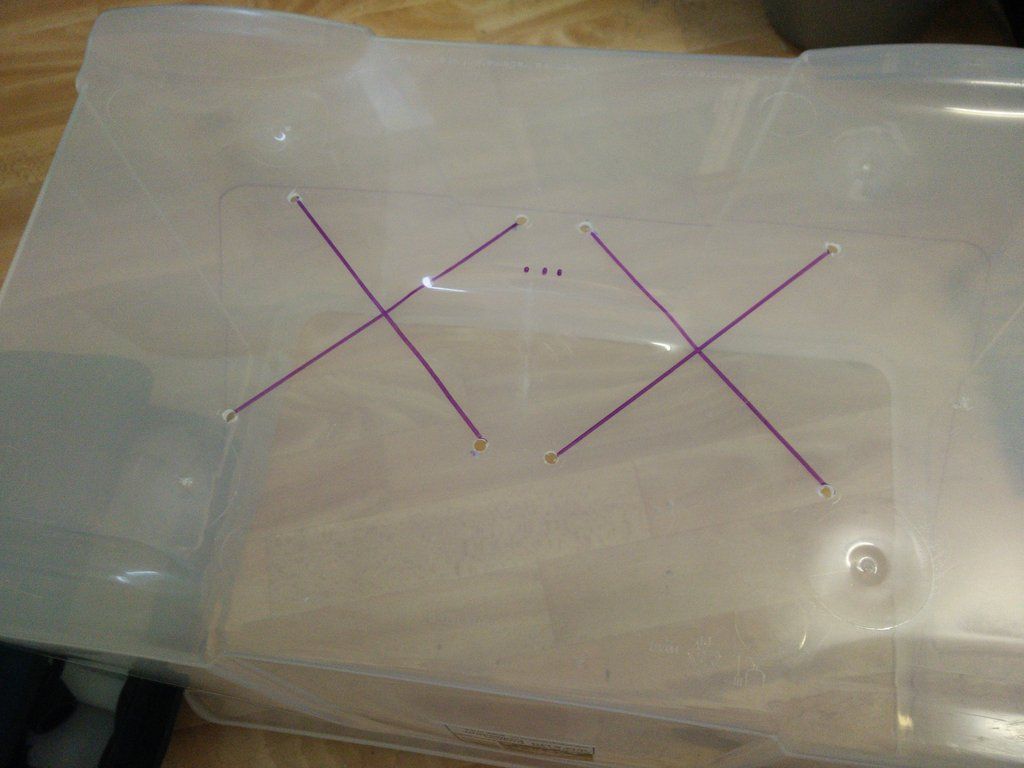

Let me explain. There's a guy on one of the forums I visit called Nexxo. Nexxo is building a rig called Metaversa 02 : Ada. It's a Steam Punk build but christ, it's good. He has a lathe and many machines and has slowly been building his vision for what feels like forever. As an example of this here are what his fans look like with nose cones that he has machined using a lathe and some brass.

