3-2-1 GRRR.

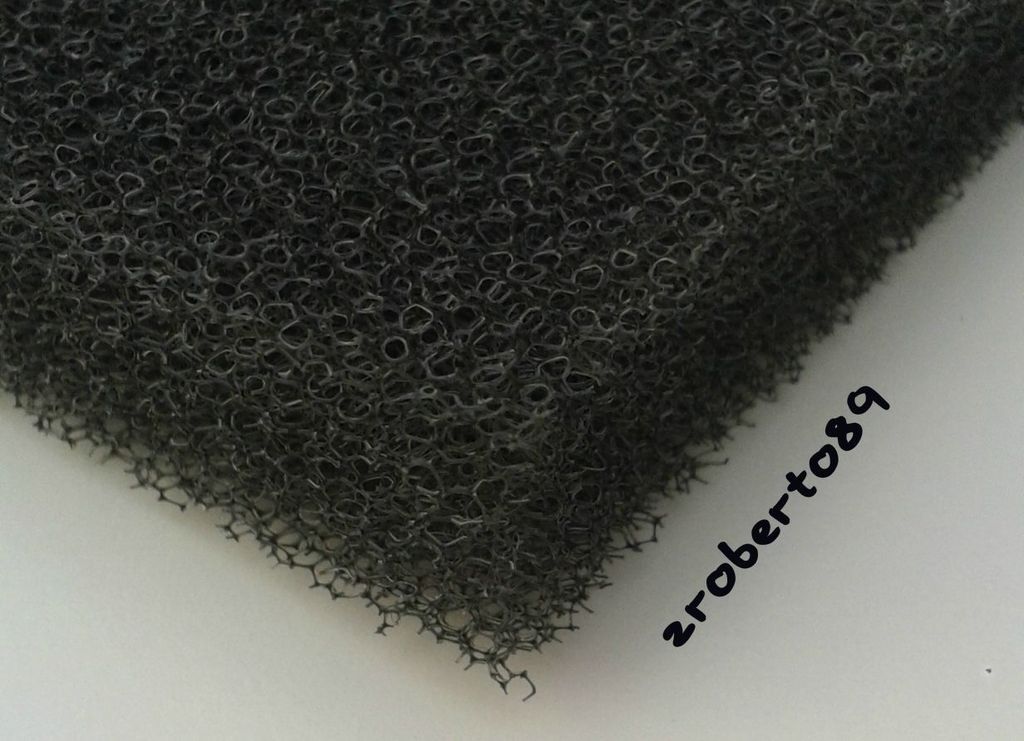

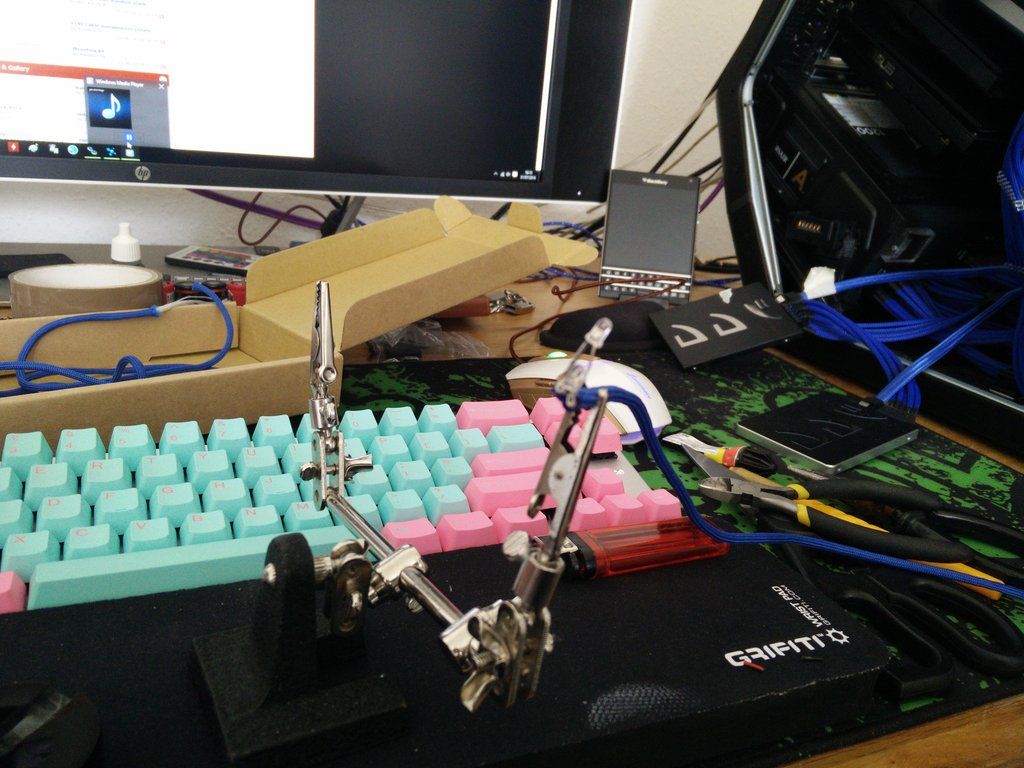

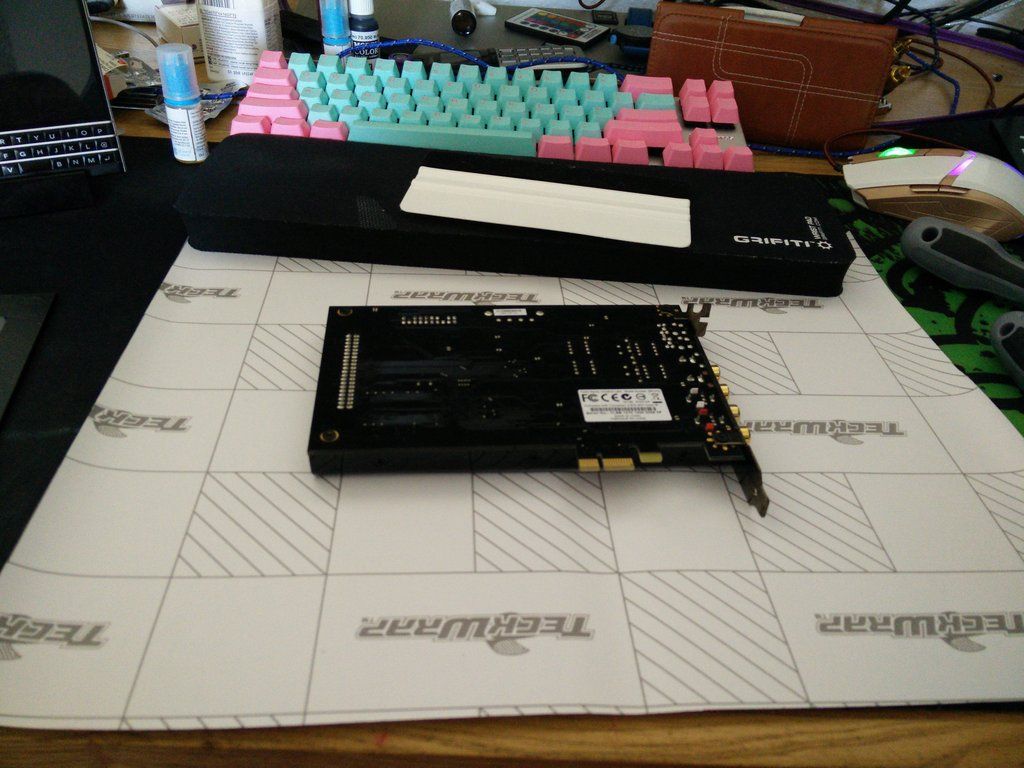

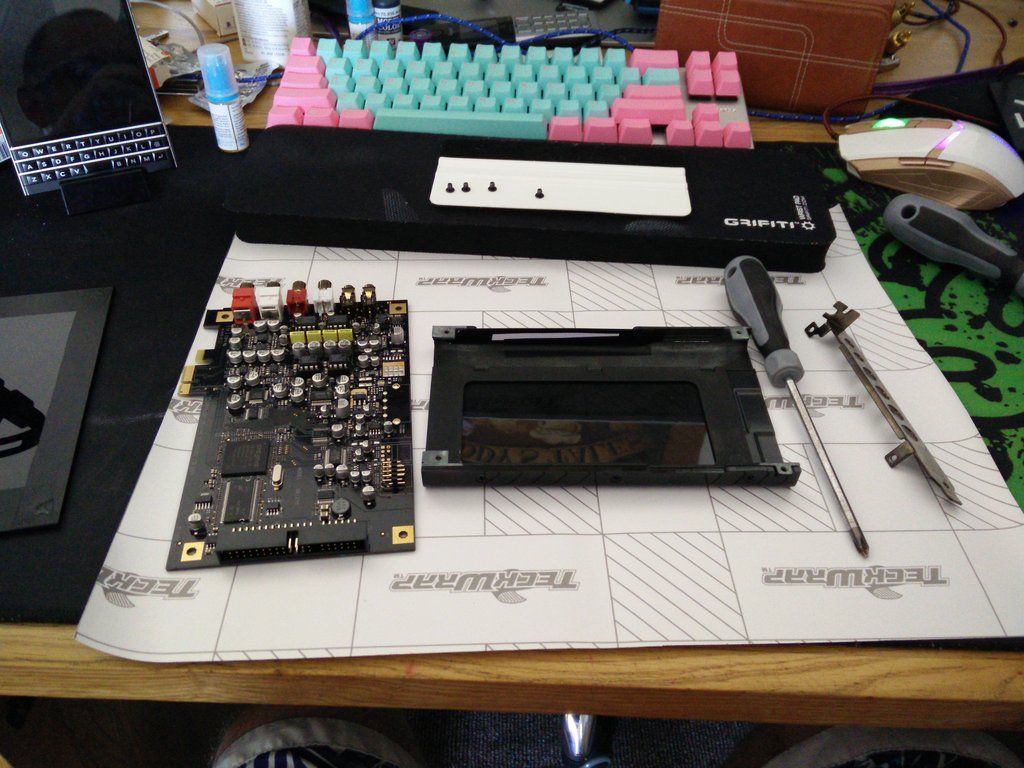

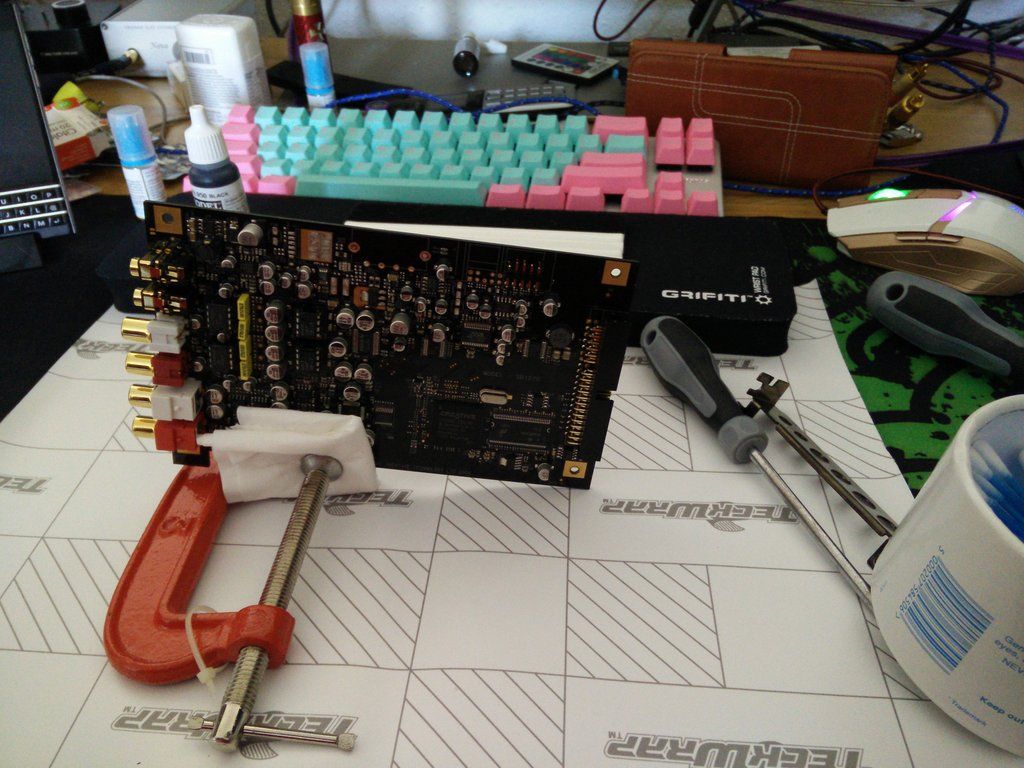

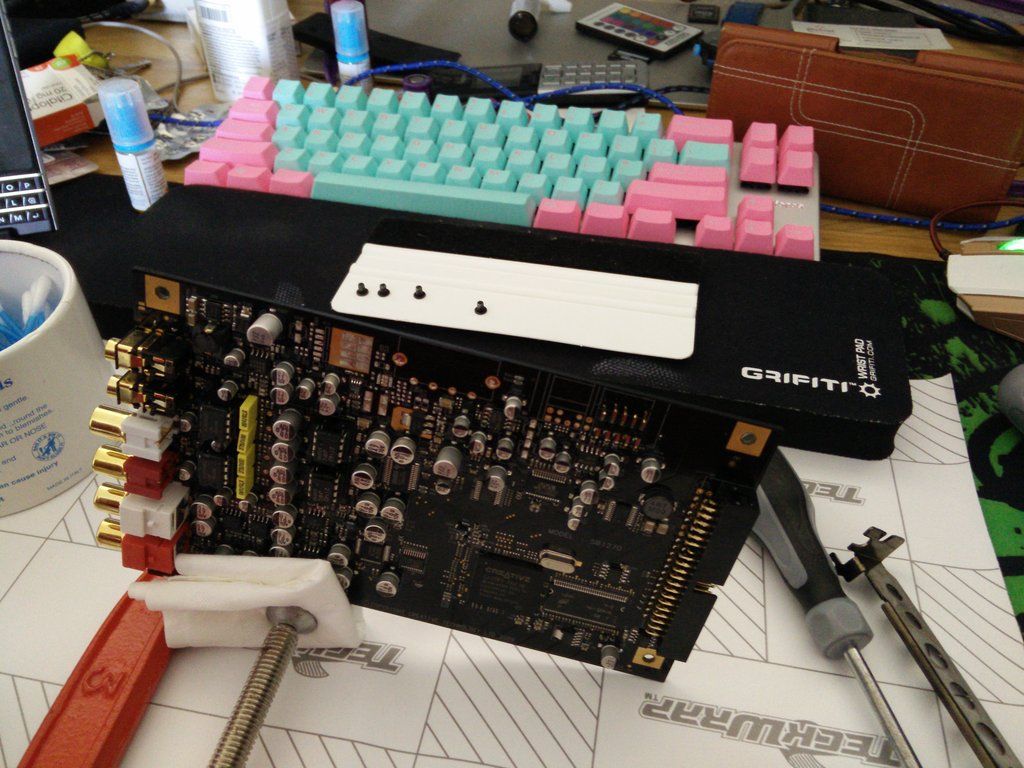

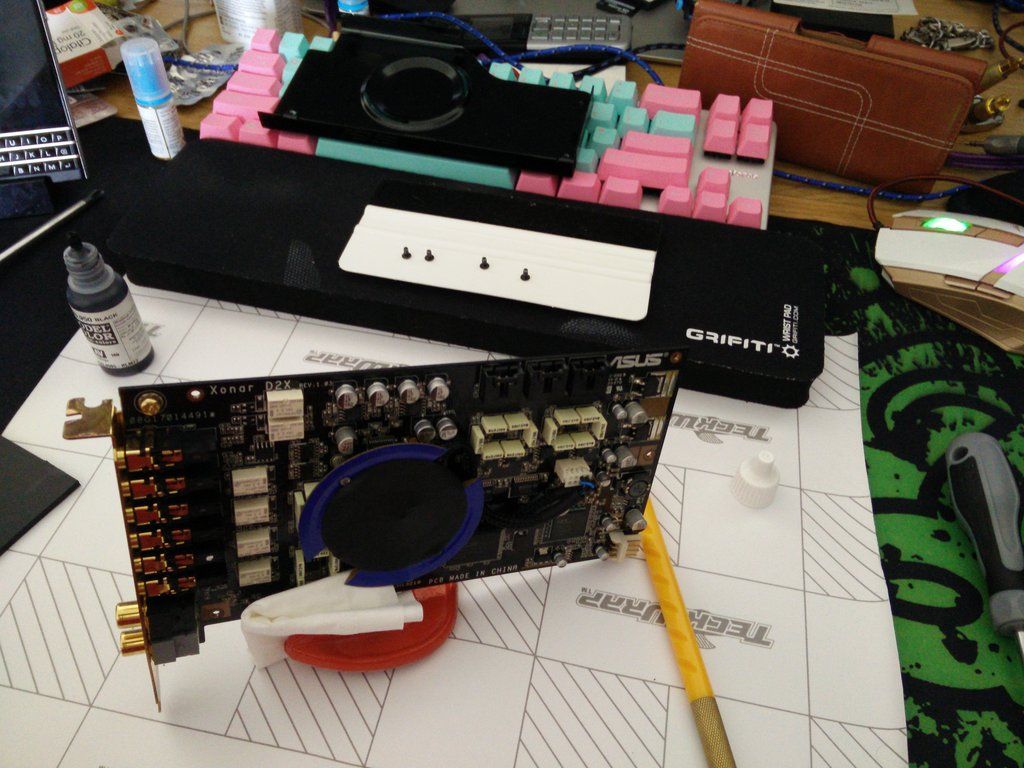

SATA cable issue !. I ordered these the other day.

They were supposedly Powercool cables. However, I was beginning to seriously doubt that because they look like paracord to me. I was right to have my doubts too, as the