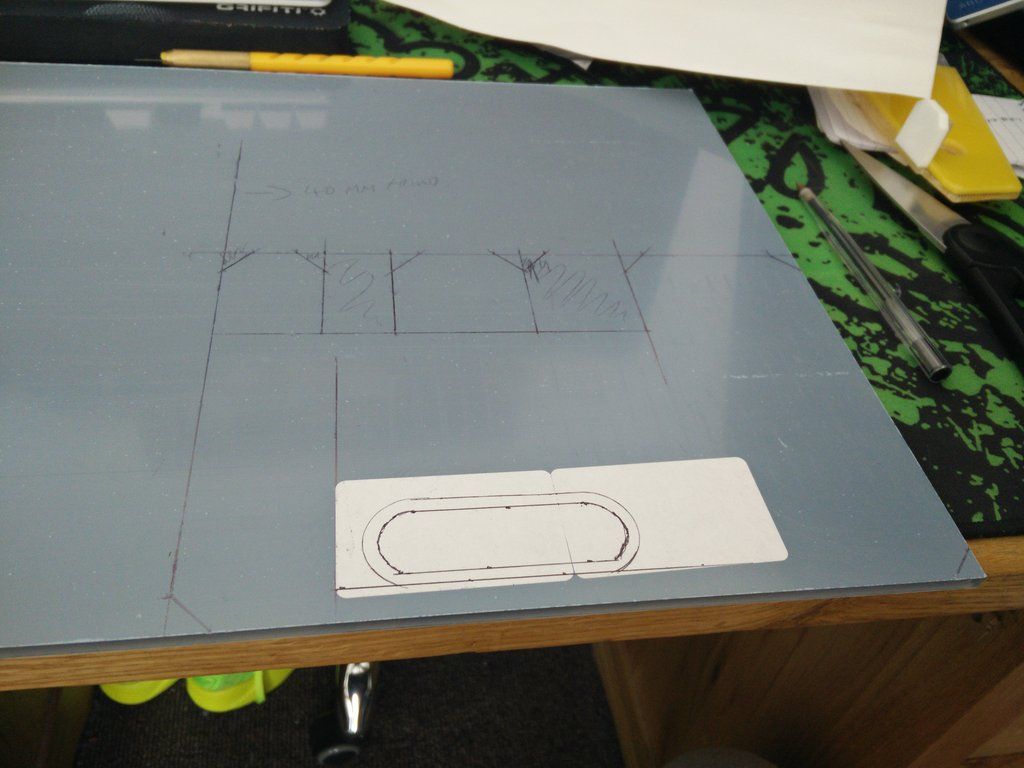

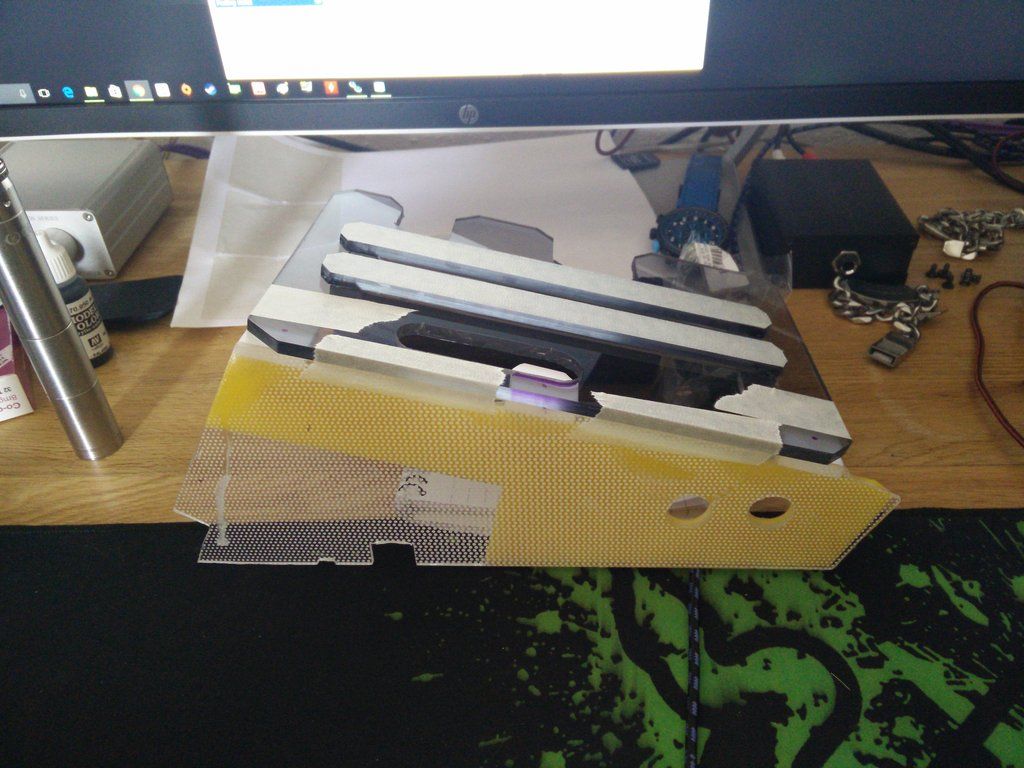

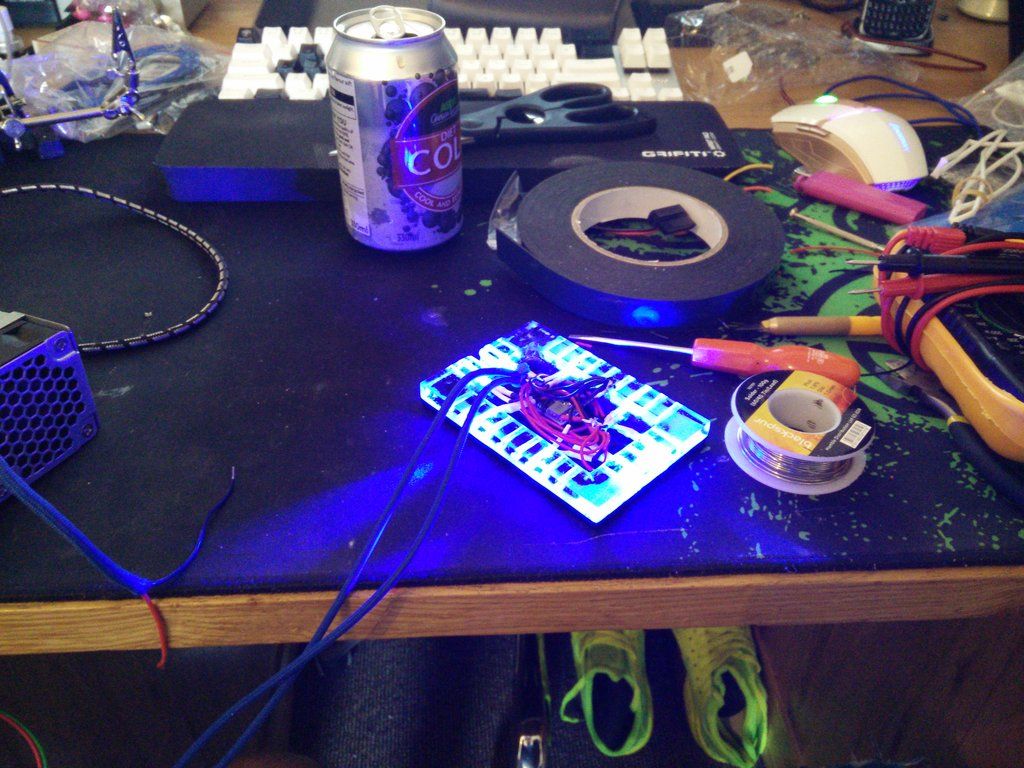

OK so here is where I am now after going to bed at 1am and then getting back out of bed at 2:30 to complete the structural work on the box.