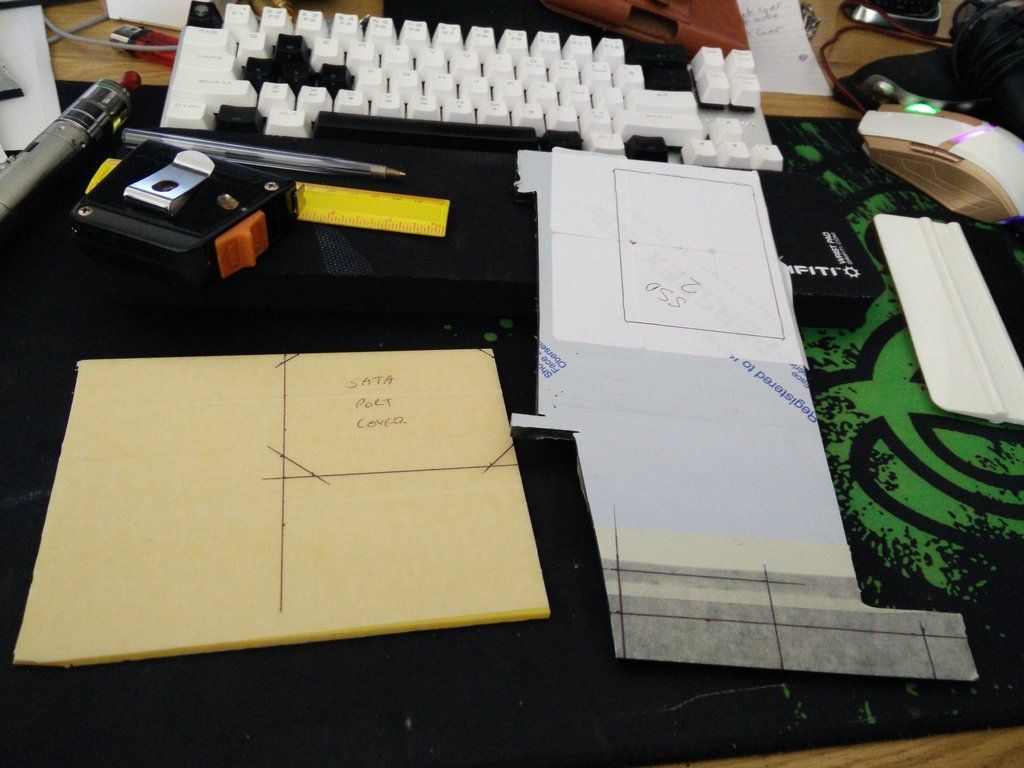

I like it. However, I ain't kidding myself. I don't have the machinery nor the knowledge of how to use them so I won't be making parts like that. I did think about contacting some one and asking if they could make one for me (in fact that was a white lie, I did contact some one but he doesn't have a lathe). Any way, he suggested that I just use a drill or Dremel to machine the part. I did know what he meant thankfully so I decided to begin.