cable in the picture is actually a Bitfenix Alchemy. It seems that somewhere every single vendor online selling these Powercool cables got the wrong memo and are actually selling these.

HONK HONK. Nasty shrink, not even black. So I grumbled to the seller who said to return them. However, when my eyes had gotten over the nasty shock I decided to take a closer look. It turned out that the braid went all the way up and was clamped in so the shrink was completely unnecessary. Why on earth would you use honking nasty shrink in a god awful shade of blue if it wasn't even necessary?

so the shrink was completely unnecessary. Why on earth would you use honking nasty shrink in a god awful shade of blue if it wasn't even necessary?

The mind boggles. Any way, thankfully I did not snap any of the little plastic flaps (lol) and they all look quite nice now.

Sorry for lack of updates BTW. Had two days from heck and am finally back to normality.

SATA cable issue !. I ordered these the other day.

They were supposedly Powercool cables. However, I was beginning to seriously doubt that because they look like paracord to me. I was right to have my doubts too, as the cable in the picture is actually a Bitfenix Alchemy. It seems that somewhere every single vendor online selling these Powercool cables got the wrong memo and are actually selling these.

HONK HONK. Nasty shrink, not even black. So I grumbled to the seller who said to return them. However, when my eyes had gotten over the nasty shock I decided to take a closer look. It turned out that the braid went all the way up and was clamped in

so the shrink was completely unnecessary. Why on earth would you use honking nasty shrink in a god awful shade of blue if it wasn't even necessary?

so the shrink was completely unnecessary. Why on earth would you use honking nasty shrink in a god awful shade of blue if it wasn't even necessary?The mind boggles. Any way, thankfully I did not snap any of the little plastic flaps (lol) and they all look quite nice now.

Sorry for lack of updates BTW. Had two days from heck and am finally back to normality.

)

)