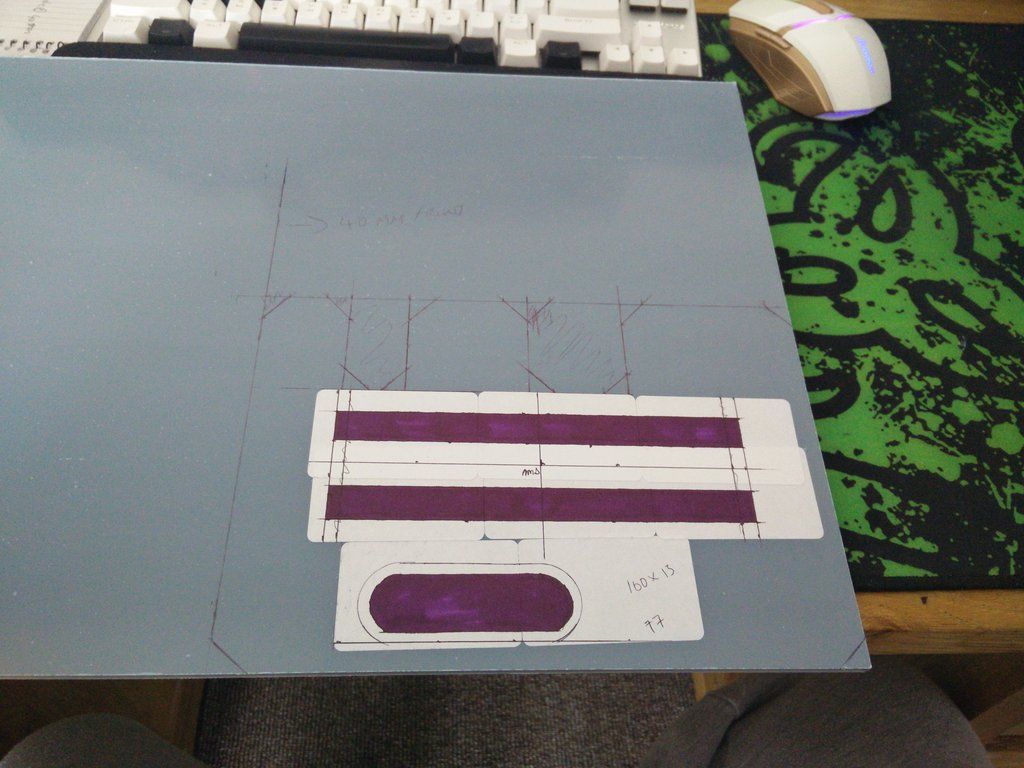

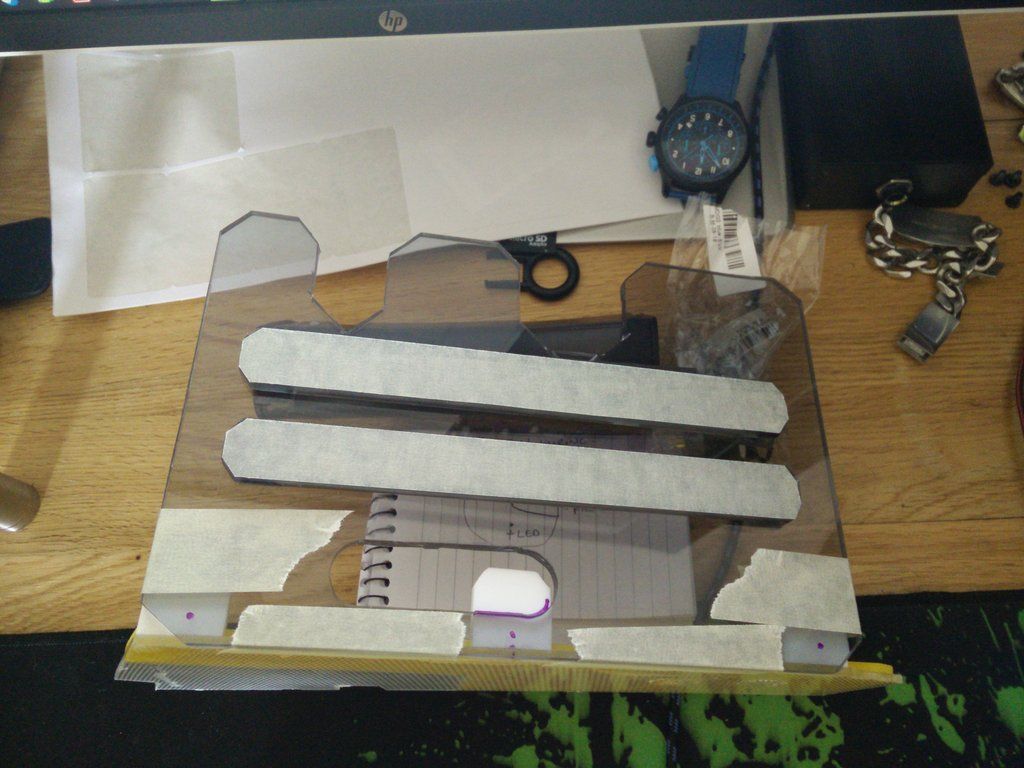

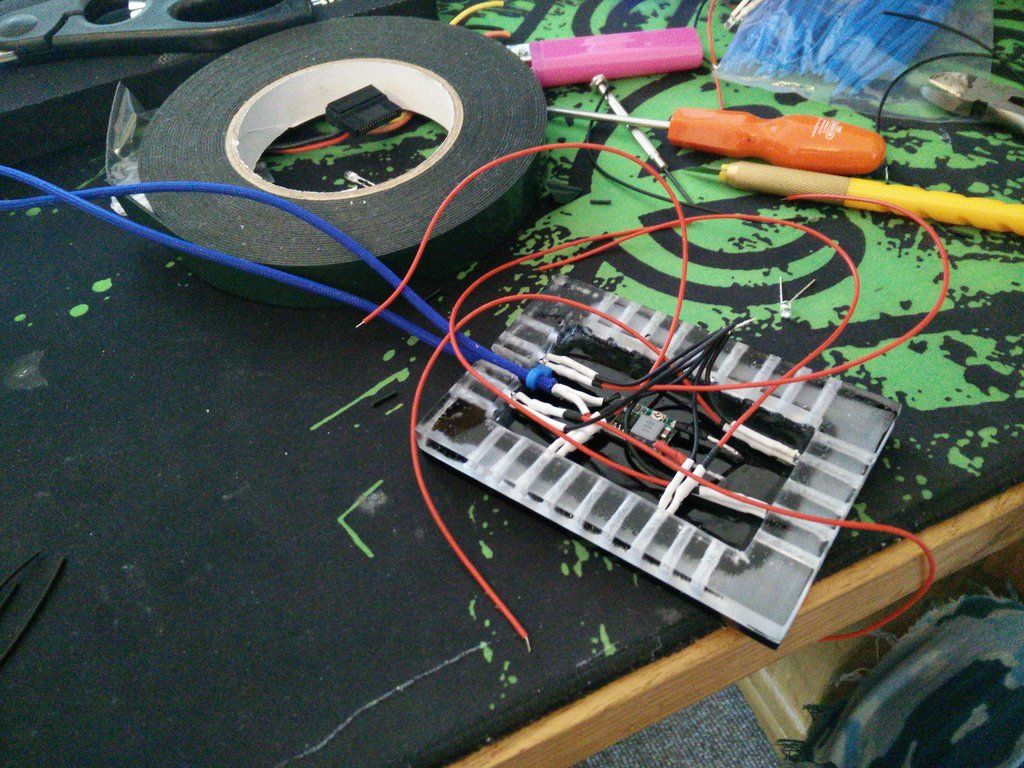

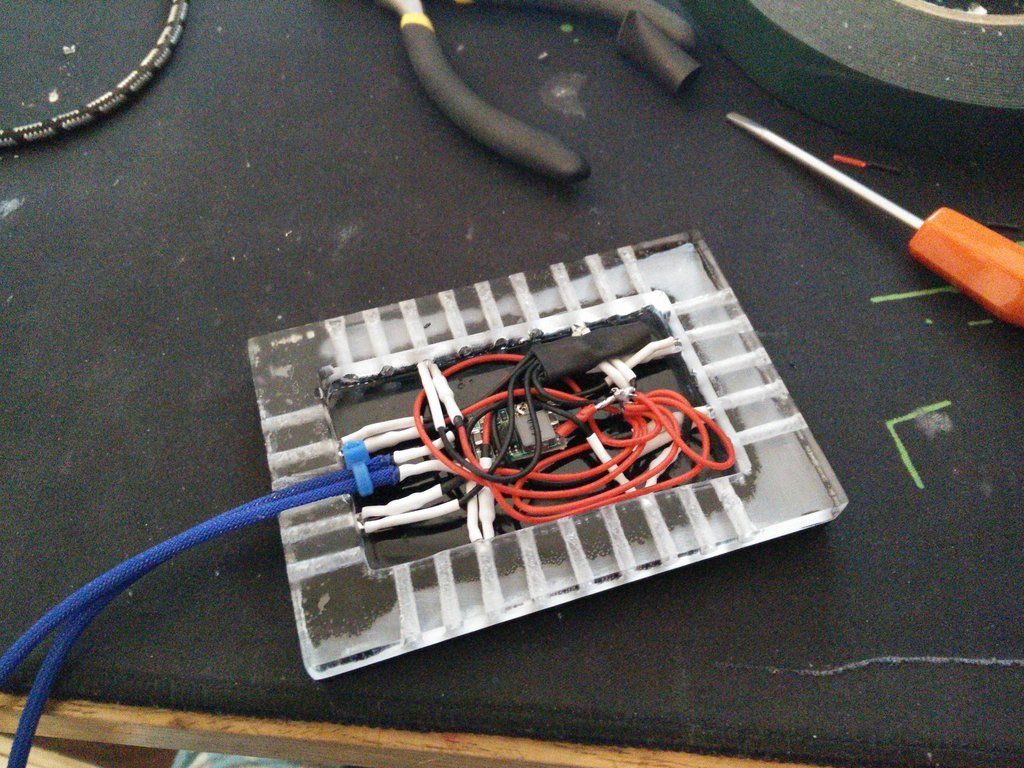