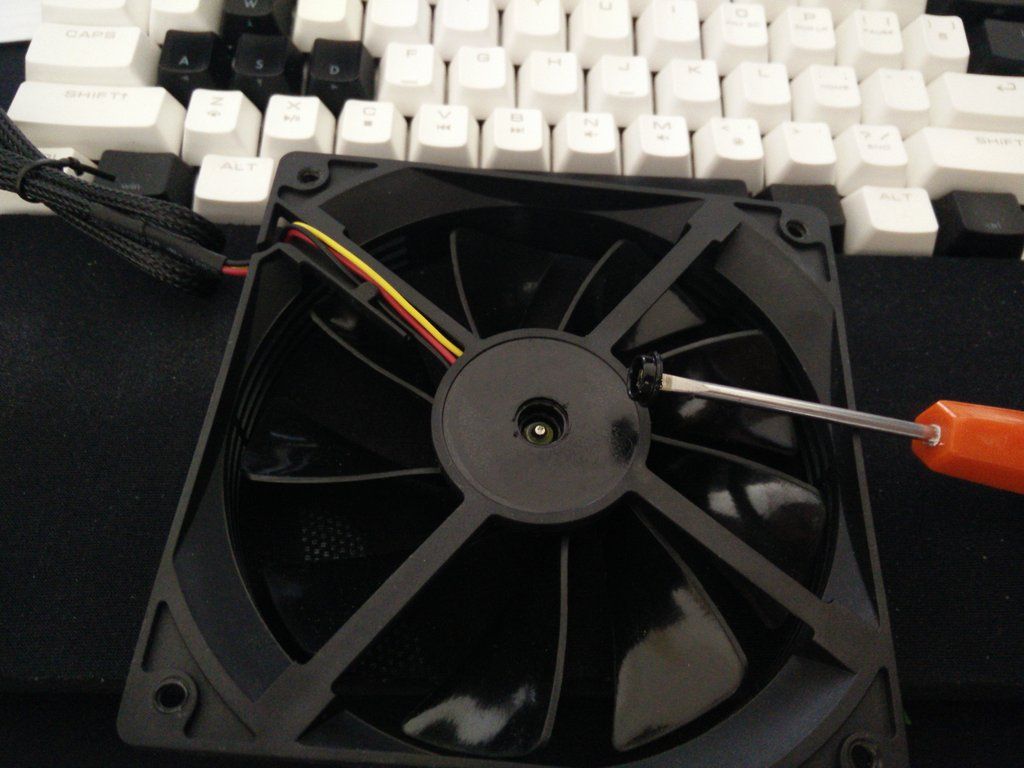

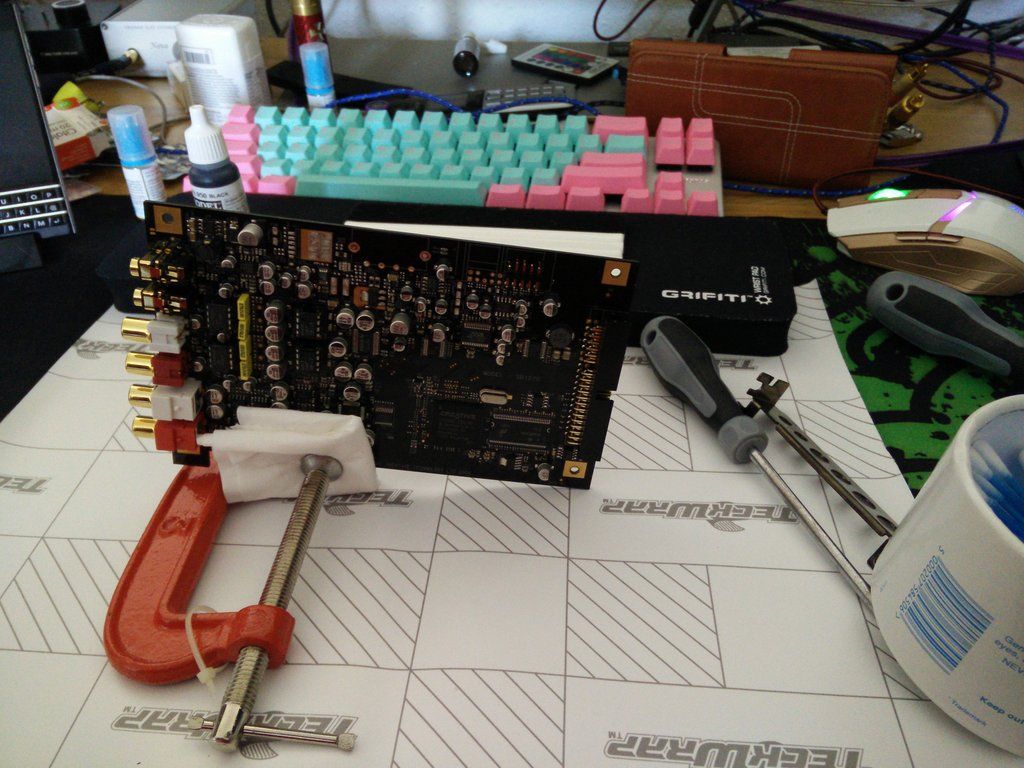

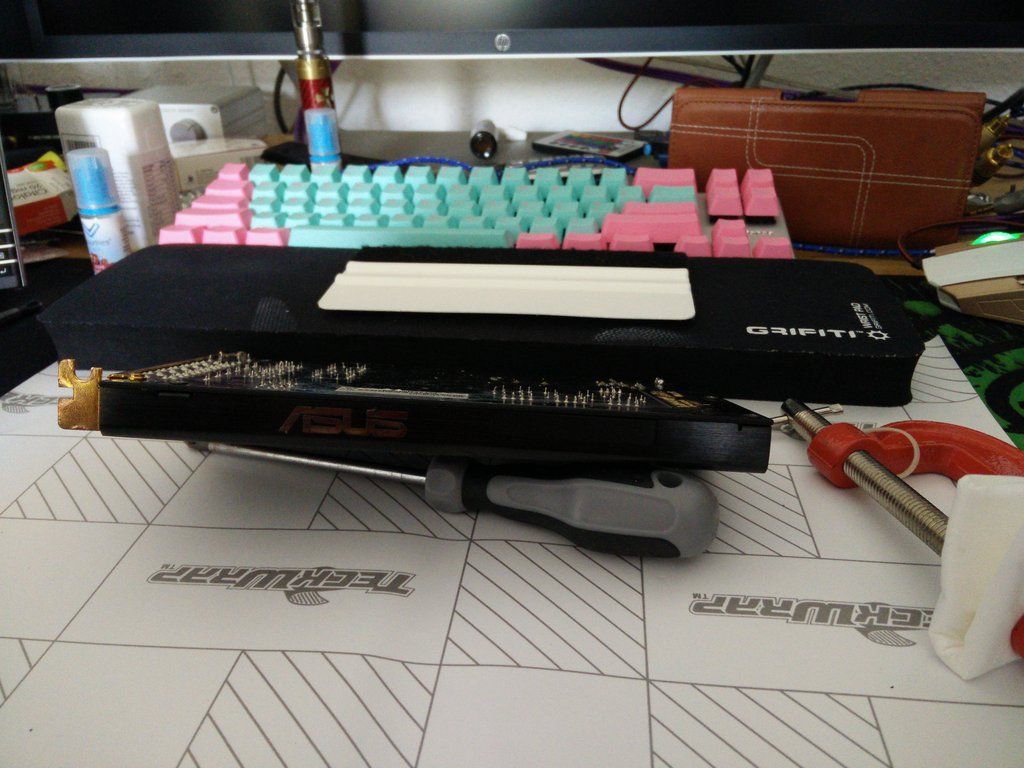

OK so first I needed to turn the fan over in order to get the blades out.

And bugger, it's a sealed unit

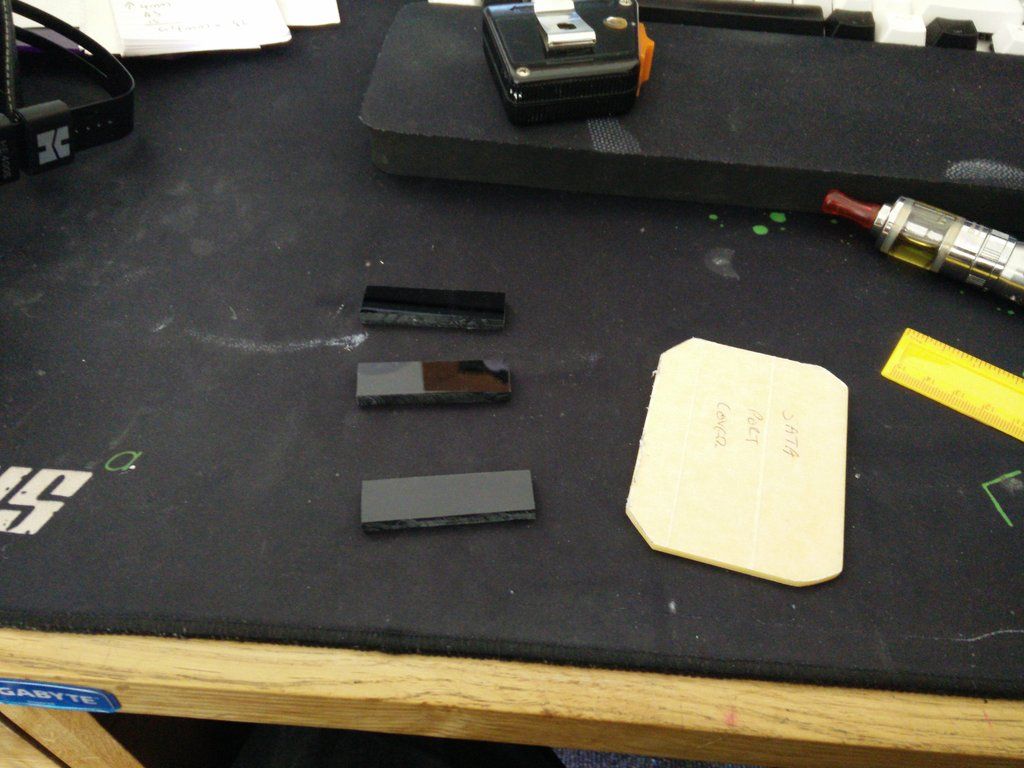

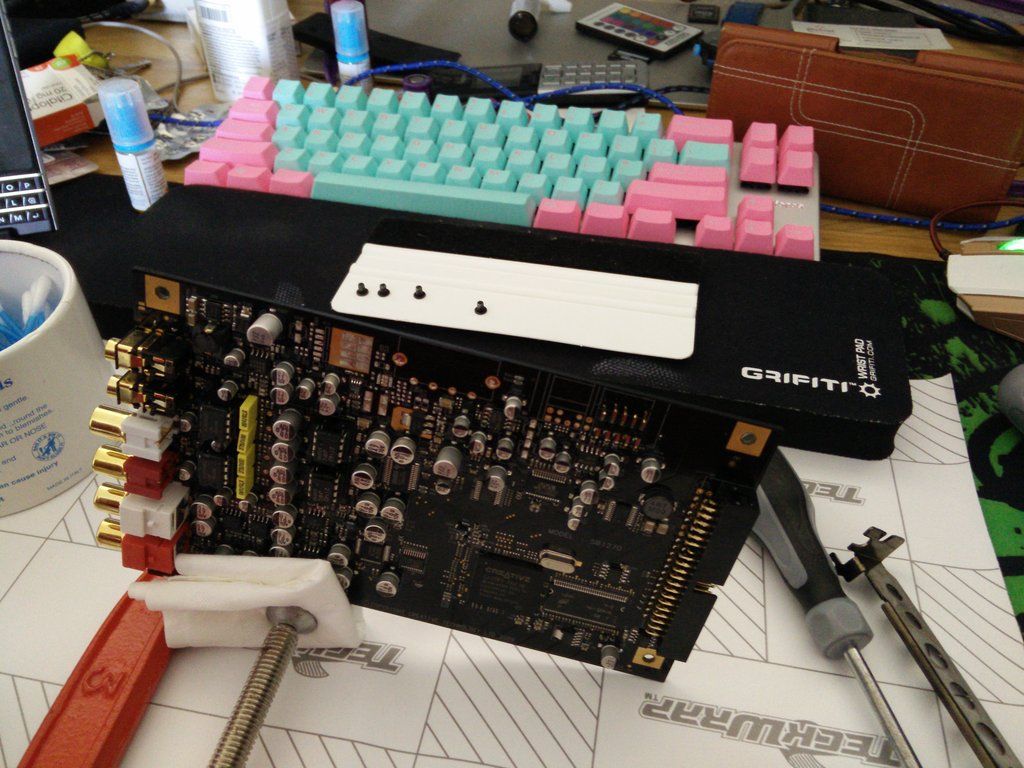

There are a few things you will find here. Firstly you find a soft rubber plug that comes out easily. Secondly you find nothing at all and can see the split washers holding the fan on and thirdly you find this, a plastic welded solid plug. It's a real pain to get them out and I tried cutting it out first with a razor blade but the edges just snapped off. After a bit of wrestling and some brute force I got this.

OK, so now I can get access to the split washer. Thankfully they used cheap glue and it snapped out pretty easy, phew. Then I removed the split washer and pulled the fan blades out.

And then I got out something I bought ages ago that I ended up not even using, a fully adjustable chuck for my rotary tool. I initially bought this thing to make it easier to switch bits and use different sized drill bits etc but it ended up being perfect for the job.