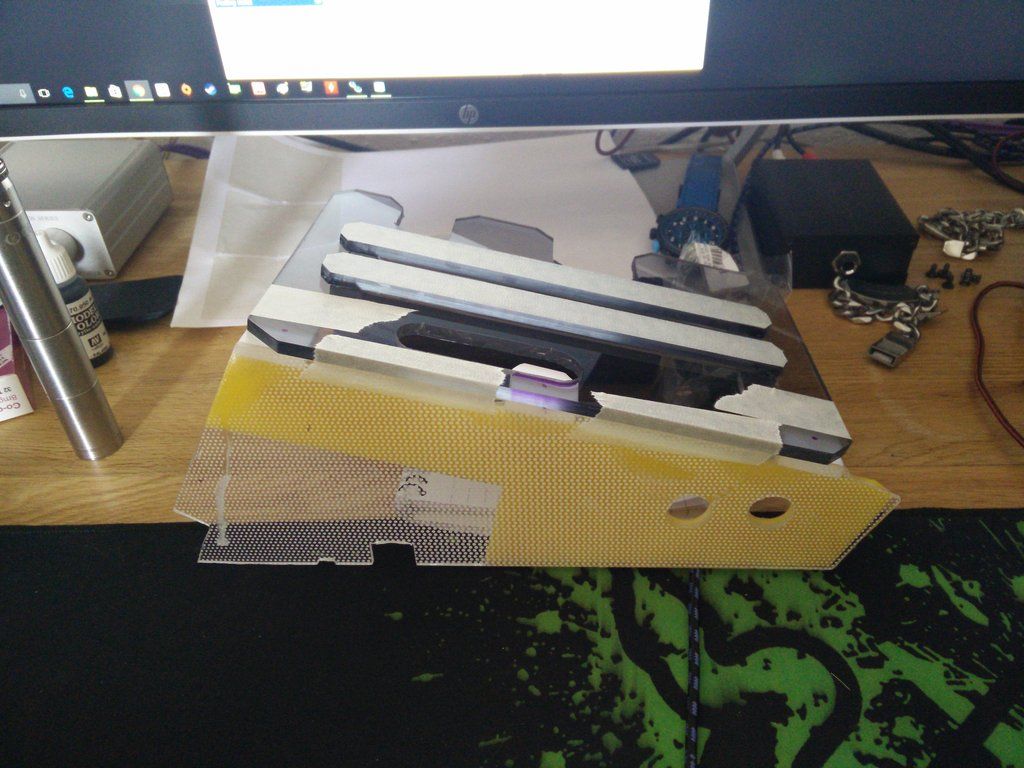

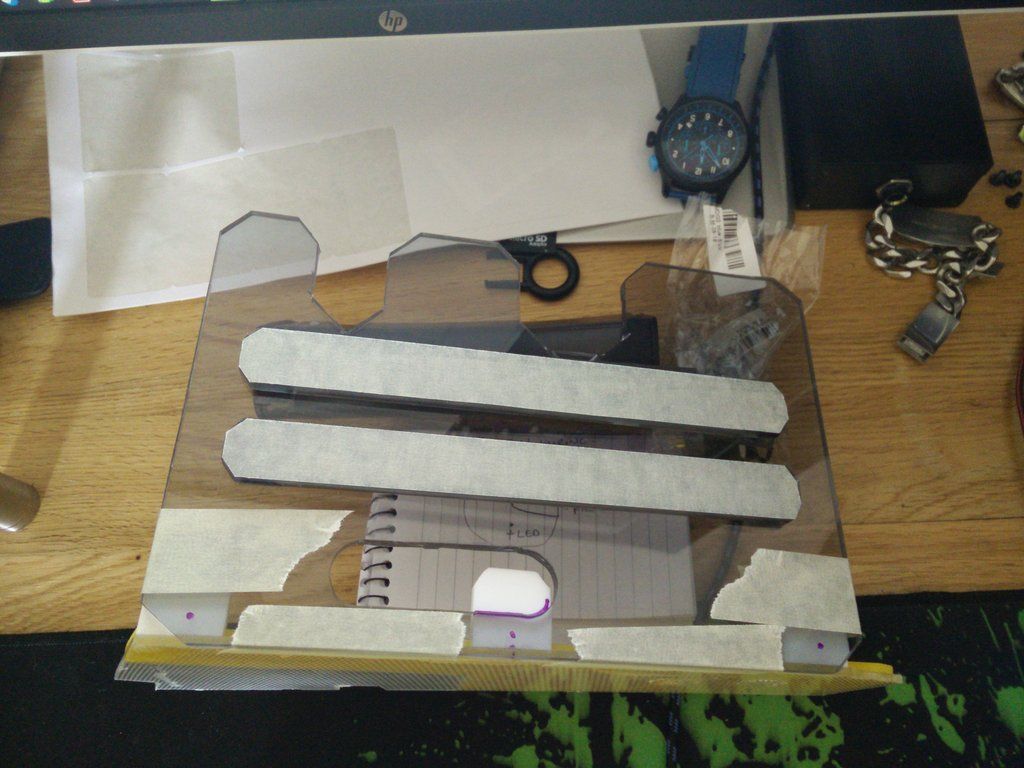

Now you can see why the rectangular holes do not matter. They are only there to allow the 6" cathode lights to sink through completely. You will also notice there are two pieces welded to the top. That now looks like this.

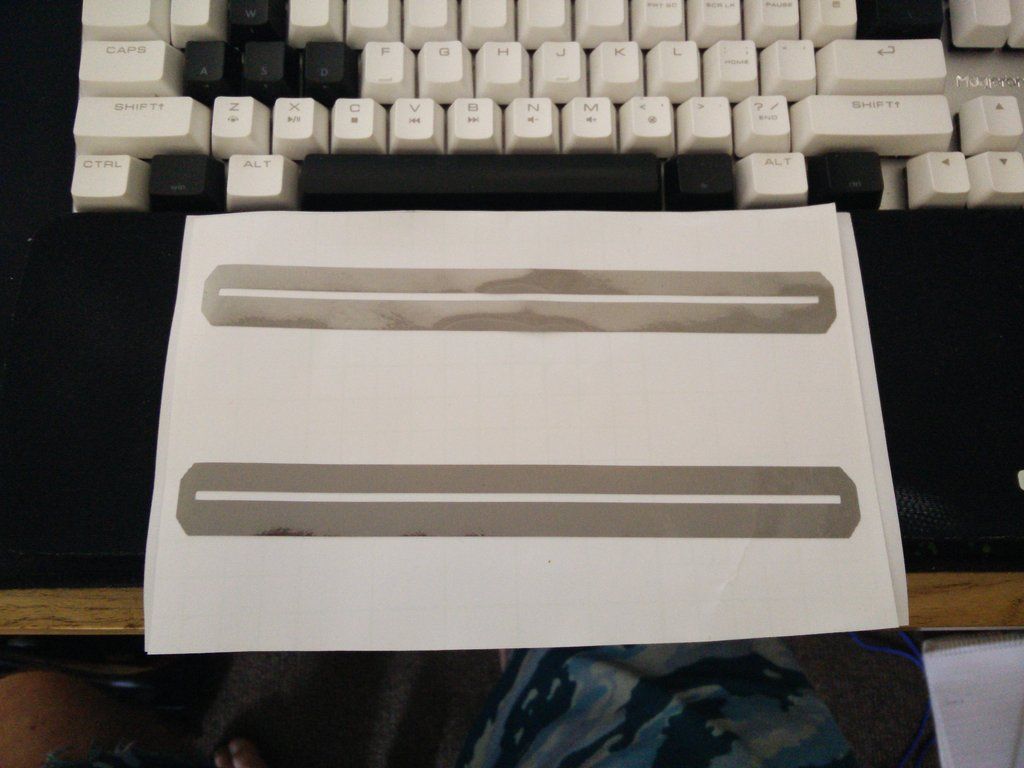

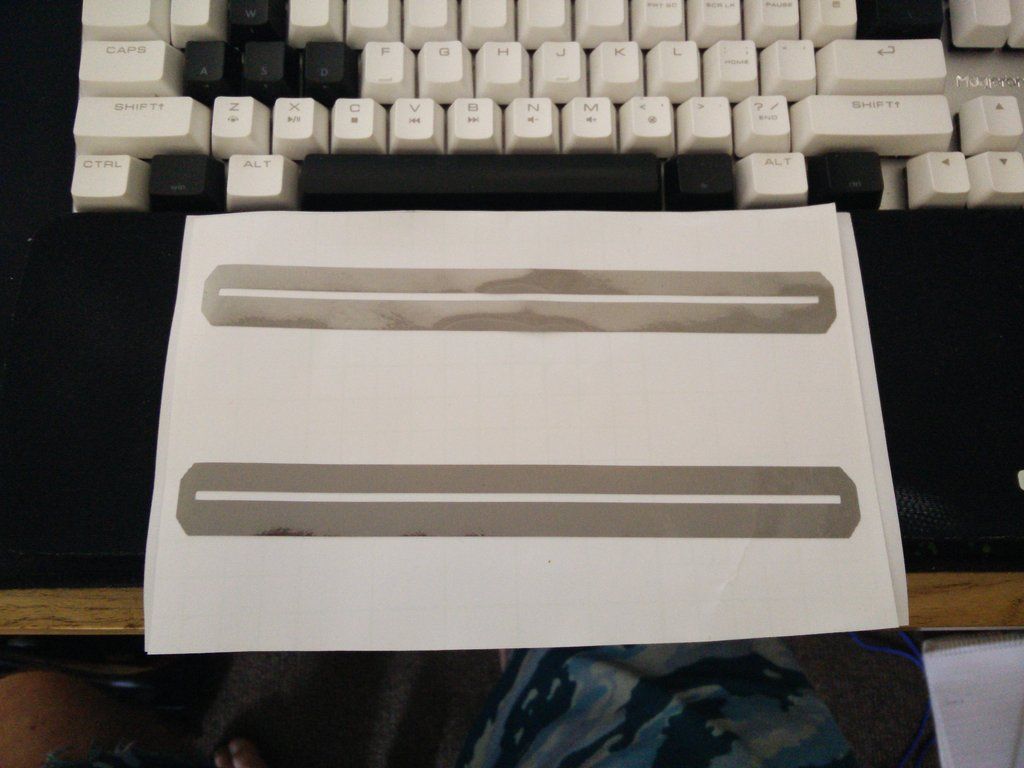

I originally planned to do this in one piece and to wrap around the cable grommet hole too but after spending a couple of hours designing things in Photoshop I decided on separate parts. Now you will note that the two strips are masked? that's because everything else you see will be painted apart from the very tops leaving those clear. I wanted it to be very *very* subtle as cathodes are like RAWR IN YOUR FACE so this was how I designed it.