OK now sadly this is where it got really messy. However it basically involved me going into the workshop (the kitchen

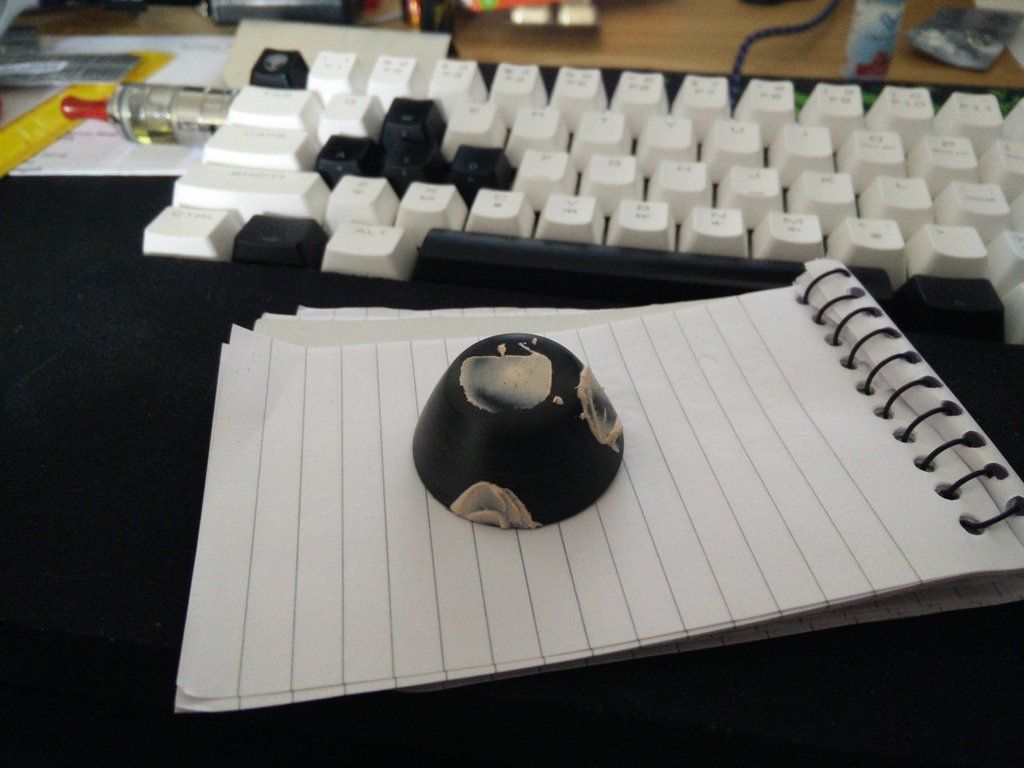

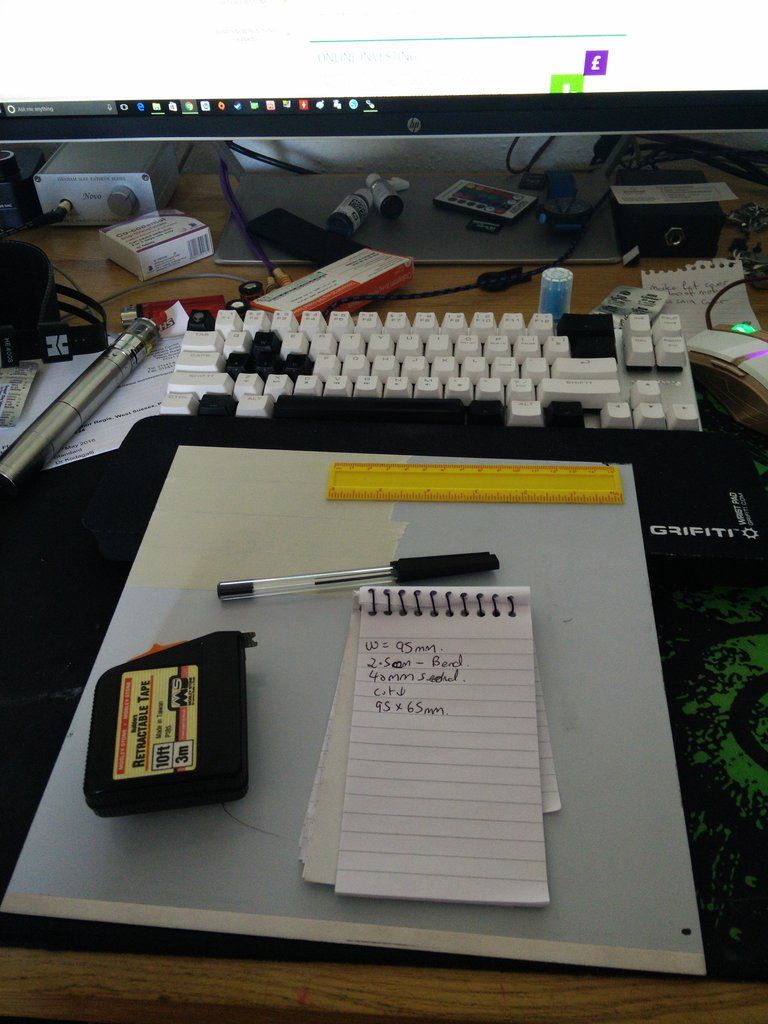

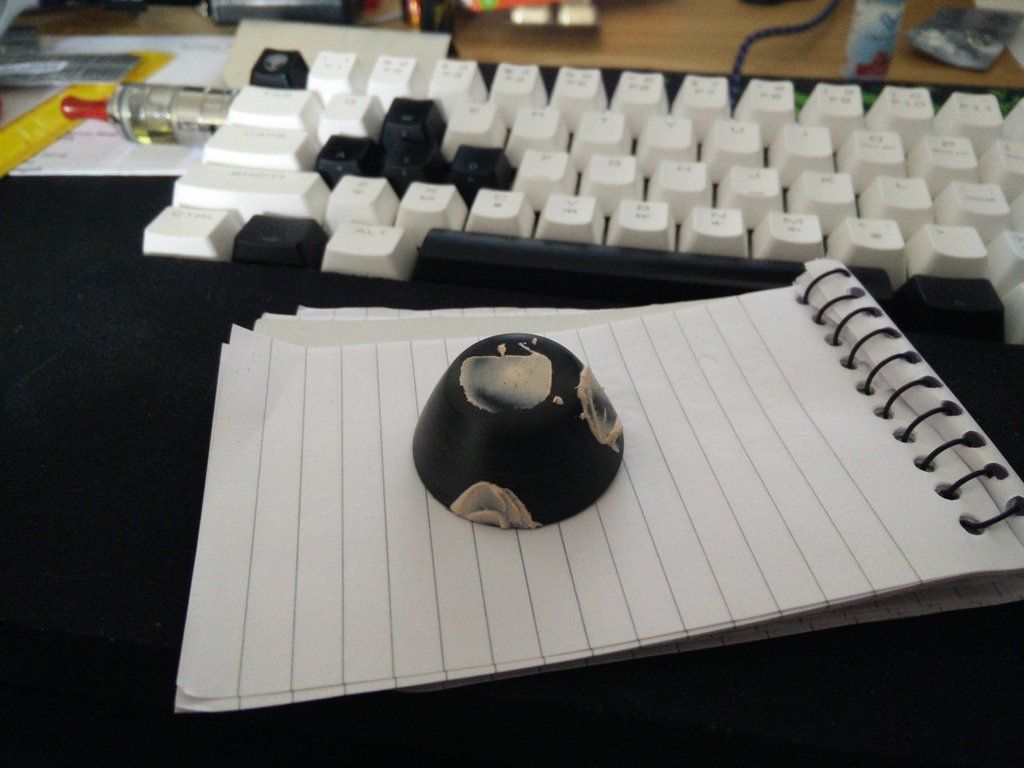

) and very carefully removing as much of the blade material as I could without damaging the cone (which didn't happen and I created a couple of cut scars). However, once I had done cutting and grinding off as much of the blades as I could I then bolted the bugger into the end of my Dremel using the chuck (which tightens at the bottom which was handy because otherwise I would not have been able to get to it to do it up !) and then slowly introduced the sandpaper to it.

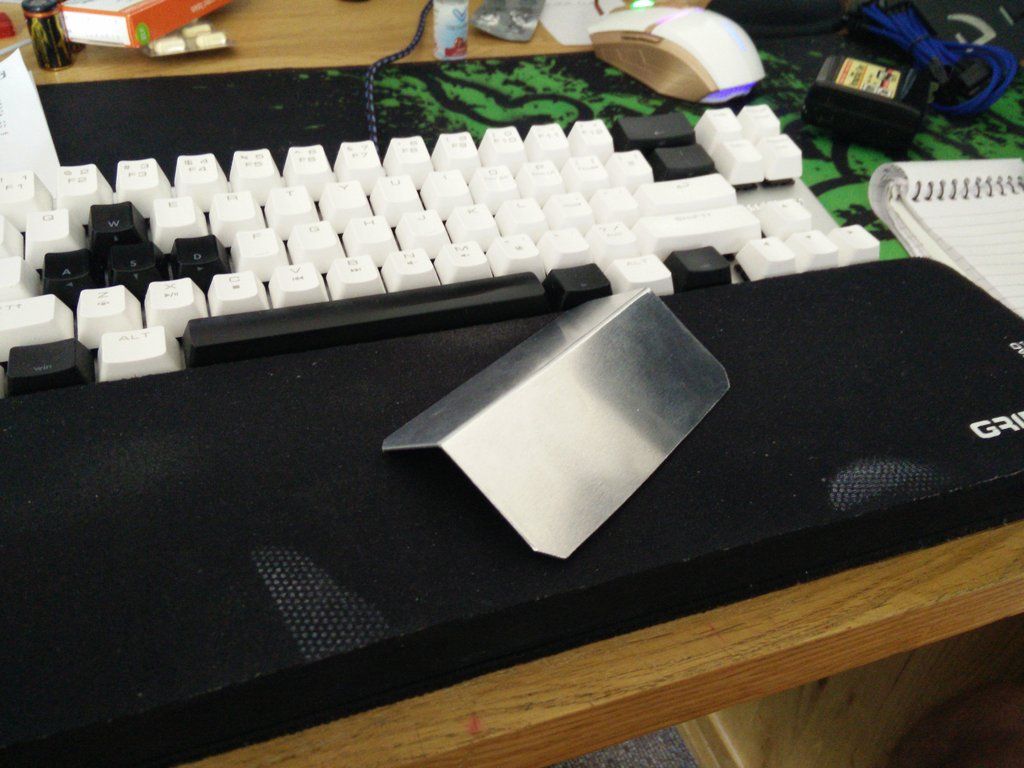

I started off with a piece of alu based cloth and then slowly moved down the grade of the sandpaper to shape the nose cone. After about 30 mins (and then 30 mins of tidying it up, jesus it made a mess !) I had this (note I have put some filler into the dremel scars)