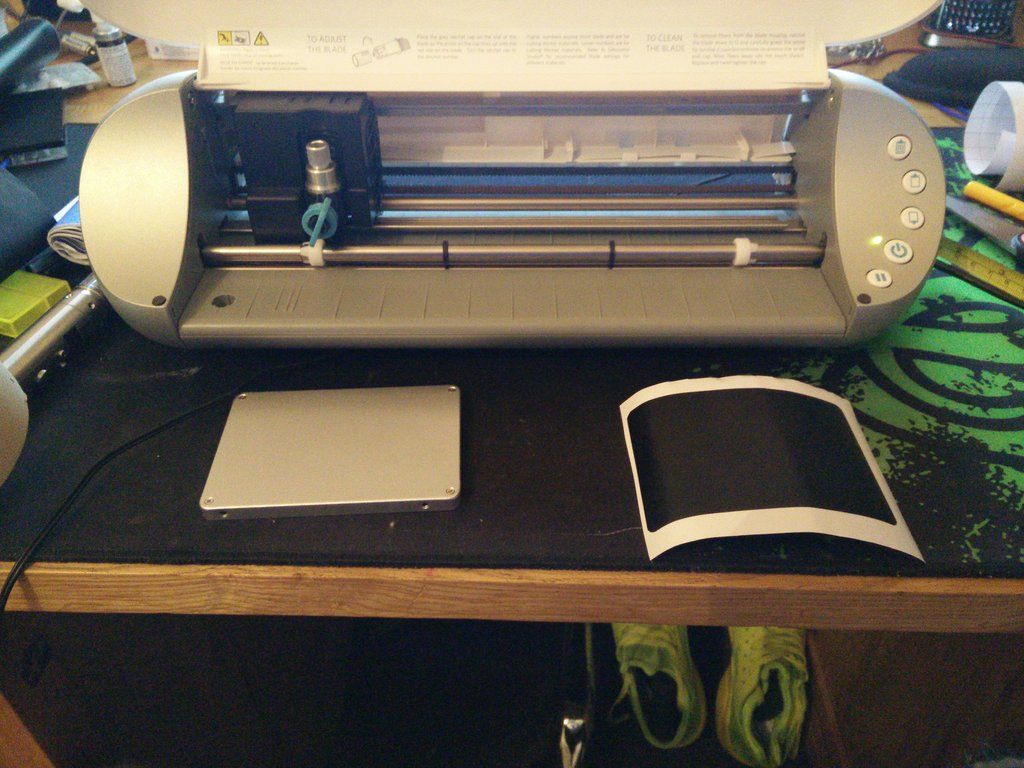

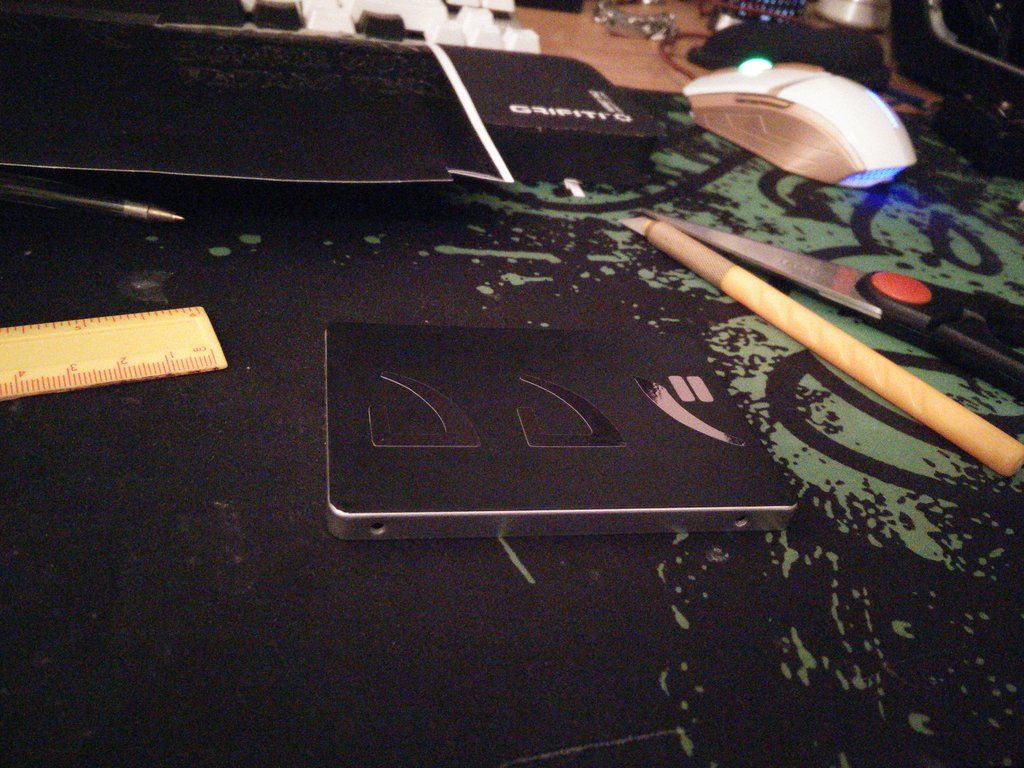

There will only be a 3mm strip letting the light through. And going on top of them when it's painted will be these.