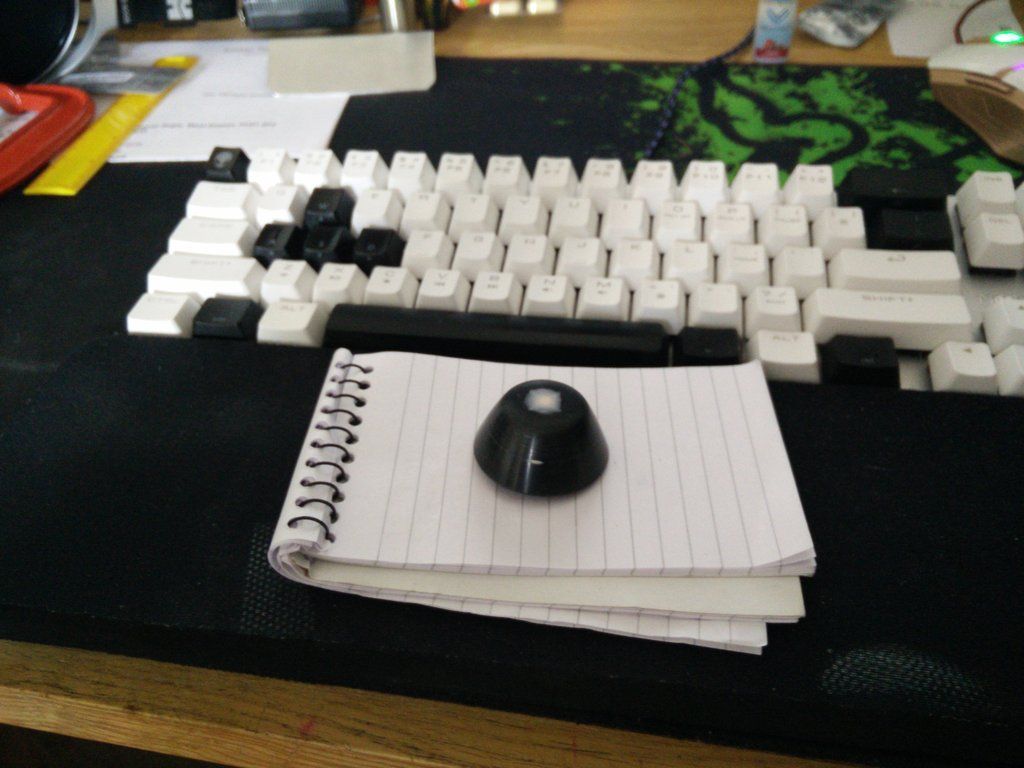

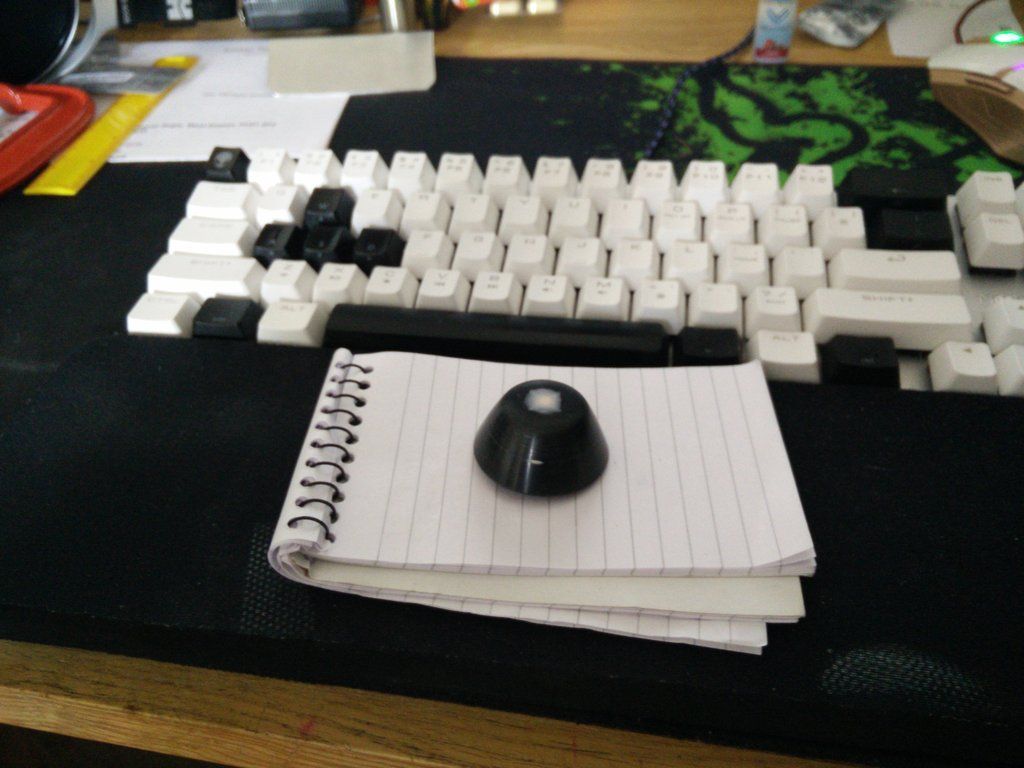

I was pretty darn pleased with myself considering I had never attempted any such thing before ! Any way, after the filler had set (took a while it's very humid in here today) I had this.

Which is pretty much ready to be primed and painted. However, I don't think I'm done yet. I've had another idea I want to implement that should take me a couple of hours to do

I think it's one of those things where all of the good stuff all happens in one day, the day you put it all back together

I think it's one of those things where all of the good stuff all happens in one day, the day you put it all back together

that means I shouldn't be prepping as I would leave oils all over the place

that means I shouldn't be prepping as I would leave oils all over the place

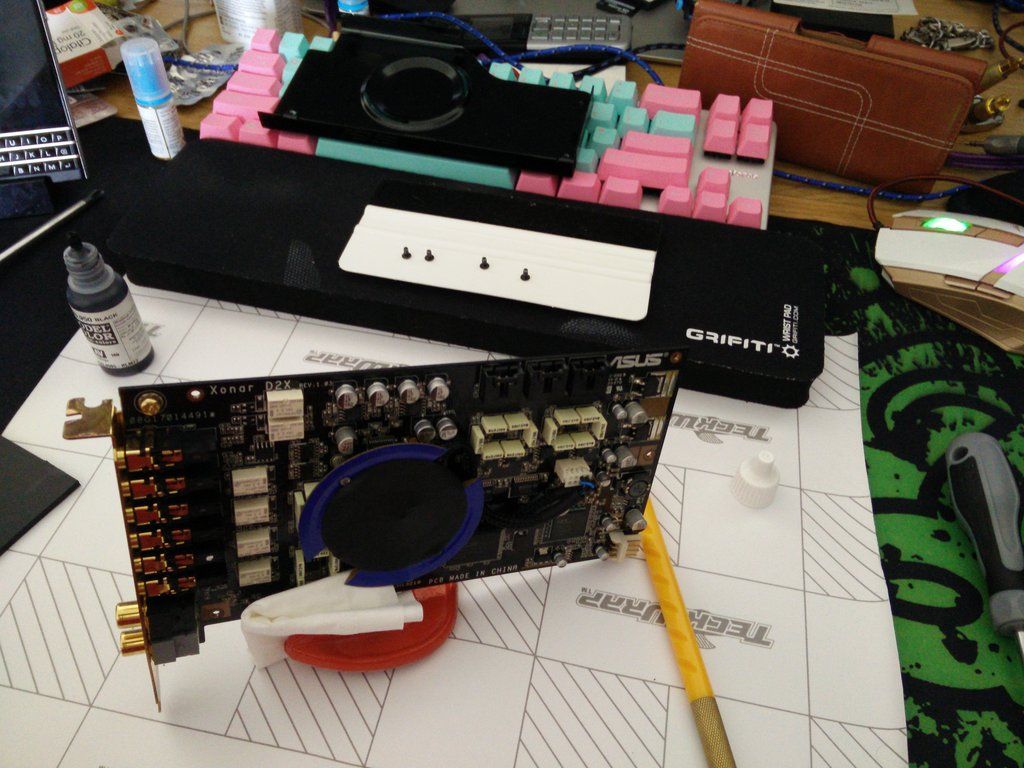

so the shrink was completely unnecessary. Why on earth would you use honking nasty shrink in a god awful shade of blue if it wasn't even necessary?

so the shrink was completely unnecessary. Why on earth would you use honking nasty shrink in a god awful shade of blue if it wasn't even necessary?

)

)