Basically I printed 2 off. One in black (to use as a cutting stencil) and one in the black chrome I mentioned earlier in the thread.

Later today I will be starting the 2-3 days of prep. Then I will fill, prep some more and keep working on cranking out these cover panels (two more to go at last count).

One I start getting paint on it will actually start to look like something

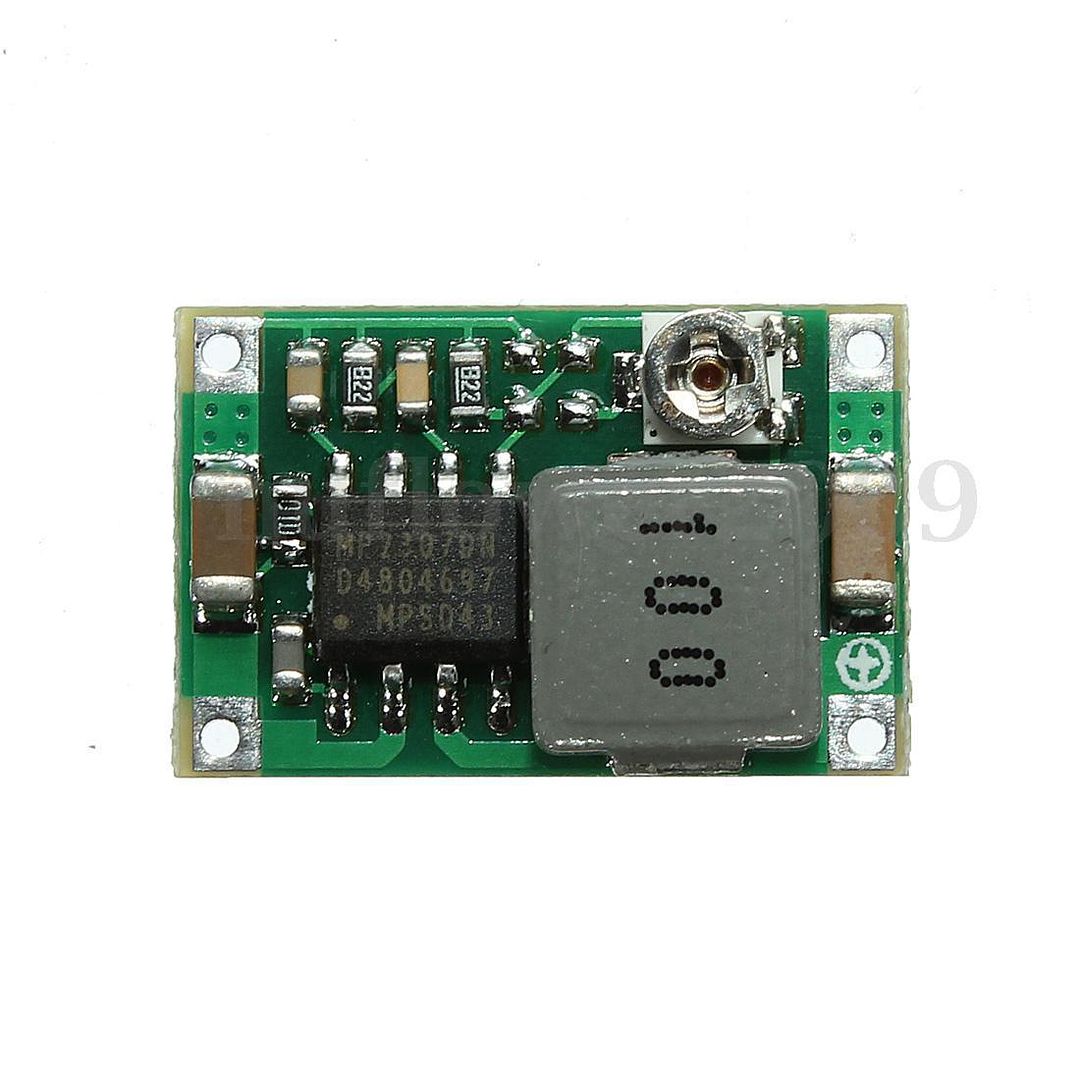

Oh yeah, and I buzzed the vandal switches last night and mapped all of the pins. No documentation pfft.

Oh yeah forgot to explain how the lights fit. At each end of the rectangle underneath I have welded on a post. This sinks them down flush so later today I will be doing all of the drilling/tapping (that's why it's taped together like that).